Method for reducing small-granular titanium dioxide in titanium dioxide

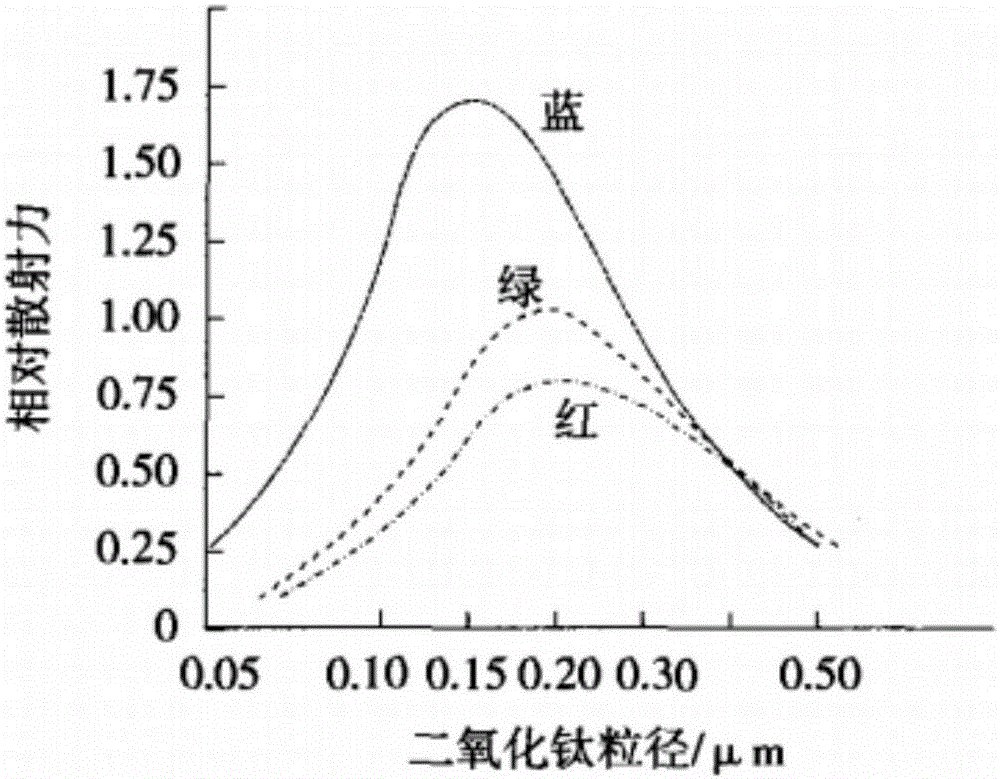

A small particle, titanium dioxide technology, applied in chemical instruments and methods, titanium dioxide, titanium compounds, etc., can solve the problem of controlling the proportion of small particles not seen, and achieve the effect of reducing the proportion, improving the covering power, and increasing the granularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The concentration is 235g / L (as TiO 2 The left and right titanium liquid and water were preheated to 96°C respectively, and the mass ratio of titanium liquid and water was 3.8 to 1. Start stirring at 75rmp, and add the preheated titanium solution to the preheated water within 20min to form a mixed solution.

[0038] Raise the temperature of the mixed solution to boiling (first boiling), and keep it in a boiling state. When the mixed solution turns steel gray (gray point), stop stirring and heating, and start stirring after 35 minutes at a speed of 35 rpm. Continue heating to boiling (second boiling), turn on the stirring speed after the second boiling to 60rpm, add water 1.5h after the second boiling, and make the concentration of metatitanic acid after hydrolysis be 165g / L (as TiO 2 Calculated), and then hydrolyzed for 2h to end.

