Gradient functional concrete tower column structure and construction method thereof

A technology of gradient function and functional structure, applied in bridge parts, erection/assembly of bridges, bridge materials, etc., can solve the lack of systematic research on the prevention and control of concrete tower column cracking, construction cracks and poor construction section joints, affecting the social environment of bridges, etc. problems, to reduce maintenance costs, avoid cracks, and improve the effect of ornamental

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

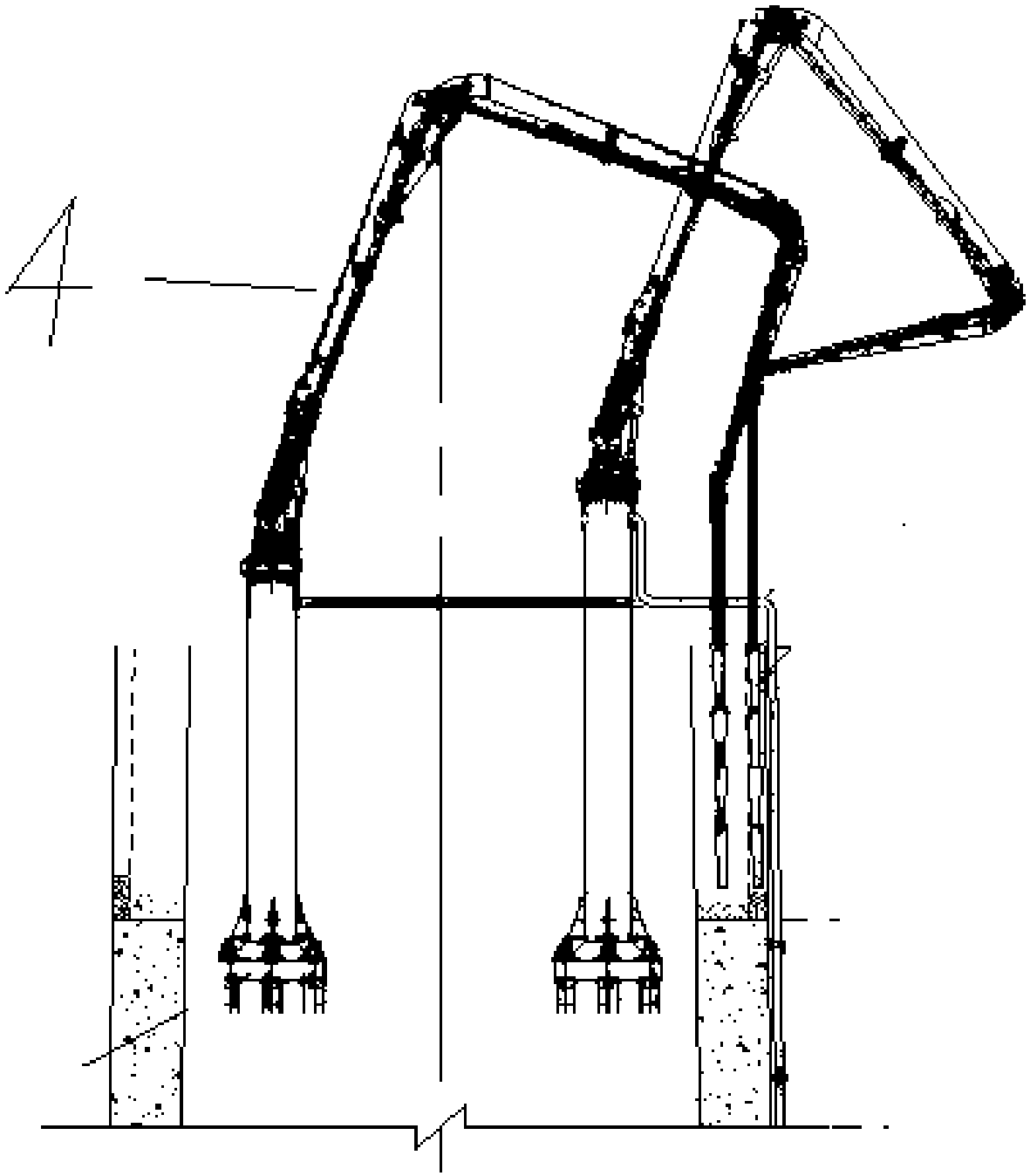

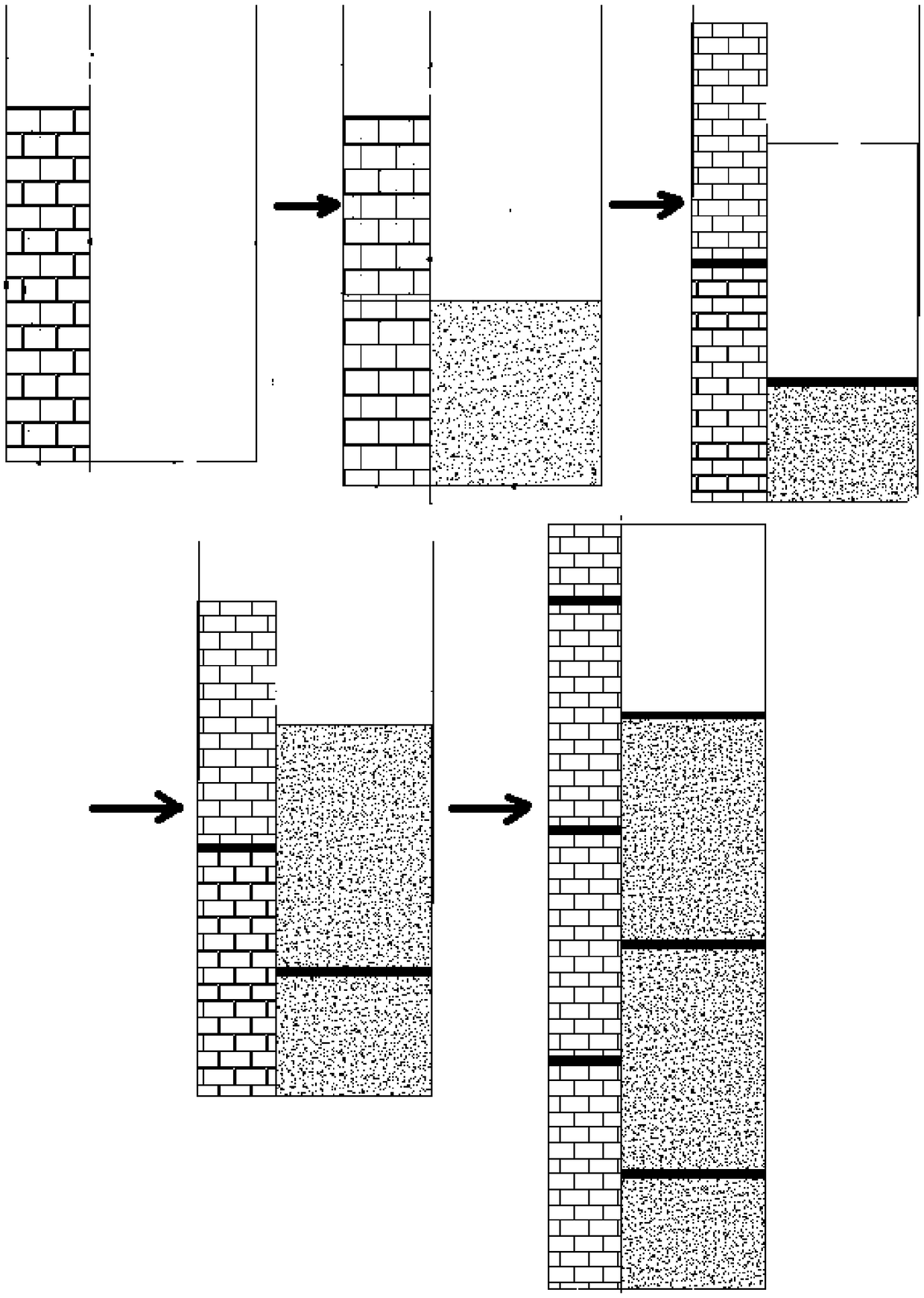

[0047] See attached picture.

