Modular honeycomb building capable of being assembled quickly

A modular and honeycomb technology, applied in buildings, small buildings, building components, etc., can solve the problems of fast construction speed, achieve short construction period, improve sound insulation, and facilitate transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

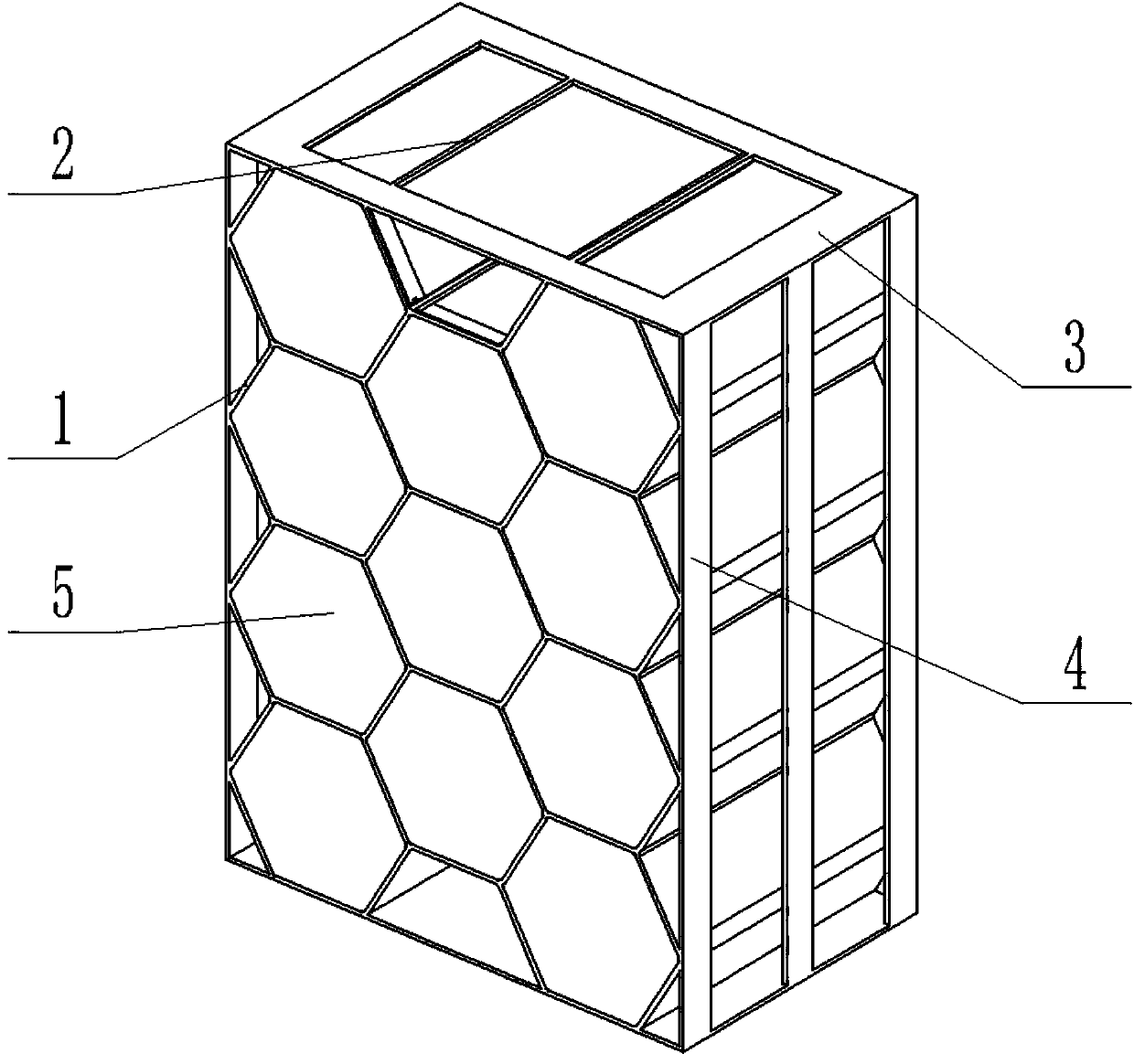

[0030] This embodiment is basically as figure 1 Shown:

[0031] A modular honeycomb building that can be assembled quickly, including a honeycomb space unit 5 and a honeycomb frame unit.