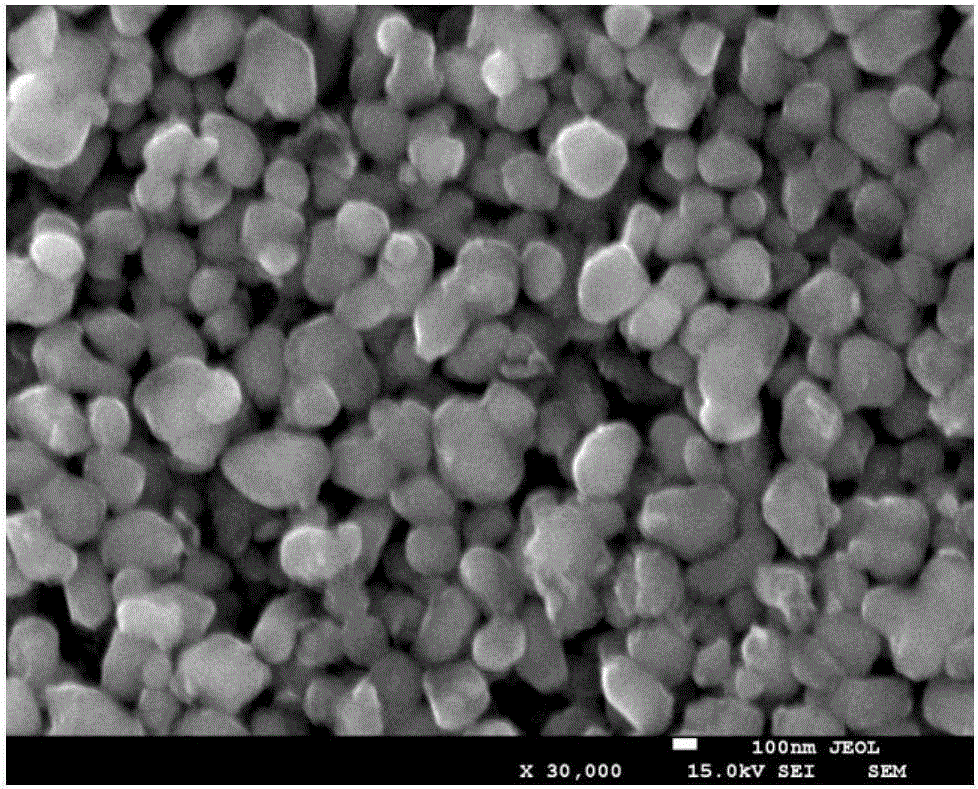

[0039] After the hydrolysis, the metatitanic acid is filtered and washed, bleached, salt treated, calcined, and post-treated to obtain ti...

Embodiment 2

[0043] The concentration is 230g / L (as TiO 2 The left and right titanium liquid and water are preheated to 96°C respectively, and the mass ratio of titanium liquid and water is 4:1. Start stirring at 75rmp, and add the preheated titanium solution to the preheated water within 20min to form a mixed solution.

[0044] Raise the temperature of the mixed liquid to boiling (first boiling), and keep boiling for a period of time. When the mixed liquid turns steel gray (gray point), stop stirring and heating for 30 minutes, then start stirring at a speed of 30rmp, and continue heating until boiling (two boiling), after the second boiling, the stirring speed was turned on at 50rpm, and 2.0h after the second boiling, water was added so that the concentration of metatitanic acid after hydrolysis was 160g / L (based on TiO 2 meter), and then hydrolyzed for 1.5h to end.

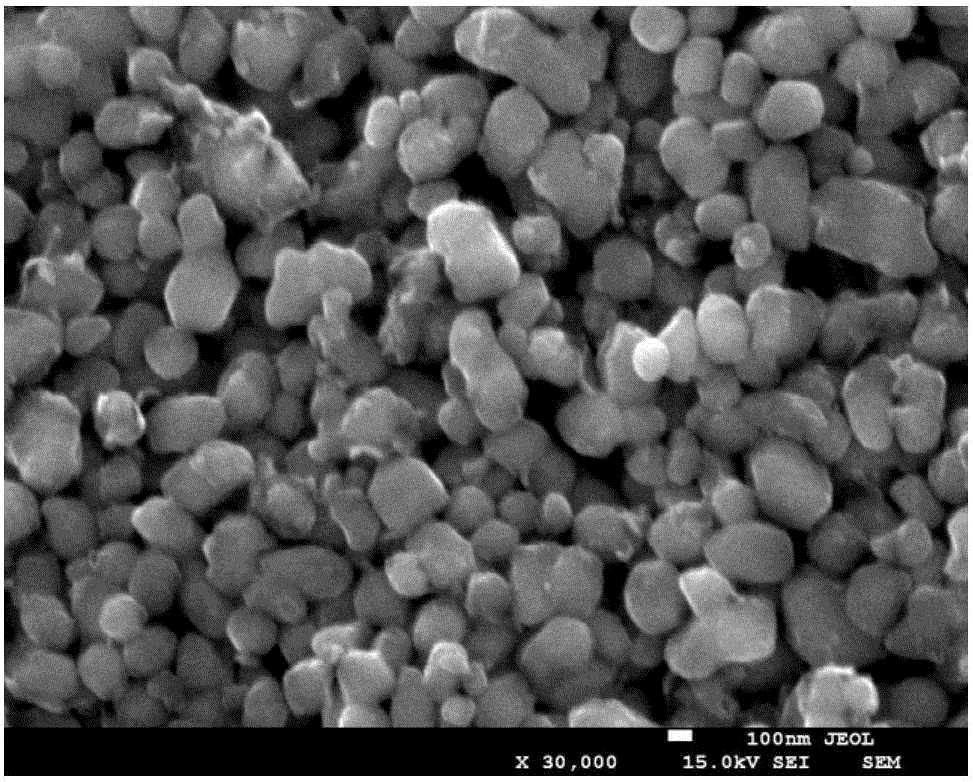

[0045] After the hydrolysis, the metatitanic acid is filtered and washed, bleached, salt treated, calcined, and post-trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com