Detergent composition

A technology of composition and cleaning agent, applied in the direction of detergent composition, detergent compounding agent, anionic surface active compound, etc., can solve problems such as viscosity increase, and achieve the effect of excellent performance and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

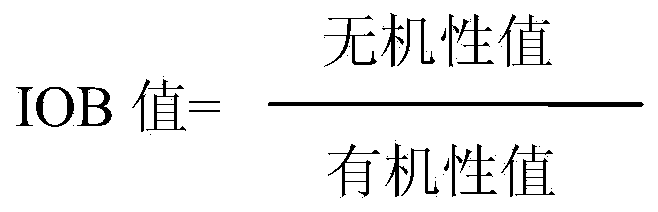

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~43、 comparative example 1~19

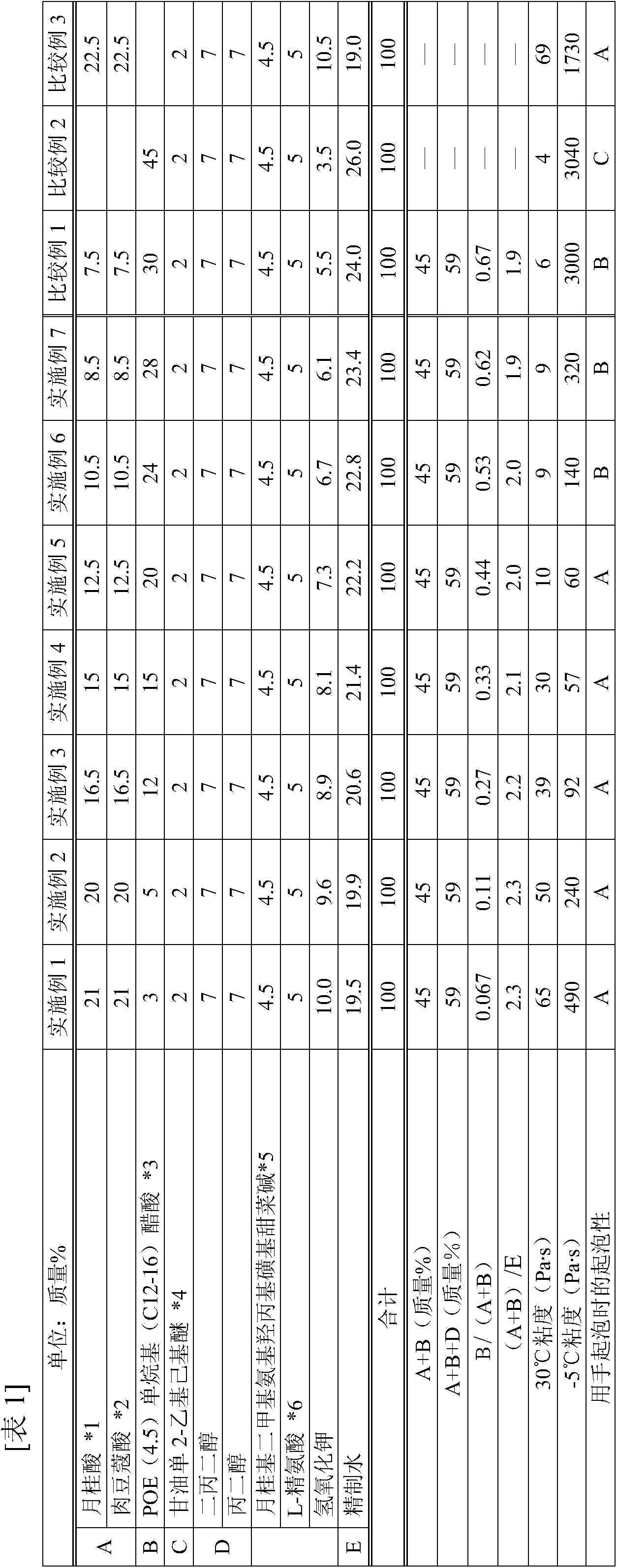

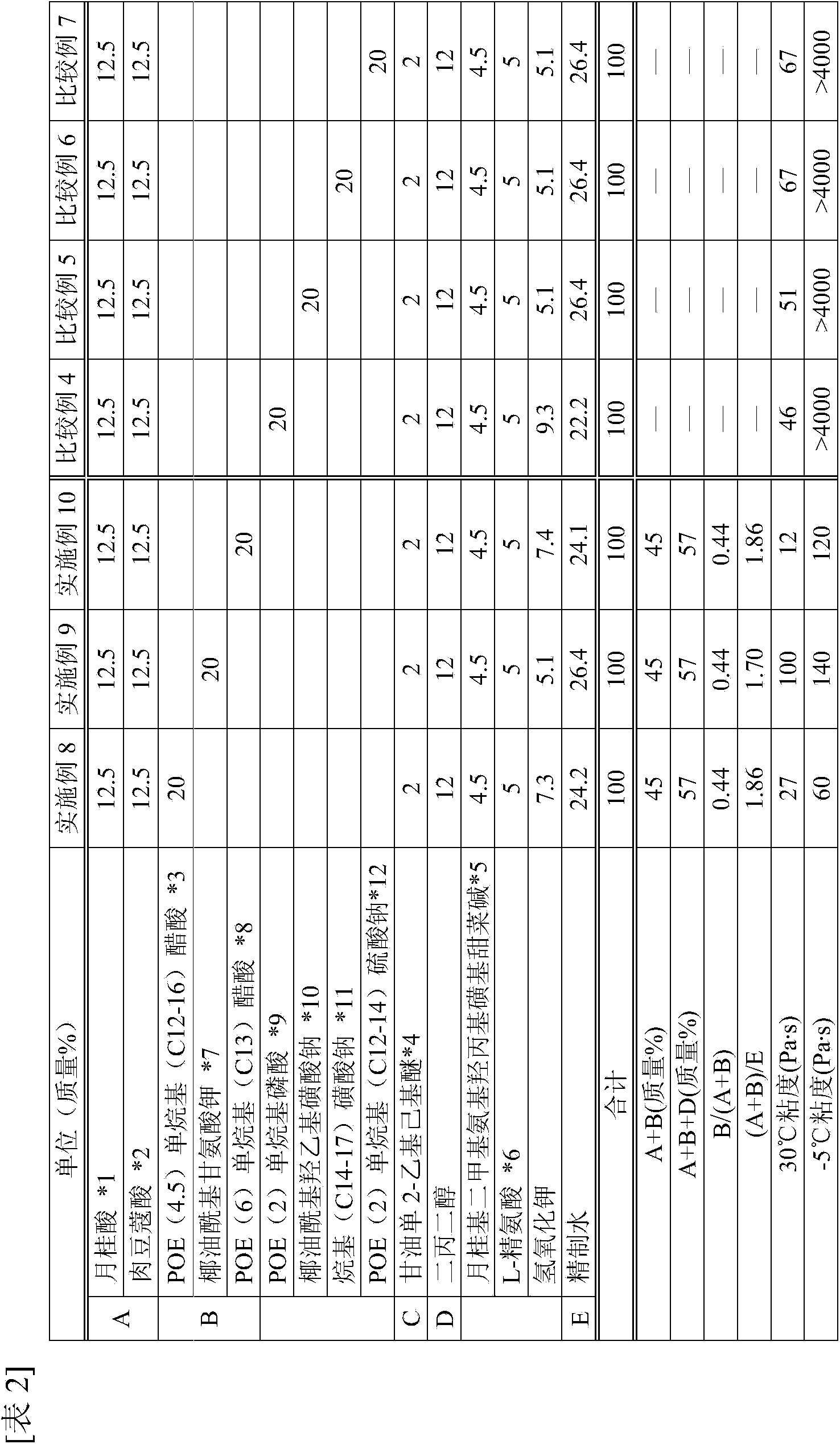

[0101] The detergent compositions shown in Tables 1 to 11 were produced, and the viscosity at each temperature, the ease of foaming during use, the amount of foam, and the like were evaluated. In addition, the numerical values in the table are all active ingredient amounts.

[0102] The components (components (A), (B), (C), (D)) shown in Table 1 to Table 11 were heated to 80°C and dissolved uniformly. Alkali and component (E) water were added for neutralization, cooled, and additives such as ethanol, polymer, perfume, etc. were added as necessary to obtain detergent compositions of Examples 1 to 43 and Comparative Examples 1 to 19.

