Injection molding permanent magnet composite material containing polyphenylene sulfide and preparation method thereof

A composite material and polyphenylene sulfide technology, which is applied in the field of injection molding permanent magnet composite materials and their preparation, can solve the problems of the influence of the magnetic properties of the composite material, the poor fluidity of the composite melt, and the difficulty in resin mixing, and achieve excellent magnetic properties and anti-resistance. Corrosion performance, excellent low temperature impact toughness, the effect of alleviating the decrease of coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

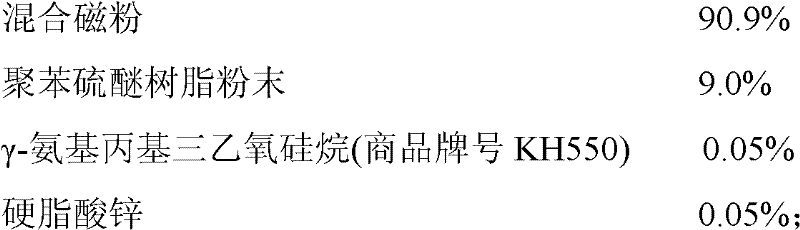

[0044] The raw materials of the present embodiment and the mass percentages of each raw material are as follows:

[0045]

[0046] The mixed magnetic powder is composed of NdFeB permanent magnetic powder MQP-B, isotropic samarium iron nitrogen permanent magnetic powder Sm 2 Fe 17 N 2.9 And strontium ferrite permanent magnet powder SrO·6Fe 2 o 3 Composition, the mass percent of each permanent magnetic powder is as follows:

[0047] MQP-B (particle size 54 ~ 150 microns) 96%

[0048] SM 2 Fe 17 N 2.9 (Particle size 5-20 microns) 3%

[0049] SrO·6Fe 2 o 3 (Particle size 5-20 microns) 1%;

[0050] The process steps are as follows:

[0051] (1) Preparation of multi-component composite magnetic powder

[0052] Measure MQP-B permanent magnet powder, Sm according to the mass percentage 2 Fe 17 N 2.9 Permanent magnetic powder and SrO·6Fe 2 o 3 Mixed magnetic powder composed of permanent magnetic powder and coupling agent γ-aminopropyl triethoxysilane (trade name KH...

Embodiment 2

[0060] The raw materials of the present embodiment and the mass percentages of each raw material are as follows:

[0061] Mixed magnetic powder 82.0%

[0062] Polyphenylene sulfide resin powder 17.8%

[0063] γ-(2,3 glycidoxy)propyltrimethoxysilane (trade name KH560) 0.2%;

[0064] The mixed magnetic powder is made of NdFeB permanent magnetic powder Nd 10.5 (FeCoZr) 83.5 B 6 , Isotropic SmFeN permanent magnet powder Sm 2 Fe 17 N 2.9 And strontium ferrite permanent magnet powder SrO·6Fe 2 o 3 Composition, the mass percent of each permanent magnetic powder is as follows:

[0065] Nd 10.5 (FeCoZr) 83.5 B 6 (Particle size 54-150 microns) 60%

[0066] SM 2 Fe 17 N 2.9 (Particle size 5-20 microns) 35%

[0067] SrO·6Fe 2 o 3 (Particle size 5-20 microns) 5%;

[0068] The process steps are as follows:

[0069] (1) Preparation of multi-component composite magnetic powder

[0070] Nd is measured according to the mass percentage 10.5 (FeCoZr) 83.5 B 6 Permanent ma...

Embodiment 3

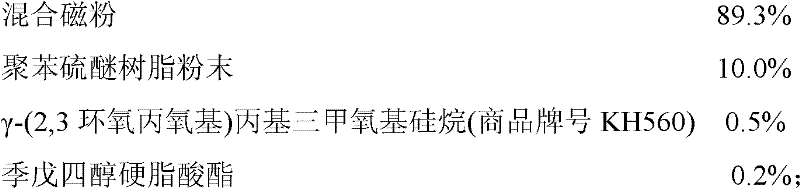

[0078] The raw materials of the present embodiment and the mass percentages of each raw material are as follows:

[0079]

[0080] The mixed magnetic powder is composed of NdFeB permanent magnetic powder MQP-A, isotropic samarium iron nitrogen permanent magnetic powder Sm 2 Fe 17 N 2.9 And strontium ferrite permanent magnet powder SrO·6Fe 2 o 3 Composition, the mass percent of each permanent magnetic powder is as follows:

[0081] MQP-B (particle size 54-150 microns) 50%

[0082] SM 2 Fe 17 N 2.9 (Particle size 5-20 microns) 5%

[0083] SrO·6Fe 2 o 3 (Particle size 5-20 microns) 45%;

[0084] The process steps are as follows:

[0085] (1) Preparation of multi-component composite magnetic powder

[0086] Measure MQP-B permanent magnet powder, Sm according to the mass percentage 2 Fe 17 N 2.9 Permanent magnetic powder and SrO·6Fe 2 o 3 Mixed magnetic powder composed of permanent magnetic powder and coupling agent γ-(2,3 glycidoxy)propyltrimethoxysilane (trad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com