Patents

Literature

36results about How to "Suppresses viscosity rise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing golf ball

InactiveUS20060249880A1High reboundExcellent manufacturabilityDomestic articlesSolid ballsSolventN-Butylamine

A method of manufacturing golf balls composed of a core and a cover of one or more layer that encloses the core, at least one cover layer being made of a thermoplastic polyurethane composition characterized by including at least 90 wt % of a thermoplastic polyurethane obtained by a polyurethane-forming reaction of an organic diisocyanate compound with a long-chain polyol and a chain extender, which thermoplastic polyurethane composition cover layer has an inherent viscosity in a DMF solvent of larger than 1.5 dl / g and an inherent viscosity in a 0.05 mol / L n-butylamine-containing DMF solution of larger than 0.5 dl / g, the golf ball manufacturing method being characterized by: conditioning the thermoplastic polyurethane to a pre-processing moisture content of 500 ppm or less, then injection molding the moisture-conditioned thermoplastic polyurethane to form the thermoplastic polyurethane composition cover layer. Golf balls produced by this method have a high rebound and excellent spin characteristics and scuff resistance, are recyclable in a molding operation, and have excellent manufacturability.

Owner:KURARAY CO LTD

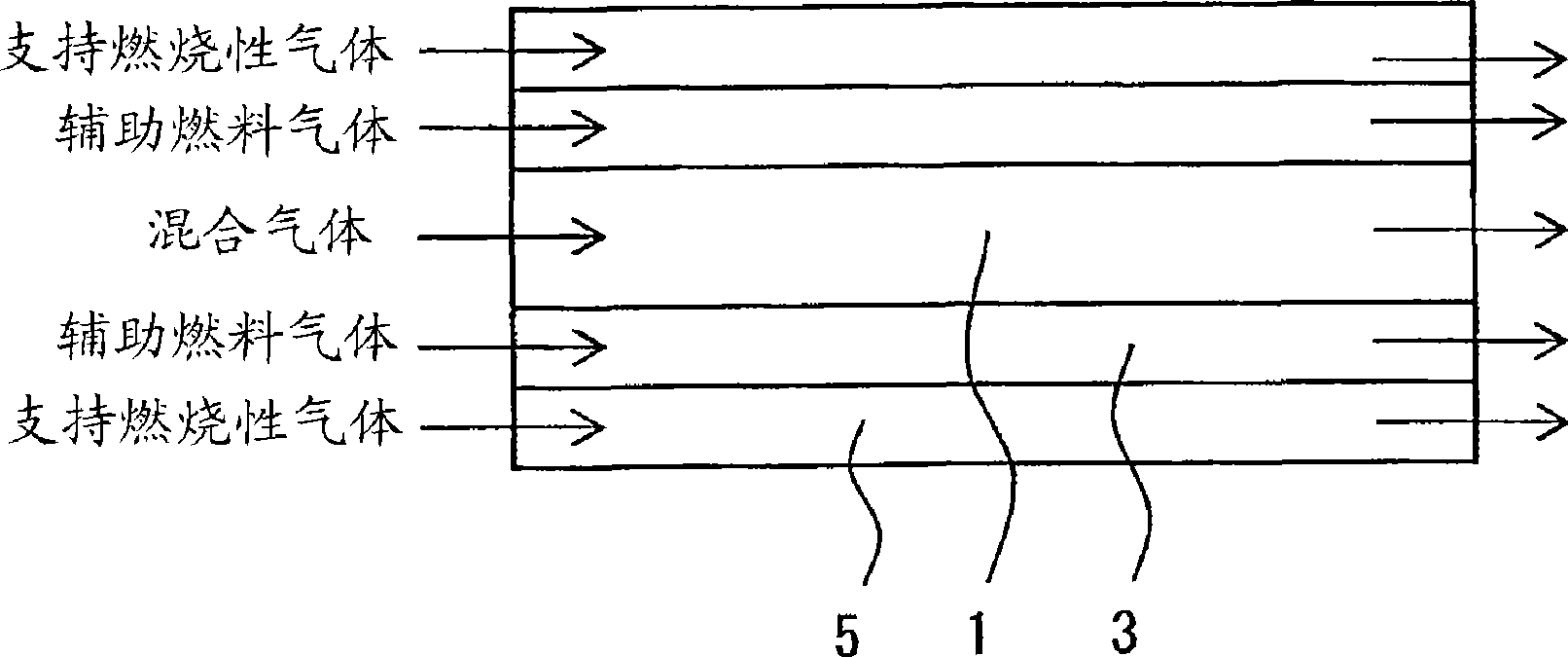

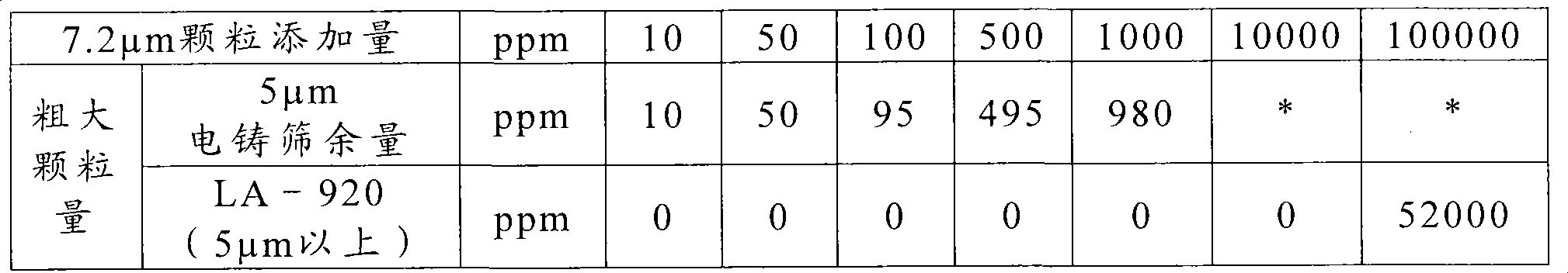

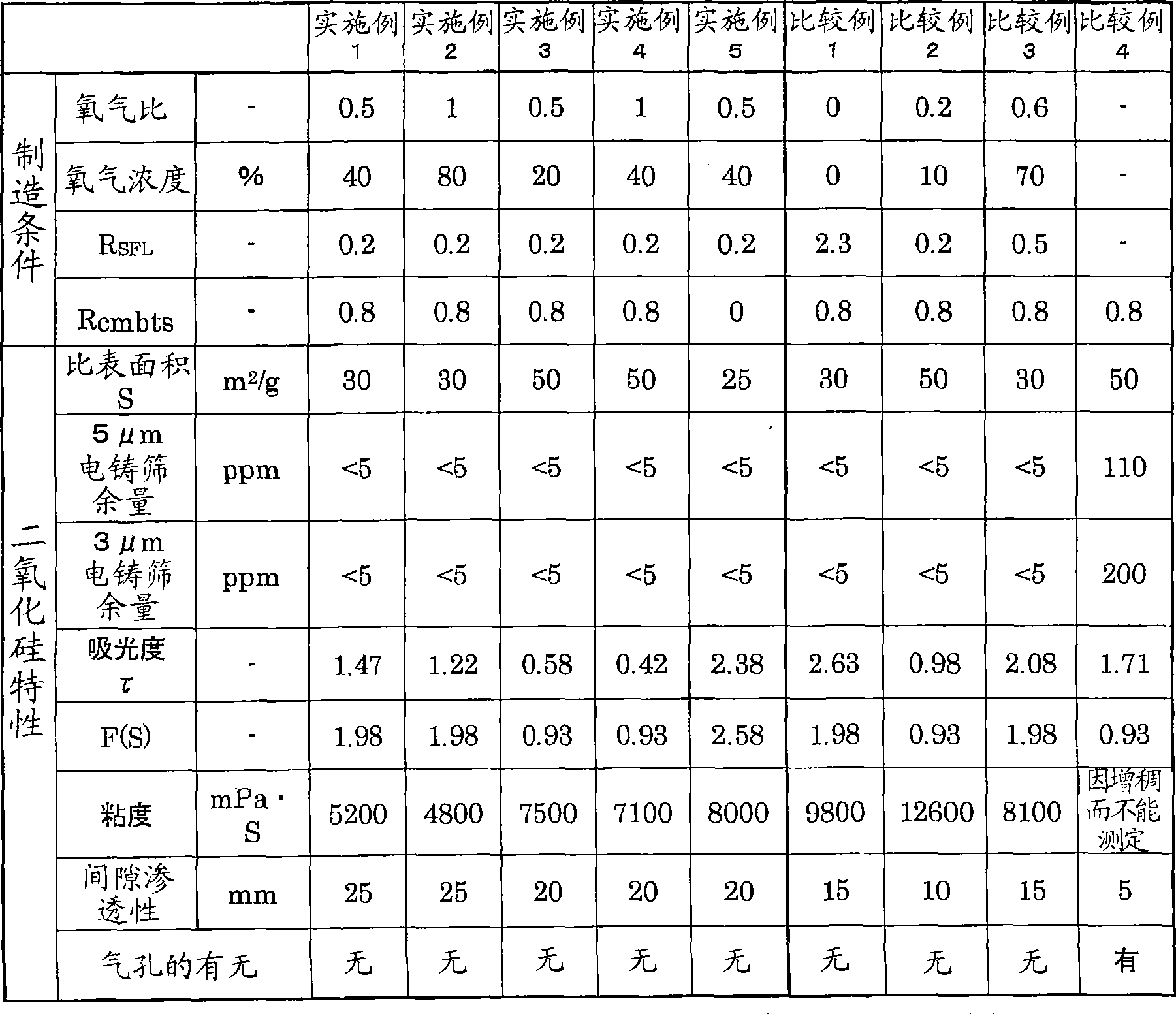

Fine dry silica particles

ActiveUS7803341B2Curb riseHigh strengthSilicaSynthetic resin layered productsEngineeringSilicon dioxide

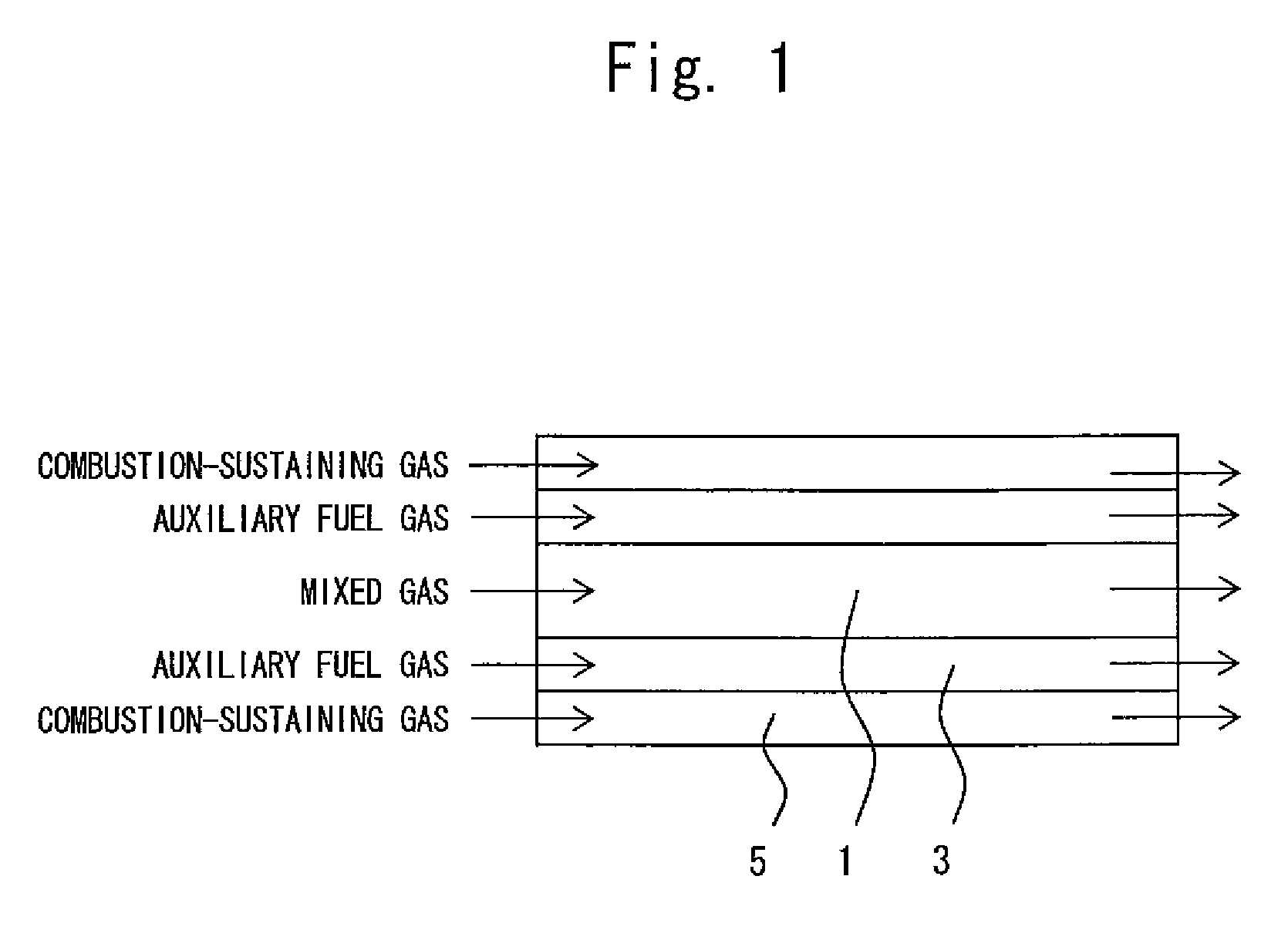

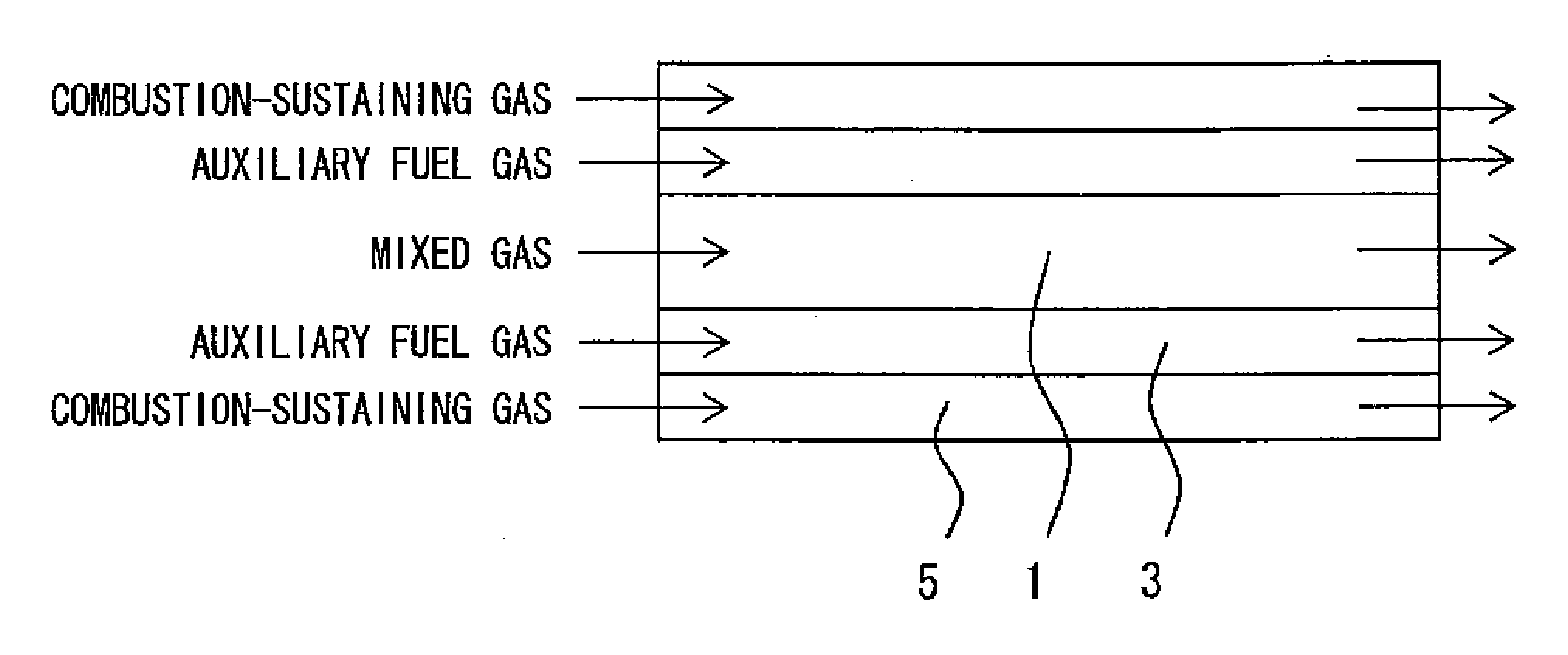

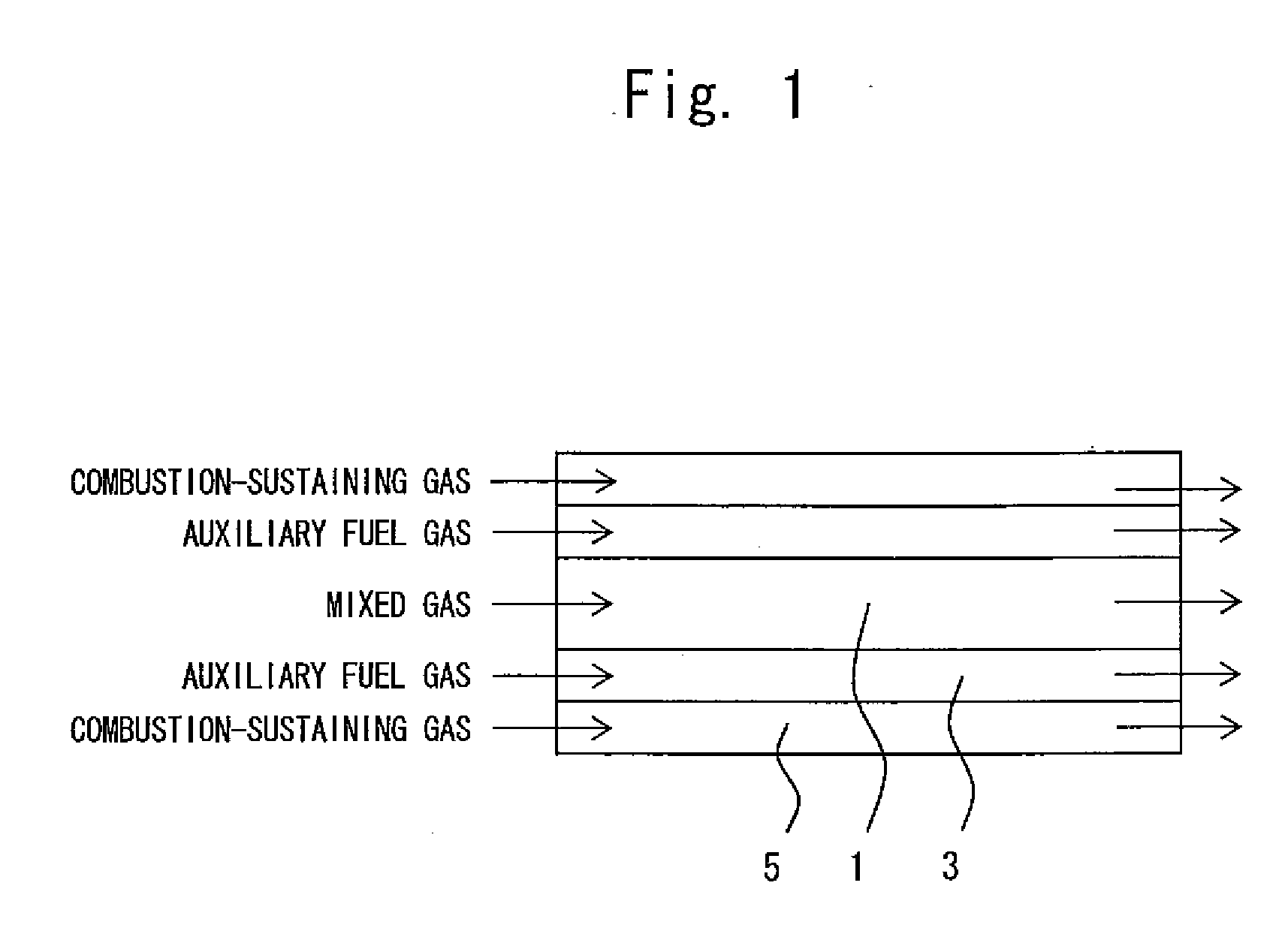

Fine dry silica particles are produced by combustion by using a burner of a multiple-pipe structure, feeding a mixed gas of a gas of a siloxane compound without containing halogen in the molecules thereof and an oxygen gas at a ratio of 0.3 to 1.5 into the center pipe of a burner, and feeding a combustible gas into the first annular pipe on the outer side of the center pipe of the burner. The fine dry silica particles has a BET specific surface area of 20 to 55 m2 / g, and wherein the water suspension containing the fine silica particles at a concentration of 1.5% by weight has an optical absorbance τ for the light of a wavelength of 700 nm satisfying the following formula (1):τ≦240S−1.4−0.07 (1)wherein S is the BET specific surface area (m2 / g) of the fine dry silica particles.The fine dry silica particles do not almost contain coarse particles or aggregated particles, have a sharpe grain size distribution, excellently disperse in the resins, suppress a rise in the viscosity when highly filled, and impart sufficiently large strength to the resin compound.

Owner:TOKUYAMA CORP

Fine dry silica particles

ActiveUS20090253851A1Curb riseHigh strengthSilicaSynthetic resin layered productsEngineeringMicroparticle

Fine dry silica particles are produced by combustion by using a burner of a multiple-pipe structure, feeding a mixed gas of a gas of a siloxane compound without containing halogen in the molecules thereof and an oxygen gas at a ratio of 0.3 to 1.5 into the center pipe of a burner, and feeding a combustible gas into the first annular pipe on the outer side of the center pipe of the burner. The fine dry silica particles has a BET specific surface area of 20 to 55 m2 / g, and wherein the water suspension containing the fine silica particles at a concentration of 1.5% by weight has an optical absorbance τ for the light of a wavelength of 700 nm satisfying the following formula (1):τ≦240S−1.4−0.07 (1)wherein S is the BET specific surface area (m2 / g) of the fine dry silica particles.The fine dry silica particles do not almost contain coarse particles or aggregated particles, have a sharpe grain size distribution, excellently disperse in the resins, suppress a rise in the viscosity when highly filled, and impart sufficiently large strength to the resin compound.

