Inflating bag sealed with binding base material and manufacture process for same

A manufacturing process and technology for adhesives, applied in the direction of cardboard articles, closure devices, containers to prevent mechanical damage, etc., can solve the problem of inability to achieve safety and practicability, increase the production cost and process complexity of air bags, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail now in conjunction with accompanying drawing.

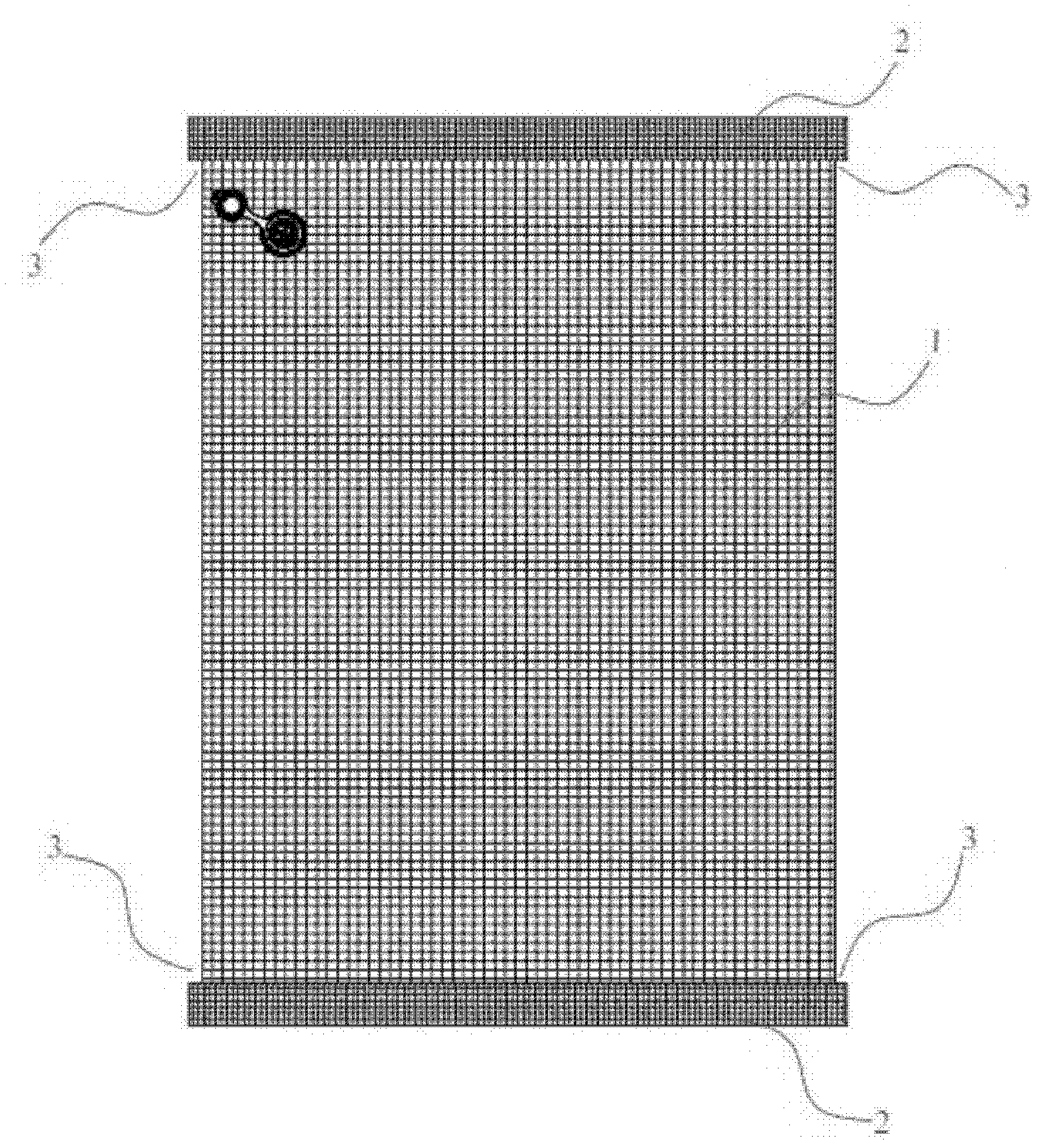

