TiC/SiC/Al composite material

A technology of composite materials and composite layers, which is applied in the field of ceramic matrix composite materials, can solve the problems that cannot be applied to large-scale industrial production, and achieve the effects of reduced production costs, good fluidity, and increased penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

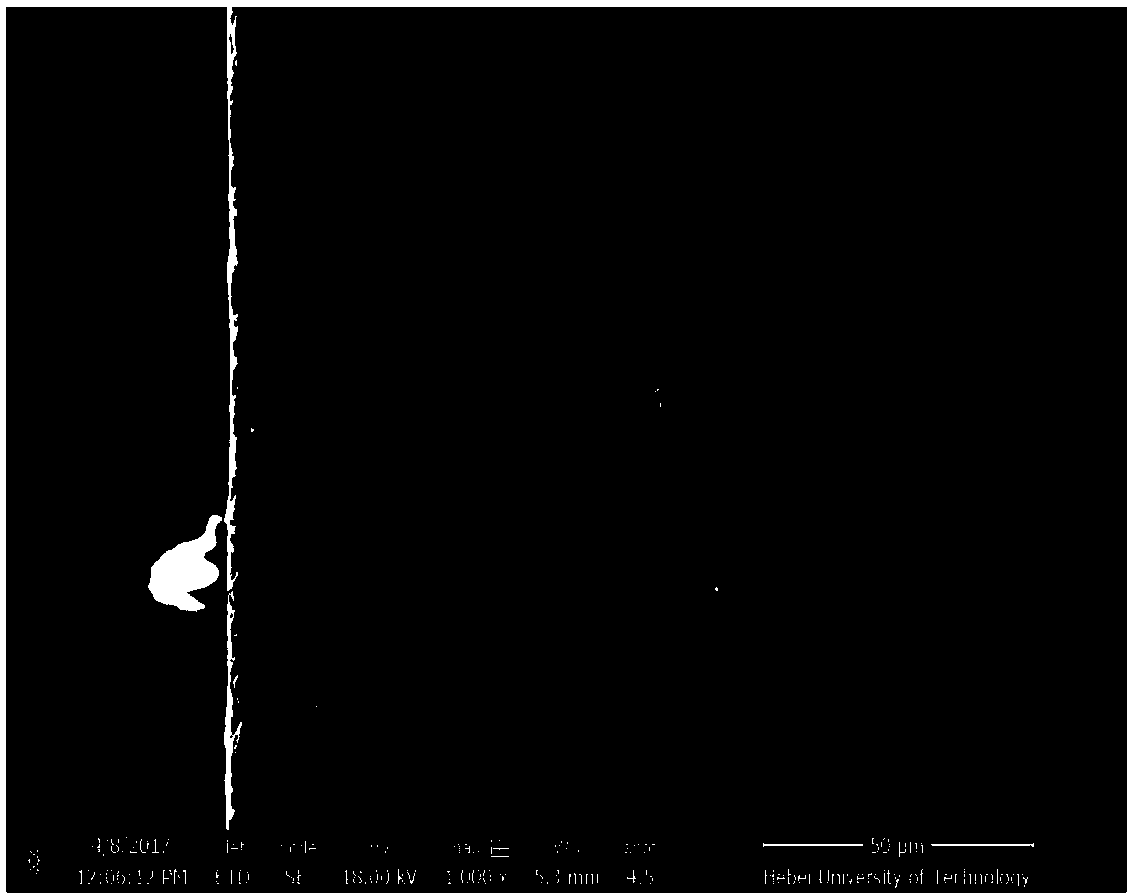

Image

Examples

preparation example Construction

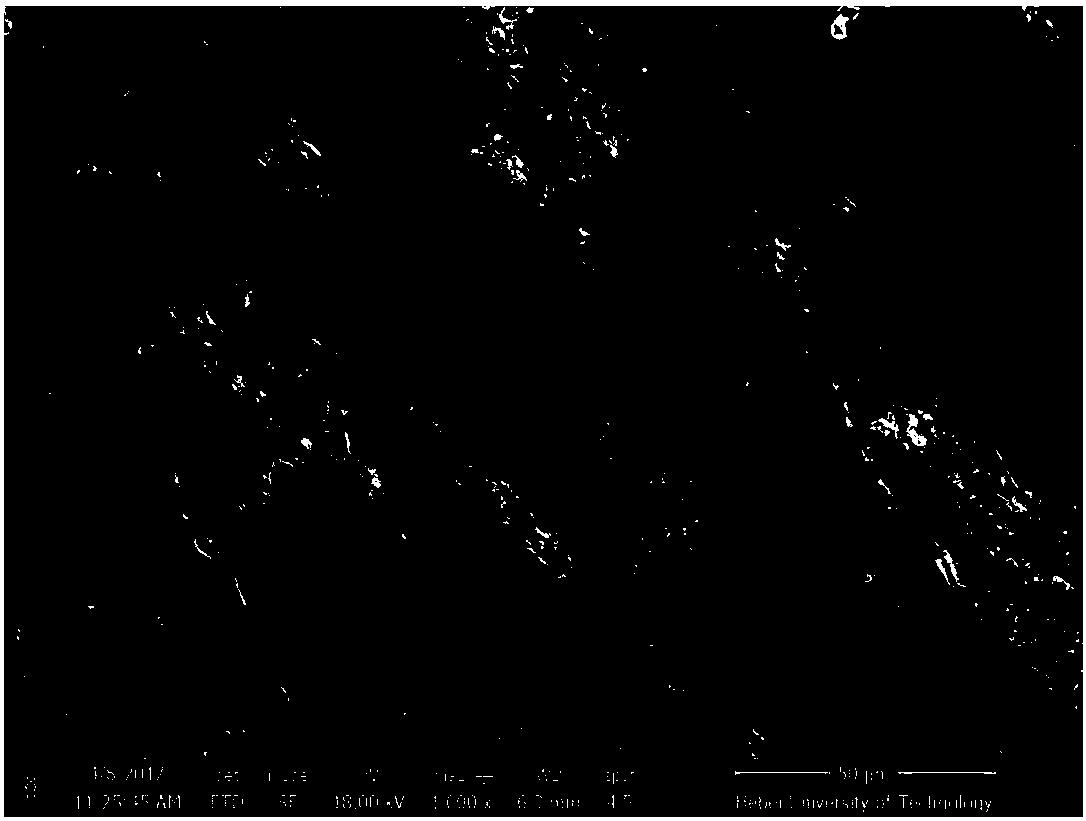

[0020] The TiC / SiC / Al composite material of the present invention, the outer layer of the composite material is a TiC reaction layer, and the inside is a SiC / Al composite layer, and the preparation method of the composite material comprises the following steps:

[0021] (1) Preparation of aluminum alloy: the mass percentage of each element in the aluminum alloy is: Al, 50-90wt.%; Ti, 5-20wt.%; Si, 5-30wt.%; Take the corresponding raw materials, grind the pure aluminum ingot with a grinding wheel, remove the surface oxide skin, place it together with pure titanium and silicon blocks in a graphite crucible, raise the temperature to 800-1200°C in a vacuum melting furnace, keep it warm for 0.5-3h, and keep stirring during the process After cooling, an aluminum alloy with uniform composition can be obtained.

