Transfer device of fuel oil

A transfer device and fuel oil technology, which is applied in transportation and packaging, ship parts, ships, etc., can solve the problems of fuel oil transfer efficiency deterioration, transfer efficiency deterioration, cost increase, etc., to prevent transfer efficiency from deterioration, prevent Effect of temperature drop and viscosity increase suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, specific embodiments of the present invention will be described.

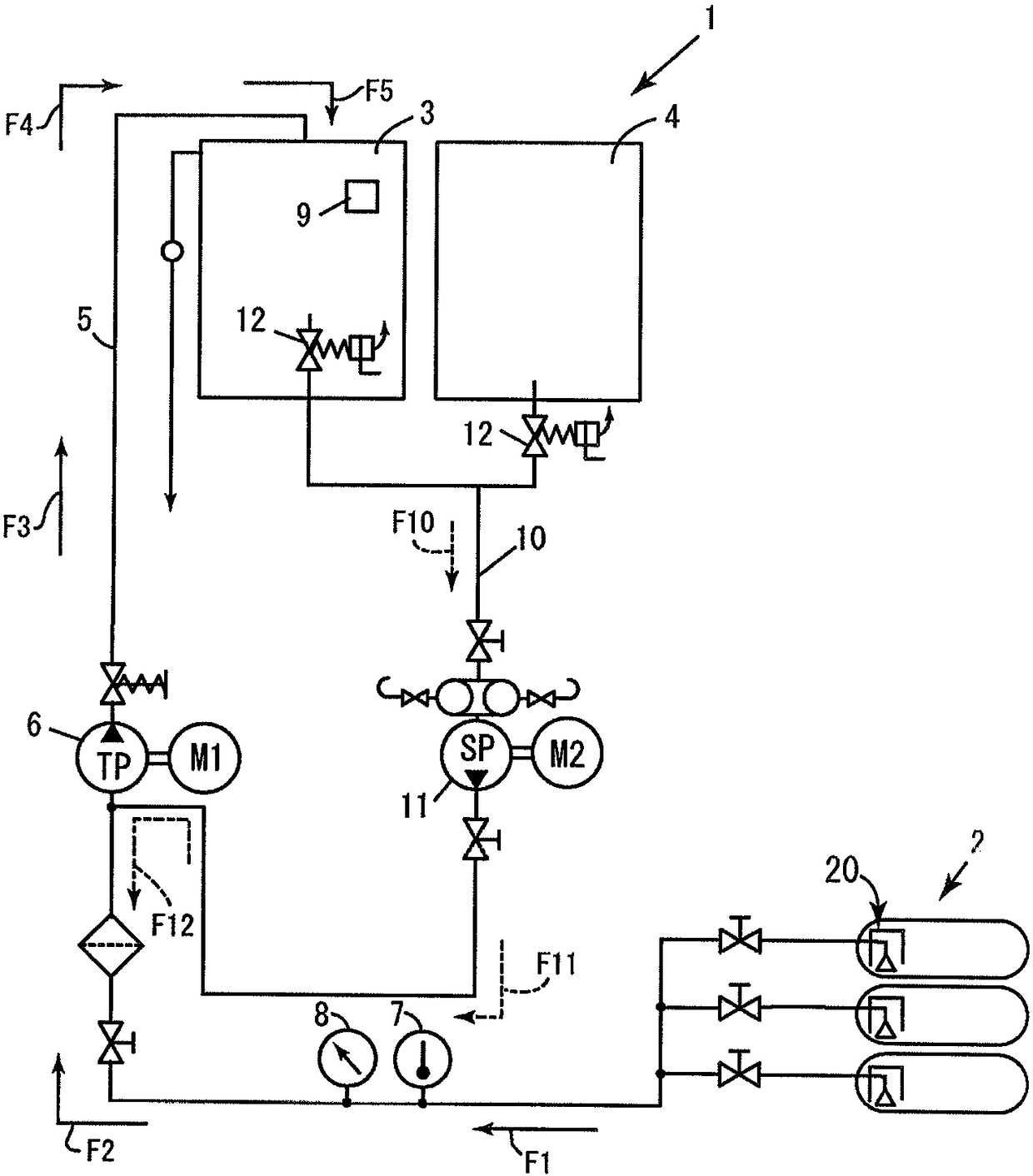

[0024] figure 1 It is a figure which shows the structure of the fuel oil transfer apparatus 1 which concerns on embodiment of this invention.

