Copying labeling machine

A labeling machine and frame technology, applied in the direction of labeling machine, labeling, labeling, etc., can solve the problems of low labeling accuracy and inability to label

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

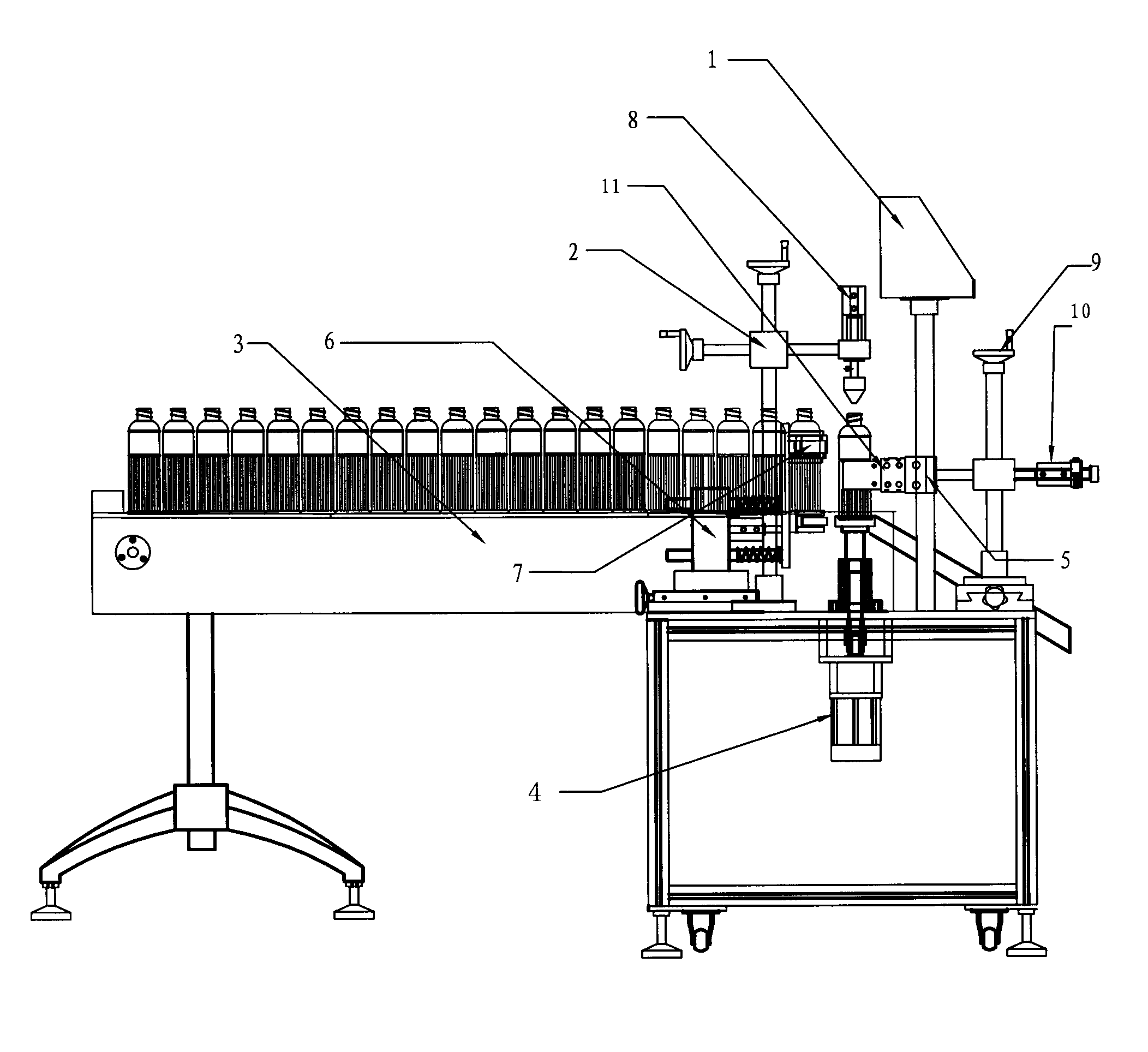

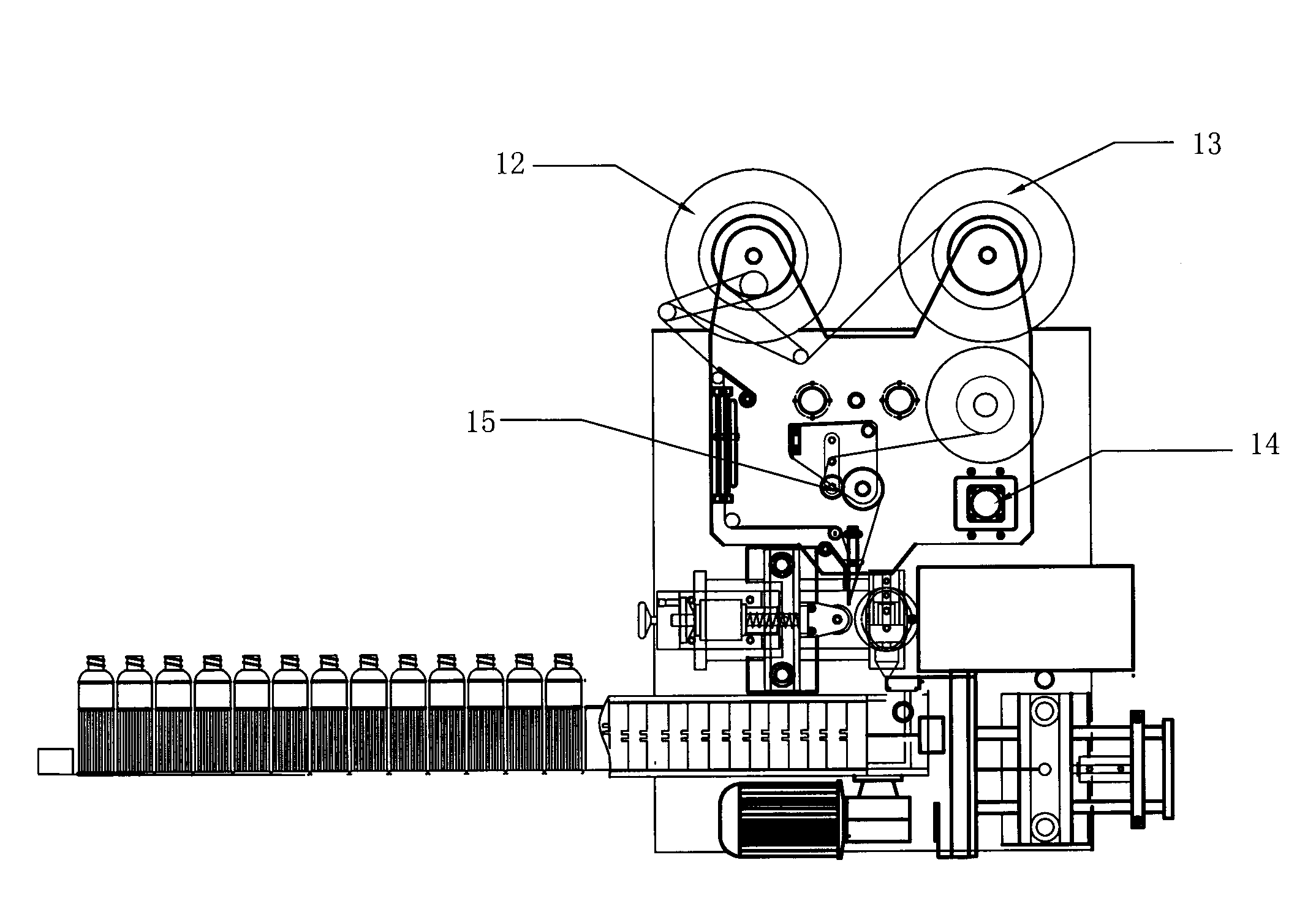

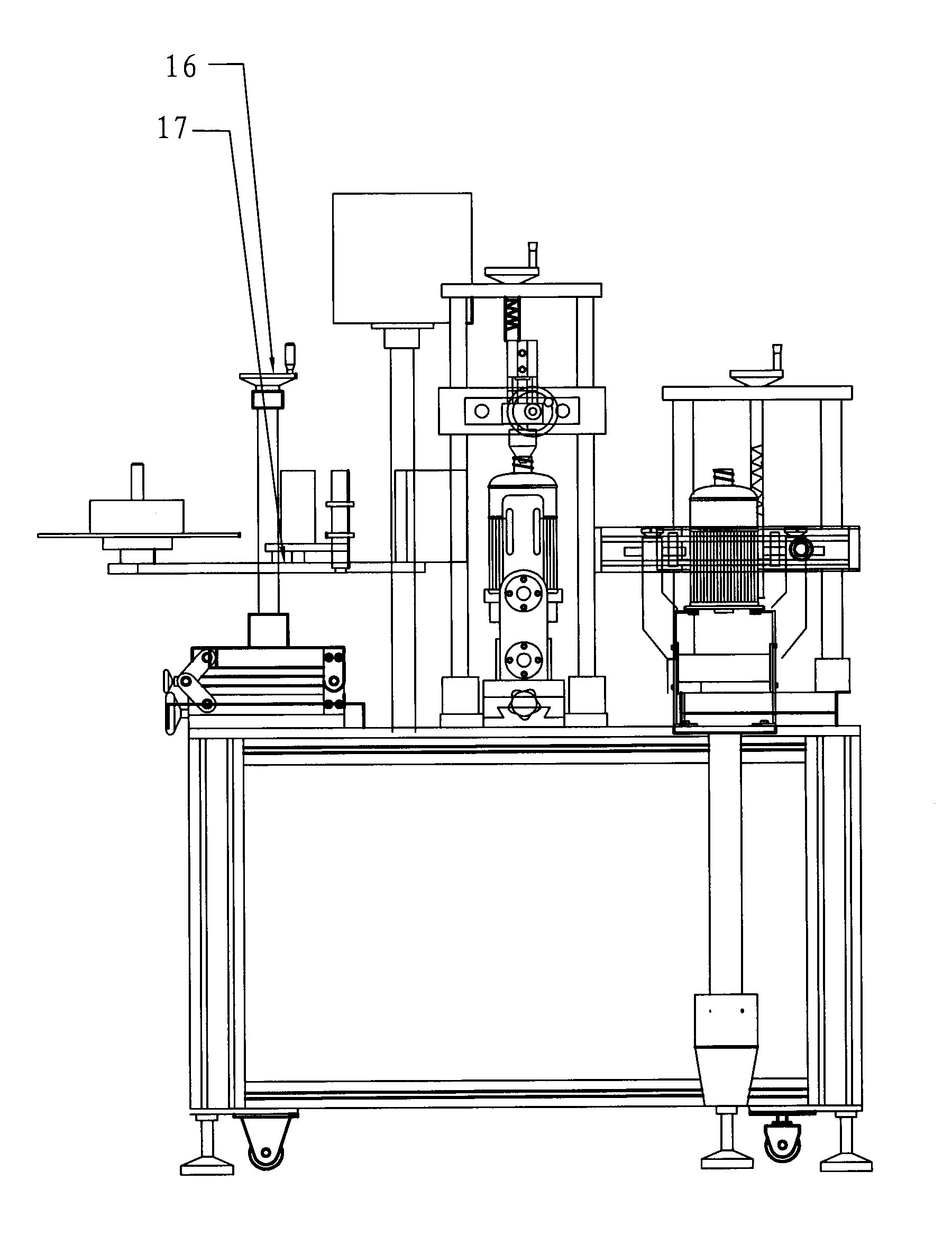

[0019] like figure 1 , figure 2 and image 3 As shown, a profiling labeling machine includes a frame, a control box 1, a bottle jacking mechanism 2, a feeding mechanism 3, a rotary servo motor 4, a robot grasping bottle device 5, a labeling profiling mechanism 6, and a label pressing device 7 , bottle top cylinder 8, bottle grasping manipulator lifting hand wheel 9, manipulator grasping bottle advance and retreat cylinder 10, bottle grasping finger cylinder 11, first label 12, second label 13, label pulling servo motor 14, label pulling roller 15 , labeling film frame height adjustment handwheel 16, labeling film frame 17, control box 1 is installed on the frame, feeding mechanism 3 is set on the frame, described labeling machine is provided with rotary servo motor 4, and described feeding mechanism 3 one ends A bottle jacking mechanism 2 is set, and the other side of the bottle jacking mechanism 2 is provided with a robot grasping bottle device 5, and the labeling machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com