Adhesive for road antiskid layer and preparation method of adhesive

A technology of bonding material and talc powder, which is applied in the field of bonding material and its preparation of colored anti-skid layer, can solve the problems of insufficient shear resistance and bonding performance, short color retention time, insufficient low temperature flexibility, etc., and achieves convenient Industrialized production, high frictional resistance, good flexibility at low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

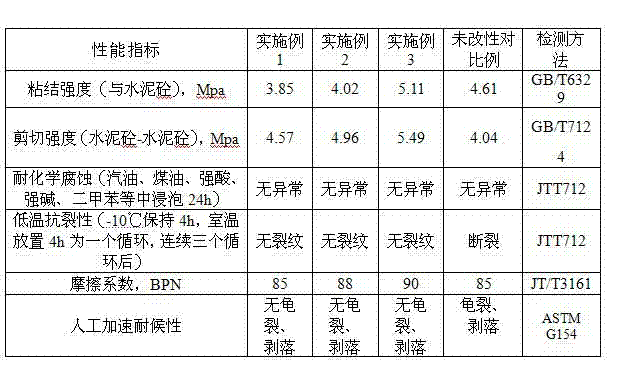

Examples

Embodiment 1

[0032] Embodiment 1: a kind of bonding material of anti-skid layer for pavement, it adopts following preparation method to make:

[0033] A. Raw material preparation

[0034] Modified epoxy resin: 120 parts of bisphenol A epoxy resin E-44, 100 parts of flexible epoxy resin 6350, 0.8% carboxyl-terminated liquid nitrile rubber (CTBN) prepolymer, 1.0% γ-aminopropyl Triethoxysilane, 0.6% of 2-hydroxy-4-n-octyloxybenzophenone in the temperature range of 60 ° C, mixed and stirred for 20 minutes, wherein the carboxyl-terminated liquid nitrile rubber (CTBN) prepolymer , γ-aminopropyltriethoxysilane and 2-hydroxyl-4-n-octyloxybenzophenone are the percentages of the total amount of bisphenol A epoxy resin E-44.

[0035] Modified epoxy resin curing agent: mix 8% of 2,4,6-tris(dimethylaminomethyl)phenol, 1.0% phenylenedioctyl phosphite and 0.5% polydimethylsiloxane 40 Mix and stir for 15 minutes at ℃; the percentage of 2,4,6-tris(dimethylaminomethyl)phenol is the percentage of the tota...

Embodiment 2

[0040] A. Raw material preparation

[0041] Modified epoxy resin: 80 parts of bisphenol A type epoxy resin E-42, 40 parts of flexible epoxy resin 6350, 0.3% of polypropylene glycol diglycidyl ether, 0.3% of vinyl trimethoxysilane, 0.2% of 2,4,6-tri-tert-butylphenol was mixed and stirred for 20 minutes within the temperature range of 60°C; wherein the polypropylene glycol diglycidyl ether, vinyltrimethoxysilane and 2,4,6-tri-tert-butylphenol The percentage content is the percentage of the total amount of bisphenol A epoxy resin E-42, wherein the polypropylene glycol diglycidyl ether, vinyl trimethoxysilane and 2,4,6-tri-tert-butylphenol The percentage content is the percentage of the total amount of bisphenol A epoxy resin E-42.

[0042]Modified epoxy resin curing agent: mix 4% methyltetrahydrophthalic anhydride, 0.2% dibutyltin dichloride, and 0.3% polydimethylsiloxane at 40°C for 15 minutes; wherein the methyl The percentage of tetrahydrophthalic anhydride is the percentag...

Embodiment 3

[0047] A. Raw material preparation

[0048] Modified epoxy resin: 100 parts of bisphenol A epoxy resin E-35, 70 parts of flexible epoxy resin 6350, 0.5% carboxyl-terminated liquid nitrile rubber (CTBN) prepolymer, 0.7% γ-aminopropyl Triethoxysilane, 0.4% of 2-hydroxy-4-n-octyloxybenzophenone in the temperature range of 60 ° C, mixed and stirred for 20 minutes, wherein the carboxyl-terminated liquid nitrile rubber (CTBN) prepolymer , γ-aminopropyltriethoxysilane and 2-hydroxyl-4-n-octyloxybenzophenone are the percentages of the total amount of bisphenol A epoxy resin E-35.

[0049] Modified epoxy resin curing agent: mix and stir 6% methyl hexahydrophthalic anhydride, 0.6% hexamethylphosphoric triamide, and 0.4% silicone glycol at 40°C for 15 minutes; wherein the methyl tetrahydrophthalic anhydride The percentage content is the percentage of bisphenol A type epoxy resin E-35 and flexible epoxy resin 6350 total; The percentage of the total amount of type A epoxy resin E-35.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com