Owner:TOKUYAMA CORP

Inkjet recording medium and method for manufacturing the same

InactiveUS20070166474A1Excellent ozone resistanceSuppresses viscosity riseLiquid surface applicatorsDuplicating/marking methodsWater solubleMordant

A method for manufacturing an inkjet recording medium including at least inline-mixing an ink receiving layer forming liquid containing inorganic fine particles and a water-soluble binder and a mordant mixture solution containing a basic poly aluminum hydroxide compound and a cationic polymer to form a coating liquid; and applying the coating liquid onto a support to form a coated layer and an inkjet recording medium manufactured by the manufacturing method.

Owner:FUJIFILM CORP

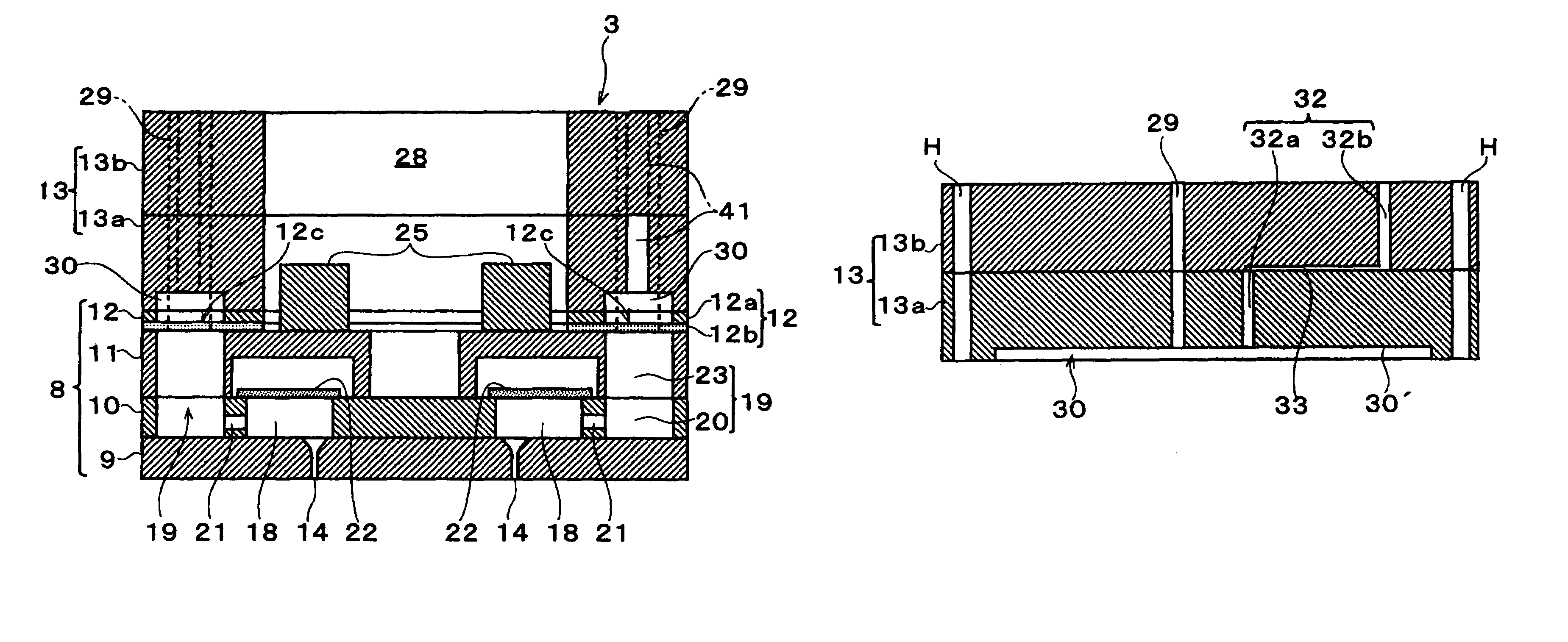

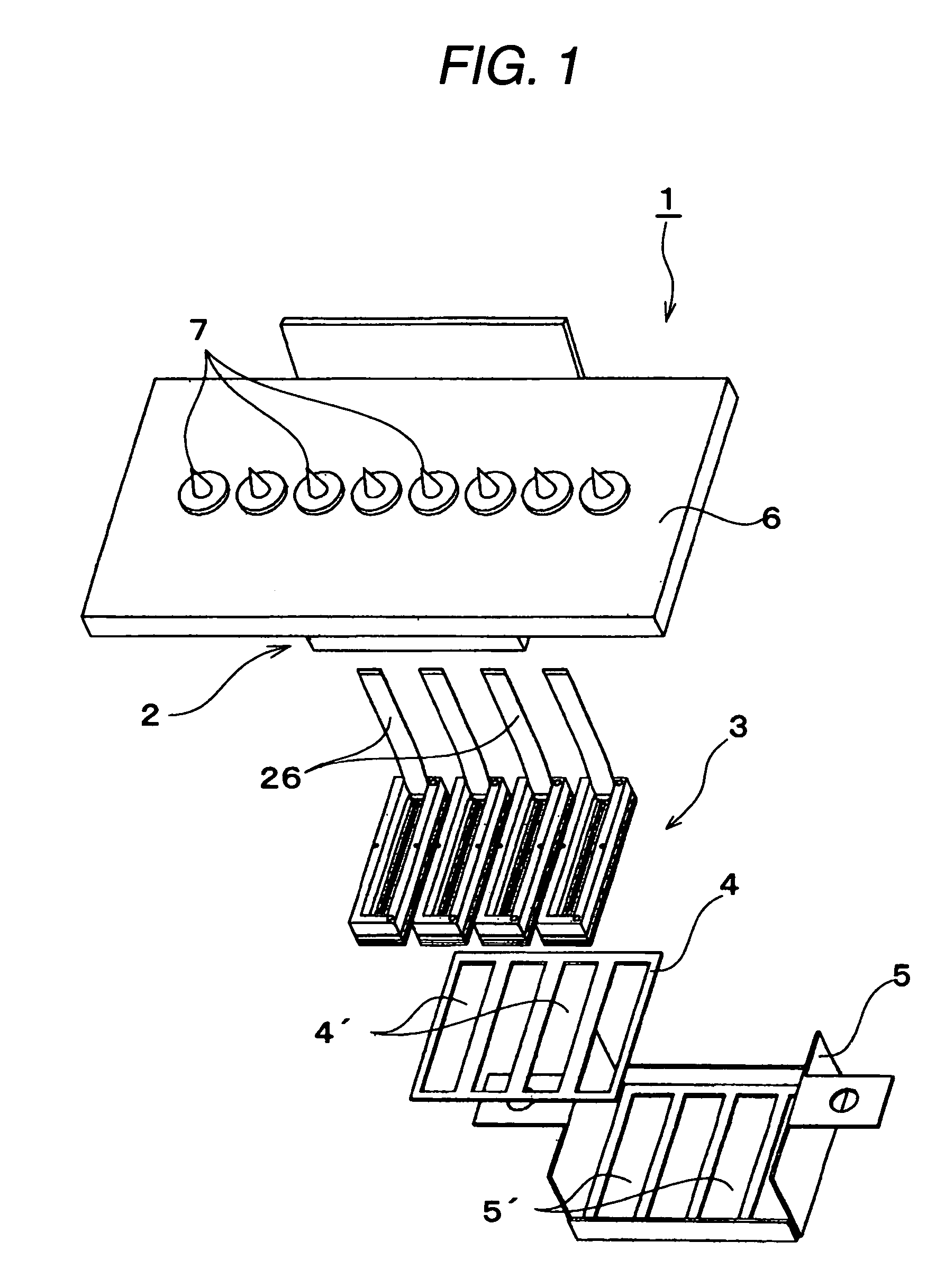

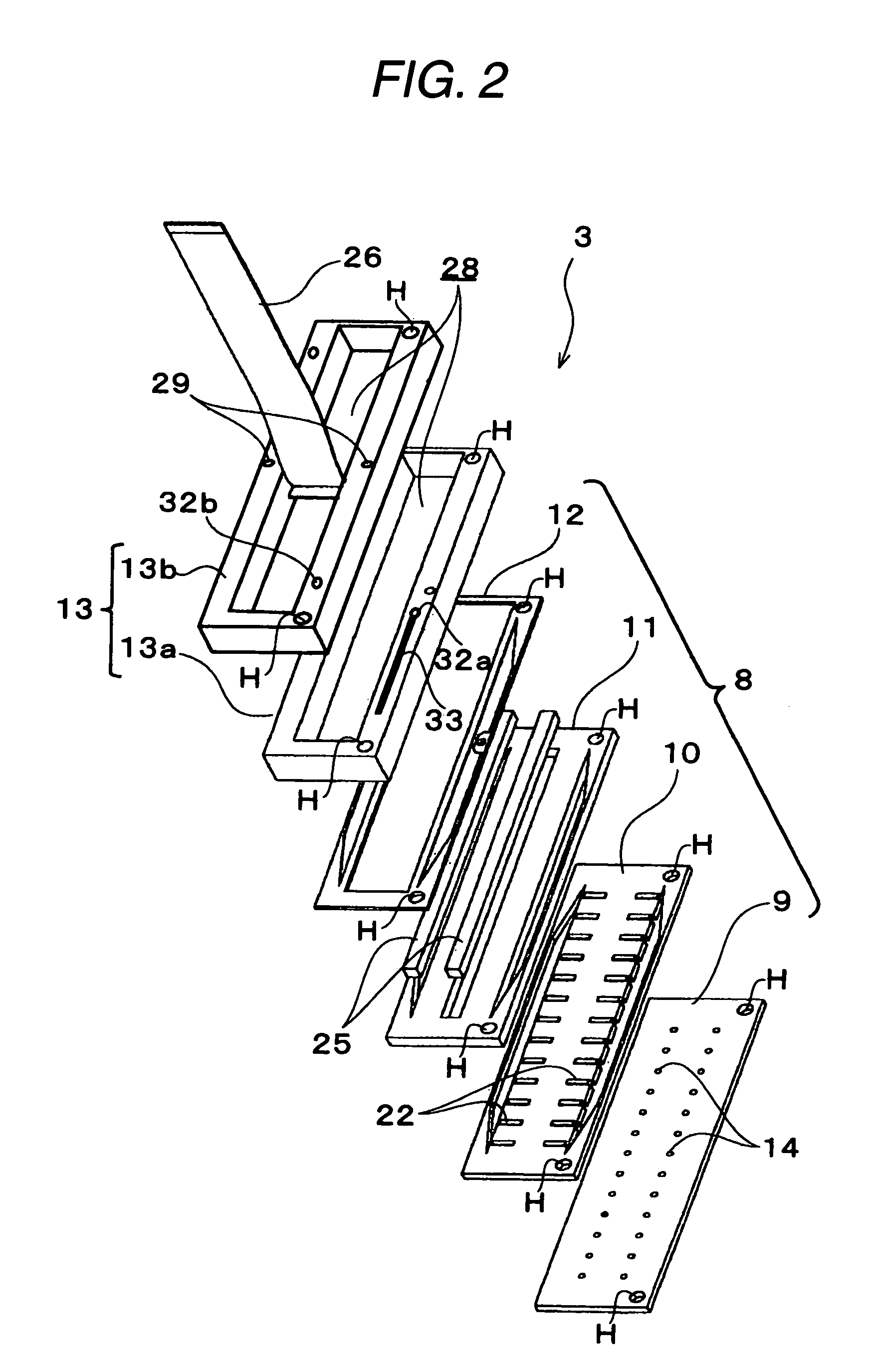

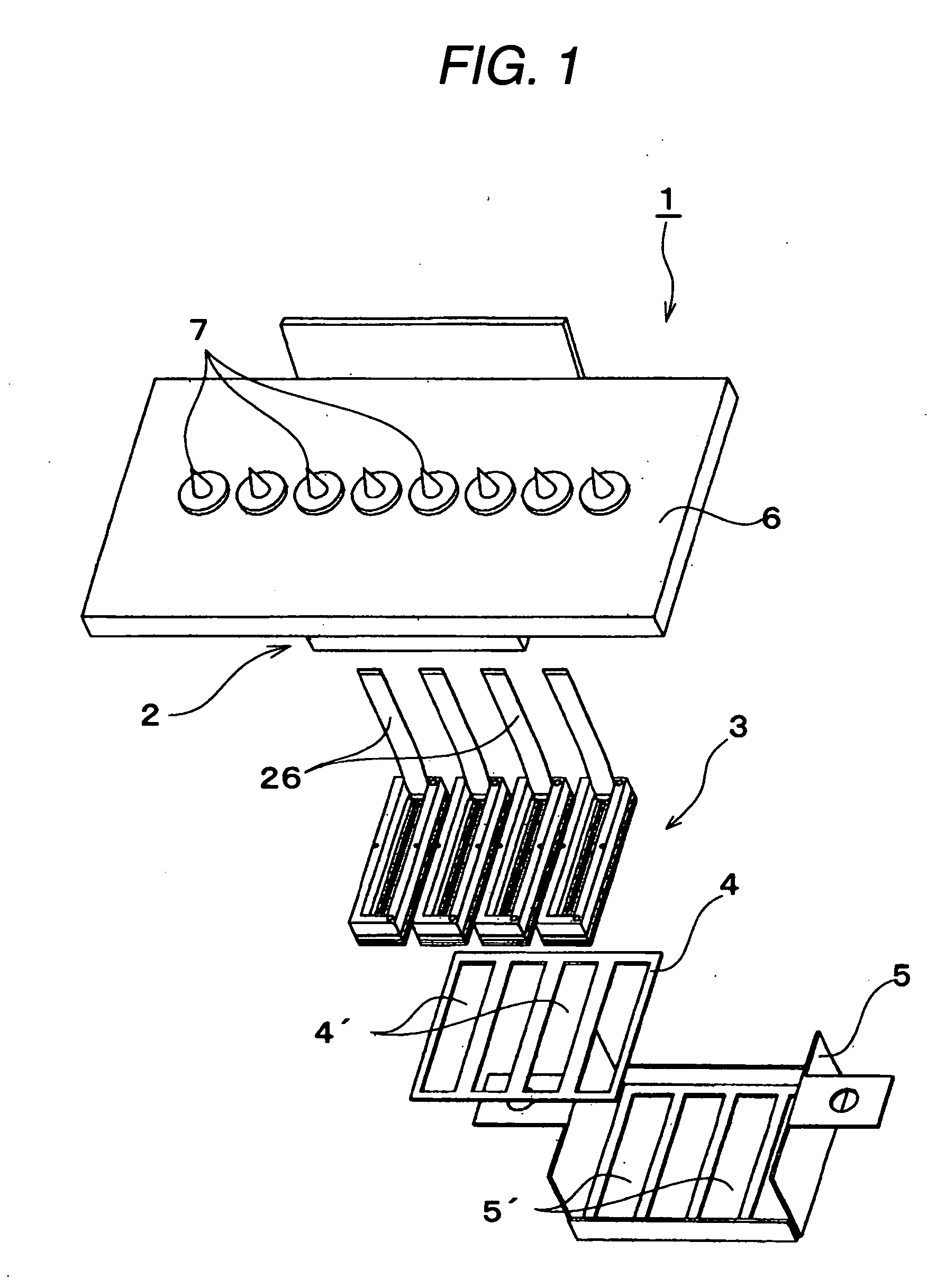

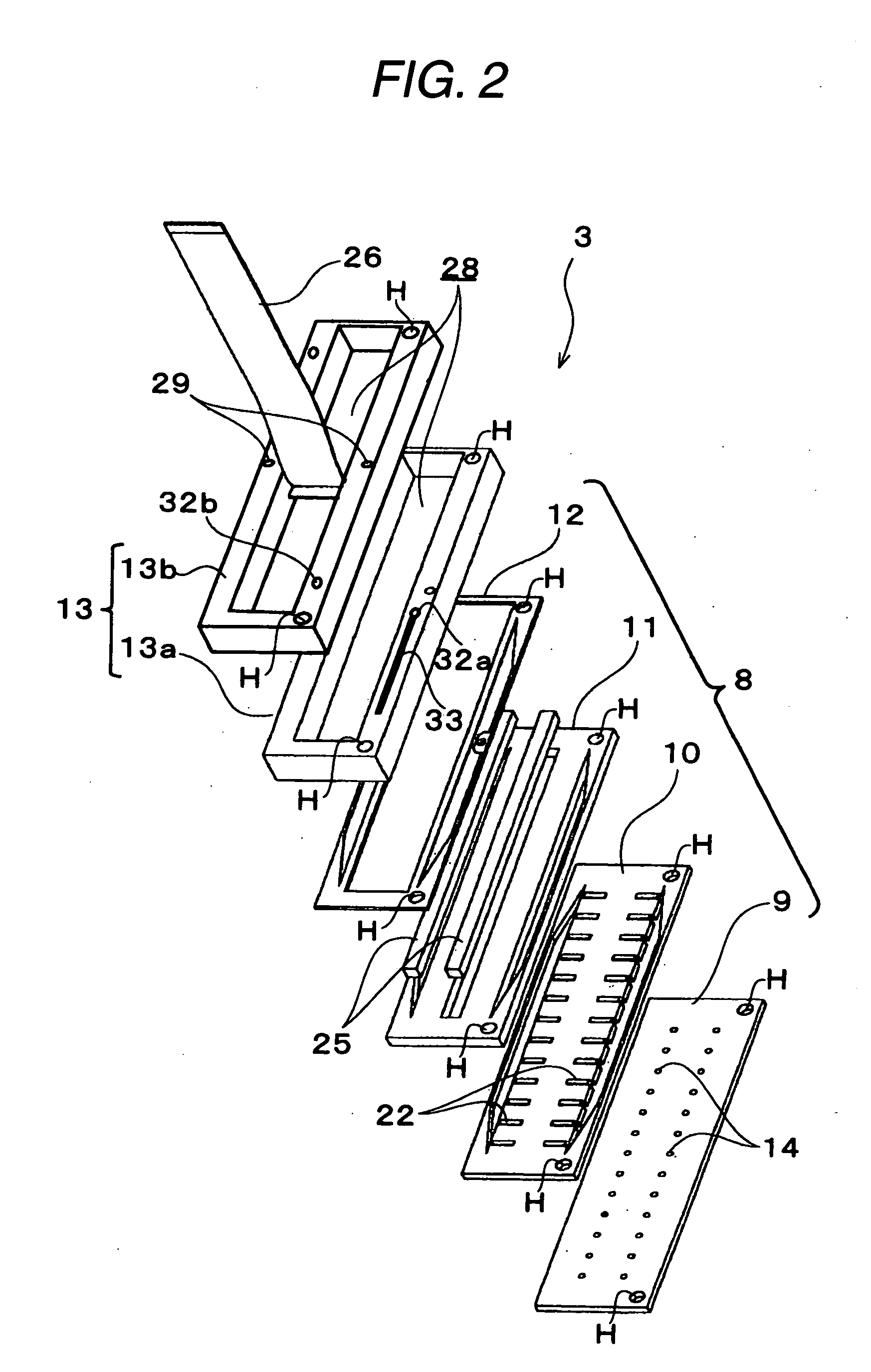

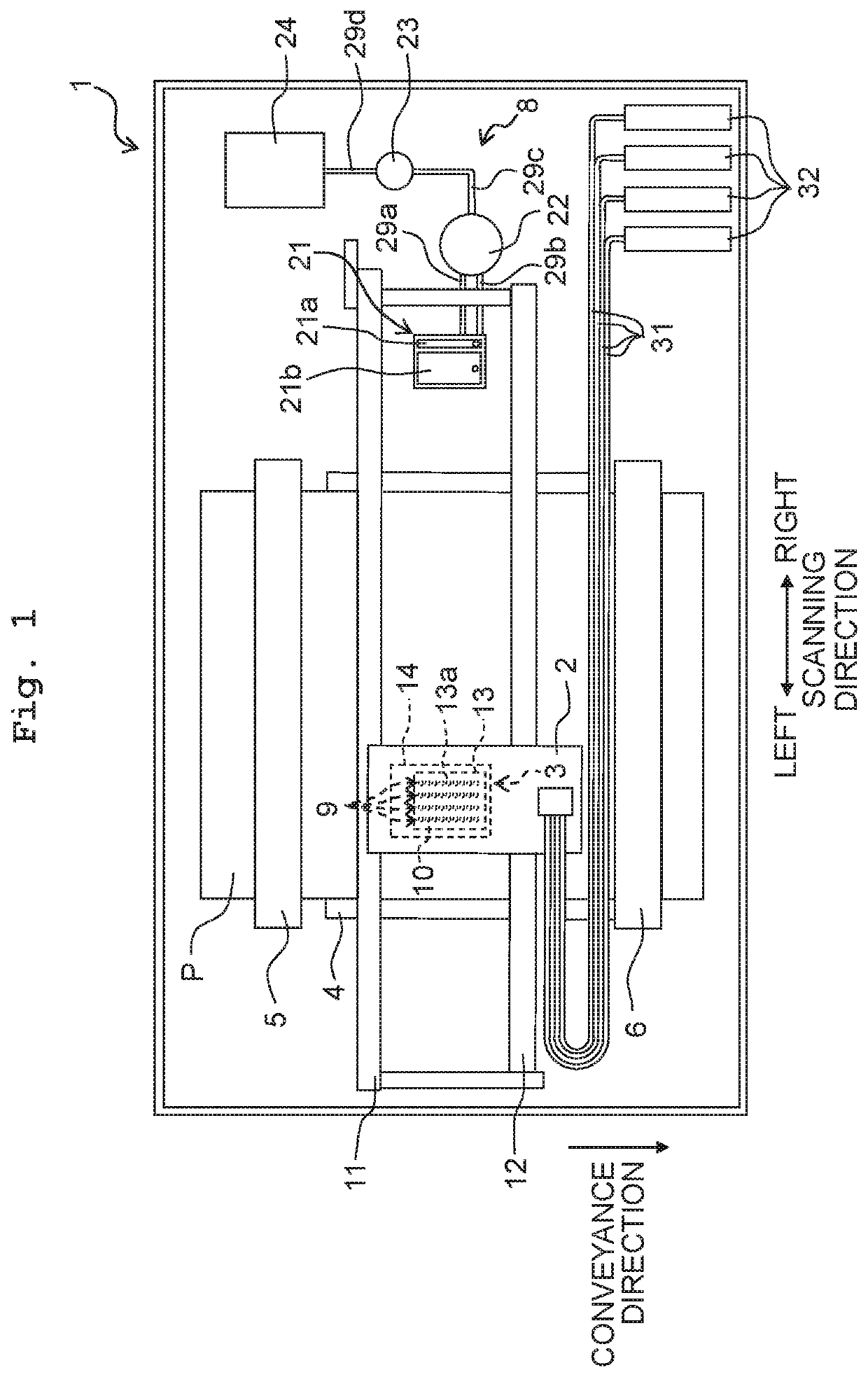

Liquid ejection head

InactiveUS7510271B2Preventing rise of viscosity of liquidMeet miniaturizationPrintingLiquid jetEngineering

A liquid ejection head including: a head main body including: a cavity unit including a passage forming base plate forming a liquid passage from a common liquid chamber to a nozzle opening via a pressure chamber; and a pressure generating source generating a change of pressure of liquid in the pressure chamber to eject the liquid in the pressure chamber as a liquid droplet from the nozzle opening; and a case member to which the head main body is attached and which includes: a first member provided with a first atmosphere opening passage; and a second member laminated on the first member and provided with a second atmosphere opening passage, wherein the first and second atmosphere opening passages communicate with each other under the laminated state and are opened to atmosphere.