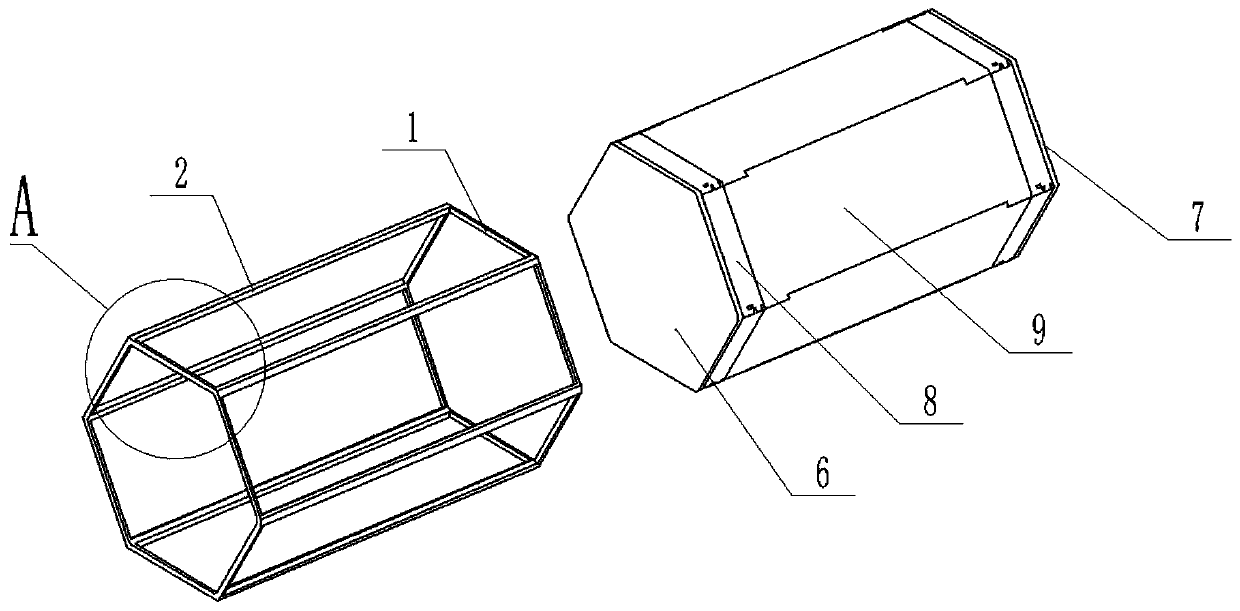

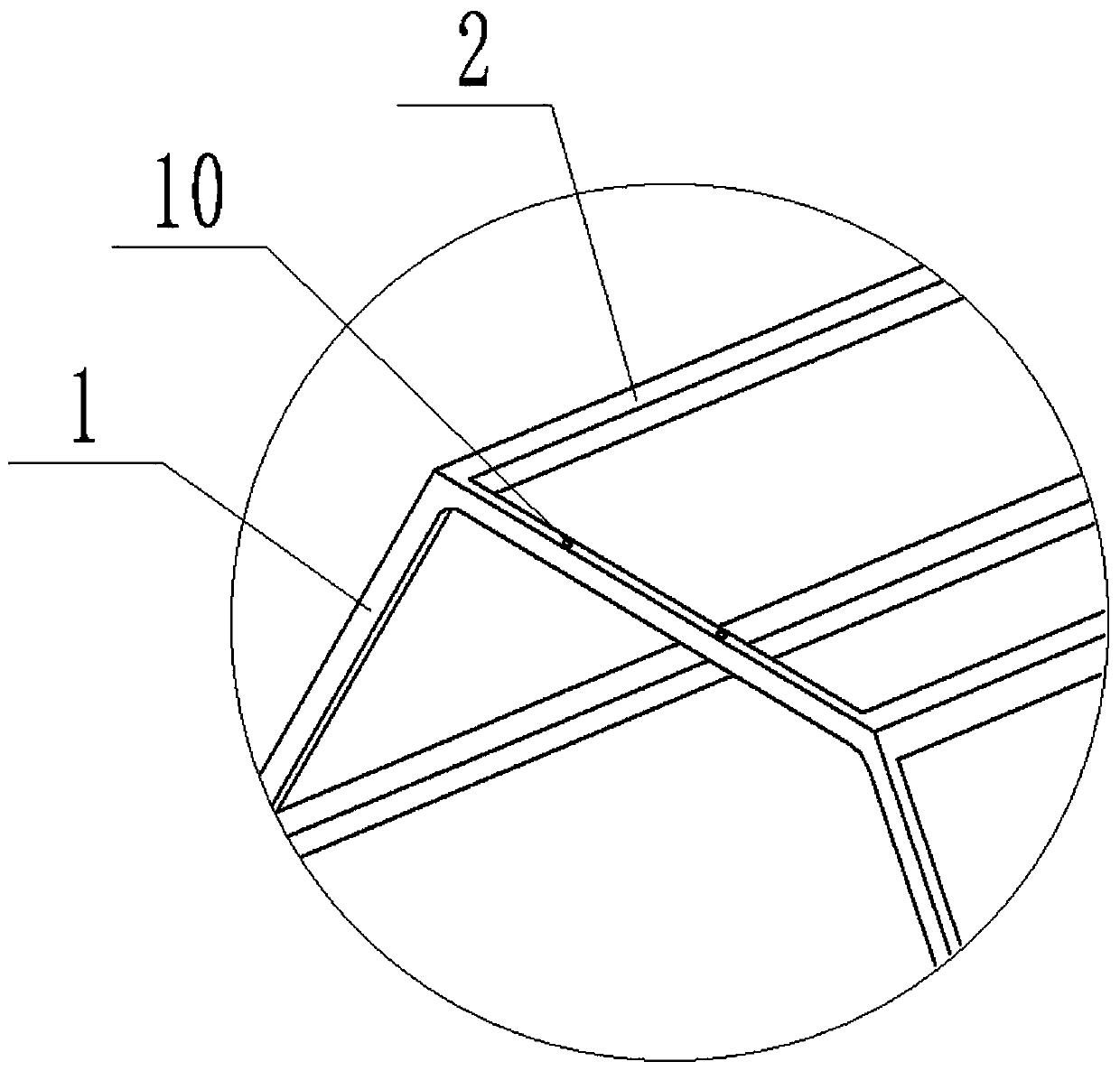

[0032] combine Figure 5-7 , The honeycomb space unit 5 includes two frames, six side panels 9 , a front panel 6 and a rear panel 7 . The skeleton includes six folding rods 8 connected head to tail. One end of the folding rods 8 is integrally formed with a cylindrical first bump 11 and a second bump 12 . There is a gap between the first bump 11 and the second bump 12 . A rotating shaft 13 is concentrically fixed on the first protrusion 11 , and the rotating shaft 13 passes through the second protrusion 12 and is flush with the front end surface of the folding rod 8 . The first protruding block 11 is provided with a first pin hole, which is a blind hole, and the second protruding block 12 is provided with a second pin hole aligned with the first pin hole, and the second pin hole is a thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com