Method for producing granules containing plant extract, method for preventing formation of micropowder from granules containing plant extract, and method for suppressing unpleasant taste of granules containing plant extract

A plant extract and manufacturing method technology, applied in food science, food forming, application and other directions, can solve the problems of large granulation load and difficult granulation, and achieve the effects of easy granulation, taste inhibition, and inhibition of viscosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

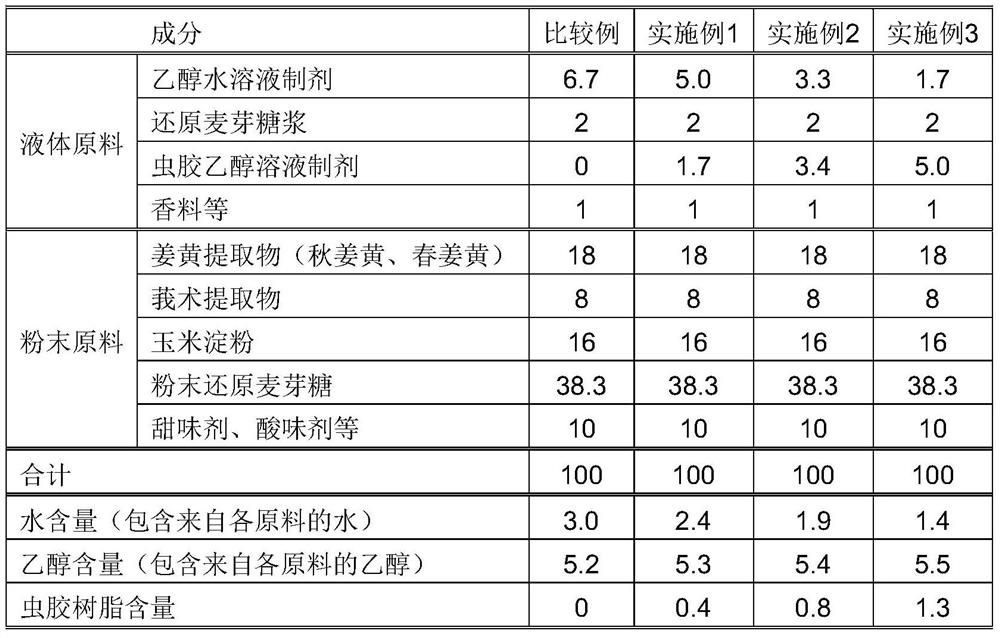

[0073] Raw materials used in Examples and Comparative Examples are as follows. Hereinafter, unless otherwise specified, "%" means "% (w / w)".

[0074] Aqueous ethanol preparation: "Kohelsin" (manufactured by Mitsubishi Chemical Foods Co., Ltd., 68% ethanol)

[0075] Reduced maltose syrup: "Amalty Syrup" (manufactured by Mitsubishi Corporation Foods Co., Ltd.)

[0076]Shellac ethanol solution preparation: "Drug HAS-312" (manufactured by Gifu Shellac Manufacturing Co., Ltd., solution preparation containing 25% shellac resin and 75% ethanol)

[0077] Powdered reduced maltose: "Lesys Fine Powder" (manufactured by Mitsubishi Corporation Foods Co., Ltd., containing 99.5% maltitol)

[0078] Corn starch: "Corn Starch" (manufactured by Sanwa Starch Industry Co., Ltd.)

[0079]

[0080] In the proportion (% (w / w)) shown in Table 1, the ethanol aqueous solution preparation, reduced maltose syrup (binder), shellac ethanol solution preparation, fragrance, etc. were mixed and dissolved ...

Embodiment 1

[0097] (embodiment 1: shellac ethanol solution preparation 1.67%)

[0098] 1-5 grade evaluation Subject 1 Subject 2 Subject 3 Subject 4 Subject 5 The average score bitterness 3 3 4 4 2 3.2 aftertaste 4 4 5 4 3 4

Embodiment 2

[0099] (embodiment 2: shellac ethanol solution preparation 3.33%)

[0100] 1-5 grade evaluation Subject 1 Subject 2 Subject 3 Subject 4 Subject 5 The average score bitterness 3 3 3 3 2 2.8 aftertaste 2 3 4 3 2 2.8

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com