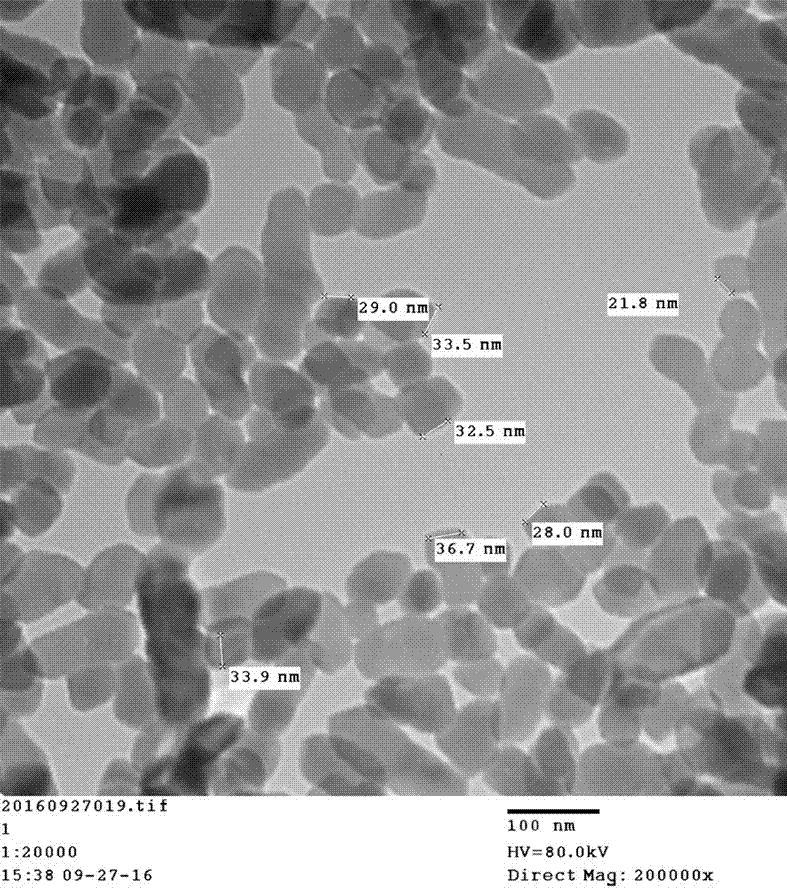

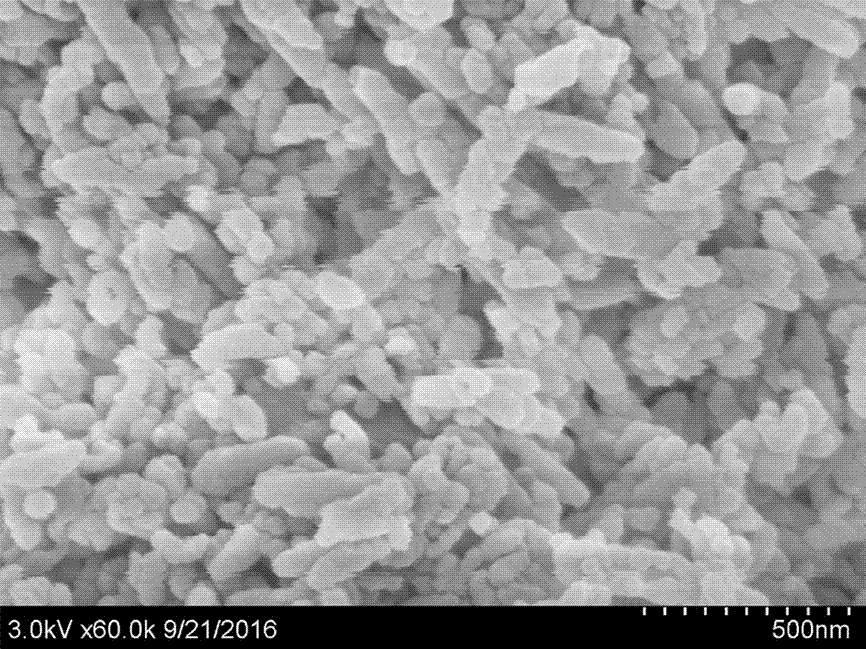

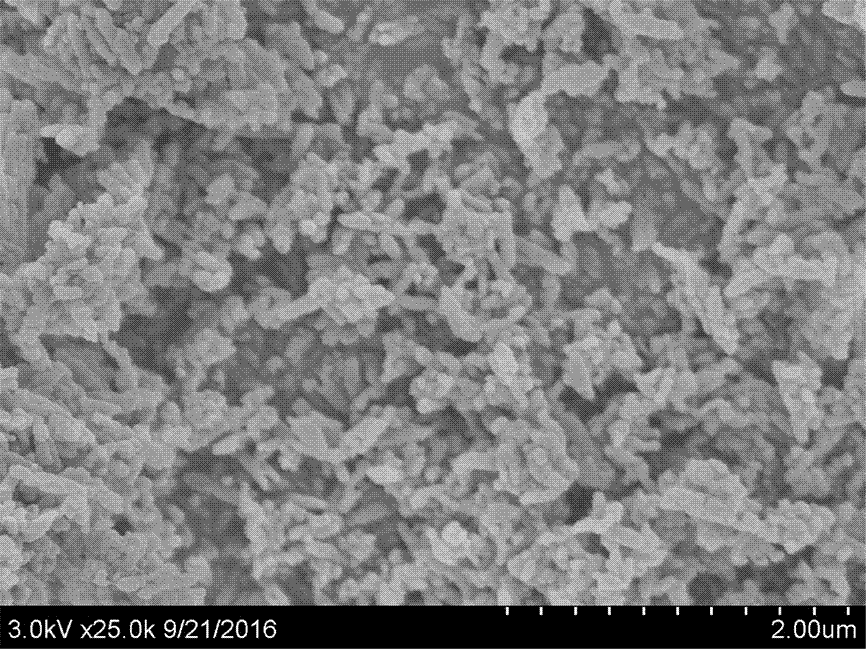

A kind of preparation technology of nano calcium carbonate

A nano-calcium carbonate and preparation technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, calcium/strontium/barium compounds, etc., can solve the problems of low production efficiency, wide particle size distribution, and poor uniformity of nano-calcium carbonate , to achieve the effect of uniform size, shortened reaction time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Place weighed 100kg of quicklime with an activity of 380 on the feeding platform of the digester; raise the temperature of 500kg of water to 50°C as digested water; turn on the digester; add digested water to 2% of the effective digestion volume of the digester / 3 place, add water and quicklime to the remaining water, gradually add to the digestion machine, digest for 45 minutes, stop digestion, pass through an 80-mesh circular vibrating sieve to obtain lime milk;

[0021] (2) Maintain at 20-25°C, adjust the concentration of milk of lime to 10 degrees Baume, add Ca(OH) in milk of lime 2 An industrial white sugar crystal form control agent of 1.0% by dry basis to obtain initial slurry;

[0022] (3) will be 0.08m 3 The initial slurry is pumped into the effective reaction volume of 0.08m 3 In the first-stage carbonization tower, carbon dioxide with a purity of 99.5% is introduced, and the flow rate of high-purity carbon dioxide is controlled to be 2.5m 3 / h, keep th...

Embodiment 2