Owner:SEIKO EPSON CORP

Detergent composition

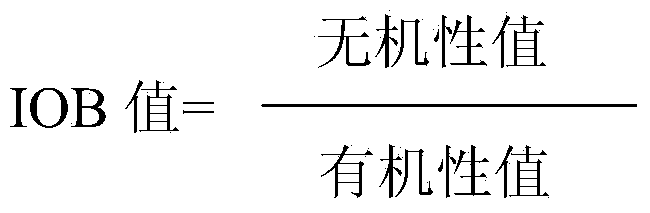

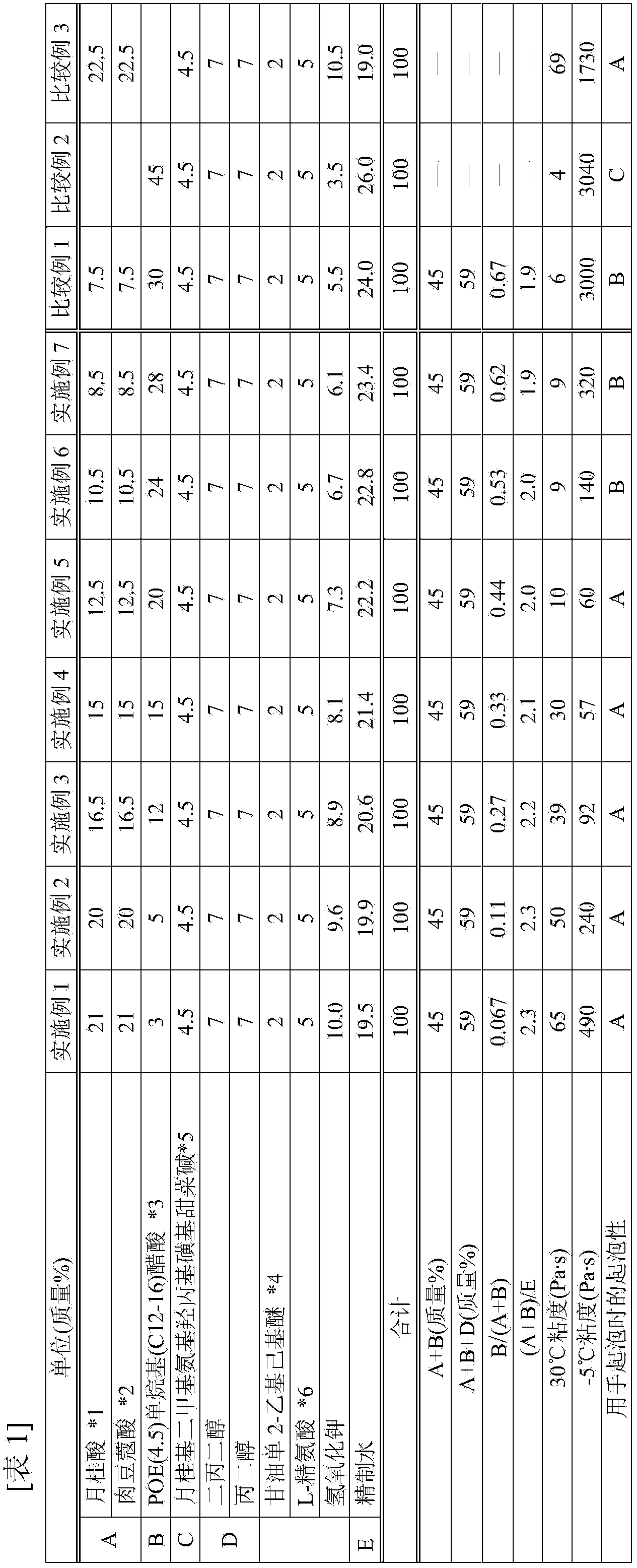

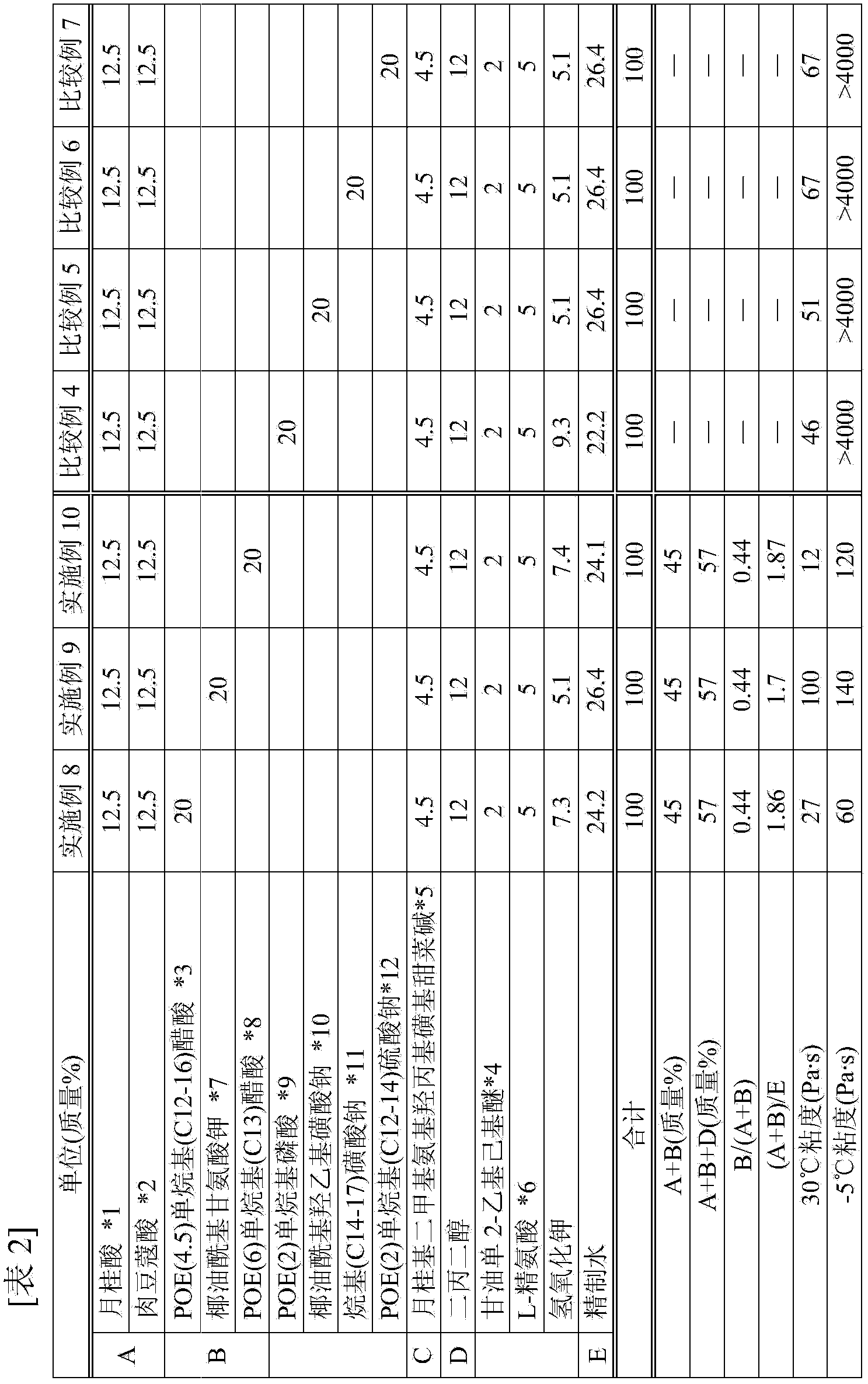

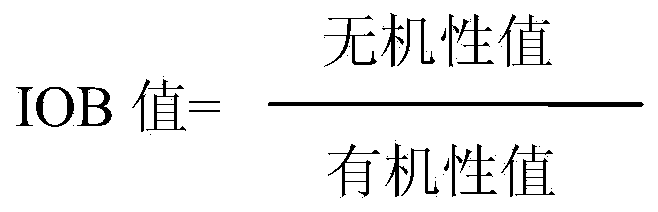

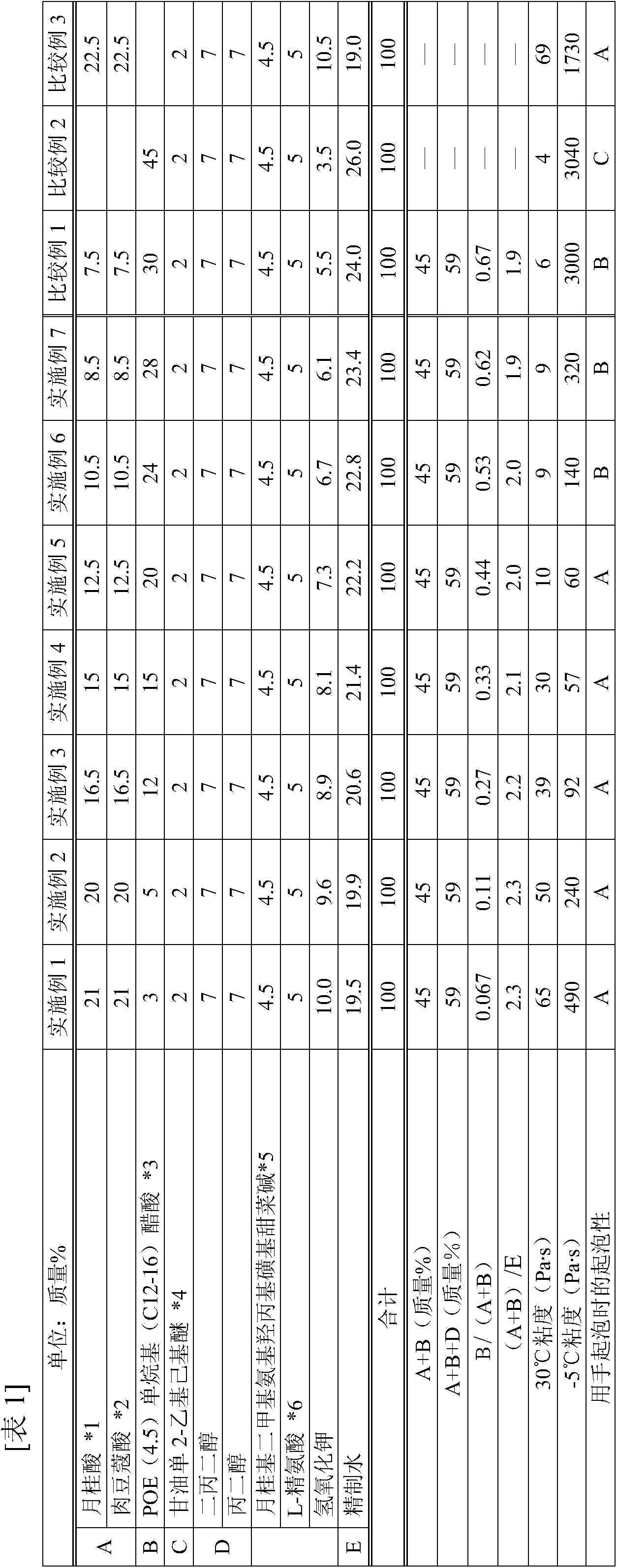

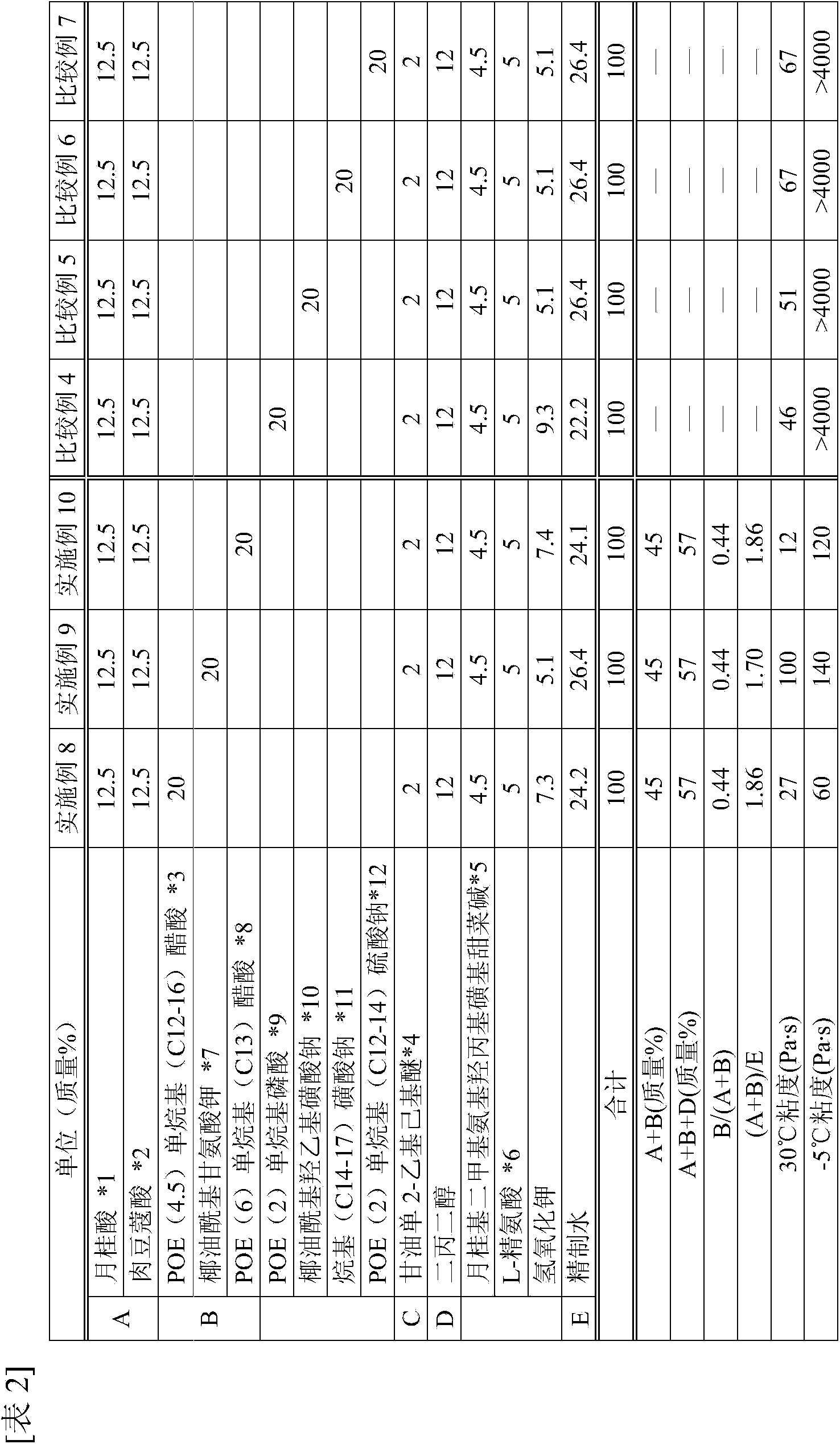

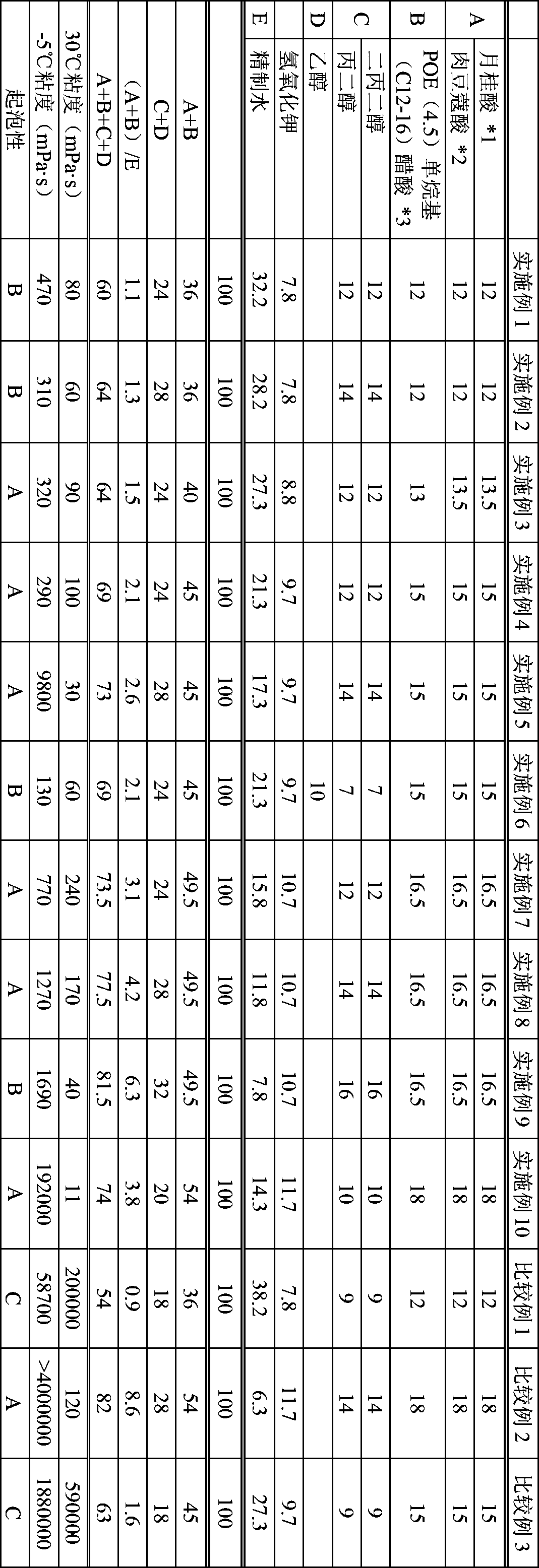

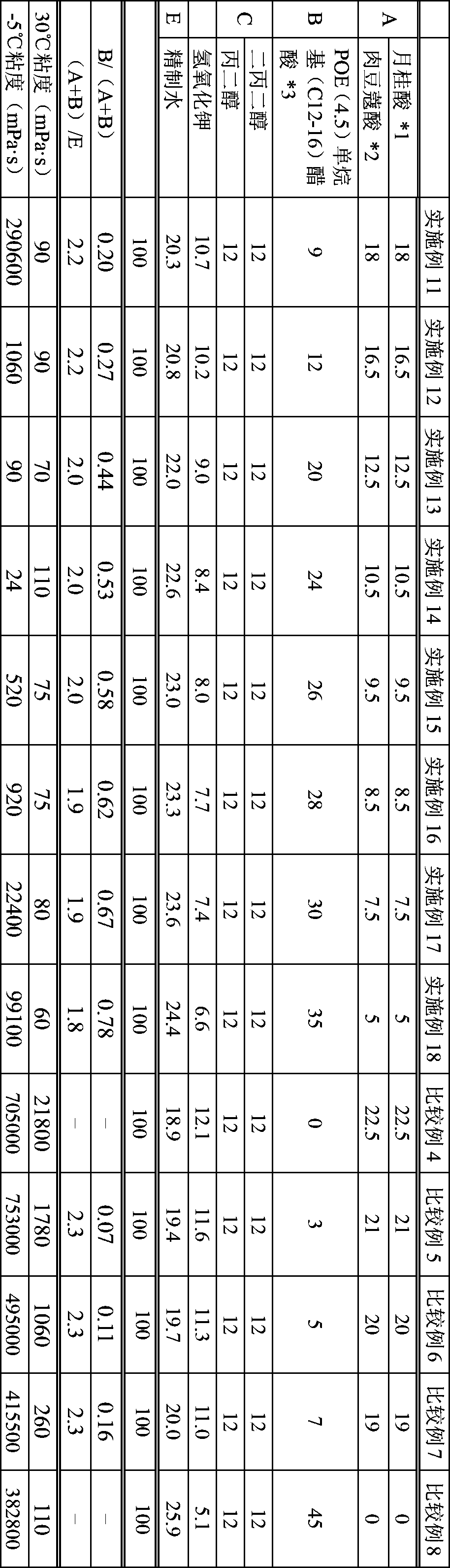

ActiveCN103800213ASuppresses viscosity riseHigh viscosityCosmetic preparationsAnionic surface-active compoundsAlcoholPolyol

The invention provides a detergent composition which contains components (A), (B), (C), (D) and (E), wherein (A) is C12-C22 fatty acids or salts thereof, (B) is an anionic surfactant with carboxylic acid or salts thereof on the hydrophilic group other than the component (A), (C) is an amphoteric surfactant, (D) is polyalcohol with the IOB value of 0.8-4 or a mixture of polyalcohol with the IOB value of 0.8-4 and C3 below monobasic alcohol, and (E) is water. On the basis of reduced mass of acid, the sum of the component (A) and component (B) ((A)+(B)) is 35-60 wt%, the mass ratio of the component (B) to the sum of the component (A) and component (B) ((B) / [(A)+(B)]) is 0.06-0.65%, the content of the component (C) is 1.5-15 wt%, and the content of the component (D) is 6-18 wt%.

