The method of accurate loading-and-filling ball of two sections of milling mine

A technology of precise ball filling and two-stage grinding, which is applied in grain processing and other directions, can solve the problems of extensive methods and poor effects, and achieve the effects of good product particle size characteristics, wide application range and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

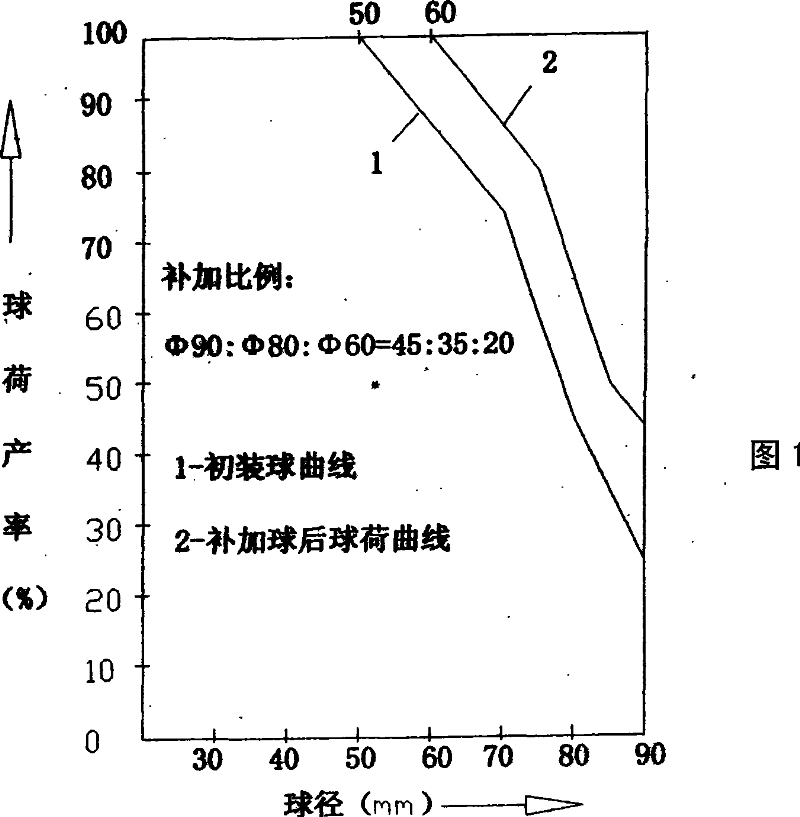

Embodiment 1

[0040] Embodiment 1. Yunnan Daya Nonferrous Metals Company Shizishan Copper Mine Concentrator, the original production scale is 1850 tons / day. The beneficiation plant adopts three sections and one closed-circuit crushing, and the crushing particle size is ≤12mm. The concentrator is a two-stage grinding process, the first stage of the mill is a 3.2×3.1 meter grid ball mill, and the second stage of the mill is a 3.2×3.1 meter overflow ball mill. Due to the unreasonable loading of balls in the two-stage grinding of the dressing plant, the productivity of the mill is only 76.5 tons / hour, and the final fineness of the product -0.074mm reaches 74%. The applicant implements precise loading and ball replenishment for the two-stage grinding of the Shizishan Copper Mine Concentrator. The specific steps are as follows:

[0041] (1) The first stage of the two-stage grinding is realized according to the following steps

[0042] ① The measured uniaxial compressive strength of the ore σ = ...

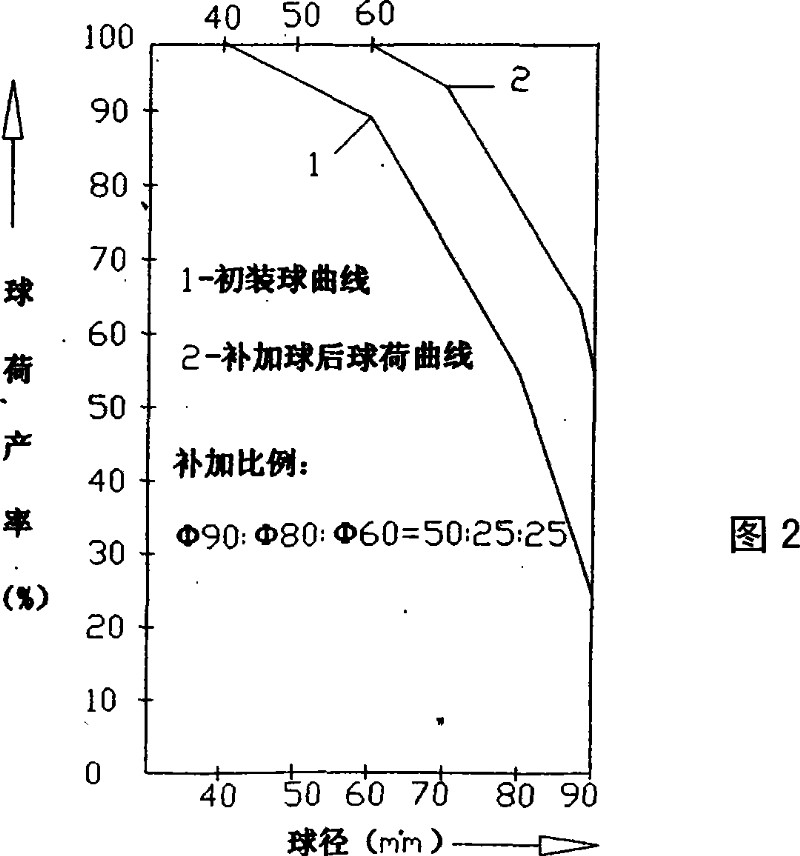

Embodiment example 2

[0064] Implementation case 2. Series II of Dahongshan Copper Mine Concentrator of Yunnan Yuxi Mining Co., Ltd. The design scale is 1,200 tons per day. The concentrator has three stages of closed-circuit crushing, and the final particle size of crushing is 16mm. The grinding process adopts two stages of grinding. , Grinding particle size requirement -0.074mm up to 70%. Due to the unreasonable loading of balls during production, the productivity of the grinding system is 70 tons / hour. The procedure for implementing precision ball replenishment on the II series is as follows:

[0065] (1) The procedure for implementing precise ball replacement on the first stage of the mill:

[0066] ①Measured ore uniaxial compressive strength σ=871.775kg / cm 2 , the compressive strength σ of irregular ore blocks 0 =398.75kg / cm 2 , Poisson's ratio μ = 0.28, the ore is medium hard and soft, and the toughness is medium.

[0067] ②Sieve and analyze the new feed ore of the first stage of grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com