Water-soluble working fluid for fixed abrasive wire saw

A fixed abrasive, water-soluble technology, used in stone processing equipment, metal processing equipment, grinders, etc., can solve the problems of complicated cleaning process, cutting operation, surrounding environmental pollution, limited improvement of processing efficiency, etc. rising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083]

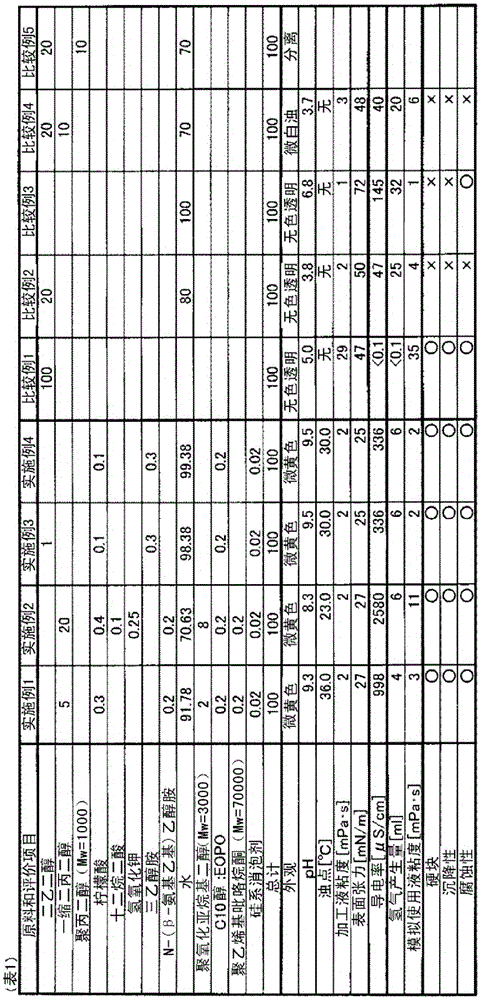

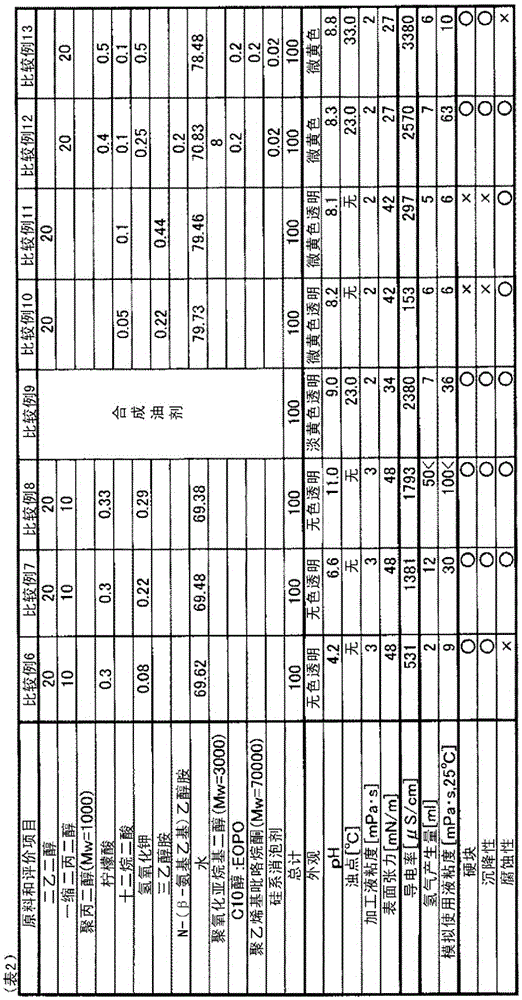

[0084] The water-soluble processing fluids for fixed abrasive wire saws of the present invention (Examples 1-4) and the water-soluble processing fluids for fixed abrasive wire saws other than the present invention (Comparative Example 1) were prepared in such a manner as to form the compositions shown in Table 1 and Table 2. ~13). The compounding quantity of each component shown in Table 1 and Table 2 is shown by mass %. Among them, Comparative Example 9 is a working fluid containing 10% by mass of a synthetic oil agent manufactured by YUSHIROCHEMICAL INDUSTRY CO., LTD. and 90% by mass of water. In addition, "C10 alcohol: EOPO" in Table 1 and Table 2 means a copolymer of an alcohol having 10 carbon atoms and ethylene oxide and propylene oxide.

[0085]

[0086] Evaluation of the items shown in Table 1 and Table 2 was performed on the prepared working fluid. "Appearance" means the result of visually observing the appearance of the machining fluid. "pH" indicates...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com