High temperature resistant release adhesive tape as well as preparation method and use of adhesive tape

A high-temperature-resistant, release-type technology, applied in chemical instruments and methods, adhesives, epoxy resin glue, etc., can solve the problems of increasing production costs and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

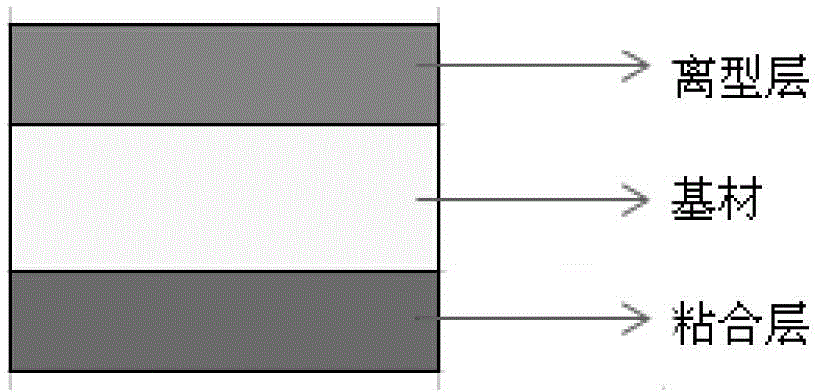

Image

Examples

Embodiment 1

[0051] Embodiment 1: Preparation of high temperature resistant release tape

[0052] 1. Making film: use a blow molding machine to make a base material mainly made of PA6 mixed with PA66; the weight ratio of PA66 to PA6 is PA66:PA6=2:1. The preparation method can be according to the conventional method. The thickness of gained film is 50um;

[0053] 2. Surface energy reduction treatment: corona treatment, 18-35kHz, 0.5-1.0s;

[0054] 3. Preparation of the release layer: use the conventional coating process, cover the release surface of the film obtained in step 1 with dimethyl silicone oil, bake (30-50 meters, 90-110°C, 3-5min) dry and then fully cool ; The resulting release layer is 10um;

[0055] 4. Prepare the adhesive layer: use the conventional coating process, cover the adhesive surface of the film obtained in step 2 with high-temperature resistant epoxy glue, and dry it after baking (30-50 meters, 90-110°C, 3-5min) Fully cooled; the resulting adhesive layer is 10u...

Embodiment 2

[0058] Embodiment 2: Preparation of high temperature resistant release tape

[0059] 1. Making film: use a blow molding machine to make a base material mainly made of PA6 mixed with PA66; the weight ratio of PA66 to PA6 is PA66:PA6=5:1. The preparation method can be according to the conventional method. The thickness of gained film is 50um;

[0060] 2. Surface energy reduction treatment: corona treatment, 18-35kHz, 0.5-1.0s;

[0061] 3. Preparation of the release layer: use the conventional coating process, cover the release surface of the film obtained in step 1 with dimethyl silicone oil, bake (30-50 meters, 90-110°C, 3-5min) dry and then fully cool ; The resulting release layer is 10um;

[0062] 3. Prepare the adhesive layer: use the conventional coating process, cover the adhesive surface of the film obtained in step 2 with phenolic resin glue, dry it after baking (30-50 meters, 90-110°C, 3-5min) and then fully cool ; The resulting adhesive layer is 10um;

[0063] 4...

Embodiment 3

[0065] Embodiment 3: Preparation of high temperature resistant release tape

[0066] 1. Making film: use a blow molding machine to make a base material mainly made of PA6 mixed with PA66; the weight ratio of PA66 to PA6 is PA66:PA6=1:5. The preparation method can be according to the conventional method. The thickness of gained film is 50um;

[0067] 2. Surface energy reduction treatment: corona treatment, 18-35kHz, 0.5-1.0s;

[0068] 3. Preparation of the release layer: use the conventional coating process, cover the release surface of the film obtained in step 1 with dimethyl silicone oil, bake (30-50 meters, 90-110°C, 3-5min) dry and then fully cool ; The resulting release layer is 10um;

[0069] 3. Prepare the adhesive layer: use the conventional coating process, cover the adhesive surface of the film obtained in step 2 with high-temperature resistant epoxy glue, and dry it after baking (30-50 meters, 90-110°C, 3-5min) Fully cooled; the resulting adhesive layer is 10u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com