Length control packaging process of metal in quartz glass capillary tube and auxiliary tool thereof

A technology of quartz glass and auxiliary tooling, which is applied in metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of inner filler metal wire melting and packaging failure, etc., and achieve reduced melting rate, beautiful shape and repeatability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A quartz glass capillary filled with metal-controlled length packaging technology, using CO 2 Type laser welding machine for the packaging of quartz glass capillary.

[0041] The CO 2 The specific welding parameters of the laser welding machine are as follows:

[0042] Laser power: 600W ~ 900W; focus mode: defocus; focus distance: 5mm ~ 10mm.

[0043] In the packaging process of the quartz glass capillary, high-purity helium is used as a protective gas, and the flow rate of the protective gas is 10 L / min to 15 L / min; the quartz glass capillary and CO 2 The relative rotation speed between the type laser welding machines is 15rpm-25rpm.

Embodiment 2

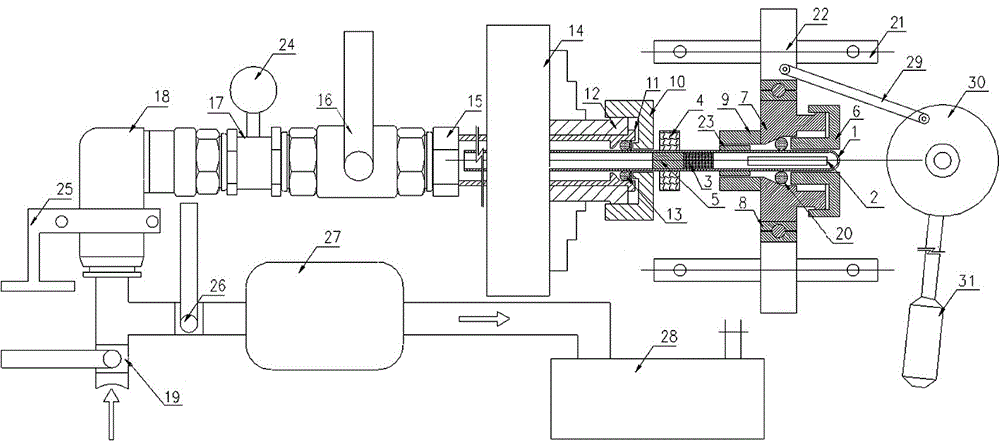

[0045] This embodiment provides an auxiliary tooling for a quartz glass capillary filled with a metal-controlled length packaging process, and the specific settings are as follows:

[0046] The auxiliary tooling includes a protective gas filling device for filling the quartz glass capillary 1 with a protective gas, a fixing device for fixing the quartz glass capillary 1, and a sample for defining the position of the sample 2 in the quartz glass capillary 1 limit components;

[0047] The fixing device includes an open end fixture connected to the protective gas filling device and makes the quartz glass capillary 1 and the protective gas filling device form a sealed cavity, which is used to fix the closed end of the quartz glass capillary 1 and can move along the quartz glass capillary 1 The closed-end fixture that moves in the direction of the central axis;

[0048] The quartz glass capillary 1 is encapsulated with CO 2 The type laser welding machine is arranged between the o...

Embodiment 3

[0050] The difference between this embodiment and Embodiment 2 is that this embodiment optimizes the specific structural settings of the auxiliary tooling, and the specific settings are as follows:

[0051] The sample limiting assembly includes a magnetic ring 4 located between the open end fixture and the closed end fixture and used to be sleeved on the quartz glass capillary 1 , and a magnetic guide column 5 arranged inside the quartz glass capillary 1 , and a non-magnetically permeable column 3 fixed at one end of the magnetically permeable column 5 .

[0052] The open end fixing member includes a stainless steel sleeve 11 whose end communicates with the protective gas filling device through a valve conversion joint 15, and a three-jaw chuck 14 that is fixedly sleeved on the stainless steel sleeve 11, sleeved on the stainless steel sleeve 11 and The conversion column 12 fixed with the three-jaw chuck 14, the first sealing ring 13 arranged at the other end of the stainless s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com