Fertilizer possessing slow-release water-retention function and preparation method of fertilizer

A fertilizer and functional technology, applied in the field of slow and controlled release fertilizers, can solve the problems of insufficient utilization rate, large amount, and ineffective use of field fertilizers, etc., and achieve the effects of reducing the amount of chemical fertilizers, good roundness, and improving soil water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare 1L of water, and when the water is heated to 80°C, slowly add 1g of carboxymethyl chitin and 10g of polyacrylamide to form a suspension; the mass ratio of the suspension to 35% formaldehyde solution is 1:1 Mix with each other to make a paste; add urea, react to form a homogeneous state, add polyphosphoric acid (polymerization degree 22) and react for 40 minutes, form a reaction to form a homogeneous liquid state instead of granulation water and steam and some nitrogen and phosphorus elements, Add it to compound fertilizer raw materials and granulate it through granulation equipment to obtain a product that is a fertilizer with slow-release and water-retaining functions. The mass ratio of formaldehyde, urea, and polyphosphoric acid is 1:1:0.2.

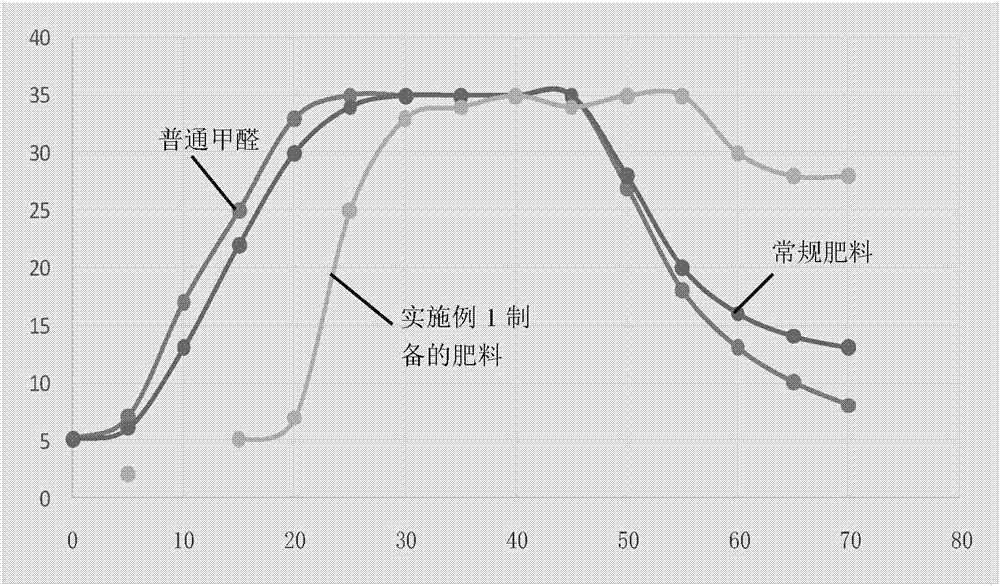

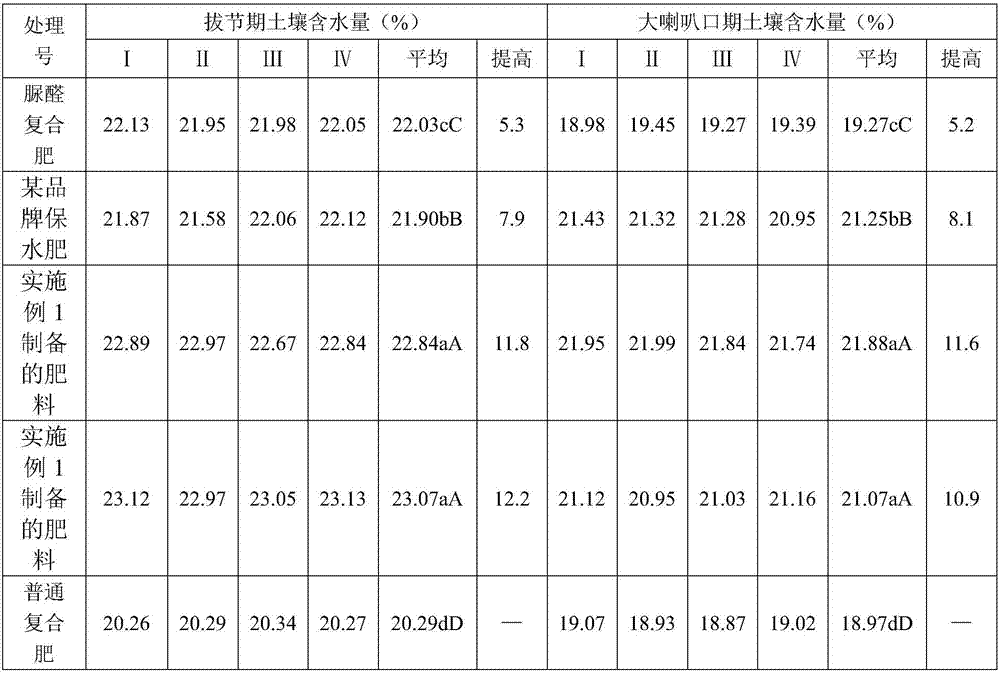

[0034] Fertilizer with slow release and water retention function compared with the same content of compound fertilizer and urea-formaldehyde compound fertilizer.

[0035] After measurement, the particle hardness reaches 3...

Embodiment 2

[0044] Prepare 500mL of water, and when the water is heated to 75°C, slowly add 1g of carboxymethyl chitin and 10g of polyacrylamide to form a suspension; the mass ratio of the suspension to 35% formaldehyde solution is 1:1 Mix with each other to make a paste; add urea, react to form a homogeneous state, add polyphosphoric acid (polymerization degree 45) and react for 40 minutes, form a reaction to form a homogeneous liquid state instead of granulation water and steam and part of nitrogen and phosphorus elements, Add it to compound fertilizer raw materials and granulate it with granulation equipment to obtain a product that is a fertilizer with slow-release water retention function, wherein the mass ratio of formaldehyde, urea, and polyphosphoric acid is 1.2:1:0.1.

[0045] Fertilizer with slow release and water retention function compared with the same content of compound fertilizer and urea-formaldehyde compound fertilizer.

[0046] After measurement, the particle hardness r...

Embodiment 3

[0048]Prepare 100mL of water, and when the water is heated to 85°C, slowly add 1g of carboxymethyl chitin and 10g of polyacrylamide to form a suspension; the mass ratio of the suspension to 35% formaldehyde solution is 1:1 Mix with each other to make a paste; add urea, react to form a homogeneous state, add polyphosphoric acid (polymerization degree 30) and react for 40 minutes, form a reaction to form a homogeneous liquid state instead of granulation water and steam and some nitrogen and phosphorus elements, Add it to compound fertilizer raw materials and granulate it with granulation equipment to obtain a product that is a fertilizer with slow-release water retention function, wherein the mass ratio of formaldehyde, urea, and polyphosphoric acid is 1.5:1:0.5.

[0049] Fertilizer with slow release and water retention function compared with the same content of compound fertilizer and urea-formaldehyde compound fertilizer.

[0050] After measurement, the particle hardness reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com