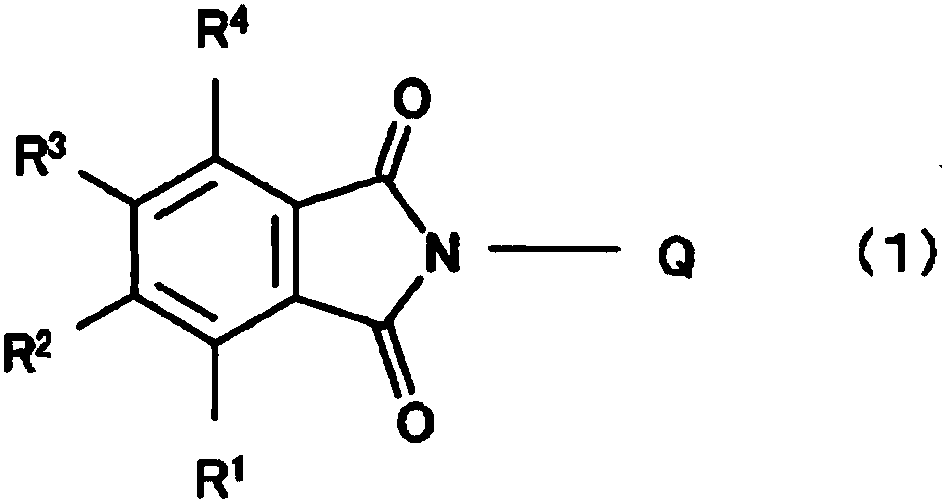

Pigment dispersion and coloring composition using phthalimide and derivatives thereof

A phthalimide, pigment dispersion technology, applied in azo dyes, organic dyes, chemical instruments and methods, etc., can solve the problems of easy agglutination, uniform dispersion of pigments, difficult to color photosensitive compositions, etc., Achieving the effect of suppressing the decrease in contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