Owner:KAO CORP

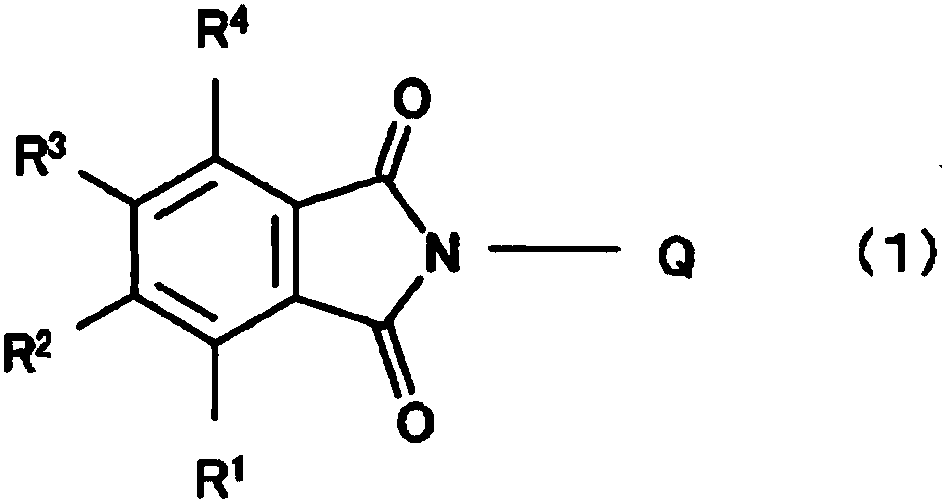

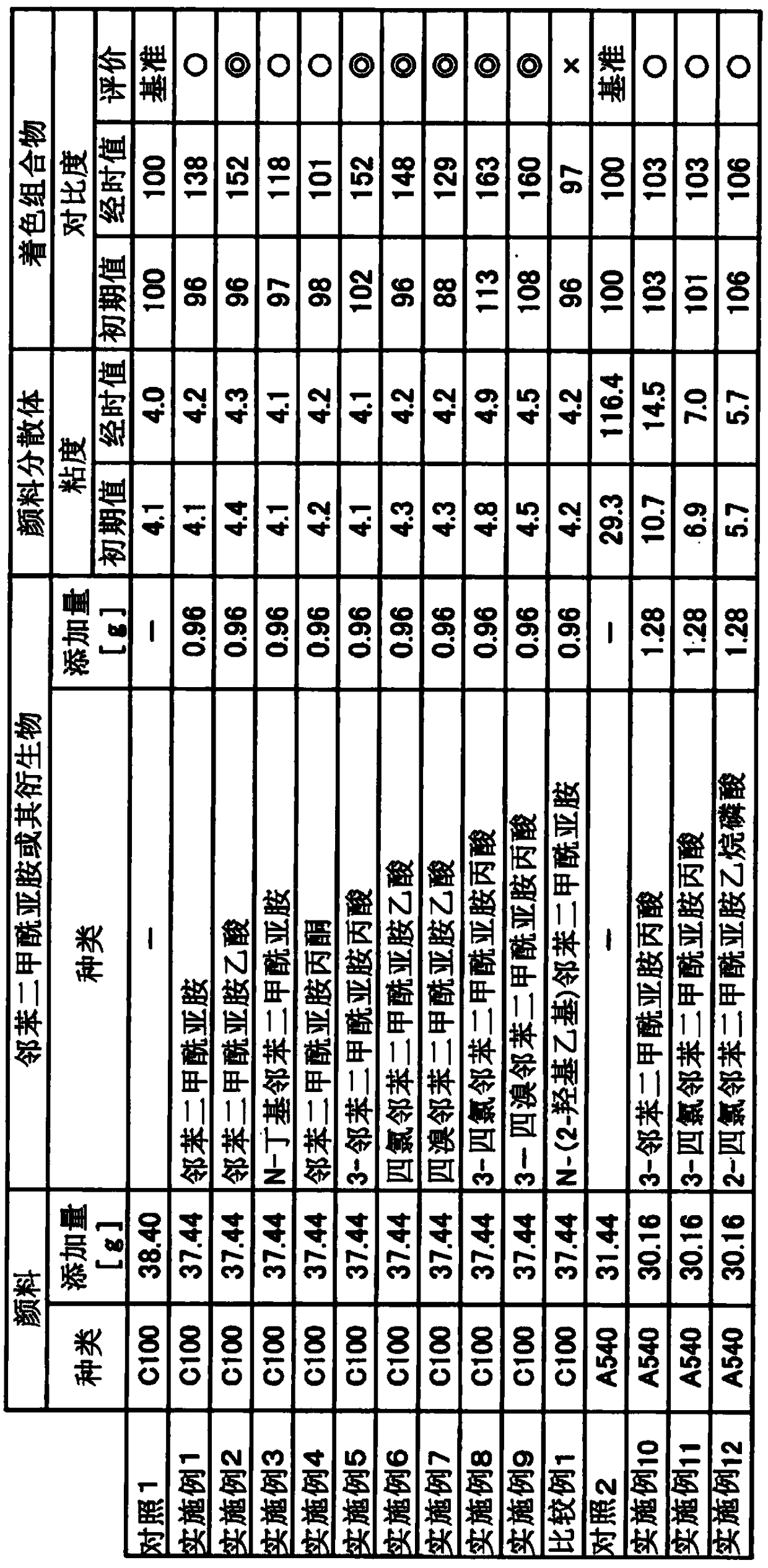

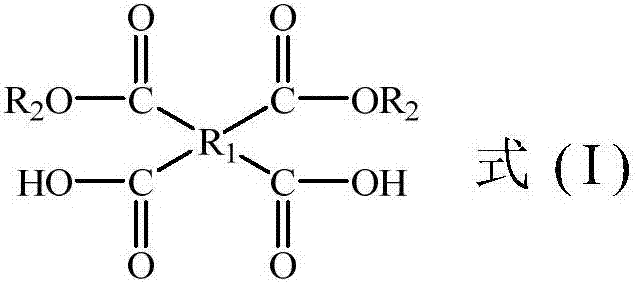

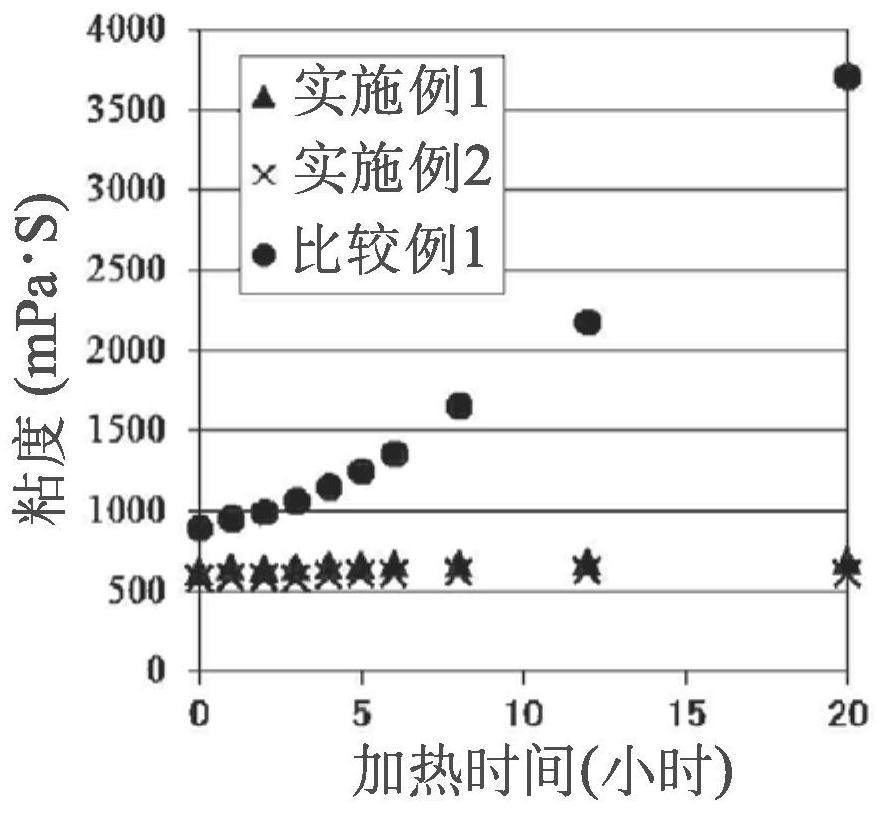

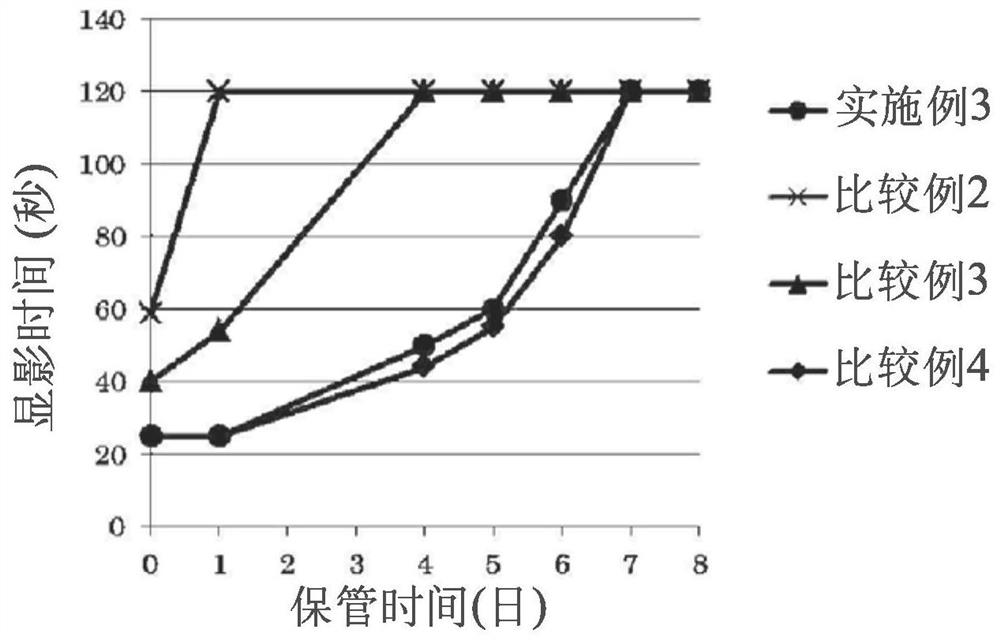

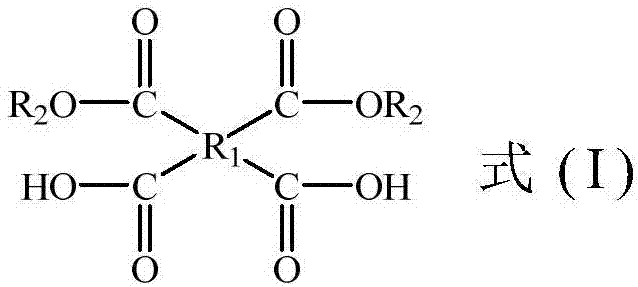

Pigment dispersion and coloring composition using phthalimide and derivatives thereof

ActiveCN108070279AReduce contrastSuppresses viscosity risePhotomechanical apparatusPorphines/azaporphinesPhosphatePigment dispersion

An object of the present invention is to provide a pigment dispersion capable of suppressing an increase in the viscosity after preparation of the pigment dispersion irrespective of the type of phthalocyanine pigment, and suppressing a decrease in the contrast of a coating film after preparing a coloring composition containing the same, and a coloring composition containing the same. The pigment dispersion containing at least one selected from the group consisting of phthalimide and a derivative thereof represented by the following formula (1), a phthalocyanine pigment, a dispersant, and a solvent. (In the formula (1), R1 to R4 are hydrogen atoms or halogen atoms, Q is (i) a hydrogen atom, and (ii) an alkyl group having 1 to 4 carbon atoms of the substituent X bonded to a terminal carbon atom or (iii) an aryl group which may have a substituent Y bonded to a carbon atom of an aromatic ring; the substituent X is an acetyl group or a carboxyl group a phosphate group or a sulfo group; thesubstituent Y is a methyl group, an acetyl group, a carboxyl group, a phosphoric acid group or a sulfo group.)

Owner:SANYO COLOR WORKS

Method for producing golf ball

InactiveUS7601290B2High reboundExcellent characteristicsDomestic articlesSolid ballsThermoplasticSolvent

A method of manufacturing golf balls composed of a core and a cover of one or more layer that encloses the core, at least one cover layer being made of a thermoplastic polyurethane composition characterized by including at least 90 wt % of a thermoplastic polyurethane obtained by a polyurethane-forming reaction of an organic diisocyanate compound with a long-chain polyol and a chain extender, which thermoplastic polyurethane composition cover layer has an inherent viscosity in a DMF solvent of larger than 1.5 dl / g and an inherent viscosity in a 0.05 mol / L n-butylamine-containing DMF solution of larger than 0.5 dl / g, the golf ball manufacturing method being characterized by: conditioning the thermoplastic polyurethane to a pre-processing moisture content of 500 ppm or less, then injection molding the moisture-conditioned thermoplastic polyurethane to form the thermoplastic polyurethane composition cover layer. Golf balls produced by this method have a high rebound and excellent spin characteristics and scuff resistance, are recyclable in a molding operation, and have excellent manufacturability.

Owner:KURARAY CO LTD

Dry-process fine silica particle

InactiveCN101454246AGood dispersionGood interstitial permeabilitySilicaDevelopersMicroparticleWavelength

Fine dry silica particles are produced by combustion by using a burner of a multiple-pipe structure, feeding a mixed gas of a gas of a siloxane compound without containing halogen in the molecules thereof and an oxygen gas at a ratio of 0.3 to 1.5 into the center pipe of a burner, and feeding a combustible gas into the first annular pipe on the outer side of the center pipe of the burner. The fine dry silica particles has a BET specific surface area of 20 to 55 m 2 / g, and wherein the water suspension containing the fine silica particles at a concentration of 1.5% by weight has an optical absorbance for the light of a wavelength of 700 nm satisfying the following formula (1): wherein S is the BET specific surface area (m 2 / g) of the fine dry silica particles. The fine dry silica particles do not almost contain coarse particles or aggregated particles, have a sharpe grain size distribution, excellently disperse in the resins, suppress a rise in the viscosity when highly filled, and impart sufficiently large strength to the resin compound.

Owner:TOKUYAMA CORP

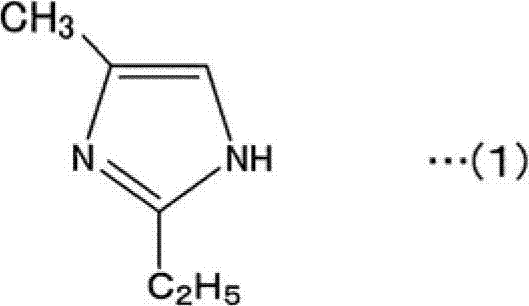

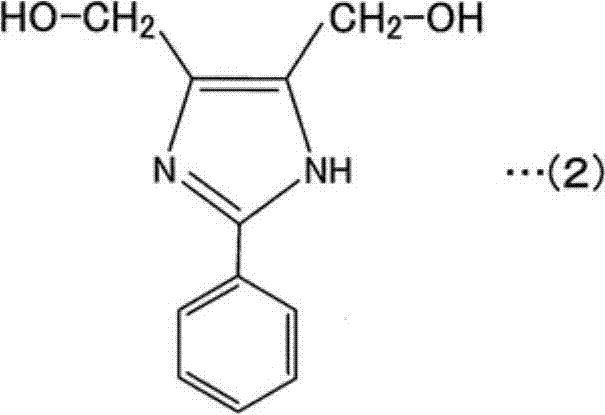

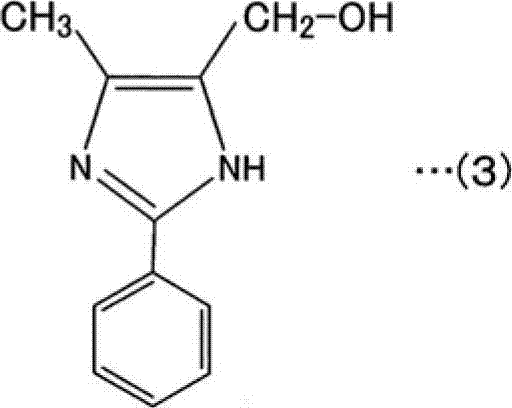

Sheet-shaped epoxy resin composition for encapsulating electronic components and electronic component device using the same

InactiveCN103160076AImprove reliabilitySuppresses viscosity riseSemiconductor/solid-state device detailsSolid-state devicesElastomerEpoxy

The invention provides a sheet-shaped epoxy resin composition for encapsulating electronic components and an electronic component device using the same, wherein the storage stability is good, and the gas output during the solidification can be reduced. The composition is the sheet-shaped epoxy resin composition for encapsulating the electronic components, and the thickness of the sheet is in a range from 150(mu)m to 1mm. the epoxy resin composition comprises the following (A) to (D) composition, and the following (E)composition. (A) is the epoxy resin, (B) is the phenolic resin, (C) is the elastomer, (D) is the inorganic filler. The (E) is at least one of the following 5-Nitro-isophthalic acid and the complex formed by the imidazoliniumcompounds represented by the following formula(1), or the 5-Nitro-isophthalic acid and the complex formed by the imidazoliniumcompounds represented by the following formula(2), or the 5-Nitro-isophthalic acid and the complex formed by the imidazoliniumcompounds represented by the following formula(3).

Owner:NITTO DENKO CORP

Liquid ejection head

InactiveUS20060256159A1Preventing rise of viscosity of liquidMeet miniaturizationPrintingLiquid jetEngineering

A liquid ejection head including: a head main body including: a cavity unit including a passage forming base plate forming a liquid passage from a common liquid chamber to a nozzle opening via a pressure chamber; and a pressure generating source generating a change of pressure of liquid in the pressure chamber to eject the liquid in the pressure chamber as a liquid droplet from the nozzle opening; and a case member to which the head main body is attached and which includes: a first member provided with a first atmosphere opening passage; and a second member laminated on the first member and provided with a second atmosphere opening passage, wherein the first and second atmosphere opening passages communicate with each other under the laminated state and are opened to atmosphere.

