Buffer layer for sulfide solid-state battery, preparation method of buffer layer, and solid-state battery

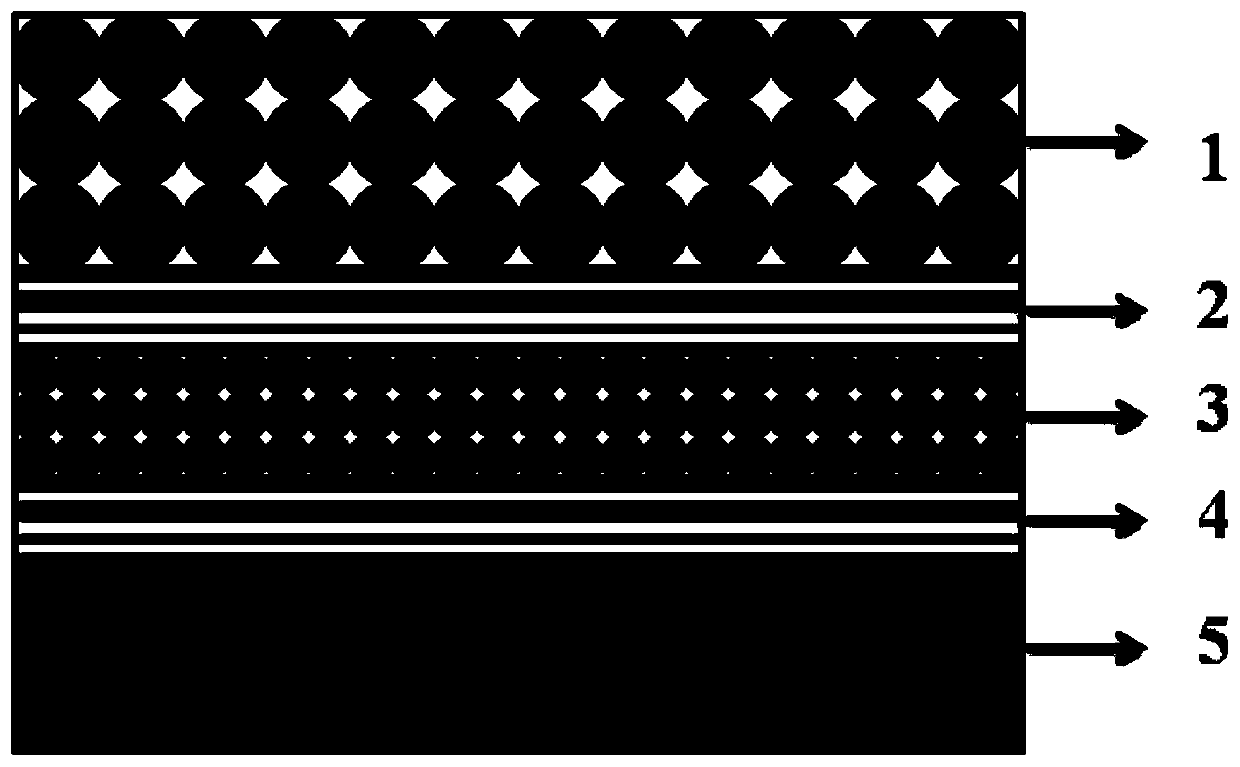

A solid-state battery and sulfide technology, which is applied in the field of power supply, can solve problems affecting the performance of solid-state lithium batteries, weak lithium ion transmission capacity, poor interface compatibility, etc., to facilitate rapid film formation, increase capacity and charge and discharge efficiency , the effect of reducing the interface stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the present invention is as follows:

[0048] (1) Preparation of sulfide composite cathode materials

[0049] Step 1: Add the sulfide electrolyte to the flowable polymer, stir until it is completely dissolved, and obtain a polymer solution containing the sulfide electrolyte; Step 2: fully mix the positive electrode active material, the polymer solution containing the sulfide electrolyte, and the conductive agent Mix it into a paste; step 3: transfer the paste obtained in step 2 to a vacuum oven, bake at 60°C for 6 hours, take it out and grind it after the solvent is completely volatilized, and obtain a composite positive electrode material; step 4: powder the composite positive electrode material Press into a sheet to obtain a sulfide composite positive electrode. The concentration of the polymer solution containing the sulfide solid electrolyte is 15-55 mg / mL. The content of the positive electrode active material in the polymer solution of t...

Embodiment 1

[0056] (1) Preparation of sulfide composite cathode materials

[0057] Step 1: Add 0.55gLi 10 Ge 1 P 2 S 12 Added to 10mL of PEO acetonitrile solution to obtain Li-containing 10 Ge 1 P 2 S 12 PEO acetonitrile solution; Step 2: Weigh the positive electrode active material LiFePO according to the mass ratio of 35:10 4 and conductive agent Super P, will contain Li 10 Ge 1 P 2 S 12 The PEO acetonitrile solution was added to it and mixed well to form a paste, LiFePO 4 Containing Li 10 Ge 1 P 2 S 12 The content of PEO in acetonitrile solution is 35mg / mL. Step 3: Transfer the paste obtained in Step 2 to a vacuum oven, bake at 60°C for 6 hours, take it out and grind it after the solvent is completely volatilized, and obtain a composite positive electrode material; Step 4: Press the powder of the composite positive electrode material into a sheet, namely A sulfide composite positive electrode was obtained.

