Slurry additive, drilling mud, and cement slurry

一种钻探泥浆、添加剂的技术,应用在土方钻采、钻孔的组合物、化学仪器和方法等方向,能够解决增加成本等问题,达到抑制粘度上升和高温脱水、低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

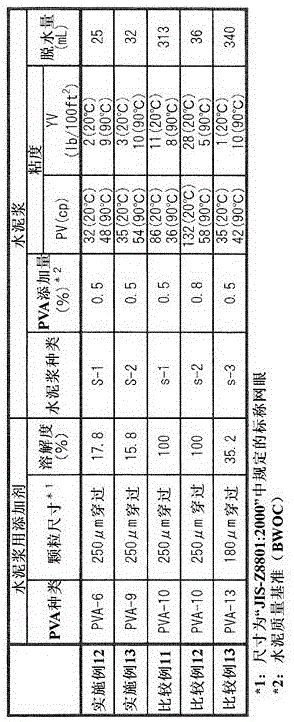

Examples

preparation example 1

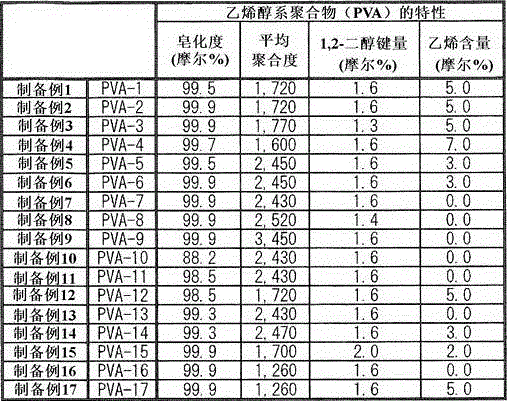

[0107] [Preparation Example 1] (Preparation of dry PVA (PVA-1))

[0108] In a 250L reaction tank equipped with a stirrer, a nitrogen gas inlet, an ethylene inlet, an initiator addition port, and a delayed solution addition port, 127.5 kg of vinyl acetate and 22.5 kg of methanol were put in and the temperature was raised to 60°C, followed by nitrogen blowing for 30 minutes. Bubble for nitrogen replacement. Then, the pressure of the reaction tank reaches 4.9Kg / cm 2 way to import vinyl. Prepare a reaction initiation solution having a concentration of 2.8 g / L by dissolving 2,2'-azobis(4-methoxy-2,4-dimethylvaleronitrile) (AMV) as an initiator in methanol , The reaction initiating solution was subjected to nitrogen bubbling to perform nitrogen replacement, and this solution was used as an initiator solution. 45 mL of this initiator solution was poured into a reaction tank adjusted to 60° C. to initiate polymerization. Introduce ethylene during the polymerization process, and ma...

preparation example 2~17

[0119] [Preparation Example 2~17] (Preparation of dry PVA (PVA-2)~(PVA-17))

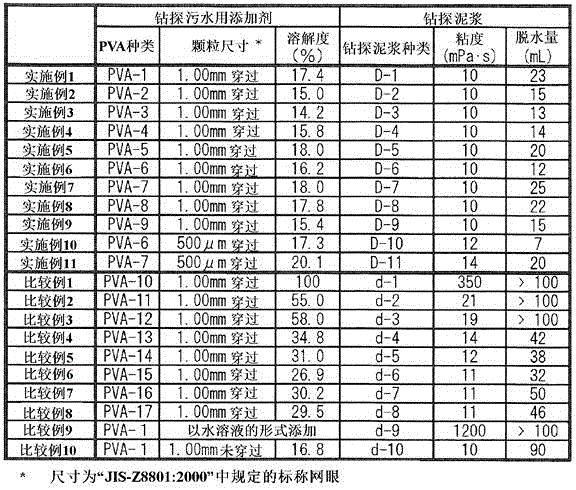

[0120] Using the same method as in Preparation Example 1, dry PVA (PVA-2)~(PVA-17) having the properties shown in Table 1 were prepared.

[0121] [Table 1]

[0122]

Embodiment 1

[0124]

[0125] 300 g of ion-exchanged water was taken in a cup of a Hamilton Beach mixer, 6 g of bentonite ("Telure E" from Terunaitto Co., Ltd.) was added and stirred thoroughly, and then left to stand for 24 hours to fully swell the bentonite. On the other hand, put dry PVA (PVA-1) on a sieve with a nominal mesh size of 1.00mm (16mesh), take 1.5g of dry PVA (PVA-1) powder that passes through the sieve, and use this powder as drilling mud Additives were added to the bentonite dispersion to obtain drilling mud (D-1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com