Safety valve of electric water heater

A technology for electric water heaters and safety valves, applied in the field of safety valves, can solve the problems of shortened service life of safety valves, high production costs, and low production efficiency, and achieve the effects of reasonable structure setting, low production costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

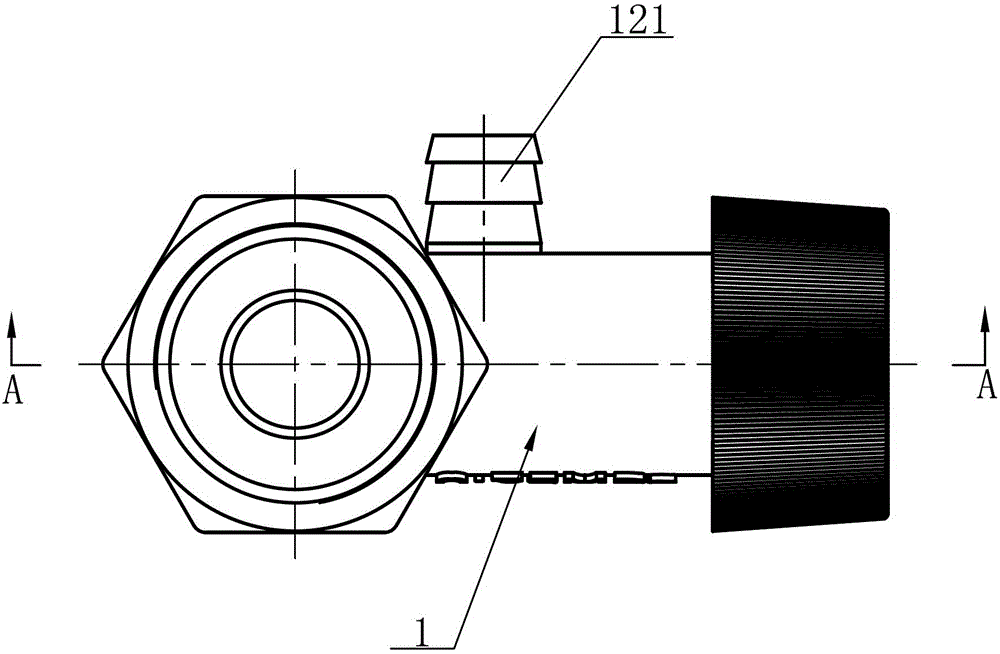

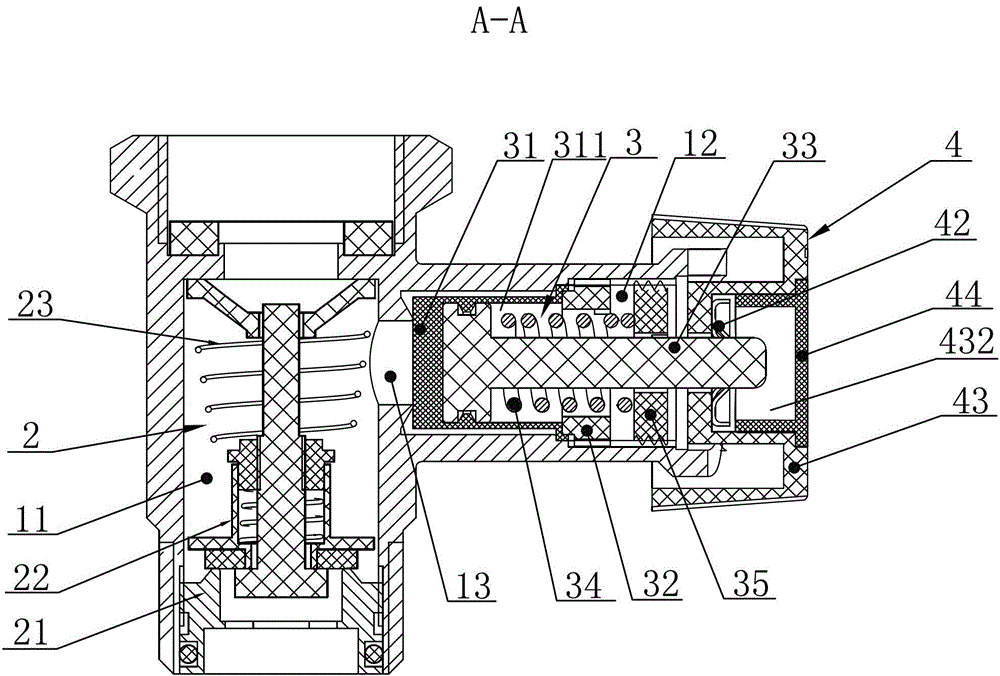

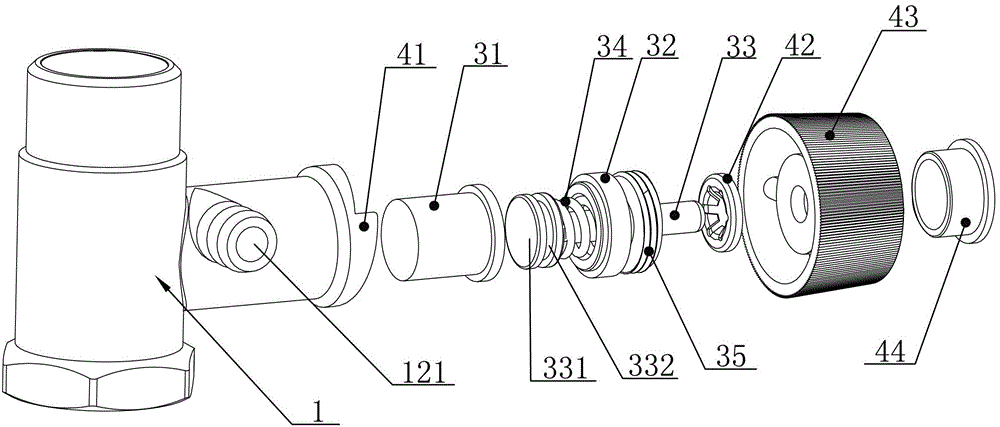

[0023] see Figure 1 to Figure 8 , a safety valve for an electric water heater disclosed in the present invention includes a valve body 1, a water inlet chamber 11 and a pressure relief chamber 12 are arranged on the valve body 1, and a water inlet chamber 11 and a pressure relief chamber 12 are arranged between A water inlet channel 13, the water inlet chamber 11 is provided with a one-way water inlet valve 2, the pressure relief chamber 12 is provided with a drain nozzle 121, and the pressure relief chamber 12 is provided with a pressure relief valve 3, the pressure relief valve 3 Including a rubber body 31, a rubber body pressure cap 32, a pull rod 33, a return spring 34 and an adjustment cap 35, the rubber body 31 is provided with a cavity 311, and the rubber body pressure cap 32 is threadedly connected to the inner wall of the pressure relief chamber 12 , the inner end of the pull rod 33 is inserted into the cavity 311 through the rubber body pressure cap 32 and fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com