Manufacturing method of electric heating push rod of electronic thermostat of engine

A manufacturing method and technology of a thermostat, which are applied in the field of engines, can solve problems such as affecting the service life of the engine, short service life, easy deformation, etc., and achieve the effects of reducing manufacturing difficulty and cost, long service life and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

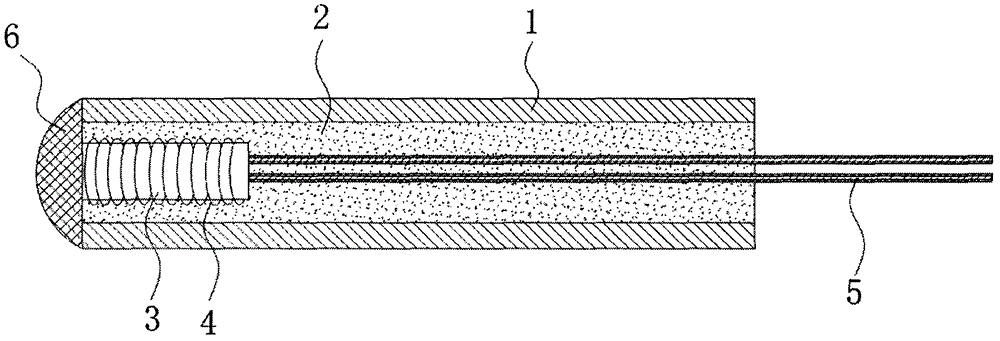

[0019] Such as figure 1 Shown, embodiment 1: a kind of manufacturing method of electric heating push rod of engine electronic thermostat, comprises: blanking: select the hollow steel pipe 1 that diameter is larger than the diameter of push rod to be processed, hollow steel pipe 1 is cut by cutting machine, cutting The length of the lower hollow steel pipe 1 is greater than the length of the push rod to be processed; welding bottom: weld and seal the bottom of the hollow steel pipe 1 through the seal 6; wire drawing: select a magnesium oxide rod whose length is 13 mm to 17 mm less than the length of the push rod to be processed 3, and the heating wire 4 is evenly wound outside the magnesium oxide rod 3; pipe penetration: insert the magnesium oxide rod 3 into the hollow steel pipe 1; filler: fill the hollow steel pipe 1 with heat transfer powder; shrink tube: put the hollow steel pipe 1 The pipe is shrunk by a pipe shrinking machine, and the diameter of the hollow steel pipe 1 a...

Embodiment 2

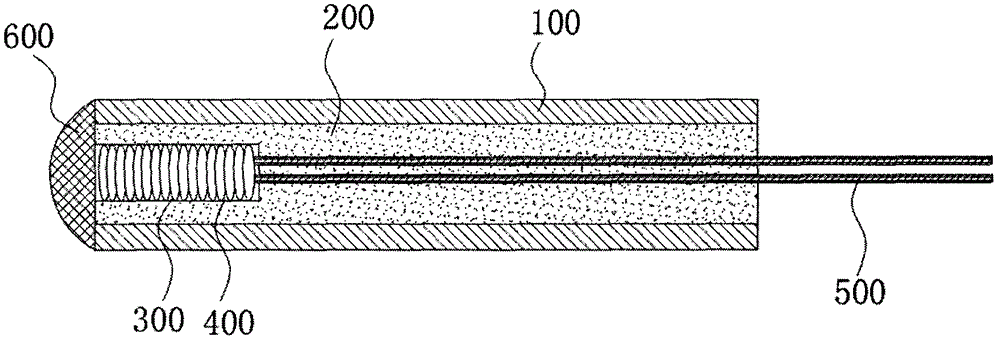

[0026] Such as figure 2 Shown, embodiment 2: a kind of manufacturing method of electric heating push rod of electronic thermostat of engine, comprises: blanking: select the hollow steel pipe 100 that diameter is larger than the diameter of push rod to be processed, hollow steel pipe 100 is cut by cutting machine, cutting The length of the lower hollow steel pipe 100 is greater than the length of the push rod to be processed; welding bottom: the bottom of the hollow steel pipe 100 is welded and sealed by the seal 600; wire making: select a magnesium oxide tube whose length is 13 mm to 17 mm less than the length of the push rod to be processed 300, and set the heating wire 400 on the magnesia tube 300; pipe penetration: insert the magnesia tube 300 into the hollow steel tube 100; filler: fill the hollow steel tube 100 with heat transfer powder; shrink tube: pass the hollow steel tube 100 through the shrink tube The pipe machine shrinks the pipe, and the diameter of the hollow s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com