Flexible sound-insulation composite material and preparation method thereof

A composite material and thermoplastic material technology, which is applied in the fields of materials and their preparation, flexible sound insulation composite materials and their preparation, can solve problems such as the inability to fully meet various technical requirements, and achieve high dimensional stability, small shrinkage and distortion. , good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

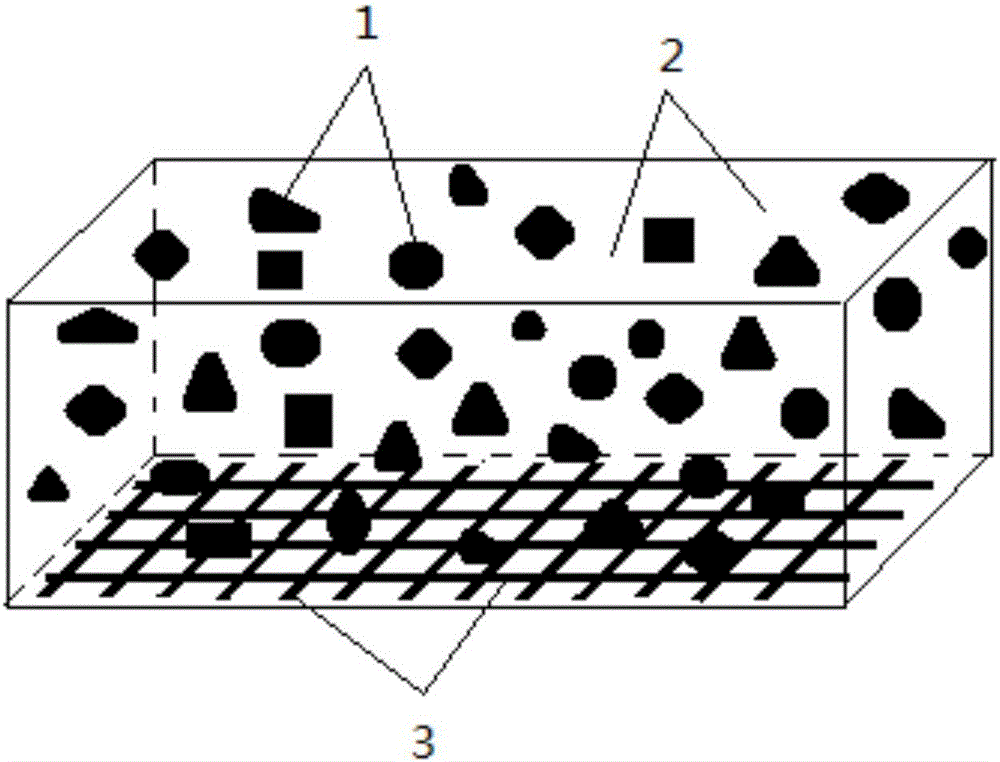

Image

Examples

Embodiment 1

[0028] A kind of flexible sound insulation composite material, the preparation method of this composite material comprises the steps:

[0029] (1) Weigh 60 parts of barium sulfate, put 2 parts of silane coupling agent into a high-speed mixer for heating and activation, the premixing temperature is 90°C, the premixing time is 6 minutes, and the rotation speed is 500 rpm;

[0030] (2) 10 parts of butadiene-acrylonitrile rubber, 40 parts of polyurethane fiber, 10 parts of tributyl citrate, 1 part of 2,6-tertiary butyl-4-methylphenol, 8 parts Add zinc borate into a high-speed machine and mix, further heat and pre-mix evenly, the pre-mixing temperature is 90°C, the pre-mixing time is 6 minutes, and the speed is 300 rpm;

[0031] (3) The raw materials of step (2) are further pre-mixed under negative pressure in a high-speed mixer, the temperature of the negative-pressure pre-mix is maintained at 90°C, the maintenance time of the negative-pressure pre-mix is 5min, and the vacuum ...

Embodiment 2

[0034] A kind of flexible sound insulation composite material, the preparation method of this composite material comprises the steps:

[0035] (1) Weigh 40 parts of calcium carbonate, 30 parts of thorium borate, and 1 part of titanate coupling agent into a high-speed mixer for heating and activation. The premixing temperature is 100 ° C, the premixing time is 5 minutes, and the speed is 450 rpm. min;

[0036] (2) With 12 parts of polyvinyl chloride, 42 parts of aramid fibers, 13 parts of tricresyl phosphate, 1.1 parts of bis (3,5-tertiary butyl-4-hydroxyphenyl) sulfide, 9 parts Parts of tris(nonylated phenyl)phosphite were added to the high-speed machine and mixed, further heated and premixed evenly, the premixing temperature was 100°C, the premixing time was 4min, and the speed was 280 rpm;

[0037] (3) The raw materials of step (2) are further pre-mixed under negative pressure in a high-speed mixer, the temperature of the negative-pressure pre-mix is maintained at 88°C, the...

Embodiment 3

[0040] A kind of flexible sound insulation composite material, the preparation method of this composite material comprises the steps:

[0041] (1) Weigh 40 parts of strontium carbonate, 40 parts of vermiculite powder, and 2 parts of aluminate coupling agent into a high-speed mixer for heating and activation. The premixing temperature is 110 ° C, the premixing time is 8 minutes, and the speed is 600 rpm. min;

[0042] (2) 20 parts of natural rubber, 50 parts of aramid fibers, 20 parts of acetyl tributyl citrate, 0.8 parts of tetrakis (Β-(3,5-tertiary butyl-4-hydroxyphenyl) Propionic acid) pentaerythritol ester, 12 parts of antimony trioxide was added to the high-speed machine for mixing, further heating and premixing, the premixing temperature was 120°C, the premixing time was 8min, and the rotating speed was 400 rpm;

[0043] (3) The raw materials of step (2) are further pre-mixed under negative pressure in a high-speed mixer, the temperature of the negative-pressure pre-mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com