Polymer, coating composition comprising same, and organic light emitting element using same

A technology of polymers and compositions, applied in the direction of electrical components, coatings, electrical solid devices, etc., can solve problems such as inability to dissolve materials well, defective devices, and changes in solution concentration gradients, and achieve excellent thermal stability and Optical stability, improved life characteristics, effects of lower driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

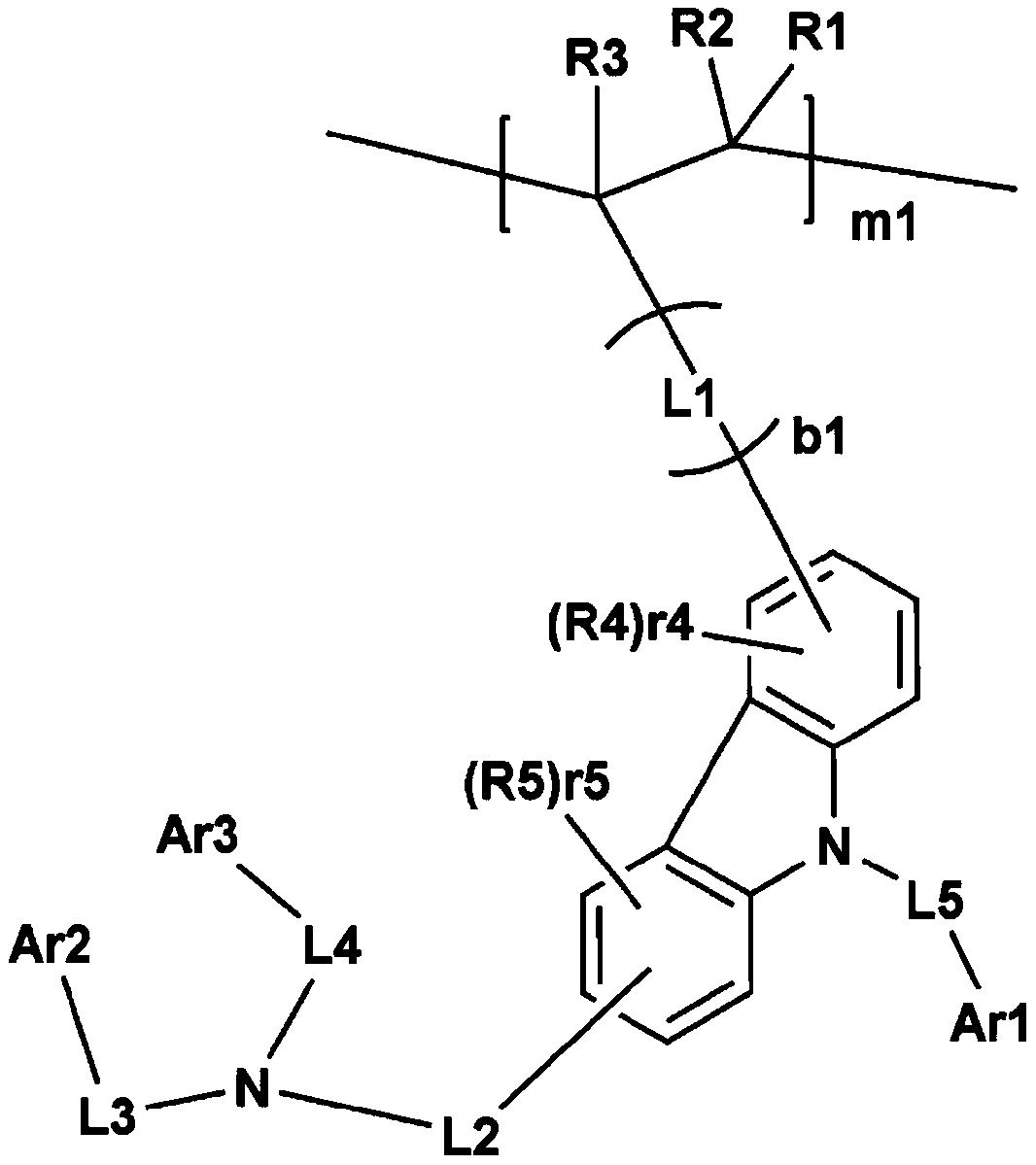

Method used

Image

Examples

preparation example 1

[0224]

[0225] (1) Preparation of Intermediate 5

[0226]

[0227] After dissolving 3-bromo-9-phenyl-9H-carbazole (9g, 27.9mmol) and 4-formylphenylboronic acid (4.18g, 27.9mmol) in anhydrous tetrahydrofuran (THF, 100mL), to it Put in Pd(PPh 3 ) 4 (0.32g, 0.28mmol) and 70ml2M potassium carbonate aqueous solution (K 2 CO 3 / H 2 0), the resulting mixture was refluxed for 6 hours. After cooling the reaction solution to room temperature, the organic layer was extracted. The reaction solution was concentrated and recrystallized with ethanol (EtOH) to obtain Intermediate 3 (8.9 g, yield 92%). MS:[M+H] + =348

[0228] Intermediate 3 (8.2 g, 23.6 mmol) was dissolved in dimethylformaldehyde (200 mL), N-bromosuccinimide (4.15 g, 23.6 mmol) was added thereto, and the resulting mixture was stirred at room temperature for 5 Hour. After distilled water was poured into the reaction solution to terminate the reaction, the organic layer was extracted. The reaction solution was ...

preparation example 2

[0233]

[0234] (1) Preparation of compound A1

[0235]

[0236] After intermediate 5 (3.65g, 8.615mmol), 4-(diphenylamino)phenylboronic acid (2.99g, 10.338mmol), Pd(PPh 3 ) 4 (498mg, 0.431mmol) and K 2 CO 3 (3.57g, 25.845mmol) was dissolved in anhydrous tetrahydrofuran (200ml) and distilled water (100ml), and the resulting solution was stirred at 70°C for 15 hours. The organic layer was extracted by using ethyl acetate and water. By using MgSO 4 After removing moisture from the organic layer, the solvent was removed under reduced pressure. The obtained material was subjected to column chromatography using ethyl acetate and hexane to separate and purify Compound A1.

[0237] MS:[M+H] + =589

[0238] (2) Preparation of compound A2

[0239]

[0240] Compound A2 was prepared in the same manner as in the method for preparing Compound A1 except that 4-(biphenylyl-4-ylamino)phenylboronic acid was used instead of 4-(diphenylamino)phenylboronic acid.

[0241] MS:[M+H...

preparation example 3

[0264]

[0265] (1) Preparation of Polymer C1

[0266]

[0267] After compound A1 (1 g) was dissolved in 5 ml of tetrahydrofuran (THF), azobisisobutyronitrile (AIBN) (4 mg) was put thereinto, and the resulting solution was stirred at 75° C. for 5 hours. Thereafter, 420 mg of polymer C1 was prepared by precipitation using ethanol and drying of the obtained solid. Mn=22,400Mw=39,500

[0268] (2) Preparation of Polymer C2

[0269]

[0270] 550 mg of Polymer C2 was prepared in the same manner as in the method for preparing Polymer C1 except that Compound A2 was used instead of Compound A1. Mn=30,400Mw=57,800

[0271] (3) Preparation of Polymer C3

[0272]

[0273] 490 mg of Polymer C3 was prepared in the same manner as in the method for preparing Polymer C1 except that Compound A3 was used instead of Compound A1. Mn=24,200Mw=43,800

[0274] (4) Preparation of Polymer C4

[0275]

[0276]620 mg of polymer C4 was prepared in the same manner as in the method for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com