Labeling adhesive for glass bottles and preparation method thereof

A technology for labeling glue and glass bottles, applied in the field of labeling glue, can solve the problems of poor, polyvinyl alcohol starch glue warped corner adhesion, etc., to achieve the effects of fast drying time, speeding up drying time, and increasing storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

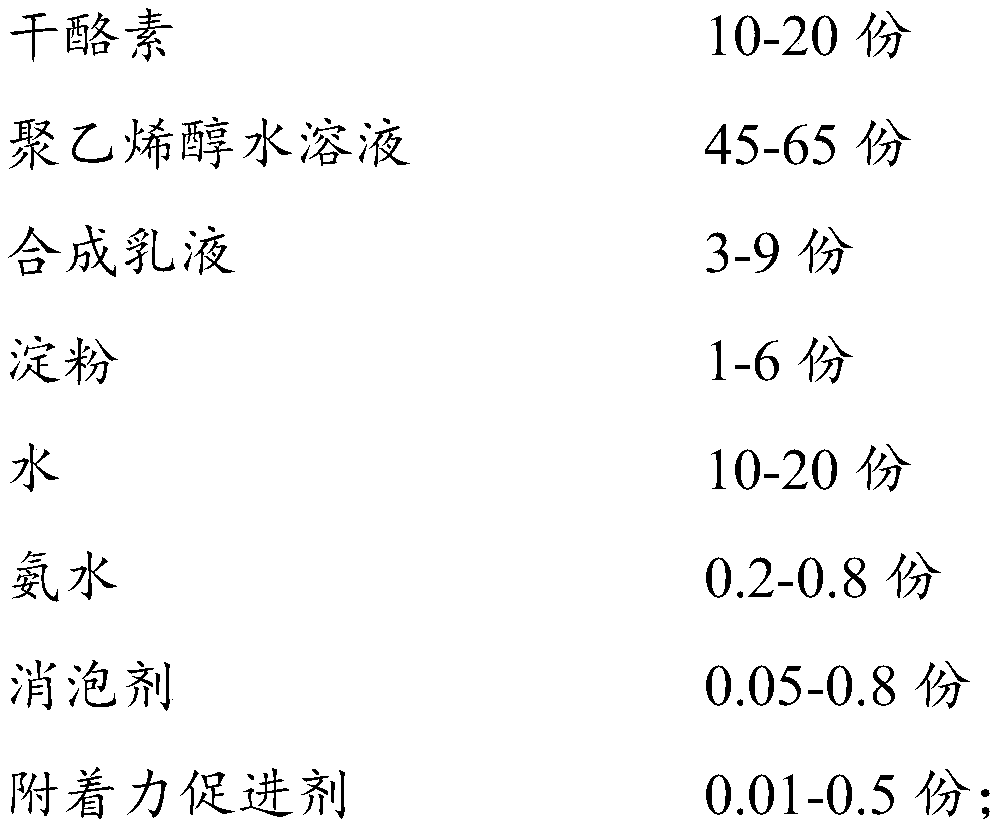

[0081] This embodiment provides a kind of labeling glue for glass bottles, in parts by weight, its preparation raw materials are as follows:

[0082]

[0083]

[0084] Wherein, the preparation method of polyvinyl alcohol aqueous solution is as follows:

[0085] Add 85 parts of tap water to the reaction kettle, then add 0.1 part of antifoaming agent Rhodia 691, and then add 15 parts of polyvinyl alcohol 1788, stir evenly, heat to 95°C, keep warm and dissolve for half an hour to obtain polyethylene Alcoholic solution.

[0086] The preparation method of synthetic emulsion is as follows:

[0087] (1) Preparation of pre-emulsion: Dilute 0.618 parts of emulsifier nonylphenol polyoxyethylene ether NP10 with 1.11 parts of water in the pre-emulsification pot, then add 0.069 parts of ammonia water to adjust the pH value to 3-4, stir for 10 minutes, add 20.8 Part of butyl acrylate and 23.1 parts of styrene, stirred for 30 minutes to make pre-emulsion;

[0088] (2) Polymerization...

