Ramie fiber salt elimination underground pipe used for saline-alkali soil and preparation method of ramie fiber salt elimination underground pipe

A technology of ramie fiber and salt-discharging concealed pipe, which is applied in the field of saline-alkali land improvement, can solve the problems of short service life, impact resistance, and easy aging, and achieve the effects of low residual deformation, good low-temperature flexibility, and strong anti-aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

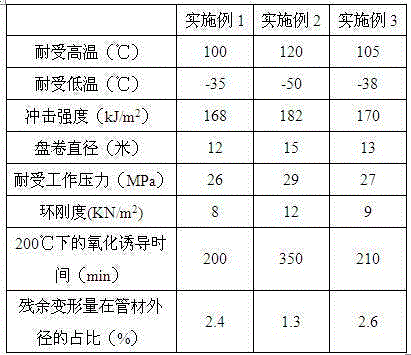

Embodiment 1

[0038] Embodiment 1 A kind of saline-alkali land uses ramie fiber to drain salt underground pipe

[0039] The raw material of described dark tube comprises the following components by weight:

[0040] 26 parts of ramie fiber, 45 parts of modified polypropylene, 4 parts of phenyl alkylsulfonate, 0.6 part of p-toluenesulfonyl hydrazide, 1.4 parts of calcium stearate, 4 parts of desulfurized rubber powder elastomer, 1 part of petroleum hydrocarbon oil , 6 parts of nano-titanium dioxide, 7 parts of silicone rubber, 5 parts of chlorinated polypropylene resin, and 1 part of sulfosalicylic acid.

[0041] Described ramie fiber, average fiber length 2.5-3.3cm, short fiber rate 20%;

[0042] The modified polypropylene is homopolypropylene and block polypropylene, and the mass ratio is 3:1.

Embodiment 2

[0043] Embodiment 2 A kind of saline-alkali land uses ramie fiber to drain salt underground pipe

[0044] The raw material of described dark tube comprises the following components by weight:

[0045] 32 parts of ramie fiber, 49 parts of modified polypropylene, 7 parts of phenyl sulfonate, 1.2 parts of p-toluenesulfonyl hydrazide, 1.6 parts of calcium stearate, 8 parts of desulfurized rubber powder elastomer, 2 parts of petroleum hydrocarbon oil , 9 parts of nano titanium dioxide, 10 parts of silicone rubber, 8 parts of chlorinated polypropylene resin, 3 parts of sulfosalicylic acid.

[0046] Described ramie fiber, average fiber length 2.5-3.3cm, short fiber rate 20%;

[0047] The modified polypropylene is homopolypropylene and block polypropylene, and the mass ratio is 3:1.

Embodiment 3

[0048] Embodiment 3 A kind of saline-alkali land uses ramie fiber to drain salt underground pipe

[0049] The raw material of described dark tube comprises the following components by weight:

[0050] 38 parts of ramie fiber, 53 parts of modified polypropylene, 9 parts of phenyl alkylsulfonate, 1.8 parts of p-toluenesulfonyl hydrazide, 1.9 parts of calcium stearate, 11 parts of desulfurized rubber powder elastomer, 3 parts of petroleum hydrocarbon oil , 12 parts of nano titanium dioxide, 14 parts of silicone rubber, 13 parts of chlorinated polypropylene resin, 5 parts of sulfosalicylic acid.

[0051] Described ramie fiber, average fiber length 2.5-3.3cm, short fiber rate 20%;

[0052] The modified polypropylene is homopolypropylene and block polypropylene, and the mass ratio is 3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com