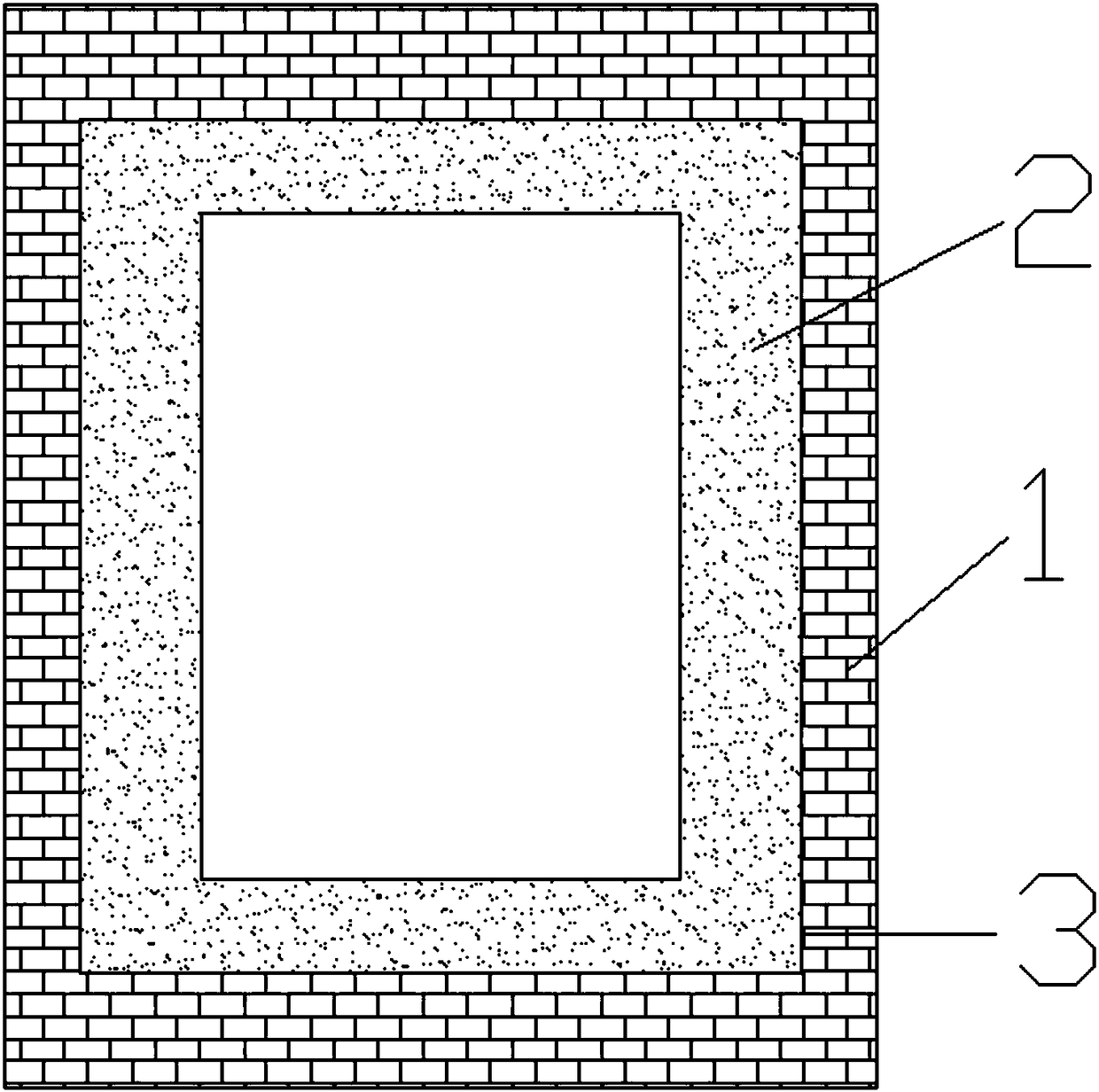

[0048] A gradient functional concrete tower structure, characterized in that: it includes a functional layer 1 and a structural layer 2 whose cross-sections are sequentially arranged from outside to inside, and a functional structural transition zone 3 is provided between the functional layer 1 and the structural layer 2, The functional layer 1 and the structural layer 2 are respectively formed by pouring, and a composition gradient transition without a macroscopic interface is formed between the three, and a bionic skin concrete tower structure is formed.

[0049] The functional layer 1 is a white fiber concrete structure with a thickness of 30-50 cm and the following ratio. Its composition and dosage are PW52.5 low-alkali white cement, and the dosage is 385 kg / m3. 25 continuous sieving ordinary stones, the dosage is 1096 kg / m3, the dosage of ordinary quartz sand with a fineness modulus of 2.15 is 701 kg / m3, the dosage of S95 grade mineral powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com