Multifunctional separation protective agent for electrostatic paint mist treatment system and preparation method of multifunctional separation protective agent

A treatment system and protective agent technology, applied in the field of environmental pollution control, can solve the problems of inability to cover the cathode plate, uneven bath liquid, and block of paint slag, and achieve excellent leveling, safety, non-corrosion, safety, and non-corrosion. Effect of increased moisturizing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

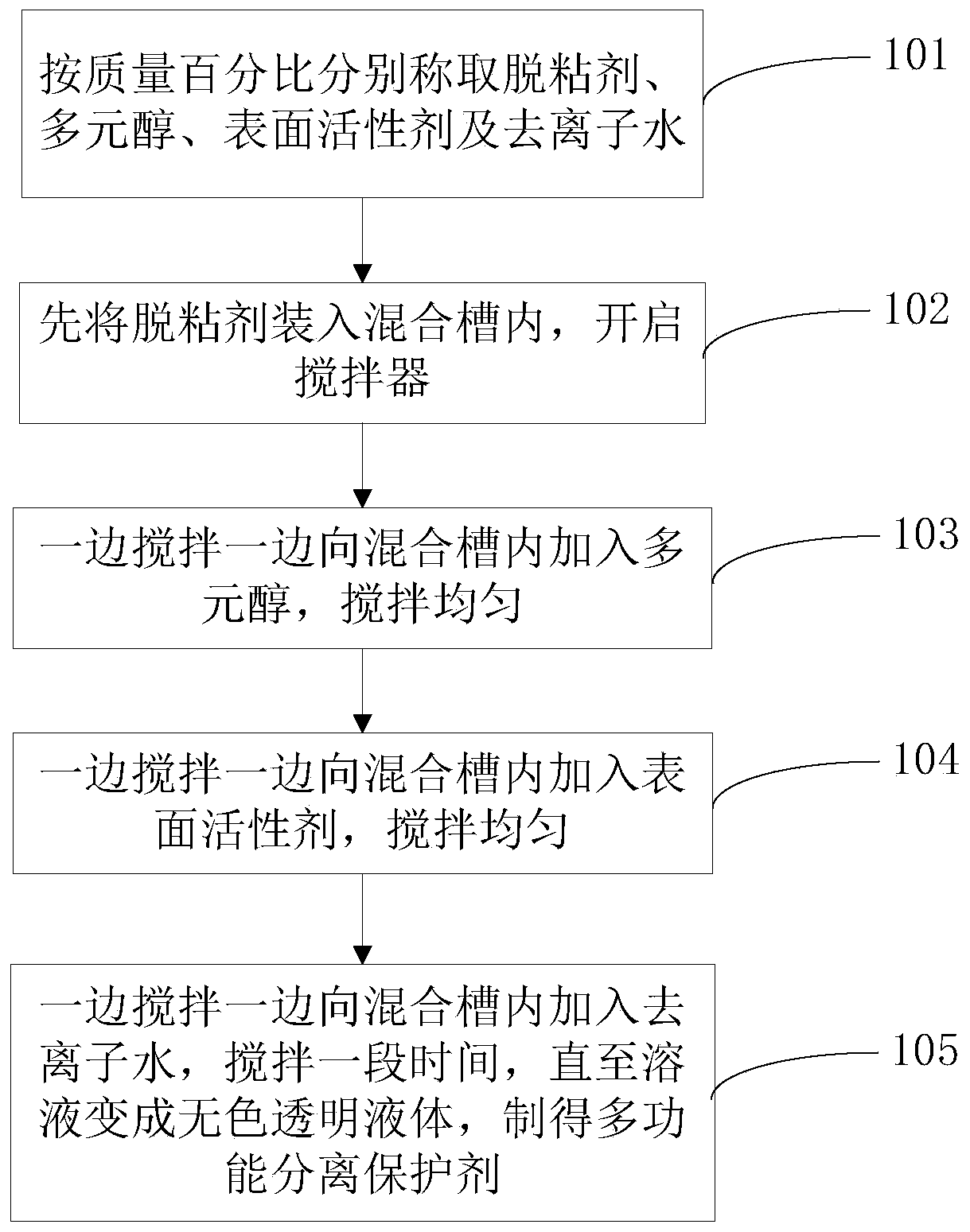

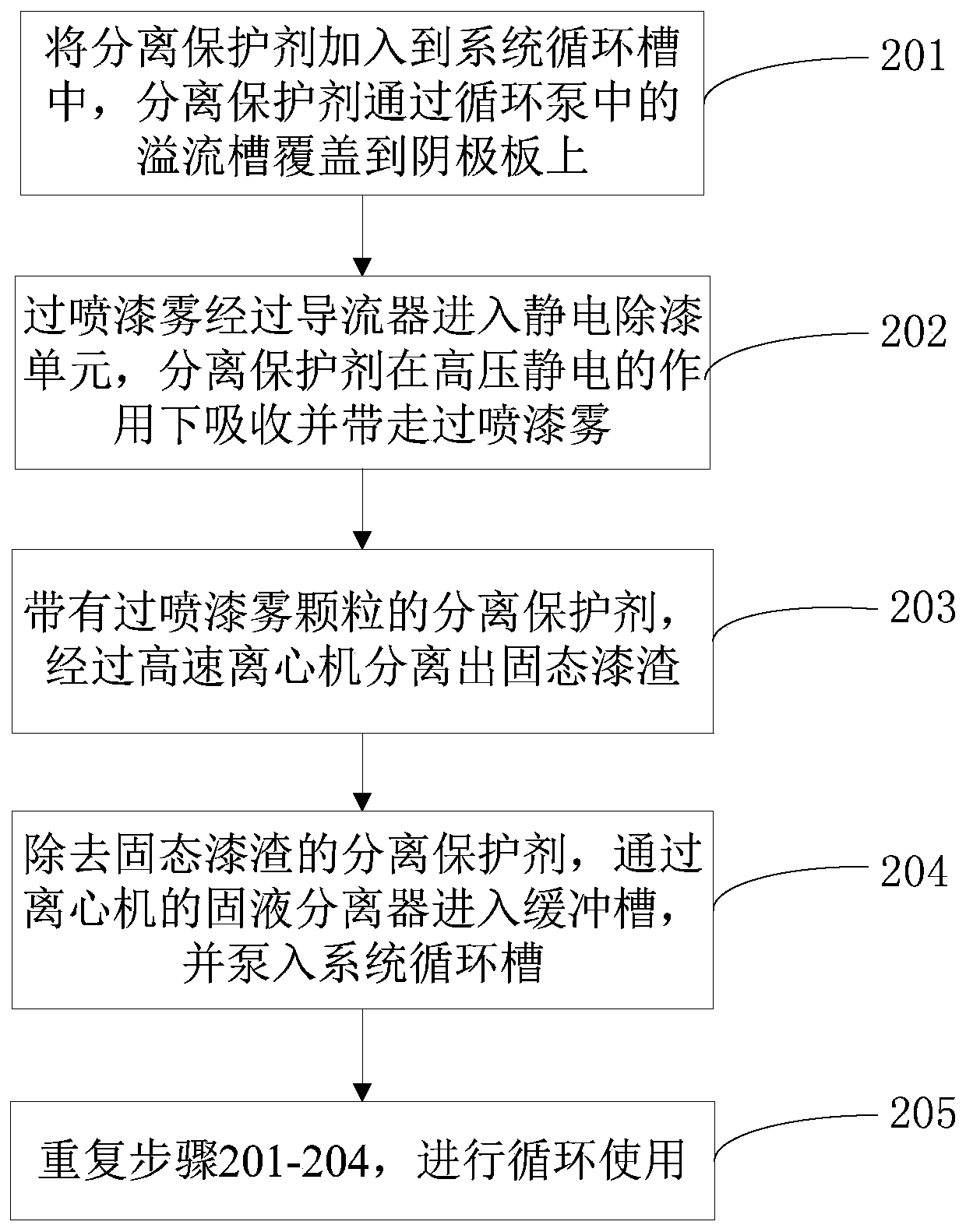

Method used

Image

Examples

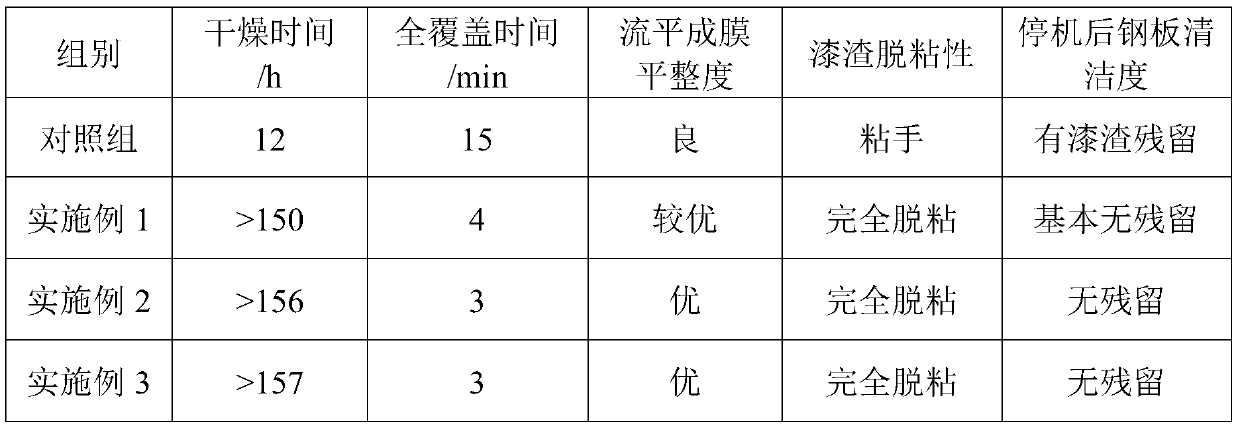

Embodiment 1

[0045] A multifunctional separation and protection agent for electrostatic paint mist treatment system, comprising the following components and mass percentages: 50% of debonding agent, 10% of polyol, 0.2% of surfactant, and 39.8% of deionized water.

[0046] The debonding agent is cationic polyamine, the solid content of the cationic polyamine is 35%, the Brookfield viscosity is 800 cps, the density is 0.9 g / ml, and the pH value is 5.

[0047] Alternatively, the debonding agent is cationic polyaluminum or cationic amino resin.