Owner:SEIKO EPSON CORP

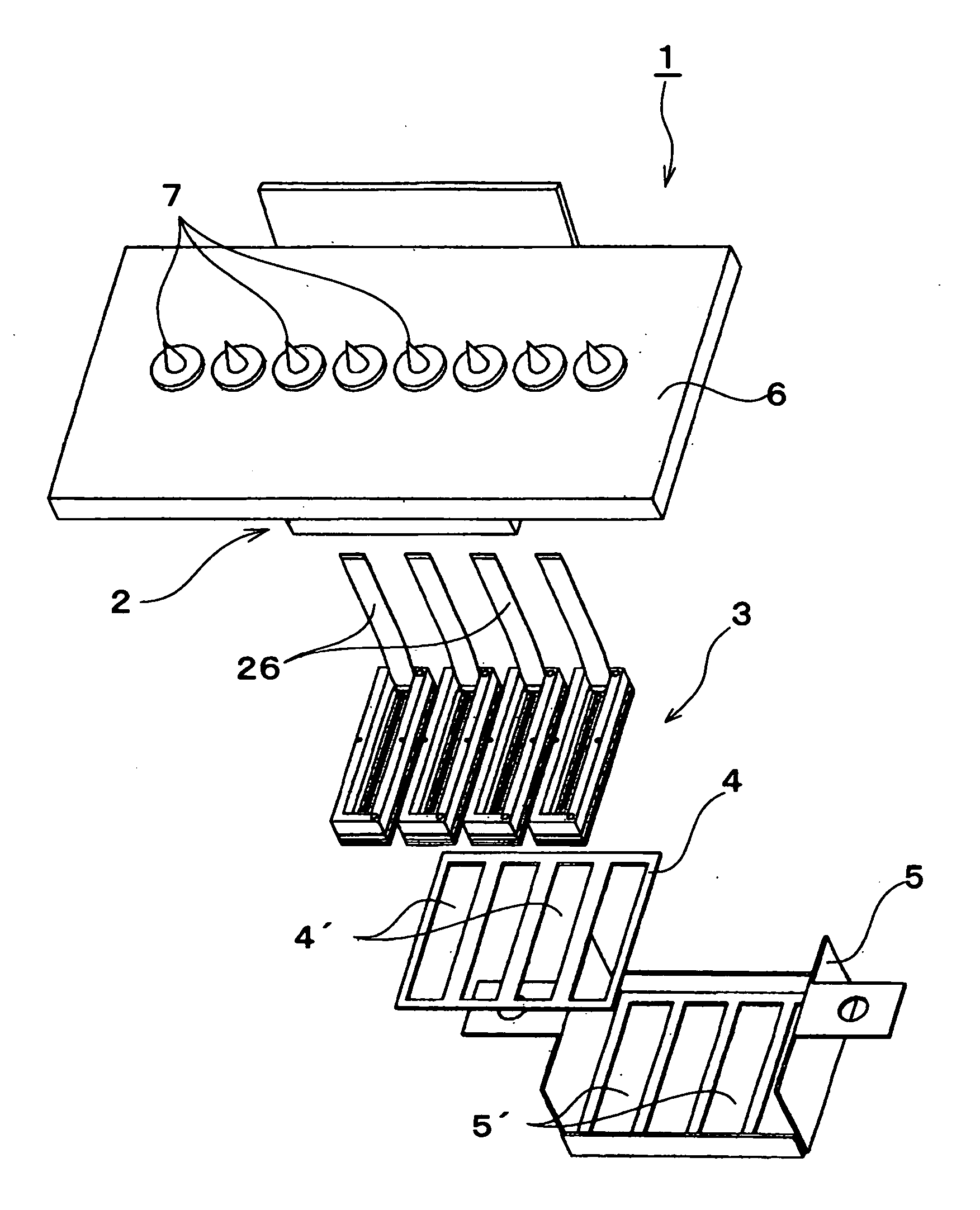

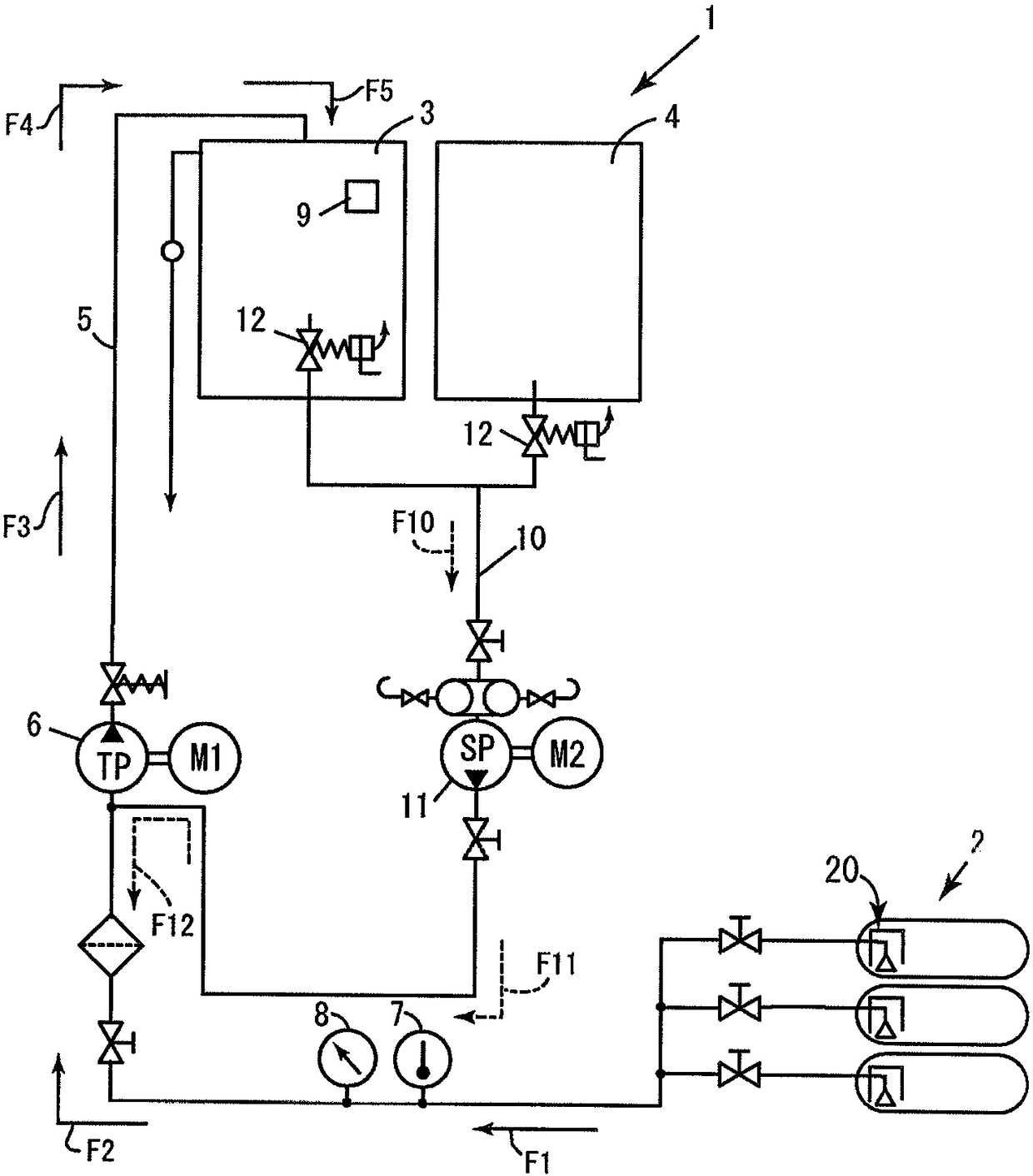

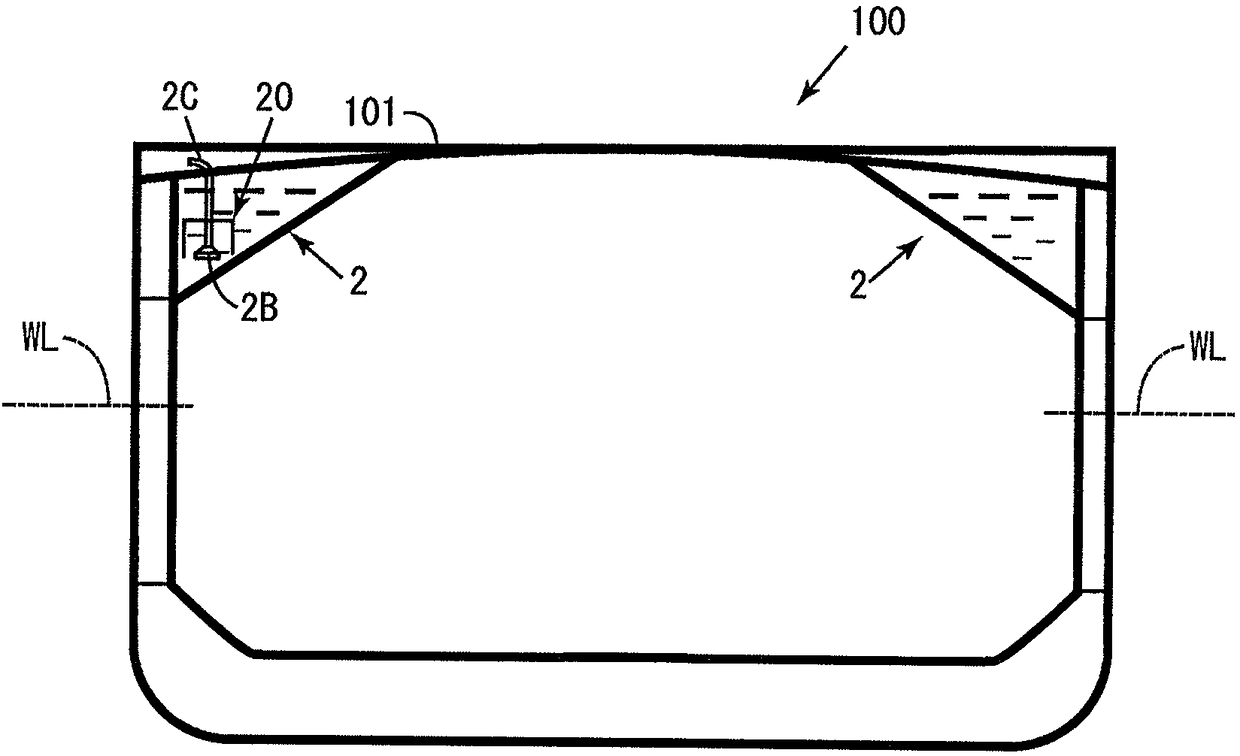

Transfer device of fuel oil

ActiveCN108202843AAvoid temperature dropSuppresses viscosity riseHull interior subdivisionAuxillariesAutomotive engineeringBell mouth

The invention provides a fuel oil transfer device capable of preventing fuel oil taken out from a fuel oil storage tank from being affected by atmospheric temperature and being in a viscosity increasing state, to prevent deterioration of transfer efficiency. The fuel oil transfer device comprises: a fuel oil storage tank (2) arranged on a position to receive heat of atmosphere; a fuel oil precipitation tank (3) for heating the fuel oil sucked from the fuel oil storage tank (2), and a fuel oil daily tank (4) for temporarily storing the heated fuel oil in the fuel oil storage tank (2) so that heated fuel oil return to the fuel oil storage tank (2) and the fuel oil can be circulated. The fuel oil storage tank (2) has a suction pipe (2C) having a bell mouth (2B) opening toward the bottom in the deepest position in a longitudinal direction; and a steam heating pipe (30) disposed in pairs near the bell mouth (2B).