[0022] (2) Pretreatment of SiC ceramics: Cut the SiC ceramics into the required corresponding size with a diamond cutting machine; then use an 800-mesh diamond grinding disc ...

Embodiment 1

[0027] The TiC / SiC / Al composite material of this embodiment, the outer layer of the composite material is a TiC reaction layer, and the inner layer is a SiC / Al composite layer. The preparation method of the composite material includes the following steps:

[0028] (1) Preparation of aluminum alloy: the mass percentage of each element in the aluminum alloy is: Al, 80wt.%; Ti, 10wt.%; Si, 10wt.%; 80g, titanium ingot 10g, silicon block 10g. Place all the above-mentioned raw materials in an alumina crucible at one time, put it in a vacuum stirring melting furnace and raise the temperature to 900°C at a heating rate of 10°C / min, and keep it warm for 1.5h, stirring continuously during this period to promote the homogenization of the ingredients, and take it out after solidification .

[0029] (2) Pretreatment of SiC ceramics: use a diamond cutter to cut SiC ceramics into a size of 40mm×5mm×5mm; then use 240 mesh and 800 mesh diamond discs to polish the surface of SiC ceramics until...

Embodiment 2

[0037] The specific preparation method of the TiC / SiC / Al composite material in this example is the same as in Example 1, except that the mass percentages of the elements in the aluminum alloy in this example are: Al, 85wt.%; Ti, 5wt.%; Si , 10wt.%.