Embodiment 2

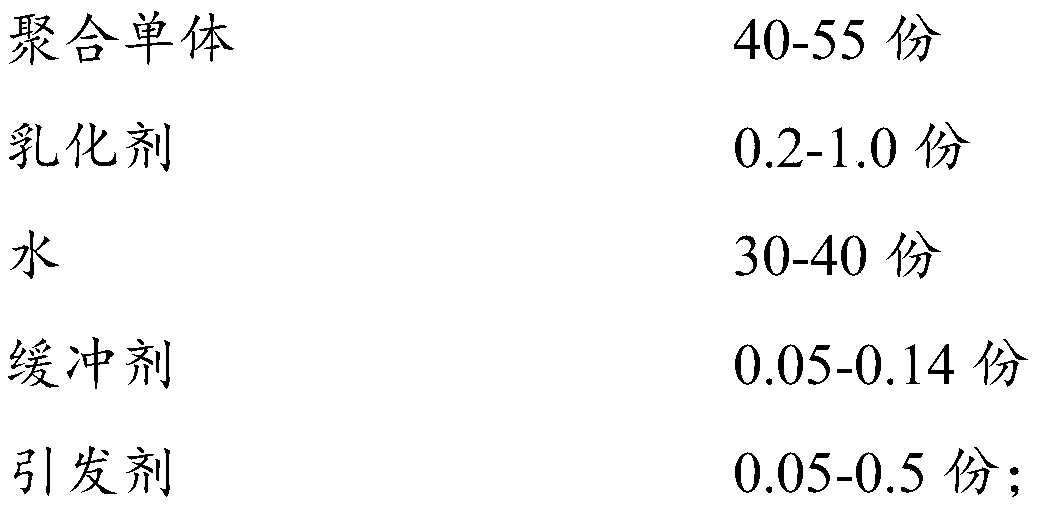

[0093] This embodiment provides a kind of labeling glue for glass bottles, in parts by weight, its preparation raw materials are as follows:

[0094]

[0095] Wherein, the preparation method of polyvinyl alcohol aqueous solution is as follows:

[0096] Add 85 parts of tap water into the reaction kettle, then add 0.1 part of antifoaming agent (Rhodia 691), then add 15 parts of polyvinyl alcohol 1788, stir evenly, heat to 95°C, keep warm and dissolve for half an hour, and obtain polyvinyl alcohol solution.

[0097] The preparation method of synthetic emulsion is as follows:

[0098] (1) Preparation of pre-emulsion: Dilute 0.618 parts of emulsifier nonylphenol polyoxyethylene ether NP10 with 1.11 parts of water in the pre-emulsification pot, then add 0.069 parts of ammonia water to adjust the pH value to 3-4, stir for 10 minutes, add 20.8 Part of butyl acrylate and 23.1 parts of styrene, stirred for 30 minutes to make pre-emulsion;

[0099] (2) Polymerization reaction: Add ...

Embodiment 3

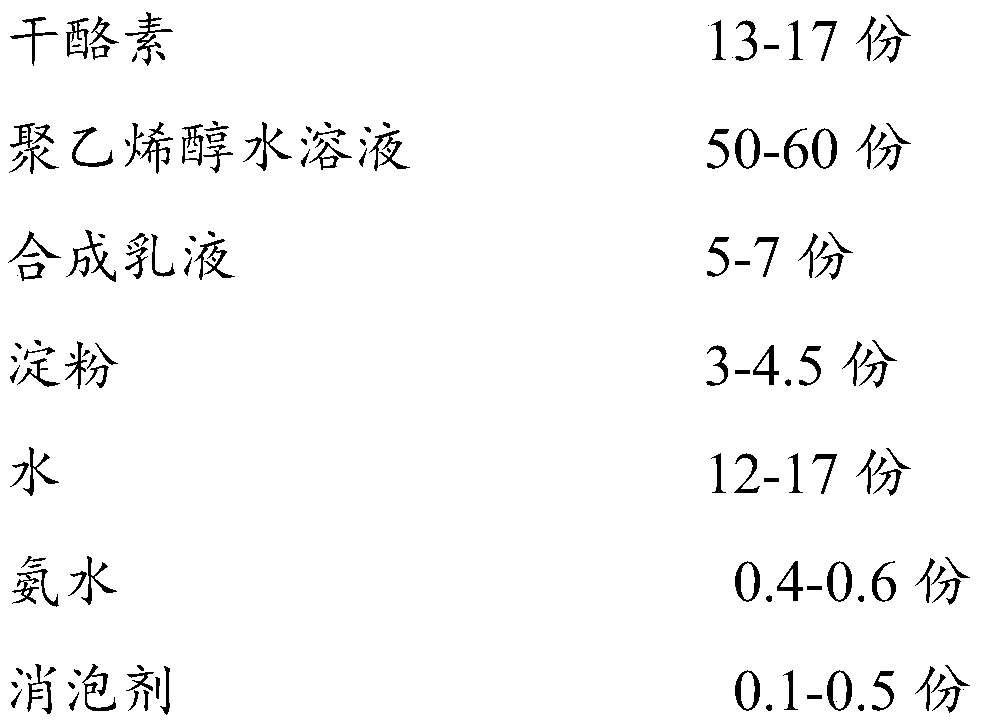

[0104] This embodiment provides a kind of labeling glue for glass bottles, in parts by weight, its preparation raw materials are as follows:

[0105]

[0106] Wherein, the preparation method of polyvinyl alcohol aqueous solution is as follows:

[0107] Add 85 parts of tap water to the reaction kettle, then add 0.1 part of antifoaming agent Rhodia 691, and then add 15 parts of polyvinyl alcohol 1788, stir evenly, heat to 95°C, keep warm and dissolve for half an hour to obtain polyethylene Alcoholic solution.

[0108] The preparation method of synthetic emulsion is as follows:

[0109] (1) Preparation of pre-emulsion: Dilute 0.618 parts of emulsifier nonylphenol polyoxyethylene ether NP10 with 1.11 parts of water in the pre-emulsification pot, then add 0.069 parts of 25% ammonia water to adjust the pH value to 3-4, and stir for 10 minutes , add 20.8 parts of butyl acrylate and 23.1 parts of styrene, and stir for 30 minutes to make a pre-emulsion;

[0110] (2) Polymerizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com