Owner:HOKUSHIN ENG

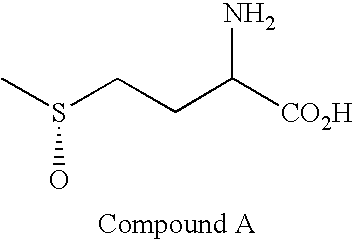

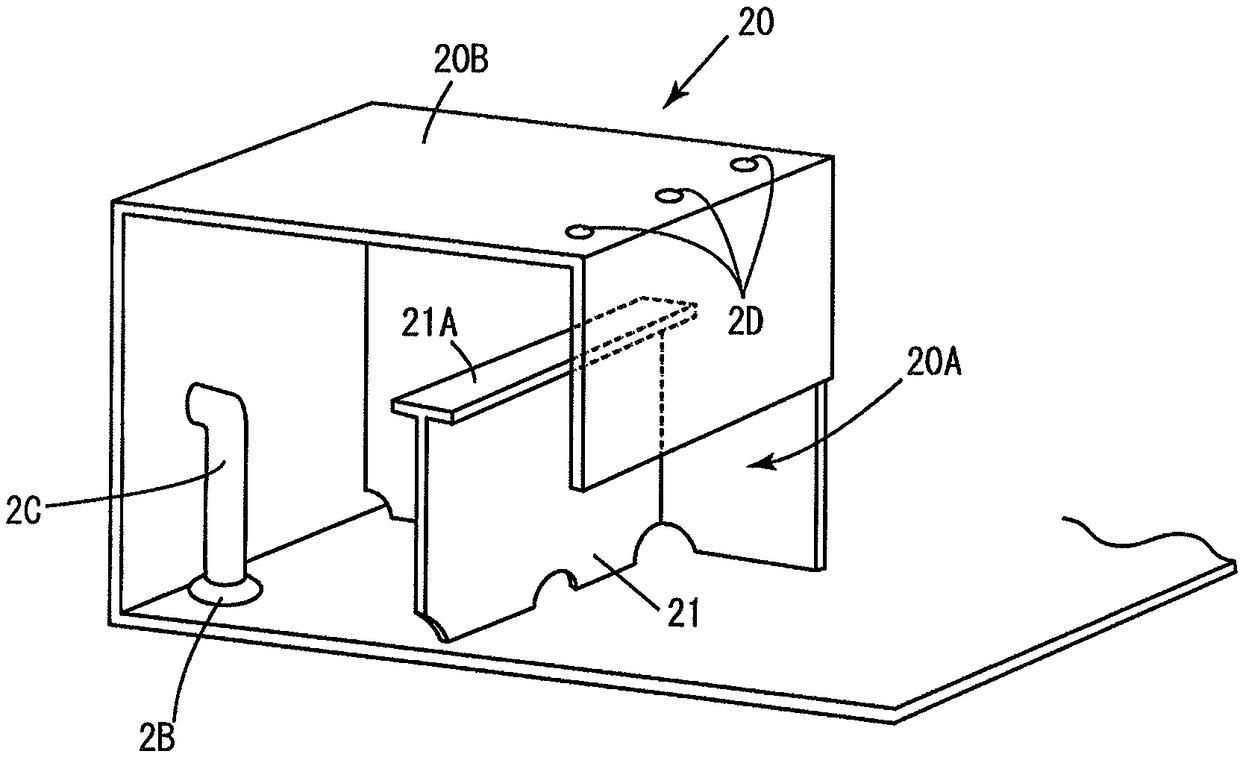

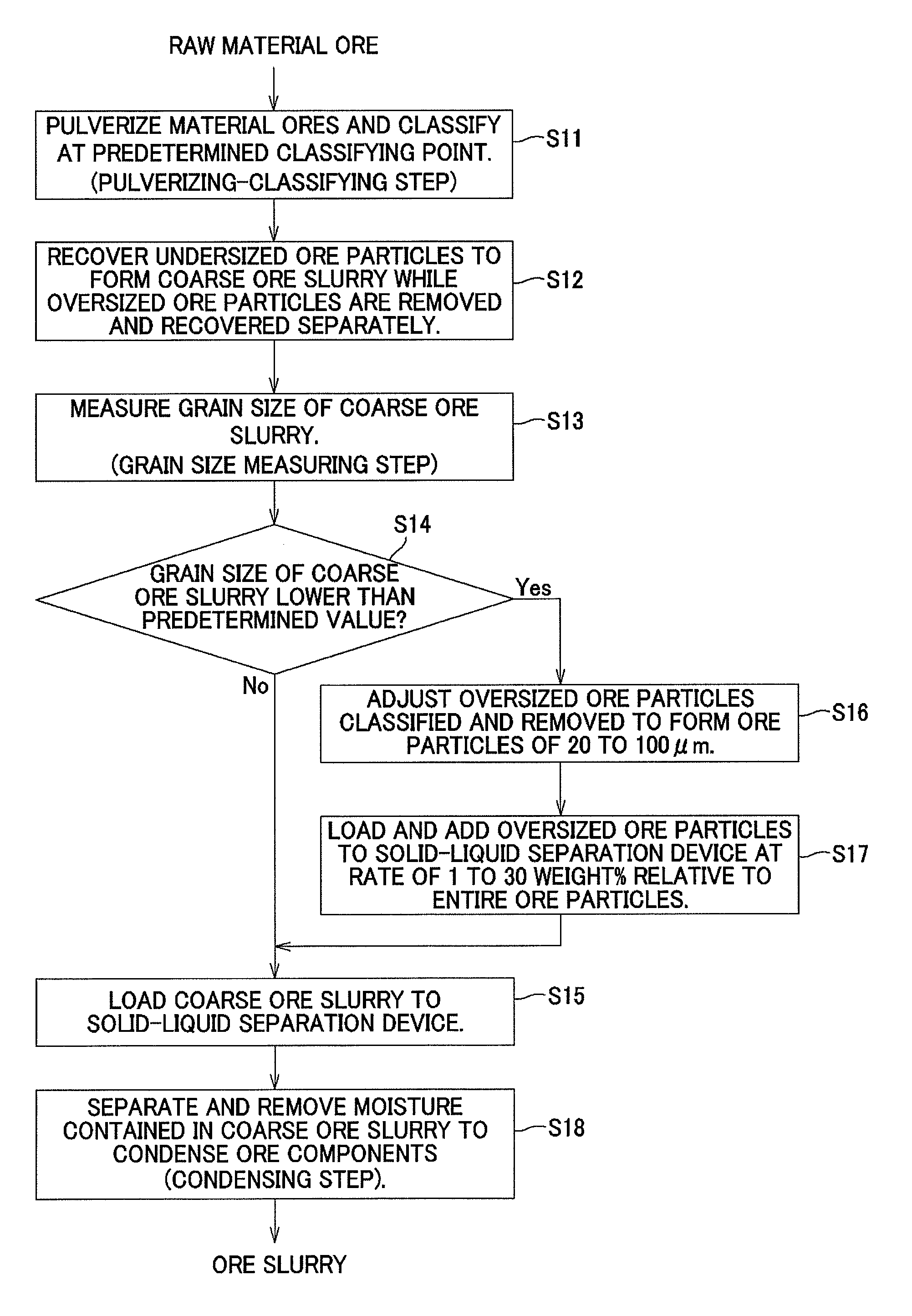

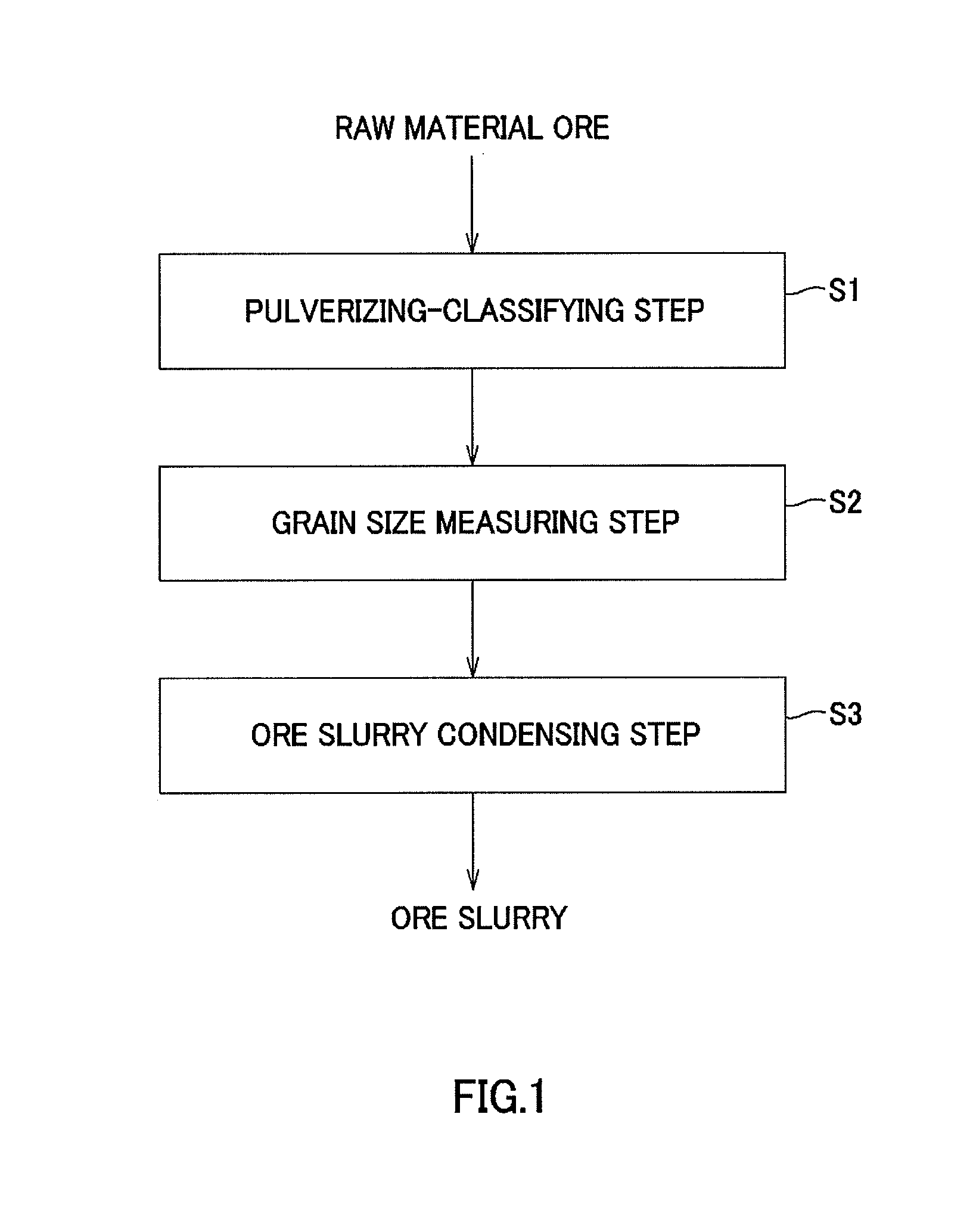

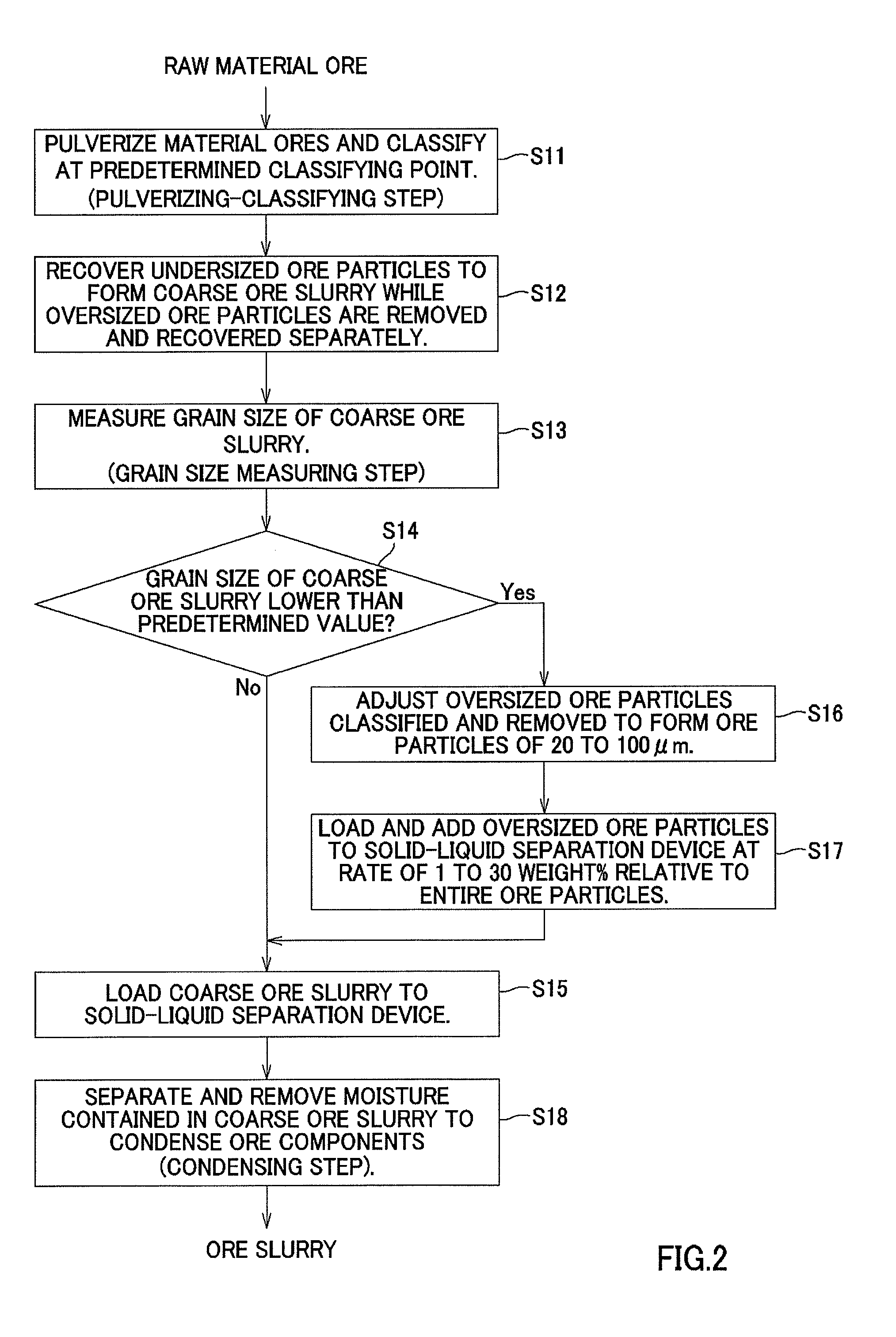

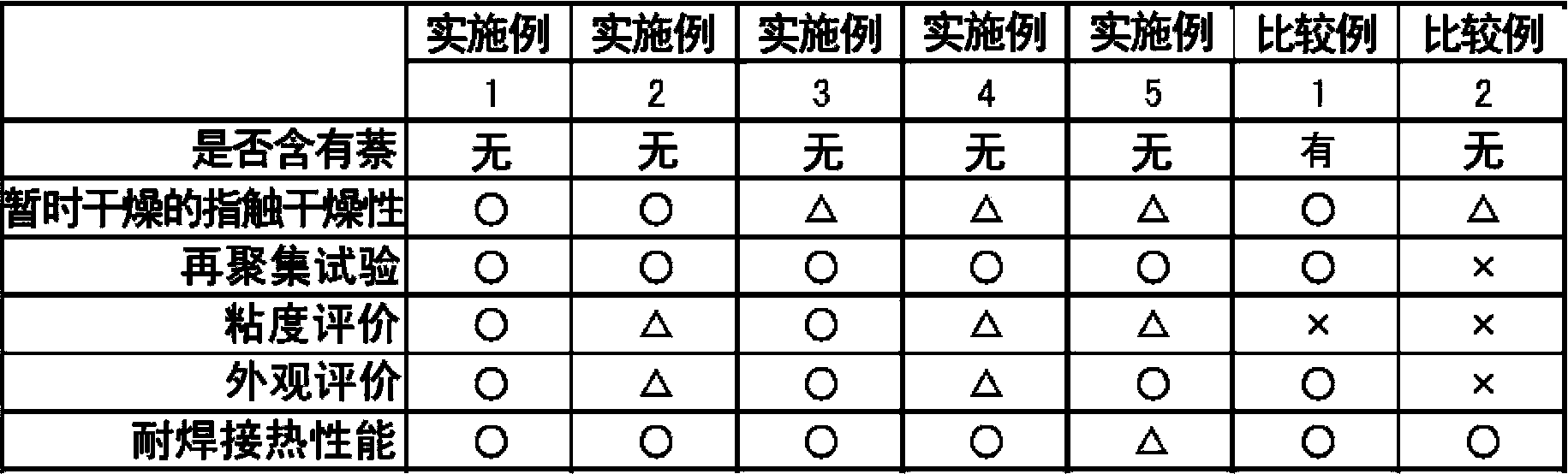

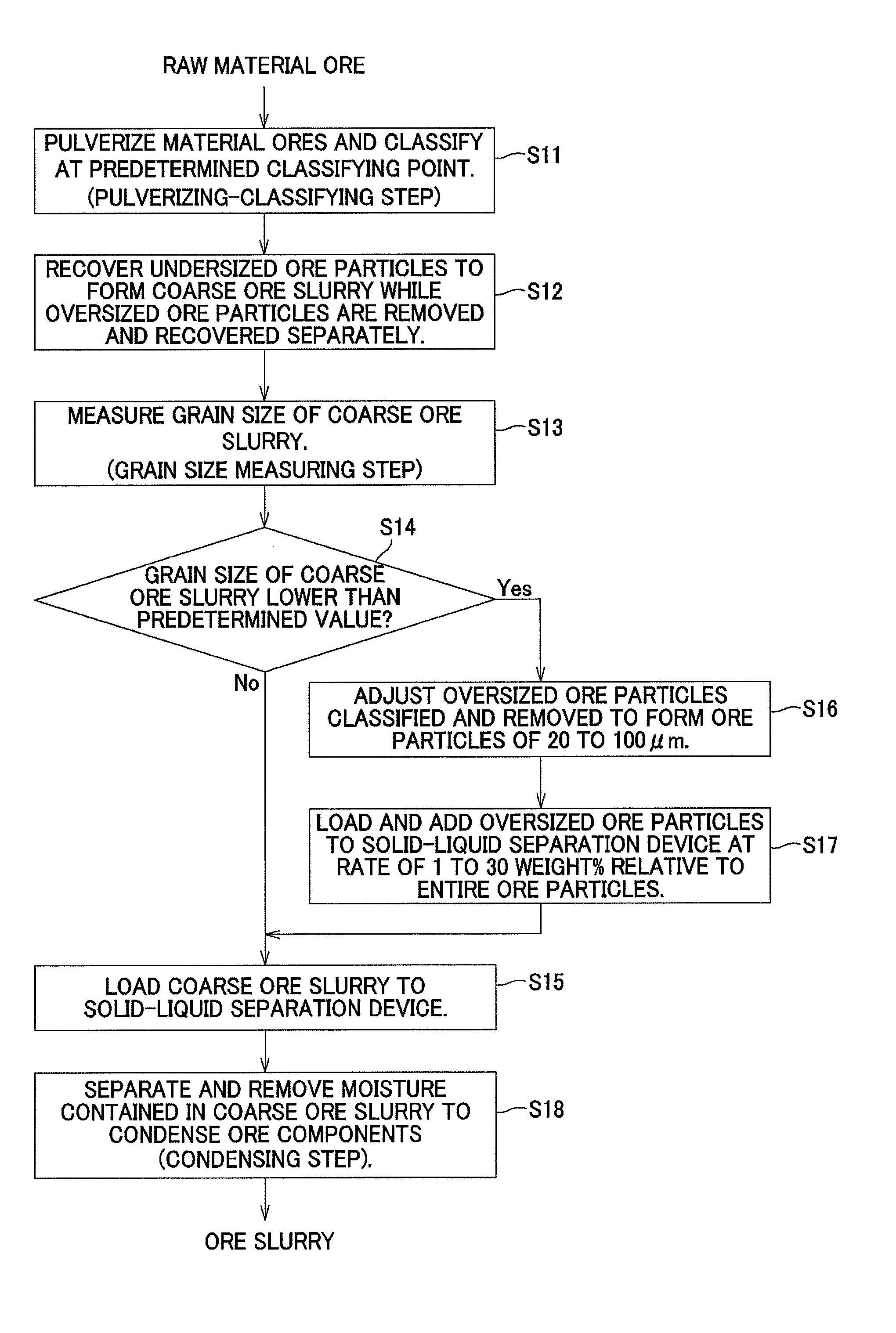

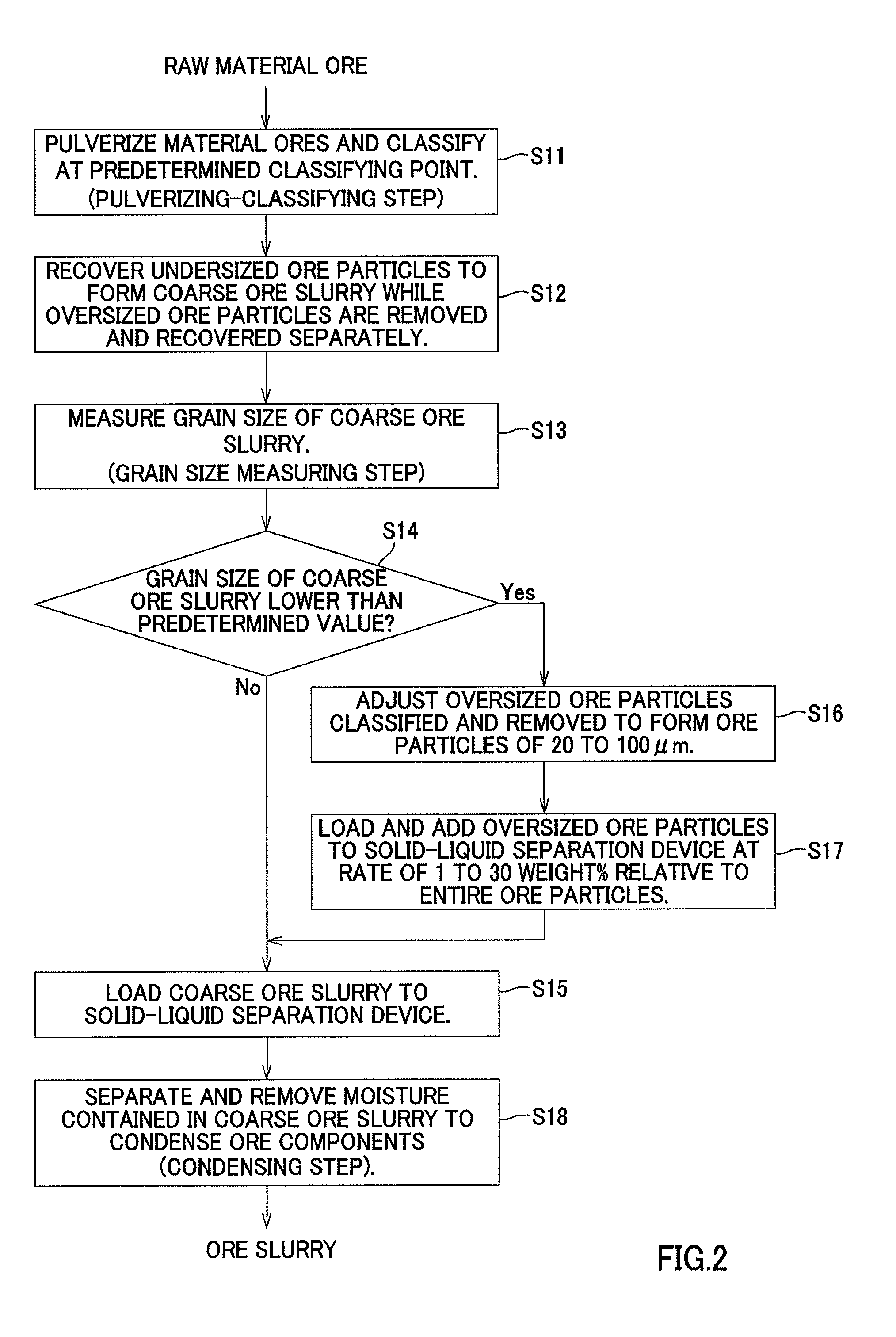

Ore slurry production method and metal refining method

ActiveUS20140151472A1Suppresses viscosity riseEfficient transportProcess efficiency improvementGrain treatmentsGranularitySlurry

Disclosed is a method for producing an ore slurry that can suppress a rise in the viscosity of the ore slurry and consequently prevent a failure in transporting the slurry, and also to provide a metal refining method utilizing such a slurry producing method. The present invention includes: a pulverizing / classifying step of pulverizing raw material ores and classifying the resulting ores at a predetermined classifying point so that oversized ore particles are removed so as to obtain a coarse ore slurry composed of undersized ore particles; a grain size measuring step of measuring the grain size of the resulting coarse ore slurry; and an ore slurry condensing step of loading the coarse ore slurry to a solid-liquid separation device and separating and removing moisture contained in the coarse ore slurry therefrom so as to condense ore components.

Owner:SUMITOMO METAL MINING CO LTD

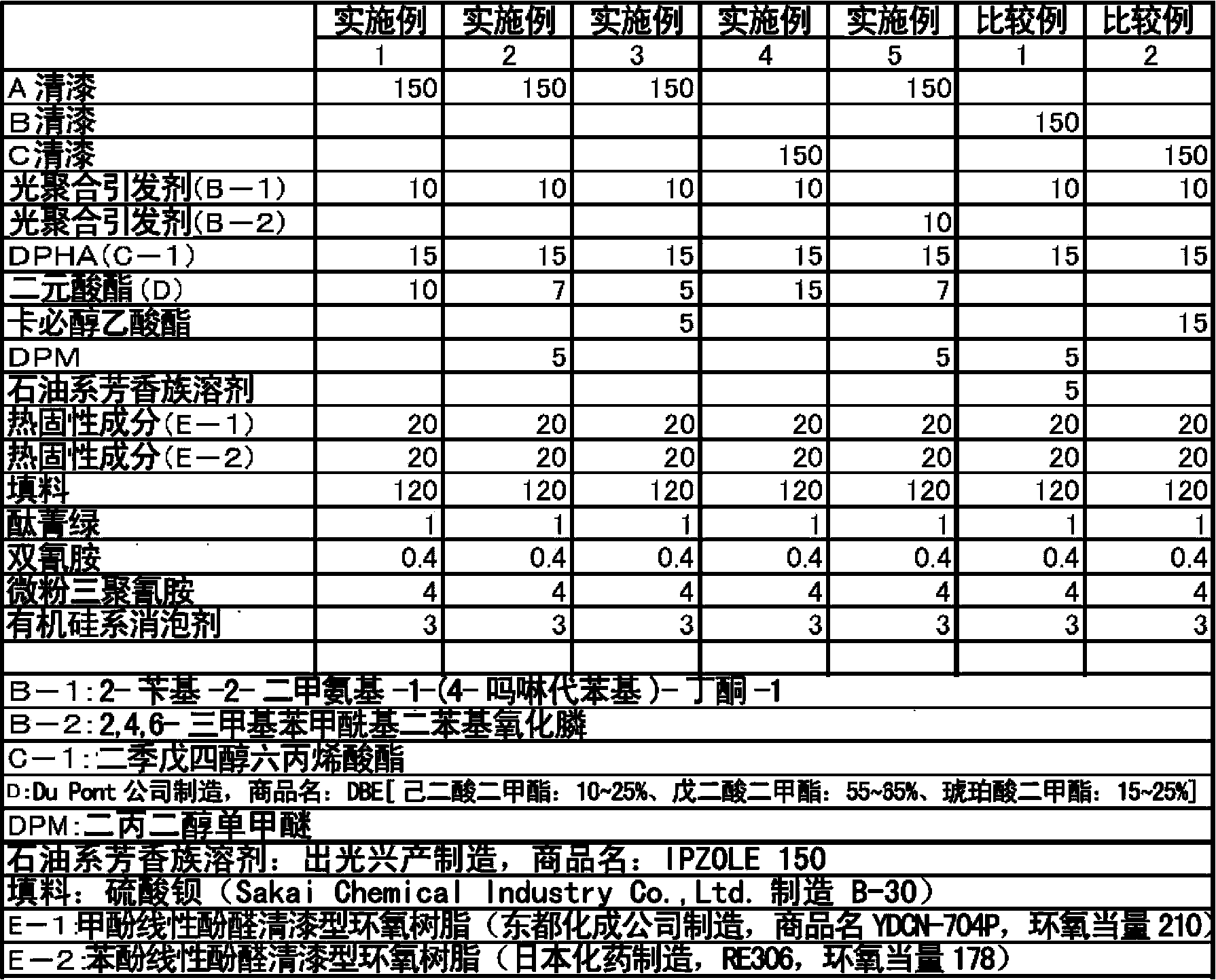

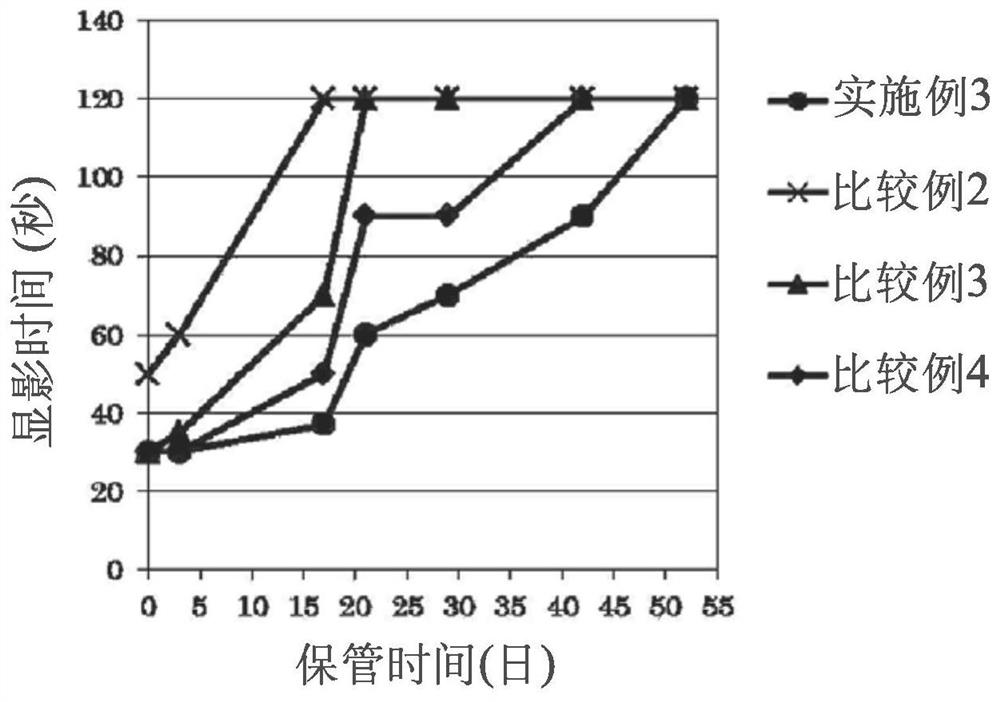

Alkali developing-type photosensitive resin composition and dry film as well as cured material and printed circuit board

InactiveCN103513515AImprove featuresReduction of poor appearancePhotomechanical apparatusNon-metallic protective coating applicationHazardous substancePrinted circuit board

The invention provides an alkali developing-type photosensitive resin composition and a dry film as well as a cured material and a printed circuit board. The alkali developing-type photosensitive resin composition does not contain coarse grains, contains few substances harmful to human bodies, has excellent storage stability and can be used for inhibiting the worsening of operating environments. The alkali developing-type photosensitive resin composition is characterized by containing a carboxyl-containing resin (A), a photopolymerization initiator (B), a compound (C) with more than two olefinic unsaturated groups in one molecule, and dibasic acid ester (D).