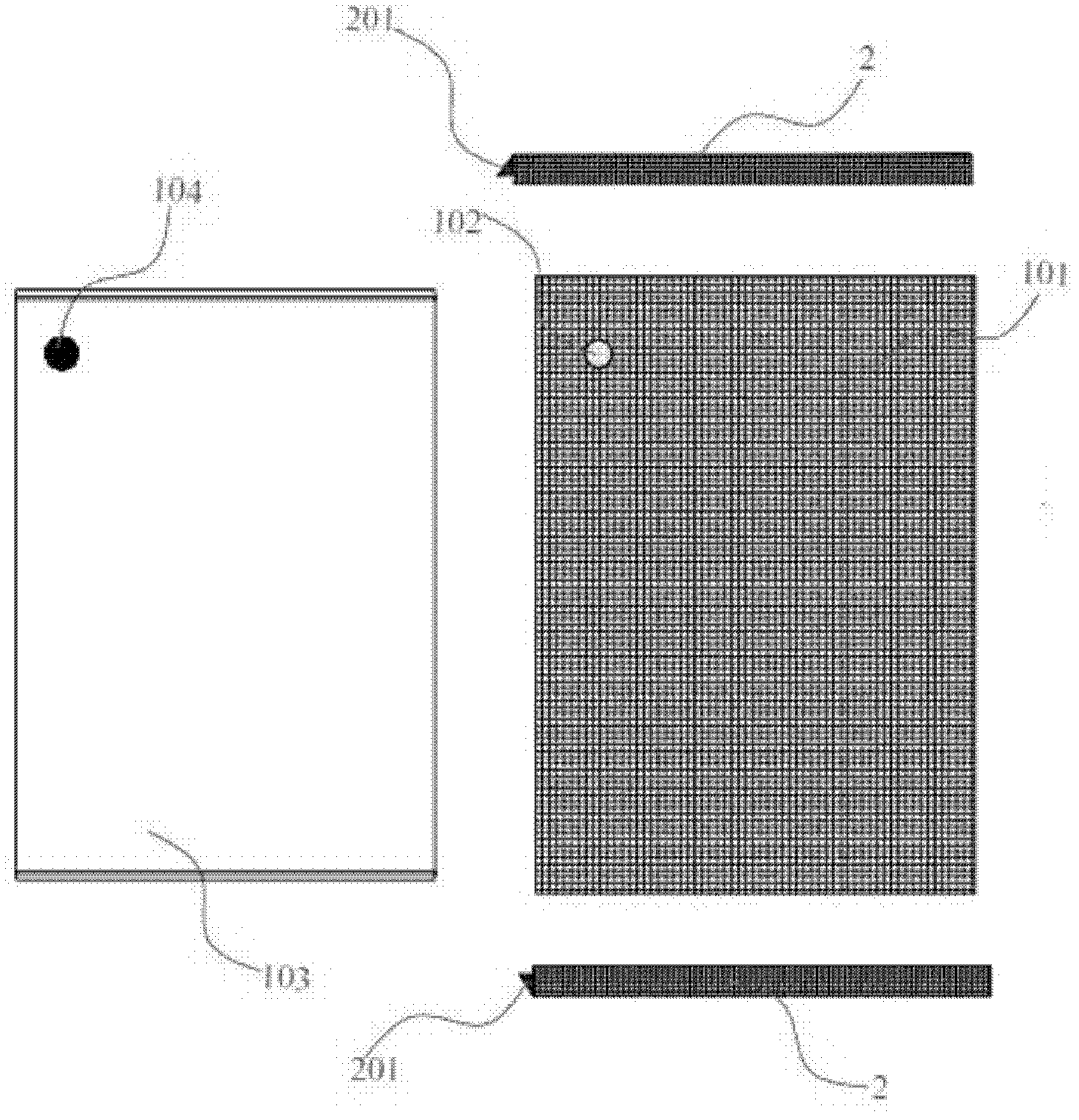

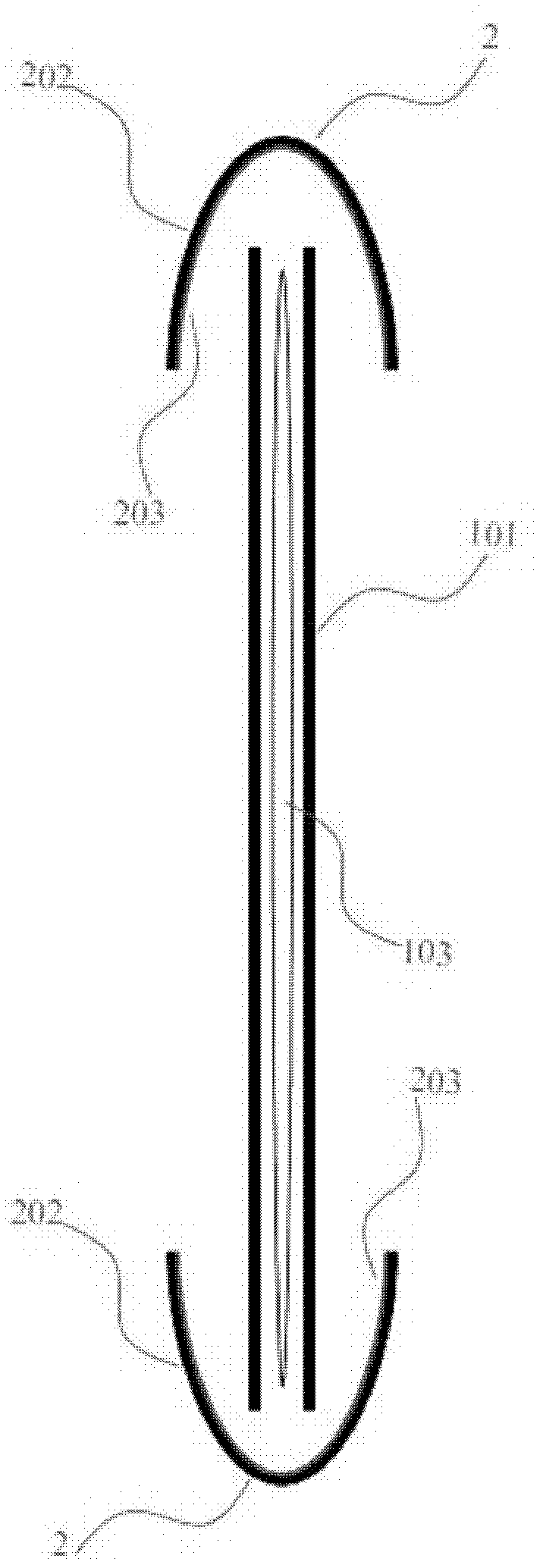

[0027] refer to Figure 1 to Figure 5 As shown, the key point of the design of the present invention is that it includes 103 inner bags, 101 outer bags, and 2 adhesive substrates. The 103 inner bag is a co-extrusion film, and a 104 air valve that can be used for inflation is arranged on the co-extrusion film. The 101 outer bag is a polypropylene woven bag, and the bag is provided with a 102 opening that allows the air valve on the inner bag to pass through and be exposed. 2 adhesive substrates at both ends as seals. 2 Adhesives The substrate has 203 adhesives on one side.

[0028] When the inflatable bag is made, at first the semi-finished product with the air valve inner bag is put into the 101 polypropylene woven bag, and the 104 air valve on the 103 inner bag cooperates with the opening position of the 101 outer bag 102 to complete the assembly. The two end openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com