Automatic bucket cover installing production line

A production line and barrel cover technology, which is applied in the field of automatic barrel capping production line, can solve the problems of affecting the quality of labeling, low stability, and insufficient labeling effect, and achieve high automation, good work stability, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

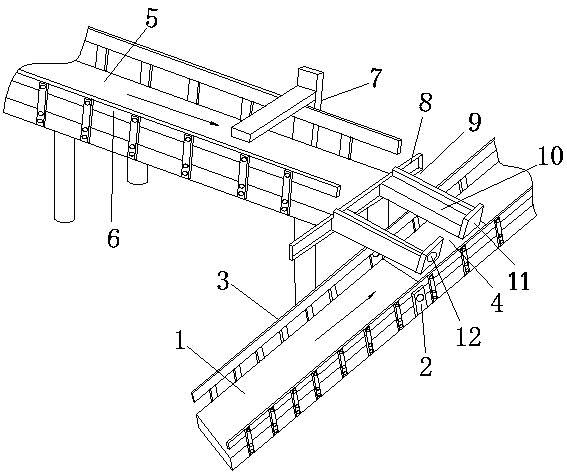

[0018] An automatic production line for capping barrels according to the present invention includes a barrel body conveying track 1 , a barrel cap transporting track 5 , and a barrel cap installation mechanism 9 . The bung conveying track 1 and the bung conveying track 5 are perpendicular to each other, the bung conveying track 5 is located above the bung conveying track 1, and the end of the bung conveying track 5 is provided with a bung installation mechanism 9, corresponding to the bottom of the bung installation mechanism 9. Barrel body conveying track 1; barrel body transporting track 1 is positioned at the position below bung cover installation mechanism 9 to set barrel body transmission stop station 4, and barrel body transmission stop station 4 is provided with laser sensor I2, when the barrel body is conveyed along the barrel body When the track 1 reaches the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com