Owner:TAIYO INK SUZHOU

Ore slurry production method and metal refining method

Owner:SUMITOMO METAL MINING CO LTD

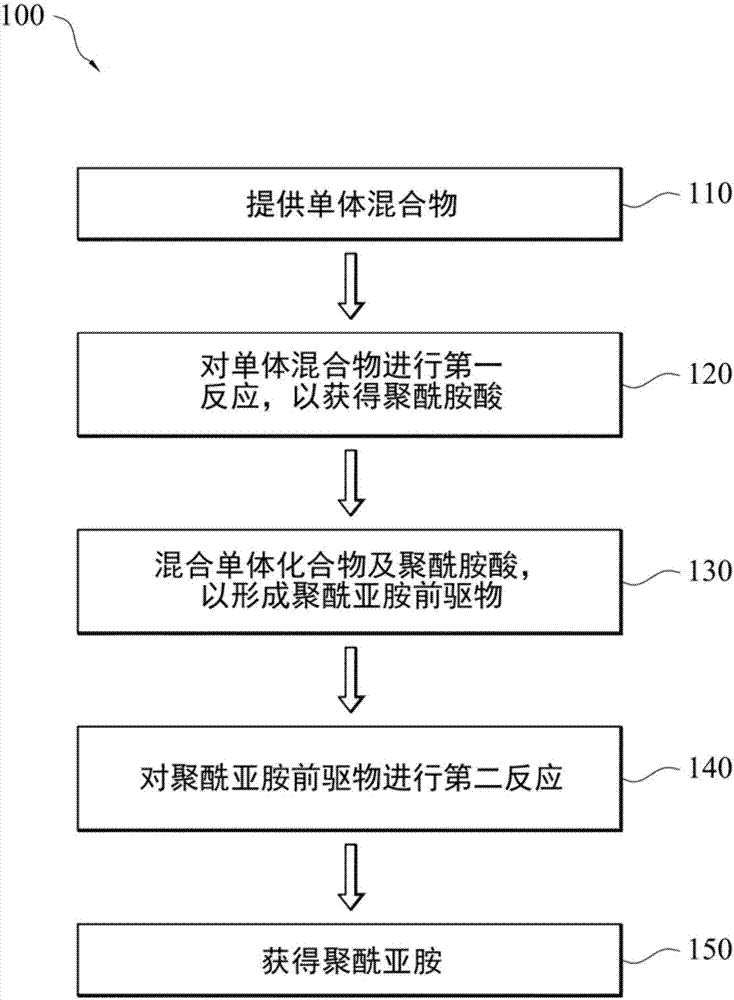

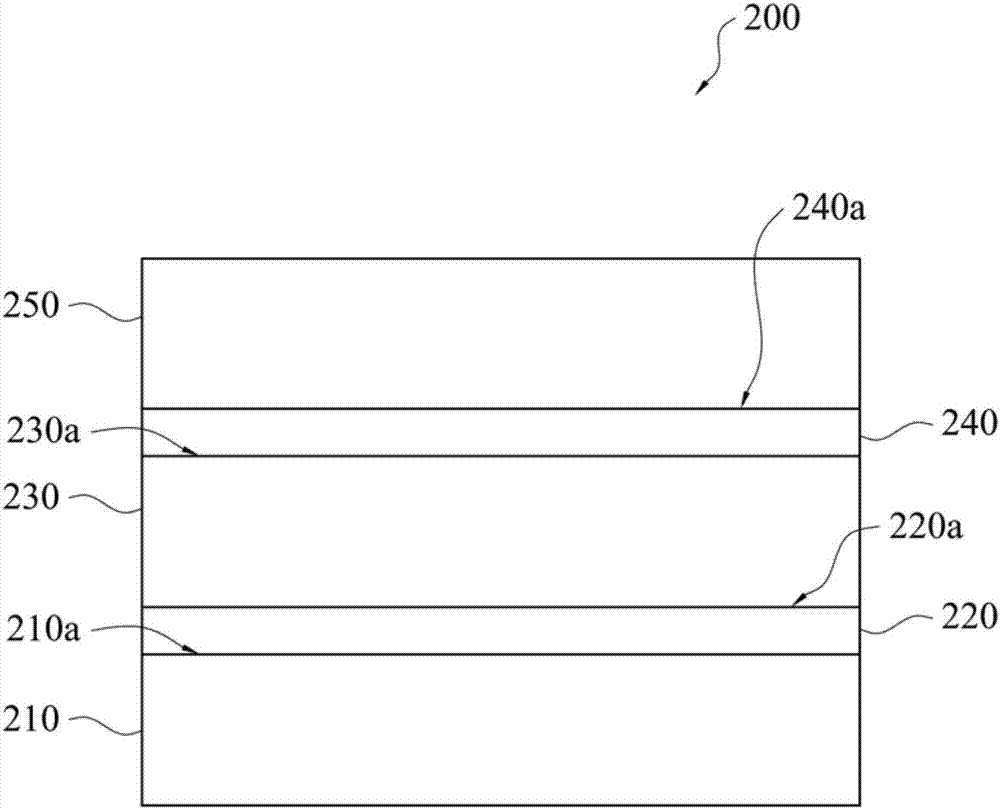

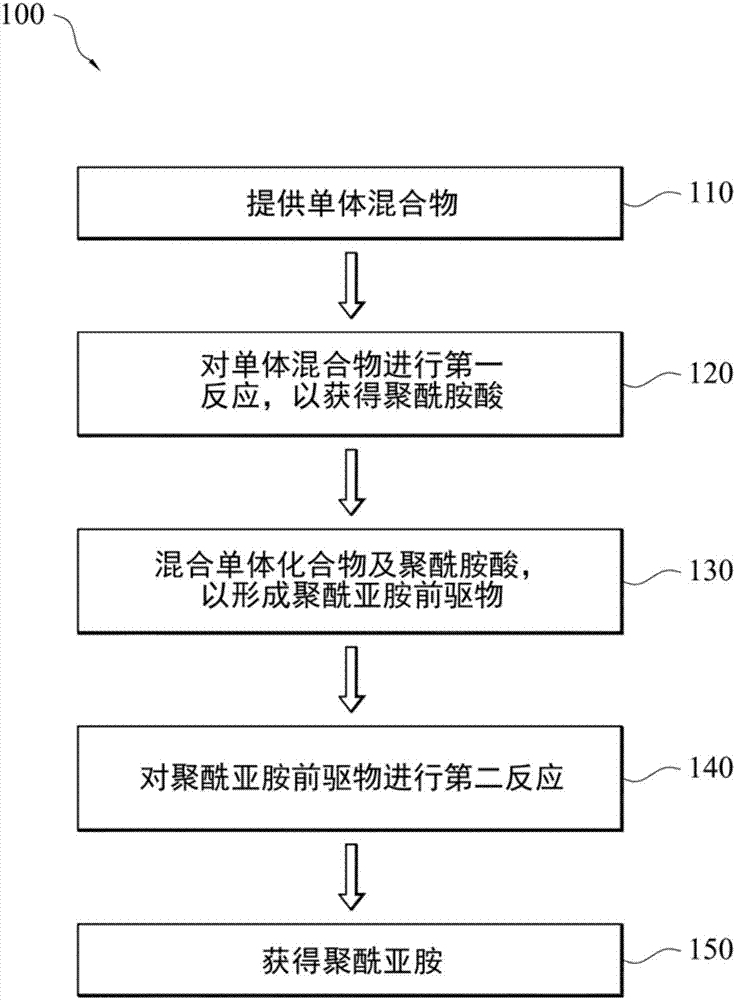

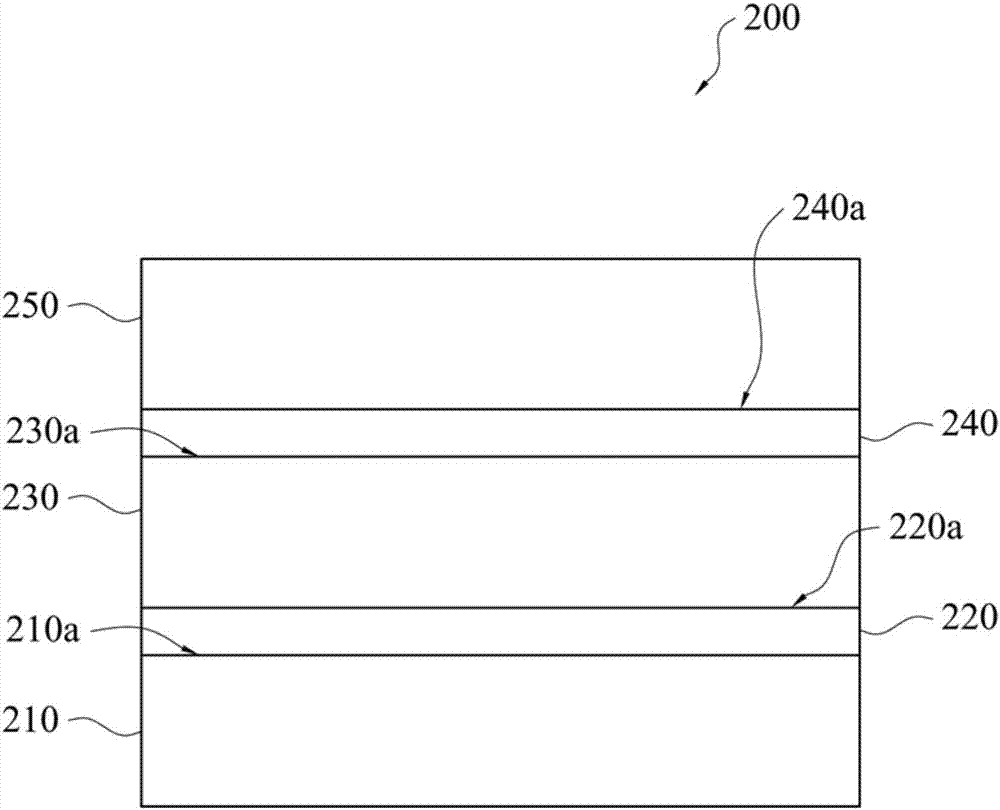

Polyimide precursor composition, preparation method of polyimide and polyimide

InactiveCN107365414AAppropriate molecular weightImprove mechanical propertiesCoatingsPolyamic acidMonomer

The present invention relates to a polyimide precursor composition, a method for preparing a polyimide, and polyimide. The polyimide precursor composition contains polyamic acid and a monomeric compound. The polyamic acid is prepared from a monomer mixture by a first reaction, wherein the monomer mixture comprises a diamine compound and a dianhydride compound. The aforementioned monomeric compound has two carboxyl groups and two ester groups. The prepared polyimide precursor composition can be further reacted to obtain a polyimide having good mechanical properties and film properties.

Owner:TAIFLEX SCI

Water-soluble working fluid for fixed abrasive wire saw

ActiveCN103391992BAvoid cloggingSuppresses viscosity riseSemiconductor/solid-state device manufacturingGrinding machinesWorking fluidCarboxylic acid

Provided is a water-soluble working fluid for a fixed-abrasive wire saw, the water-soluble working fluid comprising: (C) a carboxylic acid; (D) a compound which shows basicity on dissolution in water; and (E) water, wherein an electrical conductivity at 25°C of the water-soluble working fluid is 300 µS / cm or more and 3000 µS / cm or less; a pH at 25°C of the water-soluble working fluid is 5 or more and 10 or less; and a viscosity of a simulated fluid formed by adding 10 mass % of a silicon powder having an average particle size of 1.5 µm to the water-soluble working fluid and stirring a resultant mixture is less than 30 mPa·s at 25°C.

Owner:YUSHIRO CHEM IND CO LTD

Method for manufacturing white fine particle dispersion

ActiveUS20190352434A1Sufficient and efficient mannerGood dispersionInksCoatingsWater basedPolymer science

The present invention relates to a process for producing a dispersion of white fine particles from which a white ink that is capable of exhibiting excellent hiding power, rub fastness and water resistance even when printed on a low-water absorbing printing medium can be obtained by incorporating the dispersion of the white fine particles into the ink, and a water-based ink for ink-jet printing which contains the white fine particles. The present invention provides [1] a process for producing a dispersion of white fine particles, including step 1 of mixing titanium oxide and a polymer dispersant at a pH value that is not less than an acid dissociation exponent (pKa) of at least a part of an acid component of the polymer dispersant to thereby obtain a titanium oxide dispersion, in which an isoelectric point (A) of the titanium oxide and the acid dissociation exponent (pKa) (B) of the polymer dispersant satisfy a relationship represented by the formula: A−B≥0, the polymer dispersant contains a constitutional unit derived from a hydrophobic monomer, and a volume median particle size (D50) of particles in the titanium oxide dispersion is from 150 to 500 nm; and step 2 of adding a polymerizable monomer to the titanium oxide dispersion obtained in the step 1 to subject the polymerizable monomer to polymerization reaction, thereby obtaining the dispersion of the white fine particles, and [2] a water-based ink for ink-jet printing which contains the white fine particles obtained above.

Owner:KAO CORP

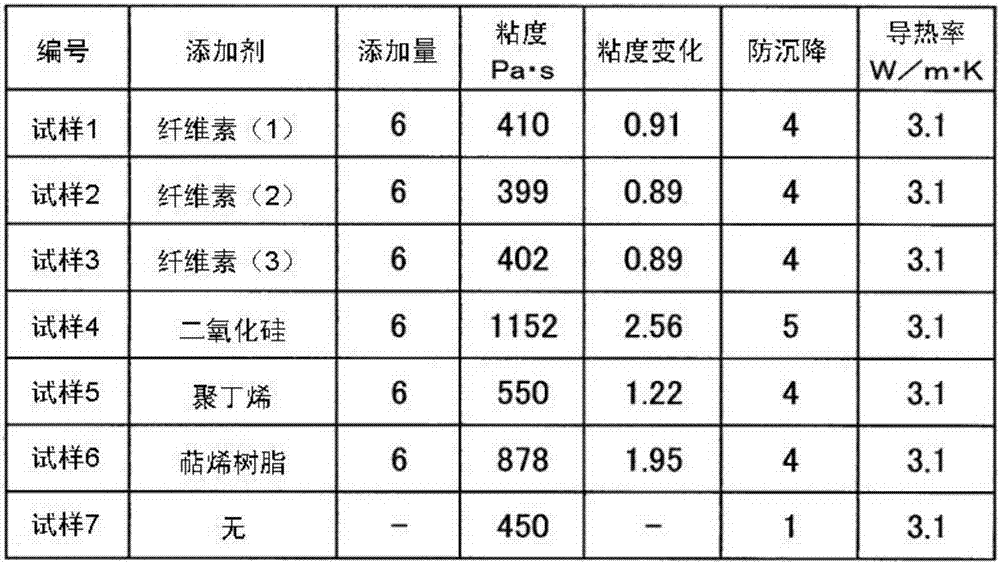

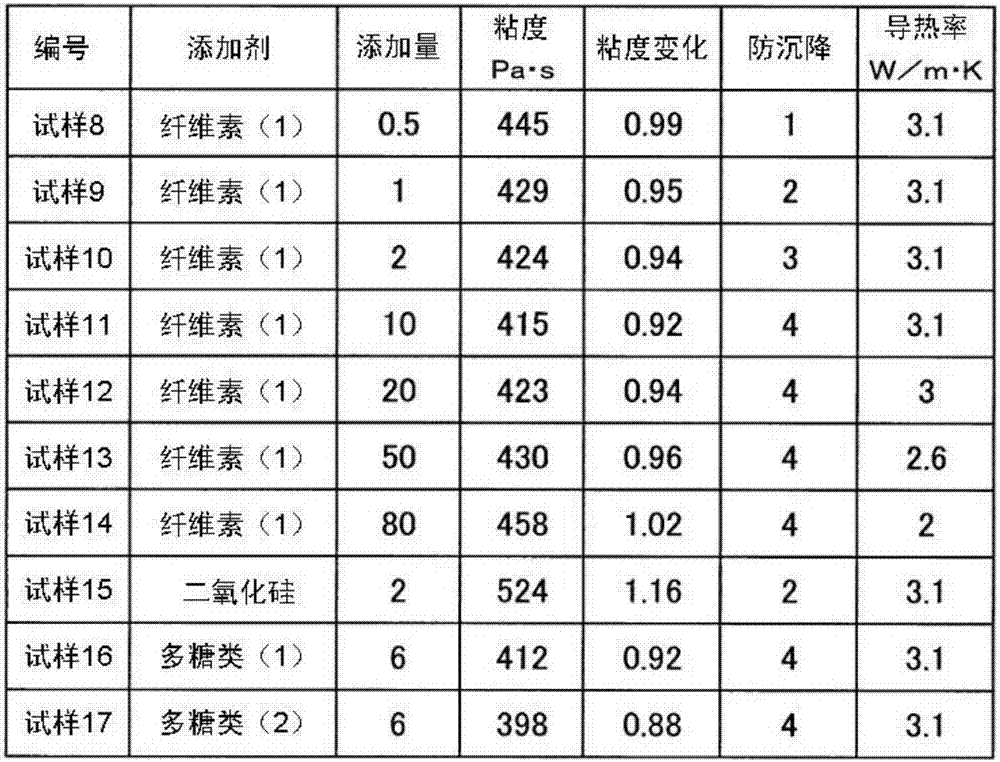

Silicone composition

ActiveCN107207858ASuppresses viscosity riseSettlement inhibitionNon-conductive material with dispersed conductive materialHeat-exchange elementsFilling materialsCellulose compounds

Owner:SEKISUI POLYMATECH CO LTD

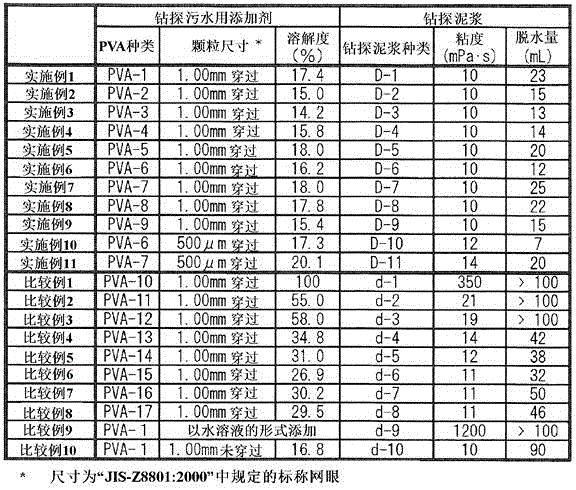

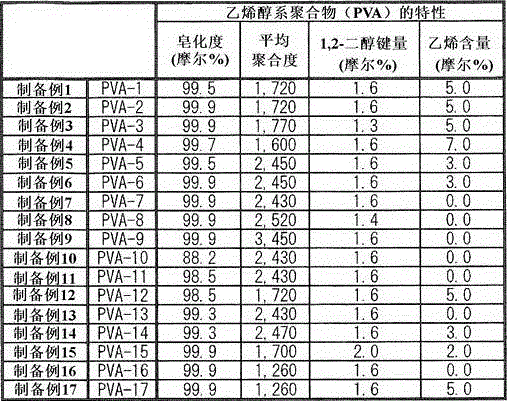

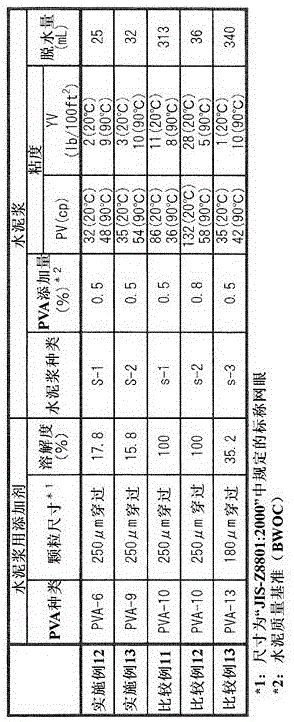

Slurry additive, drilling mud, and cement slurry

ActiveCN106459738ASuppresses viscosity riseLow costFlushingDrilling compositionSolubilityWell drilling

The present invention provides a slurry additive that, when used in a construction slurry (for example, in a drilling mud or drilling cement slurry used in well drilling, etc.) or the like, is low cost and can suppress dehydration at high temperatures as well as viscosity increase. The present invention is a powdered slurry additive that contains a vinyl alcohol polymer, the vinyl alcohol polymer having a solubility of 25% or less when soaked for 3 hours in 60 DEG C hot water, a degree of saponification of 99.5 mol% or more, an average degree of polymerization of 1,500-4,500, and a 1,2-glycol bond content of 1.8 mol% or less. The slurry additive passes through a sieve that has a nominal opening of 1.00 mm.

Owner:KURARAY CO LTD

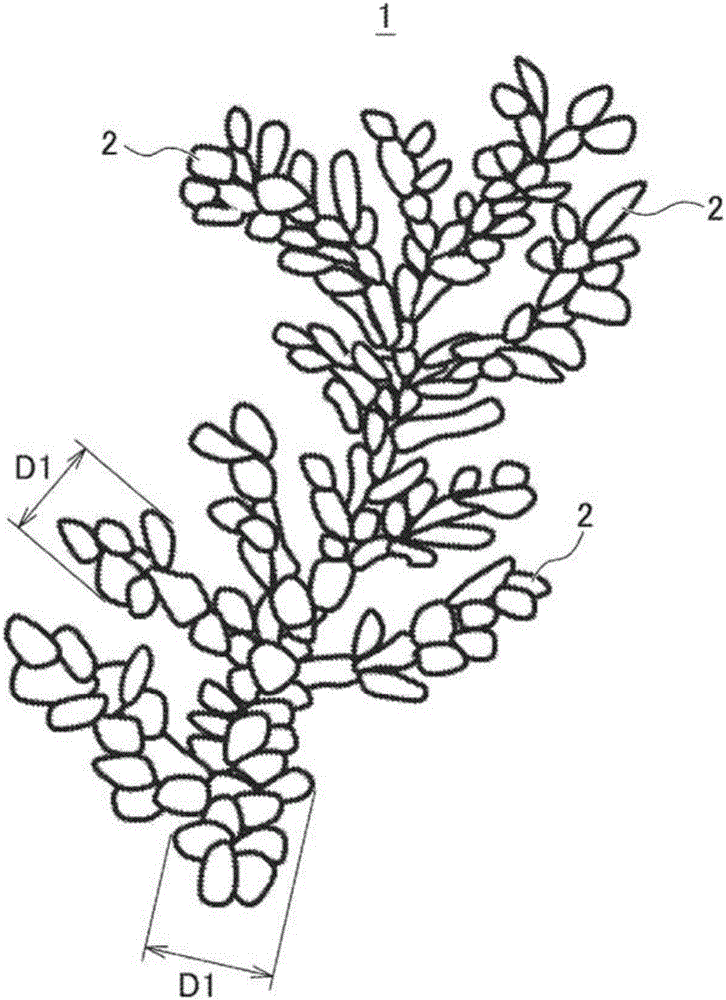

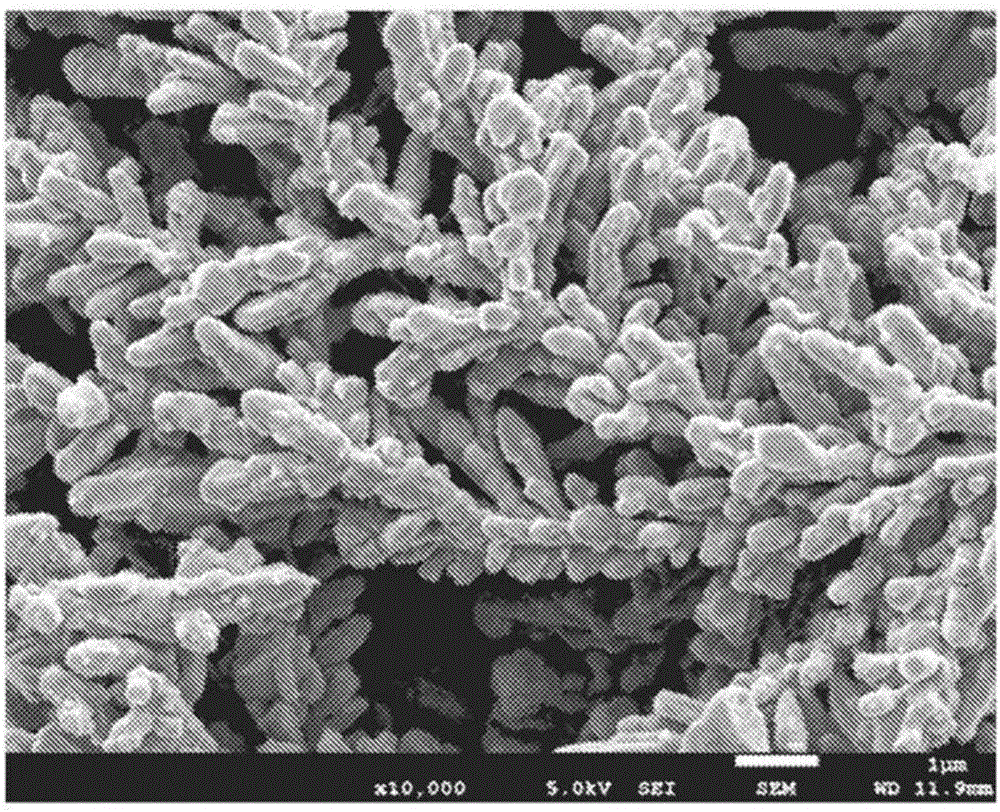

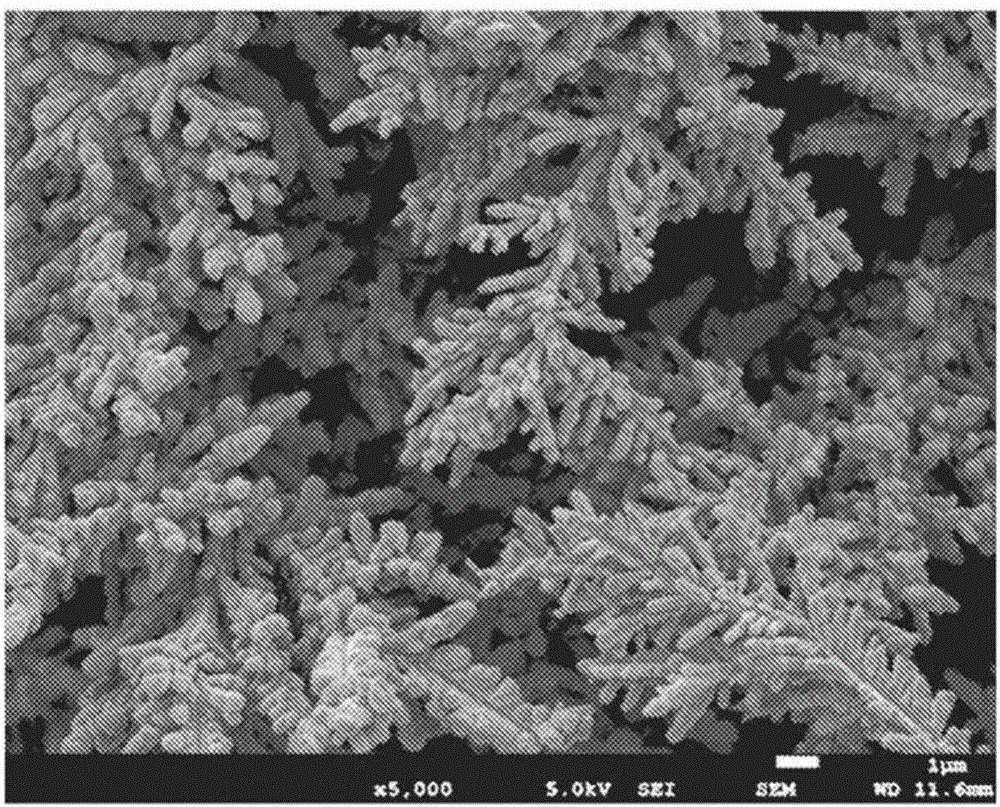

Copper powder and electrically conductive paste, electrically conductive coating, electrically conductive sheet, and antistatic coating using same

InactiveCN106457387AGood dispersionUniform dispersionPigmenting treatmentNon-insulated conductorsFlocculationElectromagnetic shielding

To provide a copper powder exhibiting a high electric conductivity suitable for a metallic filler used in an electrically conductive paste, a resin for electromagnetic shielding, an antistatic coating, etc., and having excellent uniform dispersibility required for forming a paste so as to inhibit an increase in viscosity due to flocculation. This copper powder 1 forms a branch shape having a plurality of branches through the conglomeration of copper particles 2. The copper particles 2 have a spheroidal shape, with diameters ranging from 0.2 -0.5 [mu]m, inclusive, and lengths ranging from 0.5 -2.0 [mu]m, inclusive. The average particle diameter (D50) of the copper powder 1 in which the spheroidal copper particles 2 have conglomerated is 5.0 -20 [mu]m. By mixing this tree-branch-shaped copper powder 1 into a resin, it is possible to produce an electrically conductive paste, etc., exhibiting excellent electric conductivity, for example.