[0048] All the above-mentioned detackifiers can remove the stickiness of the varnish, and are preferably cationic polyamines, which can achieve a better dispersion effect of paint slag.

[0049] The polyhydric alcohol is glycerol.

[0050] Alternatively, the polyhydric alcohol is one of ethylene glycol, polypropylene glycol, polydimethyldiallylammonium chloride, and melamine formaldehyde resin.

[0051] The above-mentioned polyols can increase the m...

Embodiment 2

[0062] A multi-functional separation and protection agent for electrostatic paint mist treatment system, comprising the following components and mass percentages: 55% of debonding agent, 15% of polyol, 0.3% of surfactant, and 29.7% of deionized water.

[0063] The debonding agent is cationic polyamine, the solid content of the cationic polyamine is 38%, the Brookfield viscosity is 1000 cps, the density is 1.0 g / ml, and the pH value is 6.

[0064] Alternatively, the debonding agent is cationic polyaluminum or cationic amino resin.

[0065] All the above-mentioned detackifiers can remove the stickiness of the varnish, and are preferably cationic polyamines, which can achieve a better dispersion effect of paint slag.

[0066] The polyhydric alcohol is glycerol.

[0067] Alternatively, the polyhydric alcohol is one of ethylene glycol, polypropylene glycol, polydimethyldiallylammonium chloride, and melamine formaldehyde resin.

[0068] The above-mentioned polyols can increase the...

Embodiment 3

[0079] A multifunctional separation and protection agent for electrostatic paint mist treatment system, comprising the following components and mass percentages: 58% of debonding agent, 20% of polyol, 0.5% of surfactant, and 21.5% of deionized water.

[0080] The debonding agent is cationic polyamine, the solid content of the cationic polyamine is 40%, the Brookfield viscosity is 1200 cps, the density is 1.1 g / ml, and the pH value is 7.

[0081] Alternatively, the debonding agent is cationic polyaluminum or cationic amino resin.

[0082] All the above-mentioned detackifiers can remove the stickiness of the varnish, and are preferably cationic polyamines, which can achieve a better dispersion effect of paint slag.

[0083] The polyhydric alcohol is glycerol.

[0084] Alternatively, the polyhydric alcohol is one of ethylene glycol, polypropylene glycol, polydimethyldiallylammonium chloride, and melamine formaldehyde resin.

[0085] The above-mentioned polyols can increase the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brookfield viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com