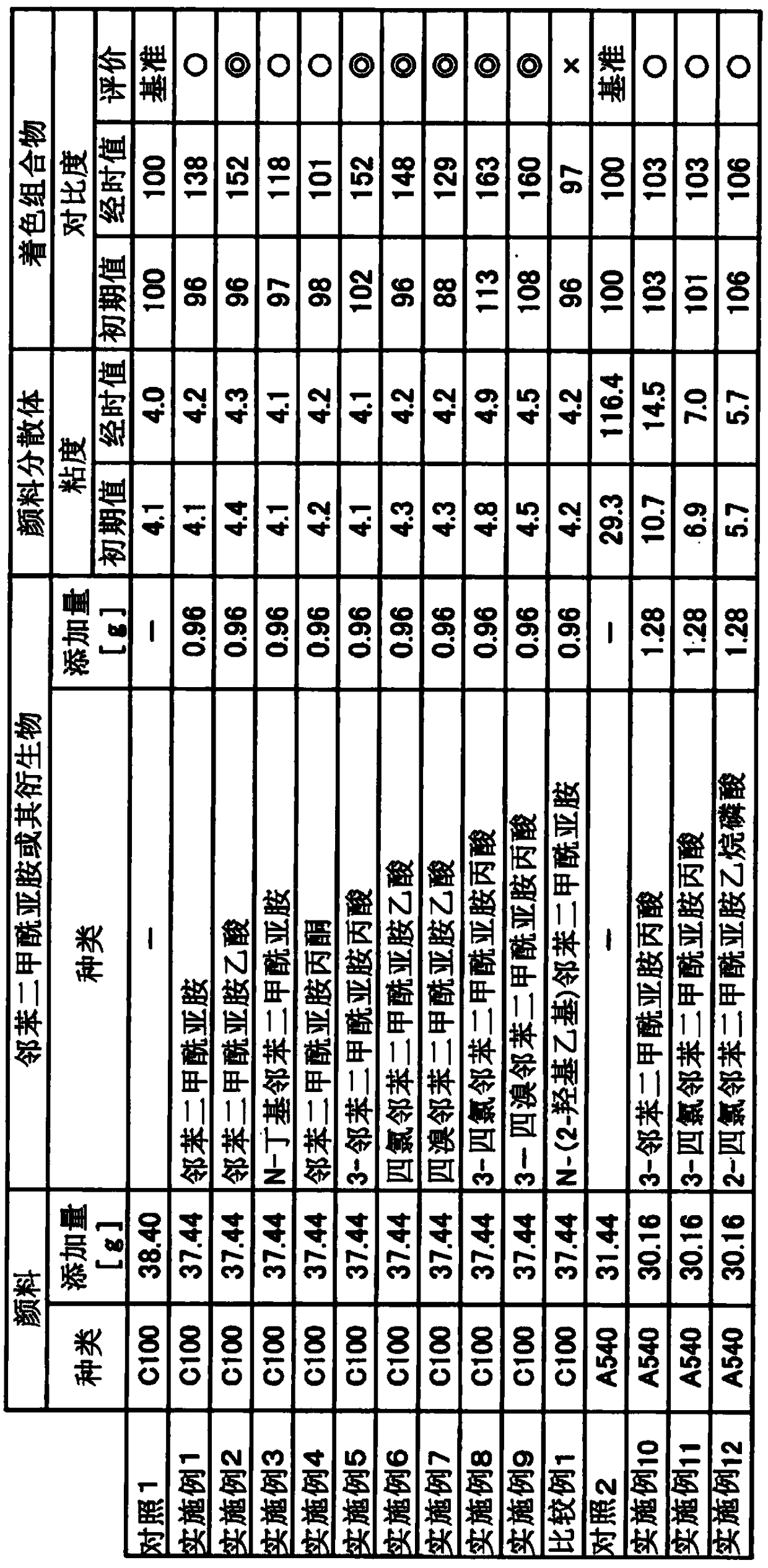

[0138] Reagents and the like used in Examples, Comparative Examples, and Controls described below are as follows.

[0139] (1) Pigment

[0140] ·C.I. Pigment Green 59

[0141] Product name "FASTOGEN GREEN C100" (it is called "C100" in a table|surface.), DIC Corporation make. It is a chlorinated zinc bromide phthalocyanine pigment, and the average number of hydrogen atoms contained in one molecule is 2 or more.

[0142] · C.I. Pigment Blue 15:6

[0143] Product name CYANINE BLUE A540, manufactured by DIC Corporation. For copper phthalocyanine pigments.

[0144] (2) Phthalimide and its derivatives

[0145] ・Phthalimide: manufactured by Tokyo Chemical Industry Co., Ltd.

[0146] ・Phthalimide acetic acid: manufactured by Tokyo Kasei Kogyo Co., Ltd.

[0147] ・N-butylphthalimide: manufactured by Tokyo Chemical Industry Co., Ltd.

[0148] ・Phthalimide acetone: manufactured by Tokyo Chemical Industry Co., Ltd.

[0149] 3-phthalimide propionic acid: manufactured by Accel Pharm...

manufacture example 1

[0163] (Production example 1) Production of phthalimide derivative (3-tetrachlorophthalimide propionic acid)

[0164] Place a 100ml eggplant-shaped flask in an oil bath, add propylene glycol monomethyl ether (hereinafter referred to as "PM") 75g, tetrachlorophthalic anhydride 20.02g (70mmol), β-alanine 6.24g (70mmol), A cooling tube was installed on the upper part, and the temperature of the oil bath was raised while stirring with a magnetic stirrer. The target substance started to precipitate when the temperature reached 130° C., so the stirring was continued for 5 minutes. Thereafter, it was cooled to room temperature, 25 g of PM was added, and stirring was continued for 30 minutes. The content was filtered with a suction filter, and the residue was washed with pure water, followed by drying at 100° C. for 18 hours. The yield was 18.7 g (yield 74%). This dried product was used in Examples described later as 3-tetrachlorophthalimide propionic acid which is a phthalimide de...

manufacture example 2

[0166] (Production example 2) Production of phthalimide derivative (2-tetrachlorophthalimide ethanephosphoric acid)

[0167] Place a 500m1 four-necked flask in an oil bath, add PM 200g, tetrachlorophthalic anhydride 41.95g (150mmol), O-phosphoethanolamine 20.70g (150mmol), 1,4-diazabicyclo[2,2 ,2]-octane 33.65g (300mmol), a cooling tube was installed on the upper part, and heated and reflowed for 6 hours while stirring with a magnetic stirrer. After leaving to cool to room temperature, the content was filtered with a suction filter, and the residue was washed with PM. After redispersing the residue in 1.5 L of methanol for 30 minutes, 300 g of 35% hydrochloric acid was added and stirred for 30 minutes. The content was filtered with a suction filter, and the residue was washed with a small amount of methanol and then dried. The yield was 42 g (69% yield). This dried product was used in Examples described later as 2-tetrachlorophthalimideethanephosphoric acid which is a phtha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com