[0103] Using each of the obtained detergent compositions, the room temperature viscosity (30°C), low temperature viscosity (-5°C), foamability, and foam volume were evaluated. The results are shown in Table 1 to Table 11.

[0104] (1)

[0105] The measurement conditions of the viscosity are as follows.

[0106] Viscometer: VISCOMETER TVB-10 (manufactu...

Embodiment 29

[0133] 3: The bubble volume is more than the standard

[0134] 2: The bubble volume is slightly more than the standard

[0135] 1: The foam volume is the same as the standard

[0136] 0: The foam volume is less than the standard

[0137] (II) Three levels of judgment standards

[0138] A: The total score is 12-15

[0139] B: The total score is 8-11

[0140] C: Total score 0~7

[0141]

[0142]

[0143]

[0144]

[0145] [table 5]

[0146]

[0147] [Table 6]

[0148]

[0149]

[0150]

[0151]

[0152] [Table 10]

[0153]

[0154] [Table 11]

[0155]

[0156] (Note) The components in Tables 1 to 11 are as follows.

[0157] *1: Made by PALMAC98-12ACIDCHEM

[0158] *2: Made by PALMAC98-14ACIDCHEM

[0159] *3: AKYPO RLM45CA made by Kao Corporation

[0160] *4: Penetol GE-EH manufactured by Kao Corporation

[0161] *5: AMPHITOL20HD manufactured by Kao Corporation

[0162] *6: Made by L-Arginine Ajinomoto

[0163] *7: AMISOFT GCK-11K manufactured by Ajinomoto

[0164] *8: Made by Emulsogen DTC Acid Clariant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com