[0058] (2) Preparation of buffer layer for sulfide solid-sta...

Embodiment 2

[0064] (1) Preparation of sulfide composite cathode materials

[0065] Step 1: Add 0.55gLi 10 Ge 1 P 2 S 12 Added to 10mL of PEO acetonitrile solution to obtain Li-containing 10 Ge 1 P 2 S 12 PEO acetonitrile solution; Step 2: Weigh the positive electrode active material LiNi according to the mass ratio of 35:10 0.8 co 0.15 Al 0.05 o 2 and conductive agent SuperP, will contain Li 10 Ge 1 P 2 S 12 Add the PEO acetonitrile solution into it and mix well to form a paste, LiNi 0.8 co 0.15 Al 0.05 o 2 Containing Li 10 Ge 1 P 2 S 12 The content of PEO in acetonitrile solution is 35mg / mL. Step 3: Transfer the paste obtained in Step 2 to a vacuum oven, bake at 60°C for 6 hours, take it out and grind it after the solvent is completely volatilized, and obtain a composite positive electrode material; Step 4: Press the powder of the composite positive electrode material into a sheet, namely A sulfide composite positive electrode was obtained.

[0066] (2) Preparatio...

PUM

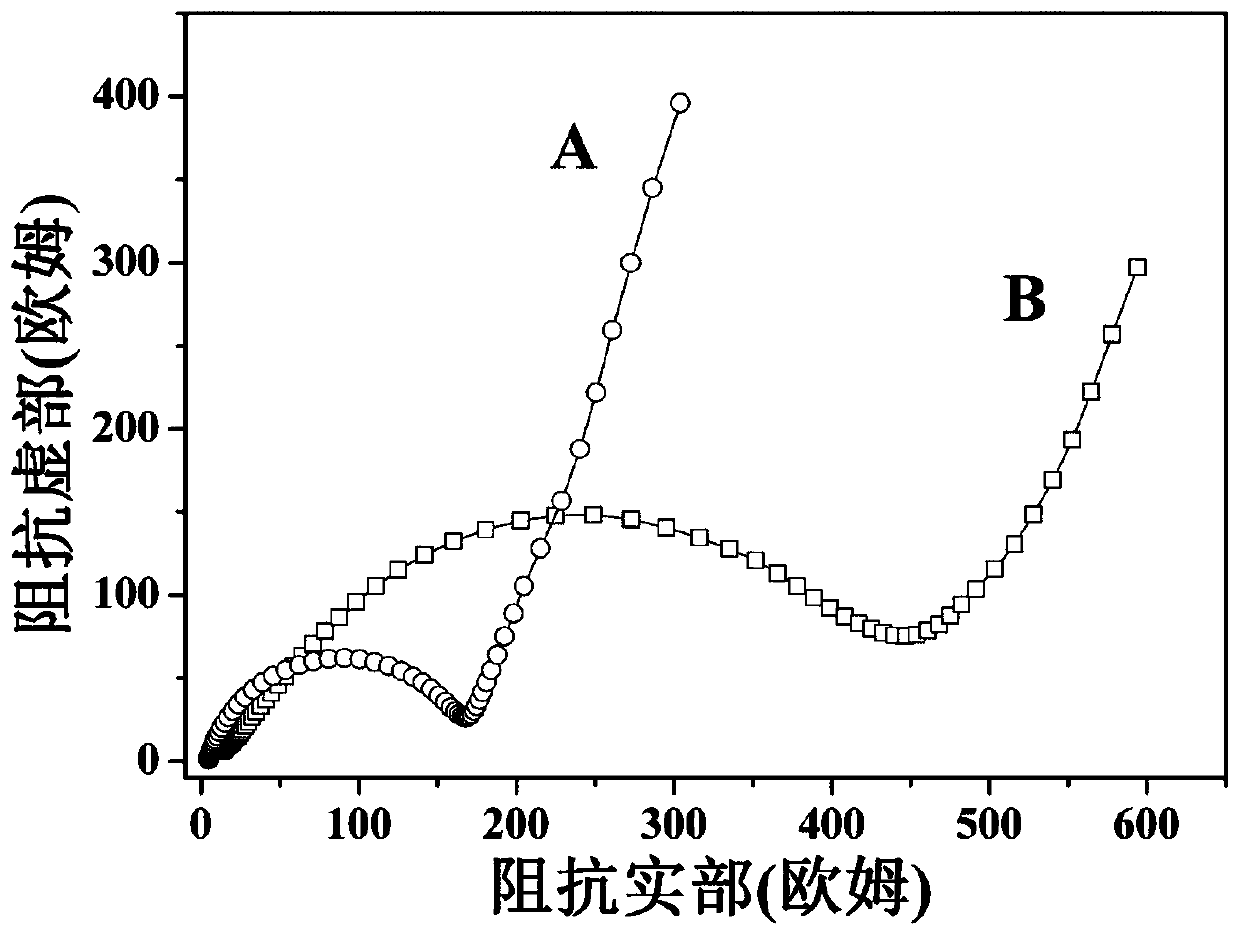

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com