Engine anhydrous cooling liquid and preparation method thereof

A water cooling and engine technology, applied in chemical instruments and methods, bulk chemical production, materials for heat exchange, etc., can solve problems such as incompatibility with water-containing antifreeze, complex cooling system structure, and inability to detect in advance, etc., to achieve recovery The effect of increasing force, improving thermal efficiency, and increasing horsepower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

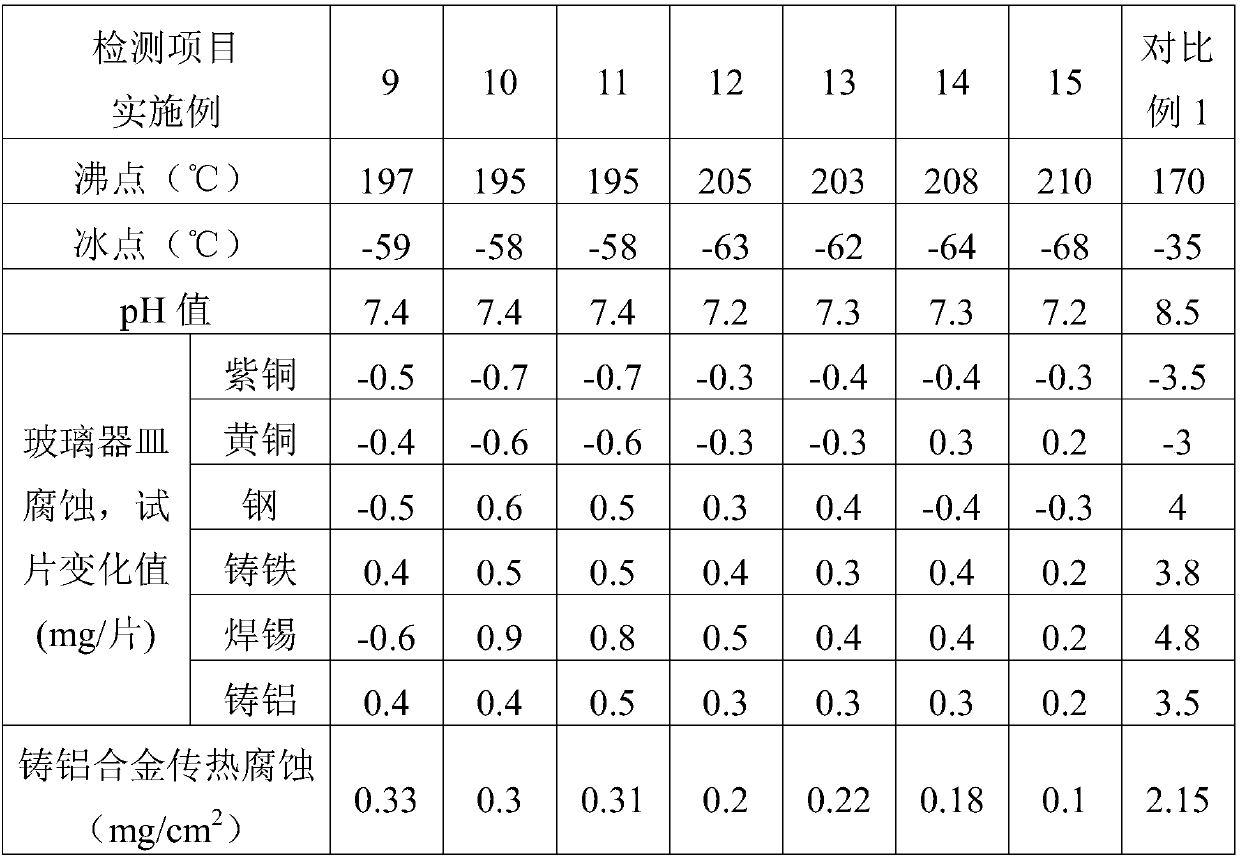

Examples

Embodiment 1

[0032] A kind of engine anhydrous coolant, comprises the raw material composition of following percentage by weight:

[0033] Propylene glycol 62%, ethylene glycol 25%, benzotriazole 4%, sodium nitrate 2%, glycerol 3%, triethanolamine 2%, sodium hydroxide 1%, pigment 1%;

[0034] A method for preparing the above-mentioned anhydrous engine coolant, comprising the following steps:

[0035] Step 1. According to the above weight percentage, take 1 / 3 of propylene glycol and heat it to 80°C, add sodium nitrate, continue heating after the sodium nitrate and propylene glycol are completely fused, add triethanolamine when the liquid temperature rises to 110°C, stir evenly, stop heating, natural cooling;

[0036] Step 2. According to the above weight percentage, take 2 / 3 of the ethylene glycol and heat it to 60°C, add glycerol and sodium hydroxide, and let it cool naturally after completely blending in;

[0037] Step 3, mixing the materials obtained in step 1 and step 2 and then stirr...

Embodiment 2

[0040] A kind of engine anhydrous coolant, comprises the raw material composition of following percentage by weight:

[0041] Propylene glycol 65%, ethylene glycol 25%, benzotriazole 3%, sodium nitrate 2%, glycerol 2%, triethanolamine 1.5%, sodium hydroxide 1%, pigment 0.5%;

[0042] A method for preparing the above-mentioned anhydrous engine coolant, comprising the following steps:

[0043] Step 1. According to the above weight percentage, take 1 / 3 of propylene glycol and heat it to 85°C, add sodium nitrate, continue heating after the sodium nitrate and propylene glycol are completely fused, add triethanolamine when the liquid temperature rises to 115°C, stir evenly, stop heating, natural cooling;

[0044] Step 2. According to the above weight percentage, take 2 / 3 of ethylene glycol and heat it to 65°C, add glycerol and sodium hydroxide, and then cool naturally after completely blending in;

[0045] Step 3, mixing the materials obtained in step 1 and step 2 and then stirrin...

Embodiment 3

[0048] A kind of engine anhydrous coolant, comprises the raw material composition of following percentage by weight:

[0049] Propylene glycol 67%, ethylene glycol 25%, benzotriazole 3%, sodium nitrate 1%, glycerin 2%, triethanolamine 1%, sodium hydroxide 0.5%, pigment 0.5%;

[0050] A method for preparing the above-mentioned anhydrous engine coolant, comprising the following steps:

[0051] Step 1. According to the above weight percentage, take 1 / 3 of propylene glycol and heat it to 75°C, add sodium nitrate, continue heating after the sodium nitrate and propylene glycol are completely fused, add triethanolamine when the liquid temperature rises to 105°C, stir evenly, stop heating, natural cooling;

[0052] Step 2. According to the above weight percentage, take 2 / 3 of the ethylene glycol and heat it to 70°C, add glycerol and sodium hydroxide, and let it cool naturally after completely blending in;

[0053] Step 3, mixing the materials obtained in step 1 and step 2 and then s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com