Method for producing MnO2 supported catalyst as well as method of using the same and apparatus for treating waste water

A supported catalyst and reaction device technology, which is applied in the fields of oxidized water/sewage treatment, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of difficult reuse of catalysts, low degradation efficiency of refractory organic substances, etc. Good catalytic degradation efficiency, enriched ozone oxidation technology, and prolonged residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The MnO of this embodiment 2 The preparation method of the supported catalyst is as follows: the activated carbon is used as the carrier, and the active part is MnO 2 Manganese acetate is formulated into a solution with a concentration of 5% by mass, and activated carbon is impregnated in the solution for 24 hours at room temperature. After evaporation and concentration, it is dried at 105°C for 2 hours, and placed in a muffle furnace at 700°C. Calcined at a temperature of 4 hours to obtain a solid catalyst, which was washed 3 times before using the catalyst.

Embodiment 2

[0020] The MnO of this embodiment 2 The preparation method of the supported catalyst is also as follows: use active aluminum oxide, white silica gel, molecular sieve, zeolite or diatomaceous earth as the carrier, and the active part is MnO 2 Manganese acetate is formulated into a solution with a concentration of 5% by mass, and one of activated aluminum oxide, white silica gel, molecular sieve, zeolite or diatomaceous earth is soaked in the solution, soaked at room temperature for 24 hours, evaporated After concentration, it was dried at 105°C for 2 hours, placed in a muffle furnace and calcined at 700°C for 4 hours to obtain a solid catalyst, which was washed three times before use.

Embodiment 3

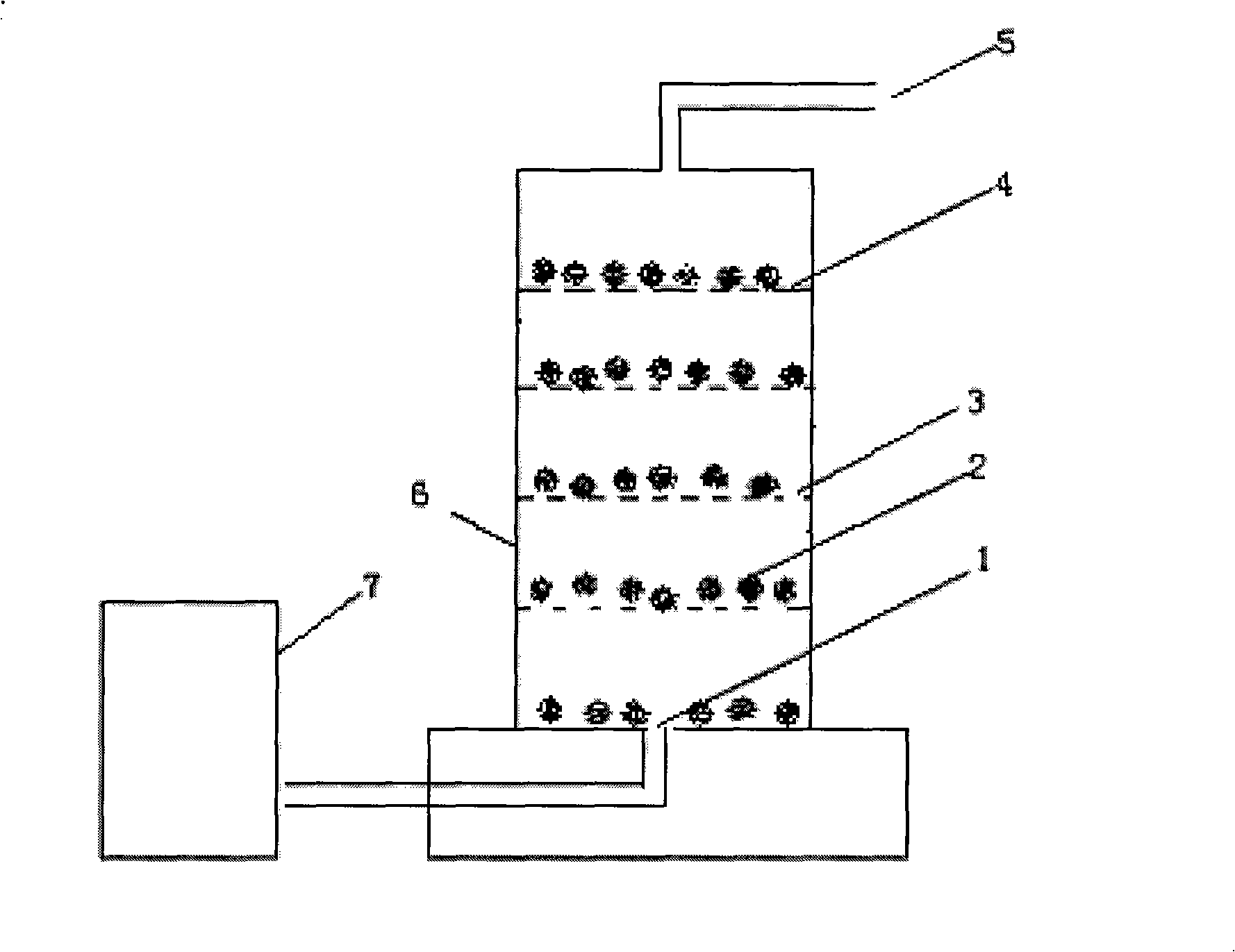

[0022] like figure 1 As shown, the ozone catalytic oxidation treatment organic wastewater reaction device of the present invention is composed of an air inlet 1, a catalyst 2, a microporous aeration 3, a separator 4, an air outlet 5, a catalyst feed port 6, an ozone generator 7, and the like. The reactor should be made of stainless steel, polyvinyl chloride, plexiglass, etc. or other materials lined with oxidation-resistant and anti-corrosion coatings. During the reaction, the gas enters the reactor through the bottom aeration device 1, and enters the upper reaction space through the microporous aeration device 3 on the partition 4 step by step. The catalyst 2 exists on each layer of partitions in the form of a fluidized bed, and the tail gas is passed The gas outlet 5 is discharged and processed by the exhaust gas absorption device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com