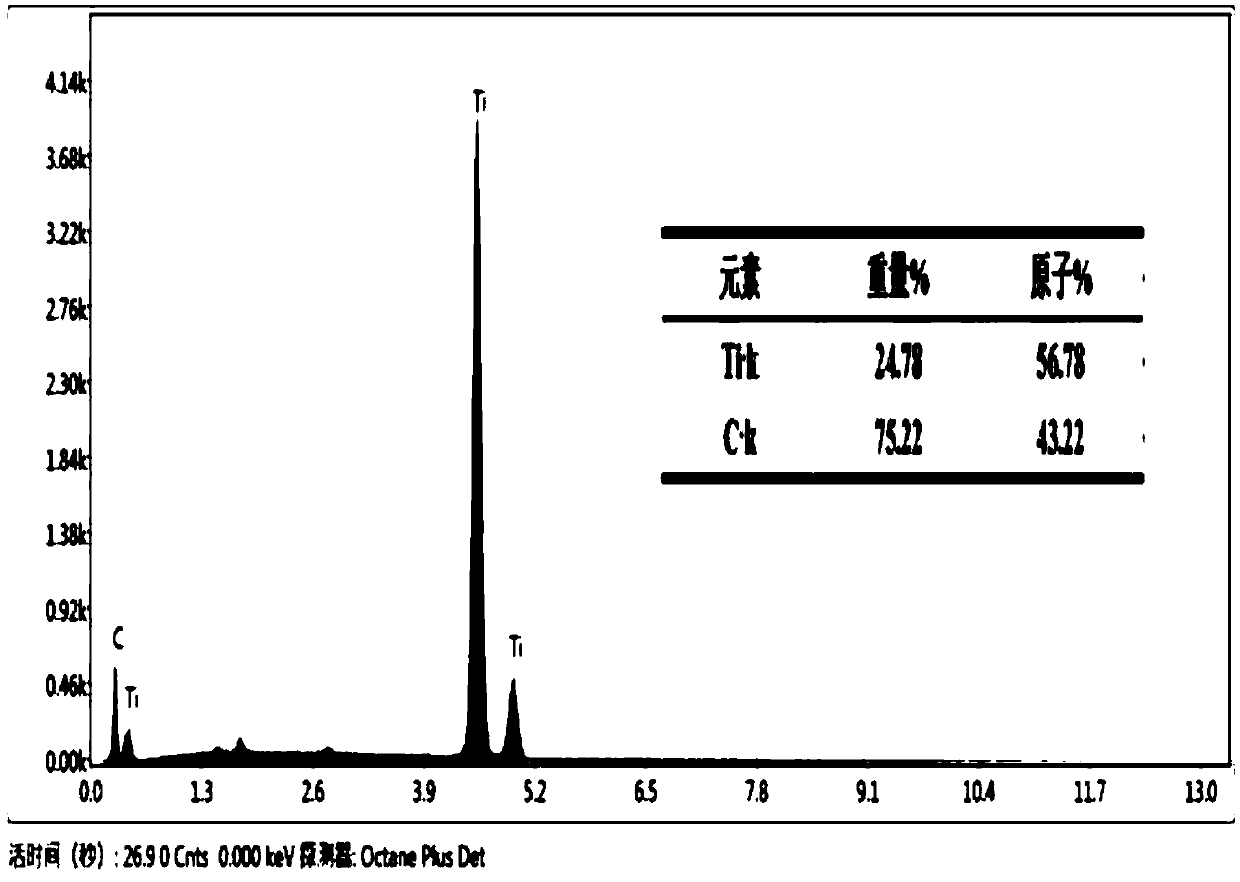

[0038] According to the test and analysis process of Example 1, the composite material obtained in this embodiment is analyzed and tested, and the specific results are: through the fracture toughness test, the average fracture toughness of the composite material obtained in this embodiment is 4.1MPam 1 / 2 , compared to pristine SiC ceramics (2.2MPam 1 / 2 ) increased by 1.9MPam 1 / 2 ; After the three-point bending strength test, the average bending strength of the composite material prepared in this embodiment is 289MPa, which is 110MPa higher than that of the original SiC ceramic (179MPa).

[0039] The preparation method of this example can obtain TiC / SiC / Al composite material, and when the impregnation time is 4h, Al can be comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com