Preparation of copper cobalt oxide composite electrode material by solvothermal method and application thereof

A technology of composite electrode and solvothermal method, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of different extraction processes and difficulty in obtaining sodium lignosulfonate, etc., and achieve a simple preparation process route, The operating conditions are easy to control and the effect of high synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing copper cobaltate composite electrode material by solvothermal method includes the following steps:

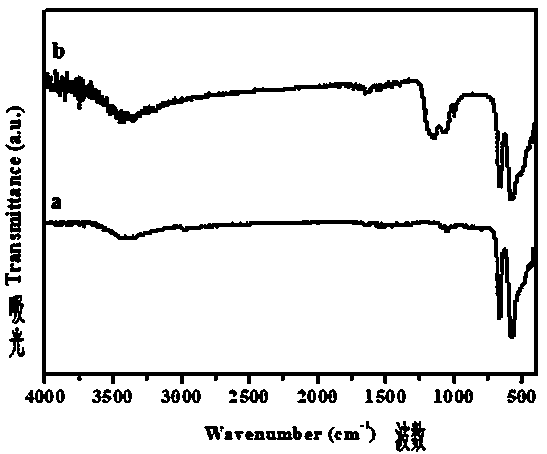

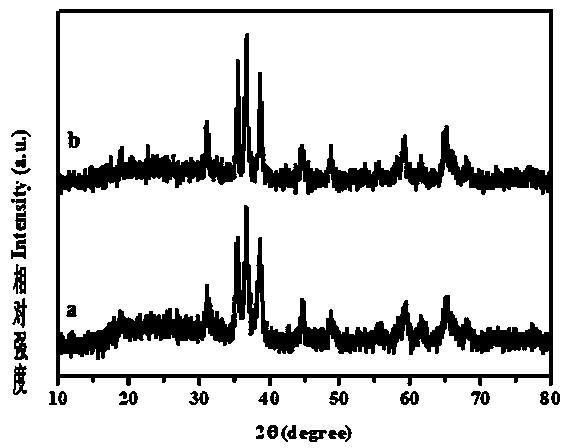

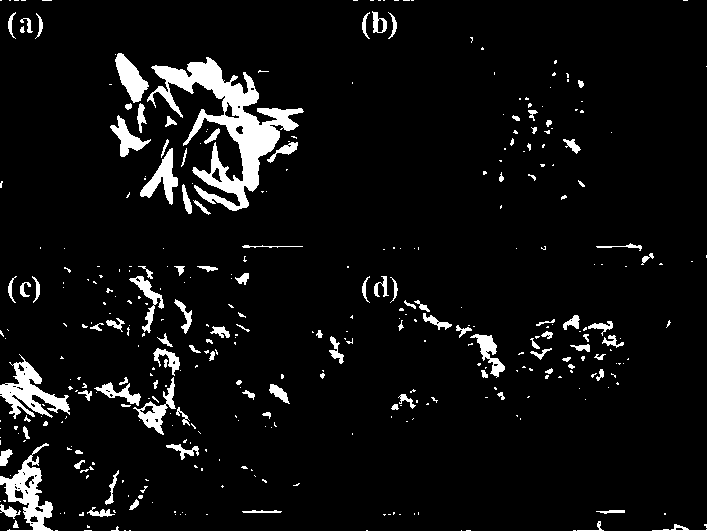

[0040] Weigh 2 mmol copper nitrate trihydrate, 4 mmol cobalt nitrate hexahydrate, and 6 mmol urea into a beaker, then add 70 mL of deionized water, magnetically stir to make it uniformly dissolved, and then transfer the mixed solution into the PTFE In the reactor lining, put the reactor in an oven and react for 5h at 130℃, then wash it, bake it in a constant temperature oven at 60℃ for 12h, and then in a muffle furnace at a temperature of 400℃ at a rate of 5℃ / min Calcination for 2h to obtain the precursor copper cobaltate (CuCo 2 O 4 ). Its FTIR such as figure 1 As shown in a, the XRD pattern is as figure 2 As shown in a, the XRD curve conforms to the XRD standard card of copper cobaltate (JCPDS NO.78-2177), indicating that copper cobaltate was successfully prepared; the SEM image is as follows image 3 As shown in middle a, the appearance is spheri...

Embodiment 2

[0042] A method for preparing copper cobaltate composite electrode material by solvothermal method includes the following steps:

[0043] Weigh 2 mmol copper nitrate trihydrate, 4 mmol cobalt nitrate hexahydrate, 6 mmol urea, and 0.2 g sodium lignosulfonate into a beaker, then add 70 mL deionized water, magnetically stir to make it uniformly dissolved, and then mix The solution was transferred to a reaction kettle lined with polytetrafluoroethylene. The reaction kettle was put into an oven and reacted at 130°C for 5 hours, then washed, dried in a 60°C constant temperature oven for 12 hours, and then in a muffle furnace at 5°C / The heating rate of min is calcined at 400℃ for 2h to obtain copper cobaltate composite material. Its FTIR such as figure 1 As shown in b, the XRD pattern is as figure 2 As shown in b, it can be seen from the figure that the copper cobaltate modified with sodium lignosulfonate has more functional groups; the XRD curve conforms to the XRD standard card of c...

Embodiment 3

[0045] A method for preparing copper cobaltate composite electrode material by solvothermal method includes the following steps:

[0046] Weigh 1 mmol of copper chloride dihydrate, 2 mmol of cobalt chloride hexahydrate, and 3 mmol of urea into a beaker, then add 50 mL of deionized water, magnetically stir to make it uniformly dissolved, and then transfer the mixed solution to PTFE In a reaction kettle lined with ethylene, put the reaction kettle in an oven at 150°C for 4 hours, then wash it, bake it in a 50°C constant temperature oven for 16 hours, and then in a muffle furnace at a temperature rise of 5°C / min at 450 Calcined at ℃ for 2h to obtain the precursor copper cobaltate (CuCo 2 O 4 ). Its FTIR such as figure 1 As shown in a, the XRD pattern is as figure 2 As shown in a, the XRD curve conforms to the XRD standard card of copper cobaltate (JCPDS NO.78-2177), indicating that copper cobaltate was successfully prepared; the SEM image is as follows image 3 As shown in c, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com