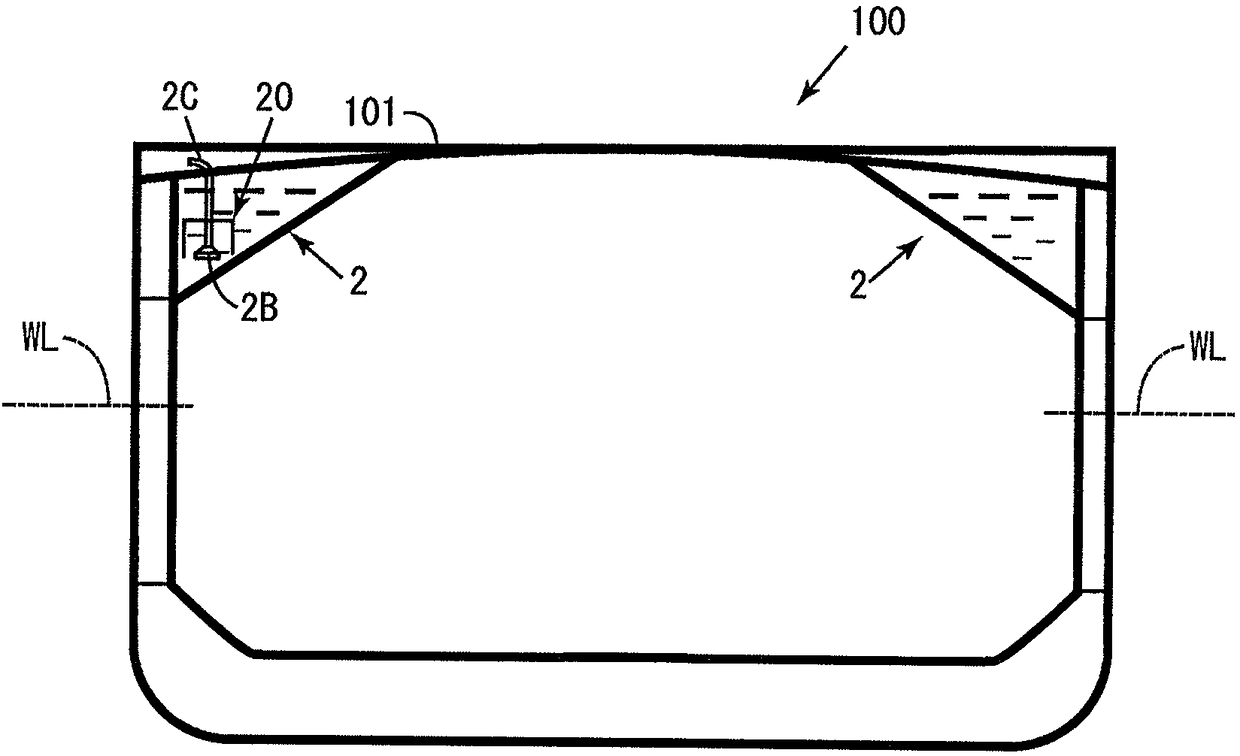

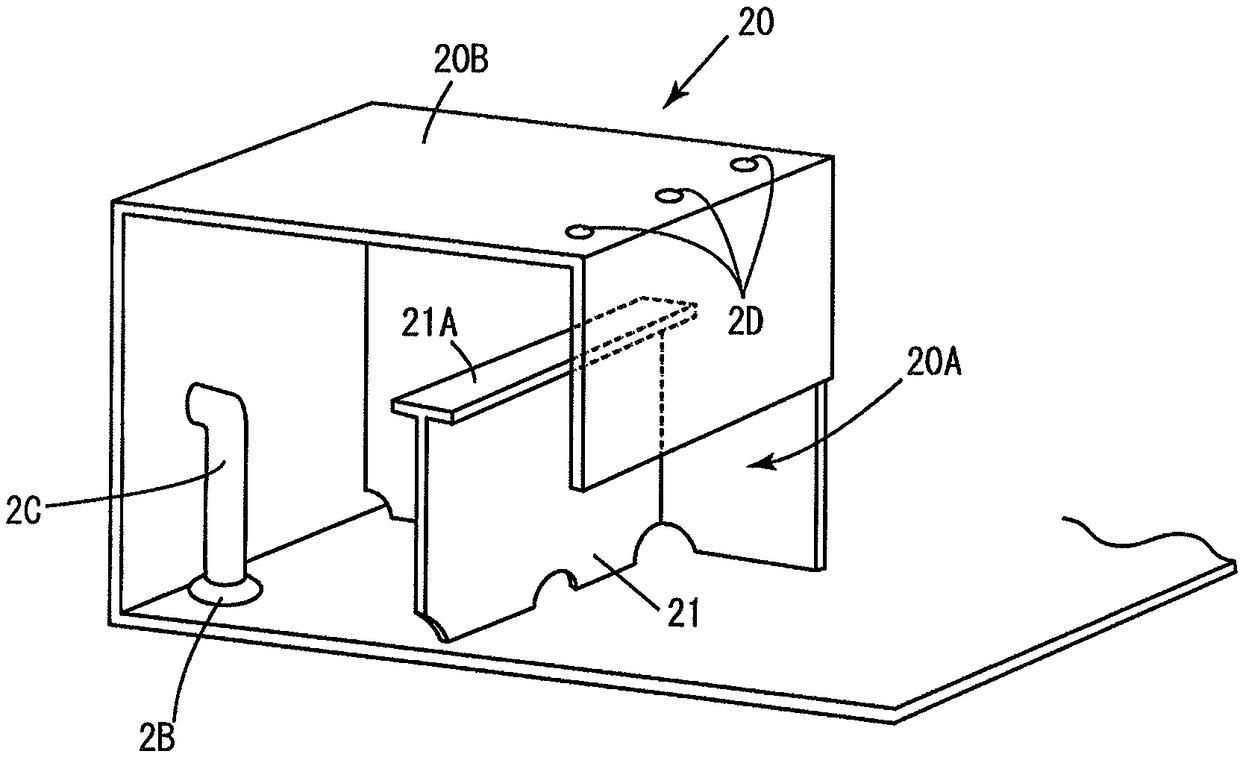

[0025] The fuel oil transfer device 1 includes a fuel oil settling tank 3 and a fuel oil daily tank 4 that communicate with a fuel oil storage tank 2 .

[0026] The fuel oil settling tank 3 is a tank for heating fuel oil, and the fuel oil is heated to a temperature of 70 to 80°C as an example by a heater not shown.

[0027] The fuel oil storage tank 2 and the fuel oil settling tank 3 are connected through a transfer pipe 5 , and a transfer pump 6 , a temperature sensor 7 and a pressure sensor 8 are arranged in the middle.

[0028] The temperature sensor 7 measures, for example, the temperature on the fuel oil inlet side of the transfer pump 6 .

[0029] The pressure sensor 8 is provided to monitor the pressure change of the fuel oil sucked into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com