Owner:SUMITOMO METAL MINING CO LTD

Detergent composition

ActiveCN103800214AGood performanceEasy to useCosmetic preparationsNon-ionic surface-active compoundsNonionic surfactantChain structure

The invention provides a detergent composition which contains components (A), (B), (C), (D) and (E), wherein (A) is C12-C22 fatty acids or salts thereof, (B) is an anionic surfactant with carboxylic acid or salts thereof on the hydrophilic group other than the component (A), (C) is a nonionic surfactant in a branched chain structure, (D) is polyalcohol of which the IOB value is 0.8-4, and (E) is water. On the basis of reduced mass of acid, the sum of the component (A) and component (B) ((A)+(B)) is 35-60 wt%, the mass ratio of the component (B) to the sum of the component (A) and component (B) ((B) / [(A)+(B)]) is 0.06-0.65%, the content of the component (C) is 1.5-20 wt%, and the content of the component (D) is 6-18 wt%.

Owner:KAO CORP

Paste composition and roasted article pattern

ActiveCN101464629BNot easy to cause sedimentation and separationSuppresses viscosity riseCoatingsPhotosensitive materials for photomechanical apparatusWater solubleViscosity

Owner:TAIYO HLDG CO LTD

Solvent-free acrylic resin composition, solvent-free acrylic adhesive using same, adhesive sheet, and production method for solvent-free acrylic resin composition

ActiveUS11286370B2Suppresses viscosity riseImprove thermal stabilityNon-macromolecular adhesive additivesEster polymer adhesivesAdhesive cementPolymer science

A solvent-free acrylic resin composition includes an acrylic resin (A), wherein the acrylic resin (A) contains 5 wt. % to 60 wt. % of a structural moiety derived from a hydroxy group-containing monomer (a1), and an acid value in the resin composition is from 0.001 mgKOH / g to 0.3 mgKOH / g. The solvent-free acrylic resin composition is suppressed in viscosity rise due to heating, and is hence excellent in thermal stability; the composition can be thickly applied when used as an adhesive; and the composition can provide an adhesive excellent in step followability, corrosion resistance, and moist-heat haze resistance.

Owner:MITSUBISHI CHEM CORP

cleaning composition

ActiveCN103800212BImprove liquiditySuppresses viscosity riseCosmetic preparationsNon-ionic surface-active compoundsHigh concentrationPolyol

Owner:KAO CORP

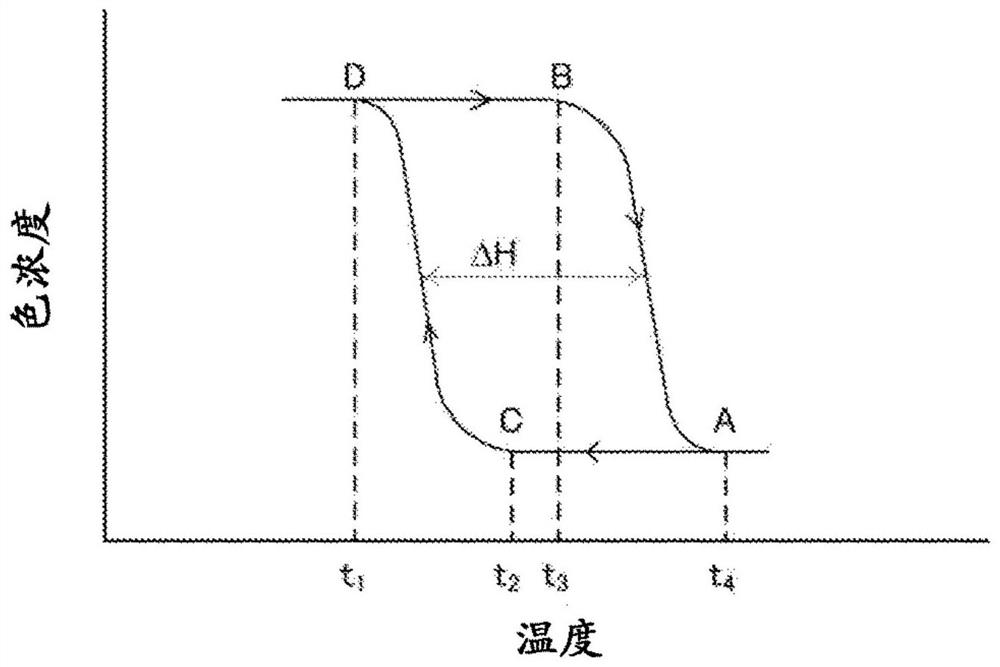

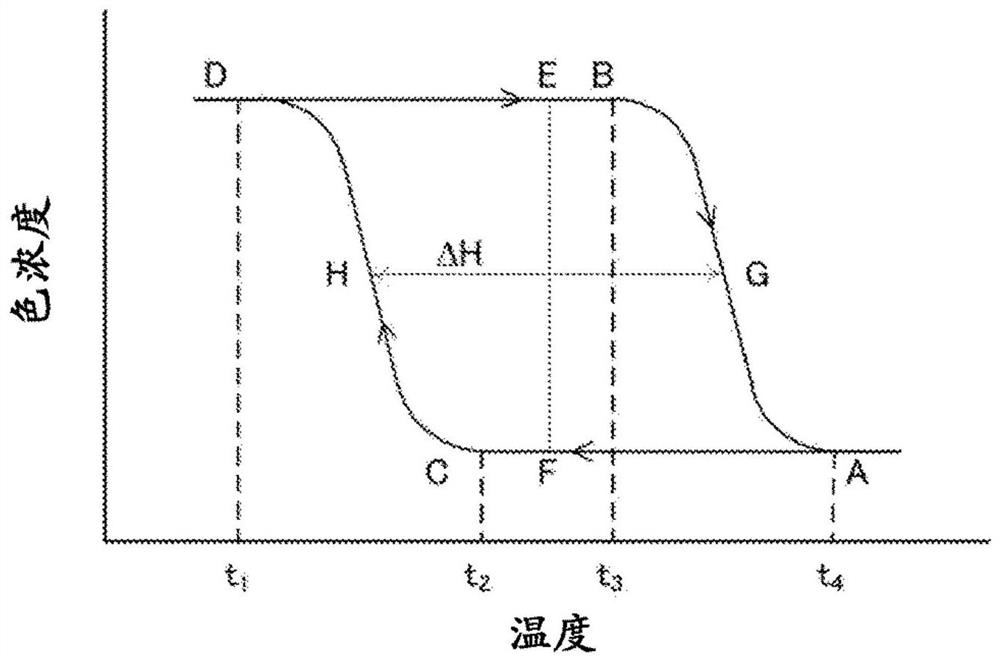

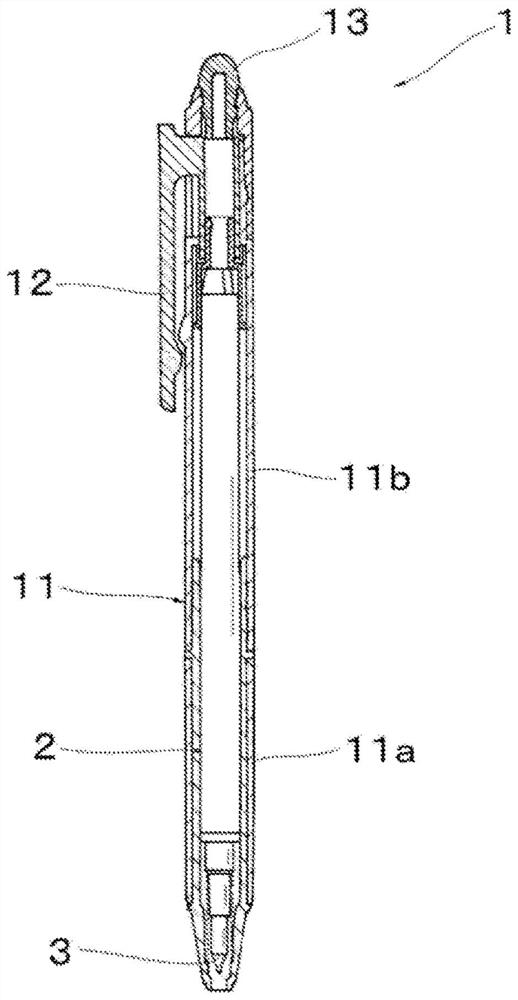

Reversibly thermochromic aqueous ink composition for writing utensils, and refill and water-based ballpoint pen each internally containing same

ActiveCN113785023ASuppresses viscosity riseDecrease in handwriting densityInksBall-point pensHandwritingPolymer science

The invention provides: a reversibly thermochromic aqueous ink composition which exhibits excellent writing performance, while being not susceptible to problems such as aggregation of a coloring agent, increase in the composition viscosity and decrease in the handwriting density; and a refill and a water-based ballpoint pen each using this reversibly thermochromic aqueous ink composition. The reversibly thermochromic aqueous ink composition contains a reversibly thermochromic microcapsule pigment enclosed in a microcapsule that is formed of an organic resin, an N-vinyl-2-pyrrolidone polymer, glycerol and water, wherein: if PMC, PPVP and PG are respective content ratios (mass%) of the reversibly thermochromic microcapsule pigment, the N-vinyl-2-pyrrolidone polymer and the glycerol with respect to the total mass of the ink composition, 0.3 <= PMC / (PPVP + PG) <= 4 and 0.2 <= PPVP / PG <= 5 are satisfied. The refill and the water-based ballpoint pen each internally containing this reversibly thermochromic aqueous ink composition are provided.

Owner:PILOT PEN CO LTD

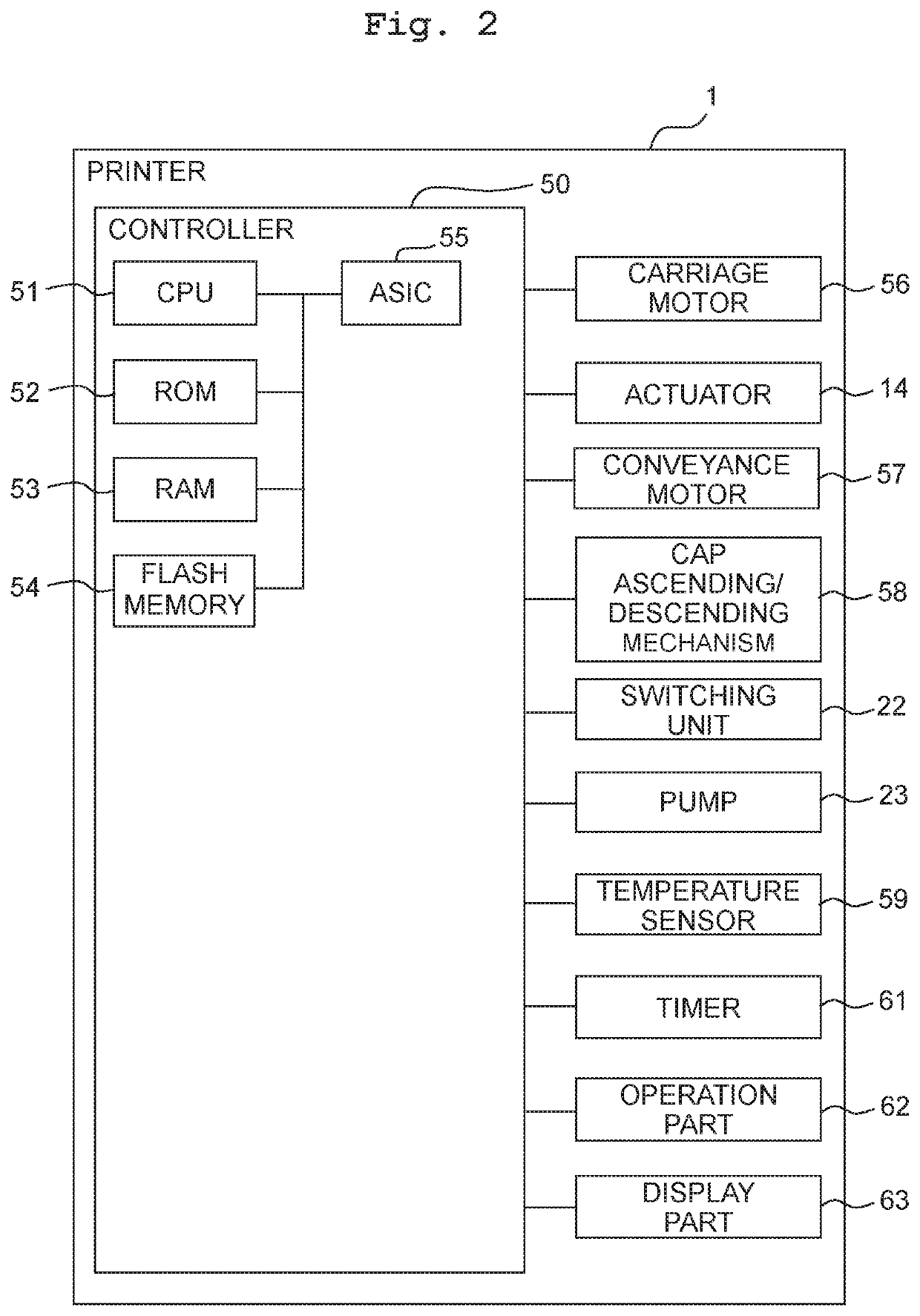

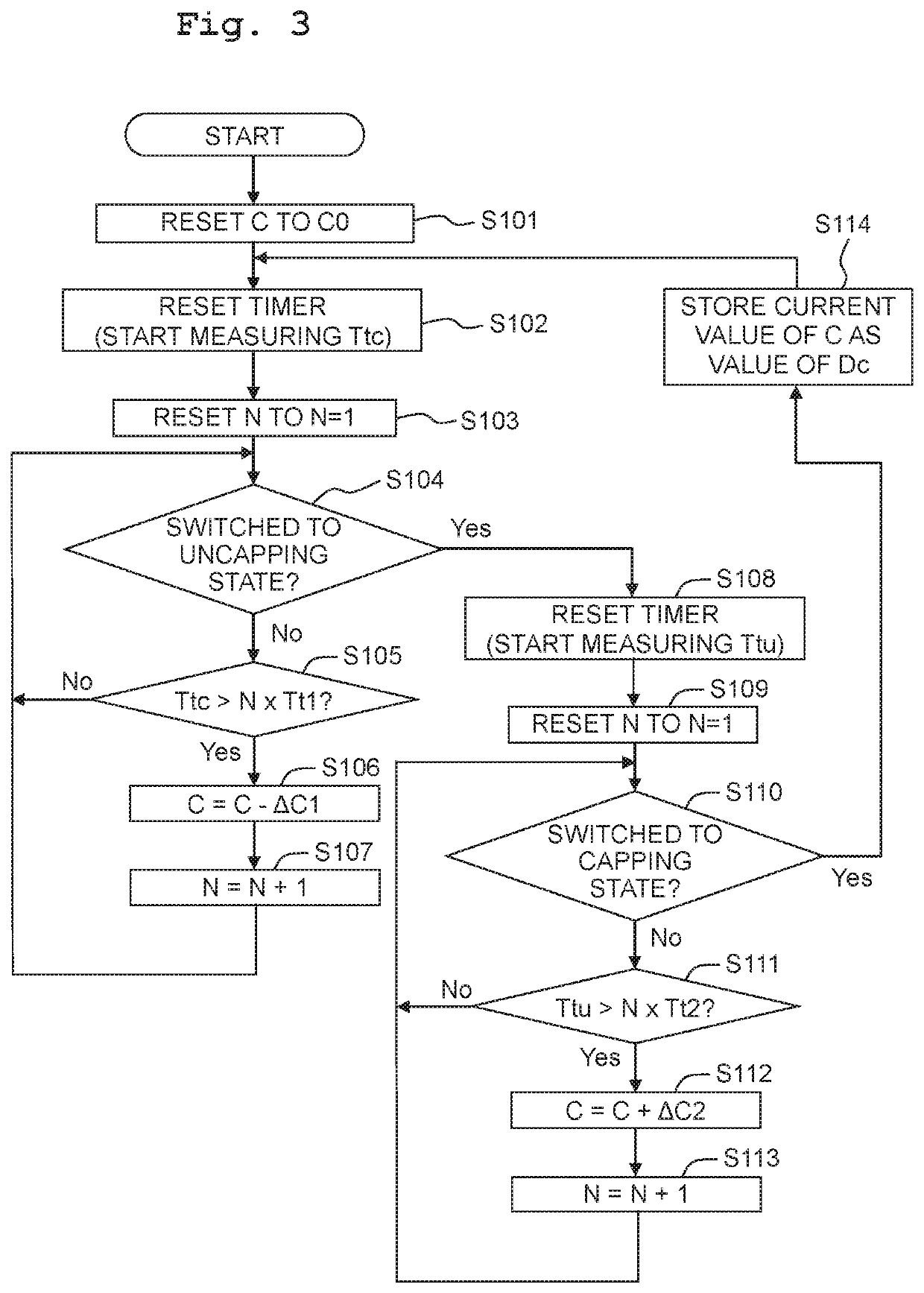

Liquid jetting apparatus including purge mechanism

ActiveUS10569551B2Reduce moistureSuppressing evaporation of water contentPrintingControl engineeringProcess engineering

There is provided a liquid jetting apparatus including: a liquid jetting head; a cap; a switching mechanism configured to perform switching of a state of the cap between a capping state and an uncapping state; a timer; a purge mechanism; and a controller. The controller performs: calculating a value of a capping-time parameter; and measuring a capping time with the timer. In a case that a purge condition regarding the capping time and the value of the capping-time parameter is satisfied, the controller causes the purge mechanism to perform a purge, and then causes the liquid jetting head to perform a jetting operation.

Owner:BROTHER KOGYO KK

Photosensitive resin composition

InactiveCN113227194AFine alkali developmentSuppresses viscosity riseCoatingsPhotosensitive materials for photomechanical apparatusPolymer scienceAlkoxy group

The purpose of the present invention is to provide a resin composition that exhibits a high storage stability in single-package form and that exhibits excellent properties and electrical characteristics for the cured product therefrom. Namely, provided are a resin composition comprising (A) a photobase generator comprising a compound represented by formula (1) (In formula (1), R1, R2, R3, R5, and R6 each independently represent, e.g., a hydrogen atom, hydroxyl group, alkoxy group, or organic group other than the preceding substituents. At least one of R4 represents an organic group that contains a thioether bond, and the other represents a hydrogen atom or an organic group that contains a thioether bond. The A represents a substituent represented by formula (1-1) or (1-2) (In formula (1-1), R7 and R8 each independently represent, e.g., a hydrogen atom, alkyl group, or heterocyclic group. In formula (1-2), R9 and R10 each independently represent an amino group or a substituted amino group.)), (B) an alkali-developable resin, and (C) a thermally reactive compound.

Owner:NIPPON KAYAKU CO LTD

Polyimide precursor composition, preparation method of polyimide and polyimide

InactiveCN107365415AAppropriate molecular weightImprove mechanical propertiesCoatingsPolyamic acidMonomer

The present invention relates to a polyimide precursor composition, a method for preparing a polyimide, and polyimide. The polyimide precursor composition contains polyamic acid and a monomeric compound. The polyamic acid is prepared from a monomer mixture by a first reaction, wherein the monomer mixture comprises a diamine compound and a dianhydride compound. The aforementioned monomeric compound has two carboxyl groups and two ester groups. The prepared polyimide precursor composition can be further reacted to obtain a polyimide having good mechanical properties and film properties.

Owner:TAIFLEX SCI

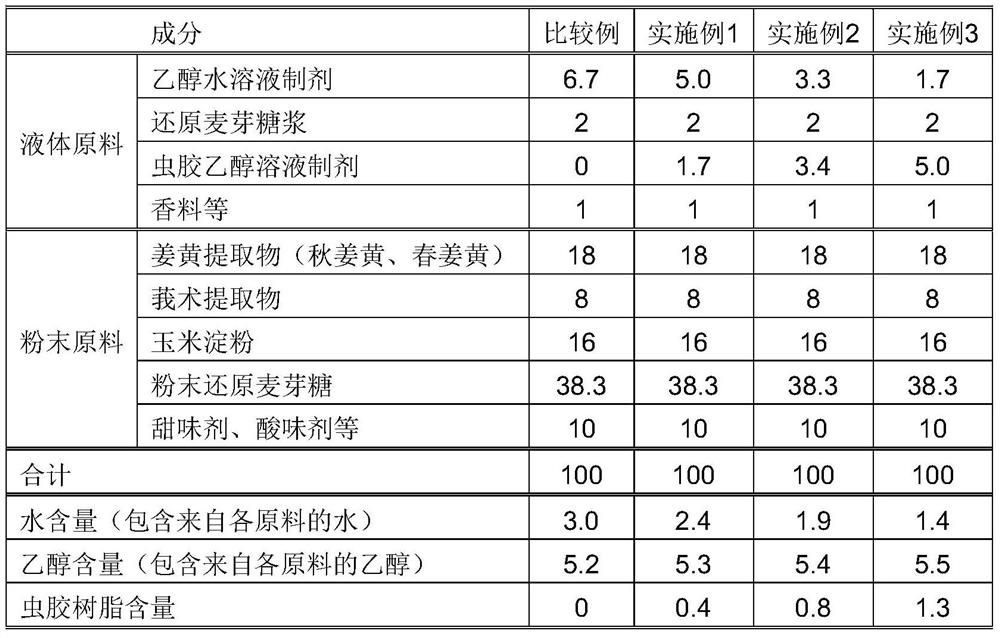

Method for producing granules containing plant extract, method for preventing formation of micropowder from granules containing plant extract, and method for suppressing unpleasant taste of granules containing plant extract

The purpose of the present invention is to prevent the increase in viscosity of a raw material mixture and also prevent the formation of a micropowder that may deteriorate production yield, and / or suppress an unpleasant taste inherent in a plant extract in the production of granules containing the plant extract by extrusion granulation. The present invention relates to a method for producing granules containing a plant extract, characterized by comprising the step of extrusion-granulating a raw material mixture containing the plant extract, wherein the water content in the raw material mixture is 1 to 10% (w / w) and the raw material mixture contains shellac.

Owner:เฮ้าส์ เวลล์เนสส์ ฟูดส์ คอร์ปอเรชั่น

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com