Technology for processing rotatable filter sealing ring fixed plate

A processing technology and filter technology, which is applied to the processing technology field of the sealing ring fixing plate of the spin-on filter, can solve the problems of increasing the investment of processes and molds, poor edge uniformity of semi-finished products, and increased material consumption. , to achieve the effect of less process and mold investment, lower scrap rate, and lower material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is further described below in conjunction with embodiment and accompanying drawing.

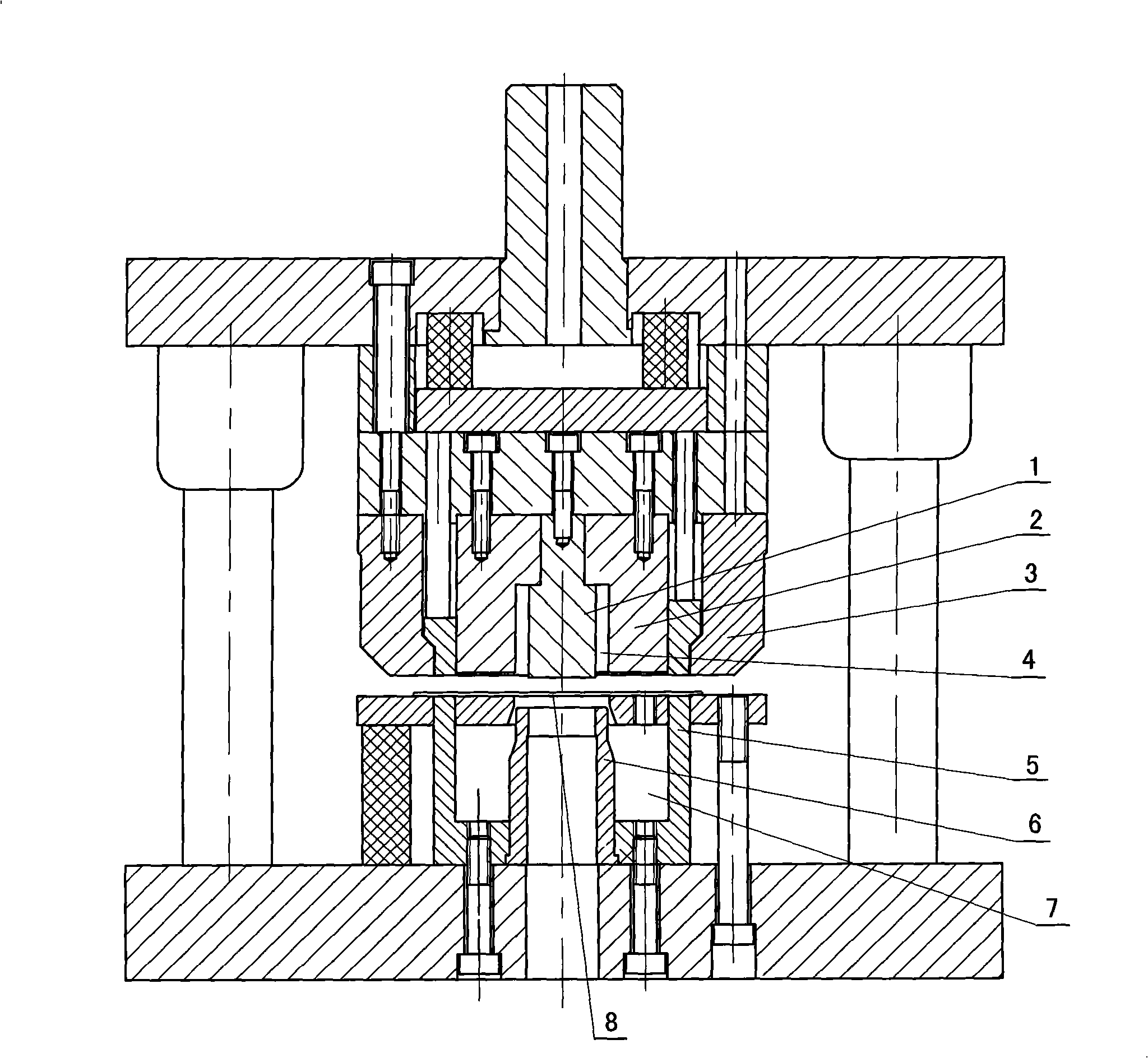

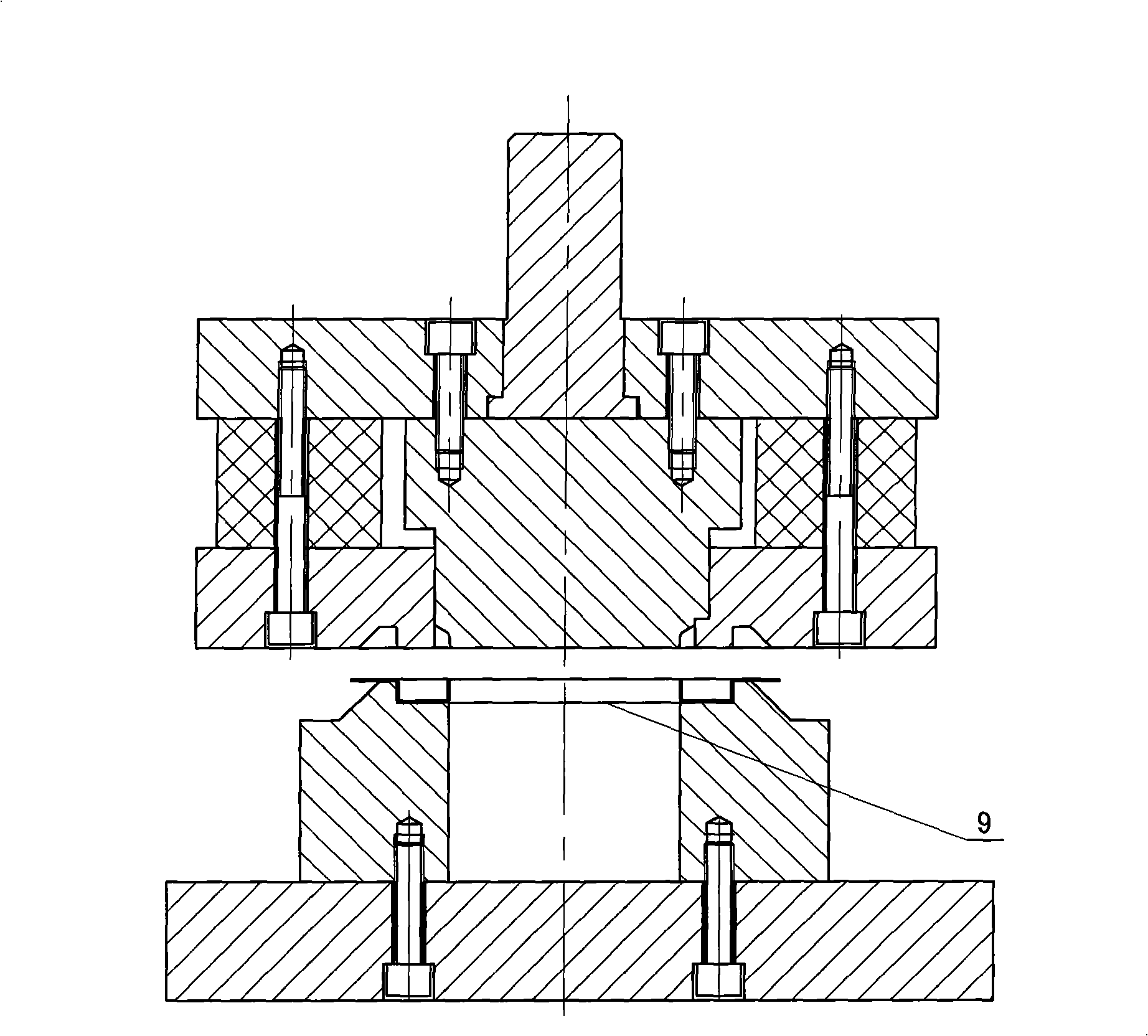

[0012] Depend on figure 1 It can be seen that, when the metal plate 8 is stamped by the mold, the following steps are included:

