High-temperature-resistant and high-pressure-resistant PP-R composite pipe material and preparation method thereof

A technology of PP-R and composite pipes, which is applied in the field of PP-R composite pipes, can solve the problems of PP-R pipes not being resistant to high temperature and pressure, and achieve fine microstructure grains, high compressive strength, enhanced resistance pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

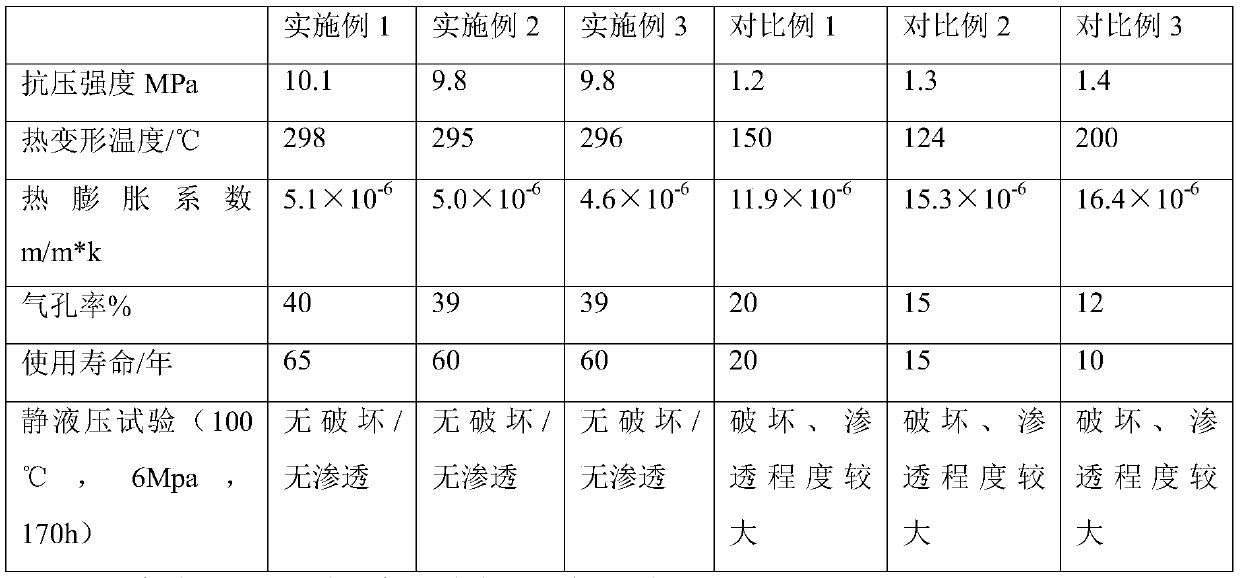

Examples

Embodiment 1

[0015] Example 1: A PP-R composite pipe with high temperature and high pressure resistance, containing the following proportioning components in parts by mass: 70 parts of polyethylene resin, 30 parts of epoxy resin, 7 parts of talcum powder, and 13 parts of methyl isobutyl ketone , 18 parts of tea stem powder, 12 parts of seaweed cellulose, 6 parts of decabromodiphenylethane, 7 parts of aluminum hydroxide, 4 parts of crosslinking agent and 4 parts of stabilizer.

[0016] The preparation method of the high temperature and high pressure resistant PP-R composite pipe comprises the following steps:

[0017] (1) Polyethylene resin, epoxy resin, talcum powder, methyl isobutyl ketone, tea stalk powder, seaweed cellulose, decabromodiphenylethane, aluminum hydroxide, cross-linked The coupling agent and the stabilizer were stirred for 40 minutes to obtain a mixture;

[0018] (2) Extruding the mixture with a twin-screw extruder at 230°C to obtain PP-R composite materials;

[0019] (3)...

Embodiment 2

[0020] Example 2: A PP-R composite pipe with high temperature and high pressure resistance, containing the following proportioning components in parts by mass: 60 parts of polyethylene resin, 25 parts of epoxy resin, 5 parts of talcum powder, and 10 parts of methyl isobutyl ketone , 15 parts of tea stem powder, 10 parts of seaweed cellulose, 5 parts of decabromodiphenylethane, 5 parts of aluminum hydroxide, 3 parts of crosslinking agent and 2 parts of stabilizer.

[0021] The preparation method of the high temperature and high pressure resistant PP-R composite pipe comprises the following steps:

[0022] (1) Polyethylene resin, epoxy resin, talcum powder, methyl isobutyl ketone, tea stalk powder, seaweed cellulose, decabromodiphenylethane, aluminum hydroxide, cross-linked The coupling agent and the stabilizer were stirred for 20 minutes to obtain a mixture;

[0023] (2) extruding and granulating the mixture with a twin-screw extruder at 220° C. to obtain a PP-R composite mate...

Embodiment 3

[0025] Example 3: A PP-R composite pipe with high temperature and high pressure resistance, containing the following proportioning components in parts by mass: 80 parts of polyethylene resin, 35 parts of epoxy resin, 10 parts of talcum powder, and 15 parts of methyl isobutyl ketone , 20 parts of tea stem powder, 15 parts of seaweed cellulose, 7 parts of decabromodiphenylethane, 10 parts of aluminum hydroxide, 6 parts of crosslinking agent and 6 parts of stabilizer.

[0026] The preparation method of the high temperature and high pressure resistant PP-R composite pipe comprises the following steps:

[0027] (1) Polyethylene resin, epoxy resin, talcum powder, methyl isobutyl ketone, tea stalk powder, seaweed cellulose, decabromodiphenylethane, aluminum hydroxide, cross-linked The coupling agent and the stabilizer were stirred for 50 minutes to obtain a mixture;

[0028] (2) extruding the mixture with a twin-screw extruder at 250°C to obtain PP-R composite materials;

[0029] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com