Flexible honeycomb sound-insulating and heat-insulating composite board

A technology of composite board and honeycomb paperboard, which is applied in sound insulation, building components, heat preservation, etc. It can solve the problems of heat insulation material loss, welding slag splashing, and affecting performance, etc., and achieve moisture resistance and weather resistance, light specific gravity, and good durability. Effect

Inactive Publication Date: 2009-12-23

耿忠平

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because of this simple laying of the sound insulation board and the heat insulation material (board) separately, usually the sound insulation board is laid on the bottom, and the heat insulation material is laid on the top; and the glass wool or mineral wool used as the heat insulation material is only covered by the outer film. During the construction period, welding slag splashes often cause fire accidents; on the other hand, the heat insulation materials during the construction period are often wetted by rain and lose their normal state of bulkiness, which affects the subsequent use performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

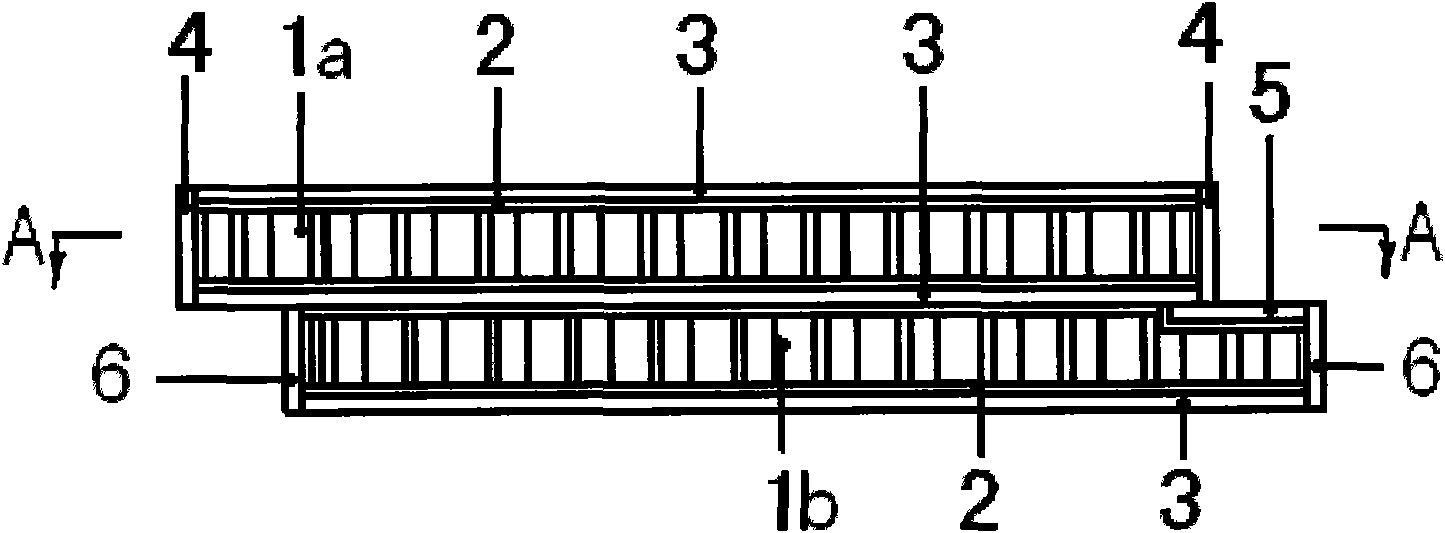