[0026] (1) Place weighed 100kg of quicklime with an activity of 360 on the feeding platform of the digester; raise the temperature of 500kg of water to 50°C as digested water; turn on the digester; add the digested water to 2% of the effective digestion volume of the digester / 3 place, add water and quicklime to the remaining water, gradually add it to the digestion machine, digest for 40 minutes, stop digestion, use 80-mesh circular vibrating sieve to get milk of lime;

[0027] (2) Maintain at 20-25°C, adjust the concentration of milk of lime to 10 degrees Baume, add Ca(OH) in milk of lime 2 An industrial white sugar crystal form control agent of 0.8% on a dry basis to obtain an initial slurry;

[0028] (3) will be 0.08m 3 The initial slurry is pumped into the effective reaction volume of 0.08m 3 In the first-stage carbonization tower, carbon dioxide with a purity of 99% is introduced, and the flow rate of high-purity carbon dioxide is controlled to be 2m 3 / h, keep the te...

Embodiment 3

[0032](1) Place weighed 100kg of quicklime with an activity of 370 on the feeding platform of the digester; raise the temperature of 500kg of water to 50°C as digested water; turn on the digester; add digested water to 2% of the effective digestion volume of the digester / 3 place, add water and quicklime to the remaining water, gradually add to the digester, digest for 45 minutes, stop digestion, use 80-mesh circular vibrating sieve to get milk of lime;

[0033] (2) Maintain at 20-25°C, adjust the concentration of milk of lime to 10 degrees Baume, add Ca(OH) in milk of lime 2 An industrial white sugar crystal form control agent of 1.2% on a dry basis to obtain an initial slurry;

[0034] (3) will be 0.08m 3 The initial slurry is pumped into the effective reaction volume of 0.08m 3 In the first-stage carbonization tower, carbon dioxide with a purity of 99.7% is introduced, and the flow rate of high-purity carbon dioxide is controlled to be 3m 3 / h, keep the temperature in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com