Dehydration and drying method and device of metallurgical slurry with no pollution

A drying method and non-polluting technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of landfill costs, fine particle size of sludge slurry, environmental pollution, etc., and meet the requirements of pelletizing and particle size dispersion Good, the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

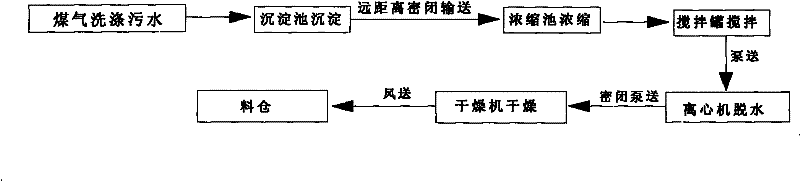

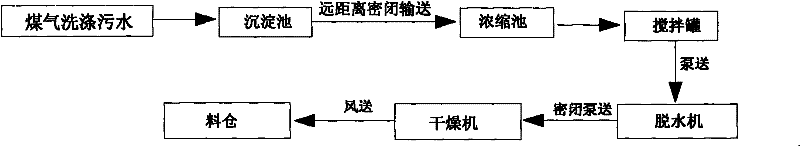

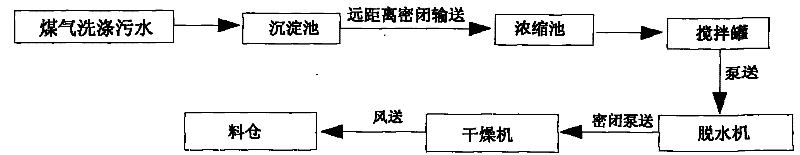

Image

Examples

Embodiment 1

[0019] Enter the centrifuge dehydration under the ratio of blast furnace gas washing mud: converter gas washing mud=1:1, the solid concentration of feed mud is 30.21%, after centrifugal dehydration, every 15min sampling, the solid concentration of mud paste is respectively 77.74%, 78.02%, 78.05%, 78.21%, 77.89%, the total C content of mud paste is 22.47%, 21.95%, 22.00%, 21.86%, 22.31%, respectively.

Embodiment 2

[0021] The blast furnace gas scrubbing sludge with a moisture content of 21.91% is dried in a dispersing dryer, and the drying inlet air temperature is 483-551°C, and a sludge powder with a moisture content of 0.77% can be obtained after drying.

Embodiment 3

[0023] The converter gas scrubbing mud with a moisture content of 22.58% enters a dispersing type dryer for drying, and the drying inlet air temperature is 552-638°C, and a sludge powder with a moisture content of 0.35% after drying can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com