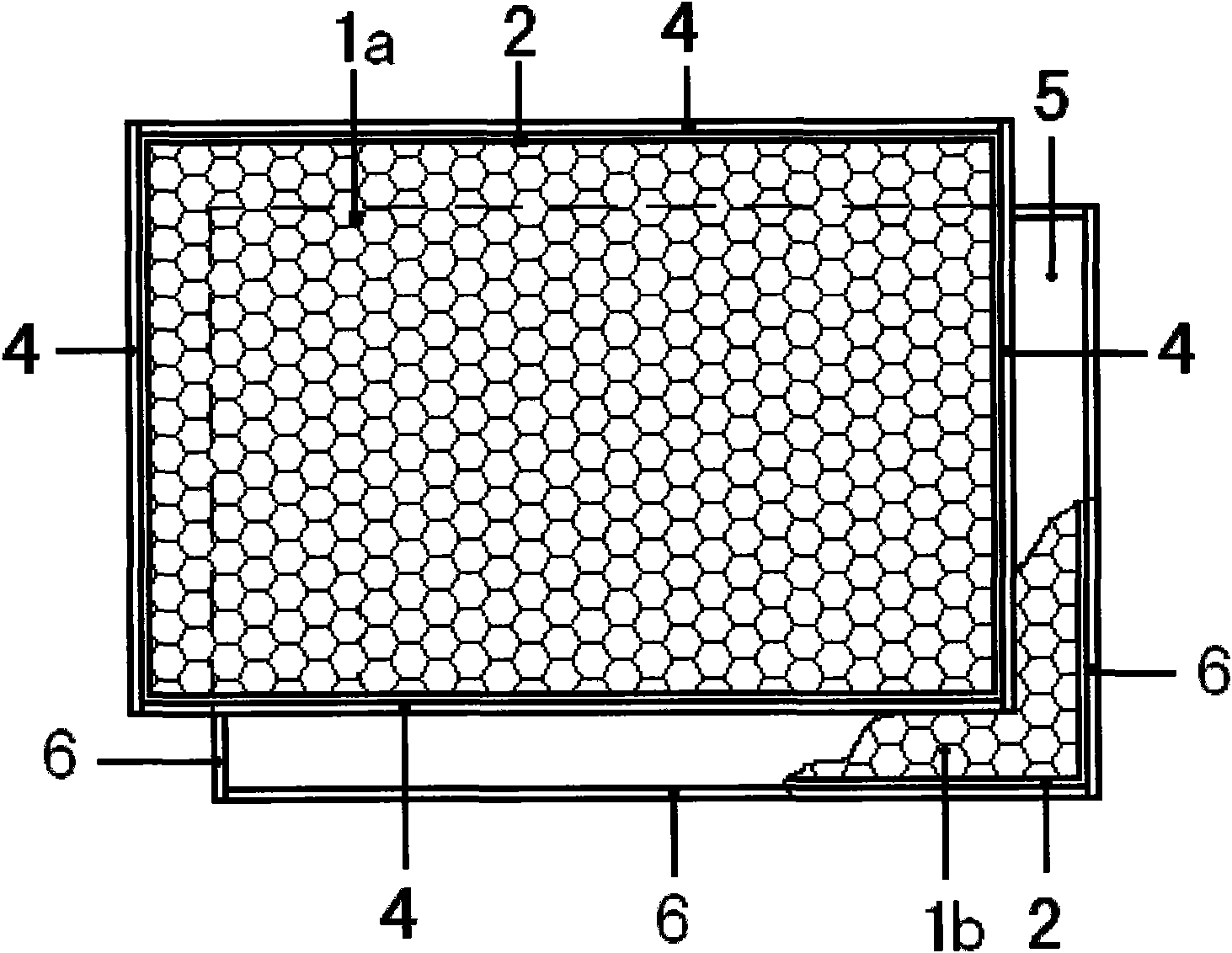

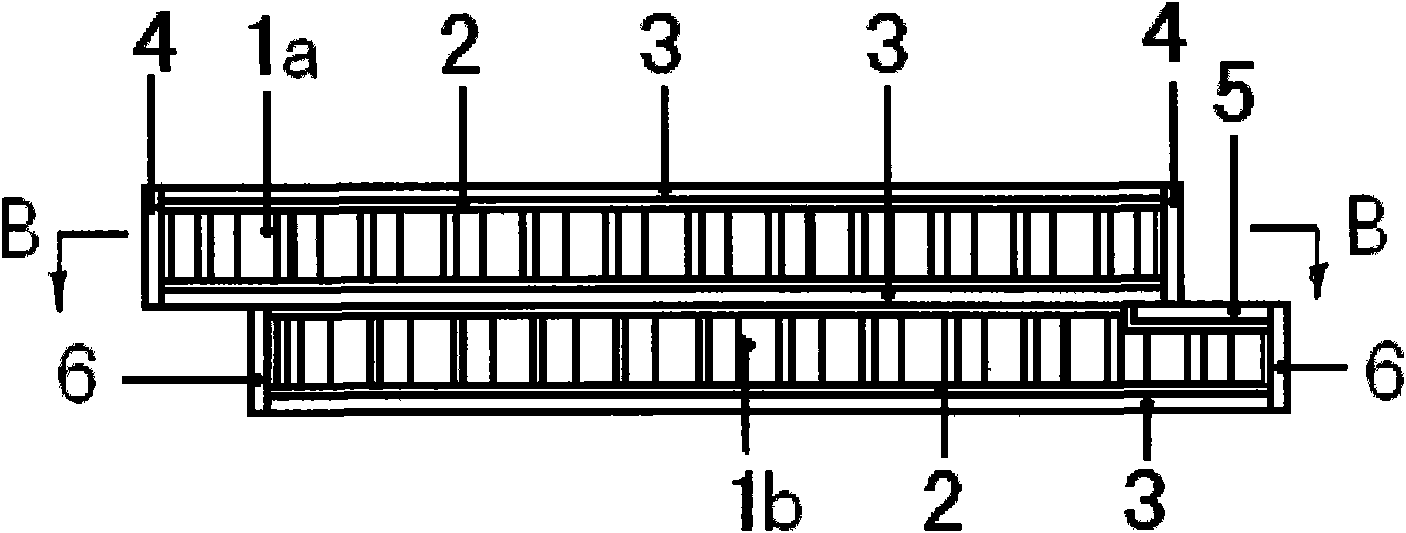

The invention relates to a flexible honeycomb sound-insulating and heat-insulating composite board having good performance in heat insulation and heat preservation, water resistance and flame resistance and belonging to the field of functional panels for building and decoration. In the invention, at least two double-layer board sound-insulating structures are formed by using the combination mode that two honeycomb cardboard filling core materials (1a, 1b) are sandwiched between an upper composite panel and a middle composite panel and between the middle composite panel and a lower composite panel respectively, wherein, the upper and the lower honeycomb cardboard filling core materials (1a, 1b) constitute hermetic air cavities between the two boards of the two double-layer board sound-insulating structures. Therefore, the honeycomb sound-insulating and heat-insulating composite board which integrates the characteristics of a single honeycomb cardboard and a single composite panel has the advantages of low density, low per-unit specific gravity, sound insulation, heat insulation, water resistance, flame resistance, high durability and the like.

Description

Technical field: The invention relates to a flexible honeycomb sound-insulation and heat-insulation composite board with good performances of sound insulation, heat insulation, heat preservation, waterproof and flame retardancy. The utility model belongs to the field of functional boards for construction and decoration. technical background: Existing sound insulation boards or heat insulation materials (boards) made of various materials, various technologies, and various processes, but often only have a single function, the sound insulation board only plays the role of sound insulation, heat insulation The material (plate) can only be insulated. When the roof of a traditional large-scale public venue building needs both sound insulation and heat insulation, it is necessary to simply stack, lay and combine these two types of panels (materials). Because of this simple laying of the sound insulation board and the heat insulation material (board) separately, usually the sound ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04B1/90E04B1/94E04C2/36E04C2/38

Inventor 吴凡王昆林

Owner 耿忠平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com