[0013] 1. During the downward movement of the upper die, first punch the metal plate 8 through the part 1 of the upper die;

[0014] 2. The part 6 of the lower die cooperates with the annular groove 4 on the upper die to realize the flanging of the edge of the punched through hole, and the matching of the part 2 on the upper die and the upper blind hole 7 of the lower die. Stretch the outside of the edge;

[0015] 3. Blanking and punching are carried out through the cooperation of the part 3 of the upper die and the edge part 5 of the lower die.

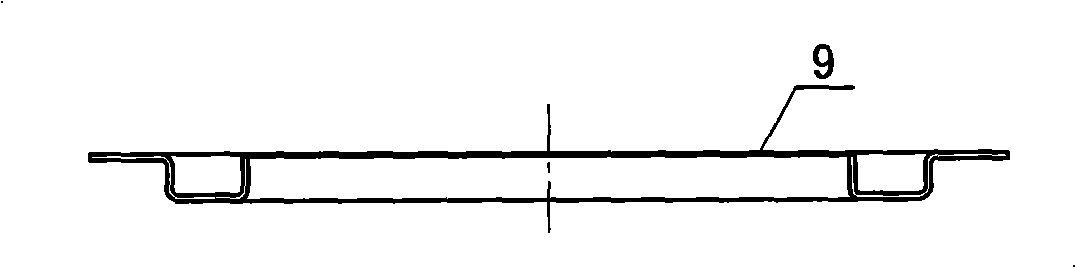

[0016] After the above steps, it is obtained as figure 2 Shown is the semi-finished product 9 of the sealing ring fixing plate.

[0017] Will figure 2 The semi-finished product 9 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com