Binary precursor and preparation method thereof, lithium ion battery positive electrode material, lithium ion battery and electric equipment

A lithium-ion battery and precursor technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve problems such as the defects of cobalt-free precursor cycle and rate performance, and achieve low cost, high capacity, and cycle performance. and good magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] The present application also provides a method for preparing the binary precursor, including:

[0081] Mix the materials including complexing agent, hydroxide and water to obtain the bottom liquid, then continuously add complexing agent, hydroxide and nickel-manganese binary mixed salt solution to the bottom liquid at the same time, coprecipitate under stirring conditions The reaction obtains the binary precursor.

[0082] In an optional embodiment, the mixed salt solution includes soluble nickel salt and manganese salt;

[0083] In an optional embodiment, the soluble nickel salt includes one or more of nickel sulfate, nickel nitrate, nickel acetate;

[0084] In an optional embodiment, the manganese salt includes one or more of manganese sulfate, manganese nitrate, and manganese acetate;

[0085] In an optional embodiment, the concentration of the nickel-manganese binary mixed salt solution is 0.5-2mol / L;

[0086] Optionally, the concentration of the nickel-manganese...

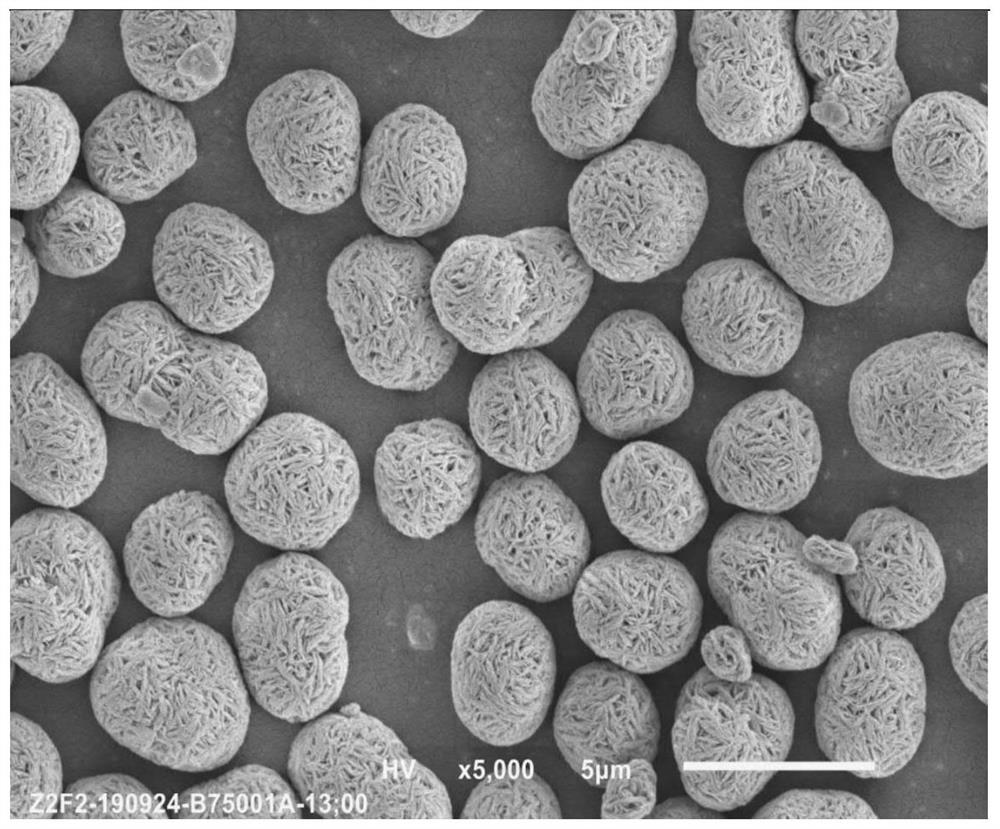

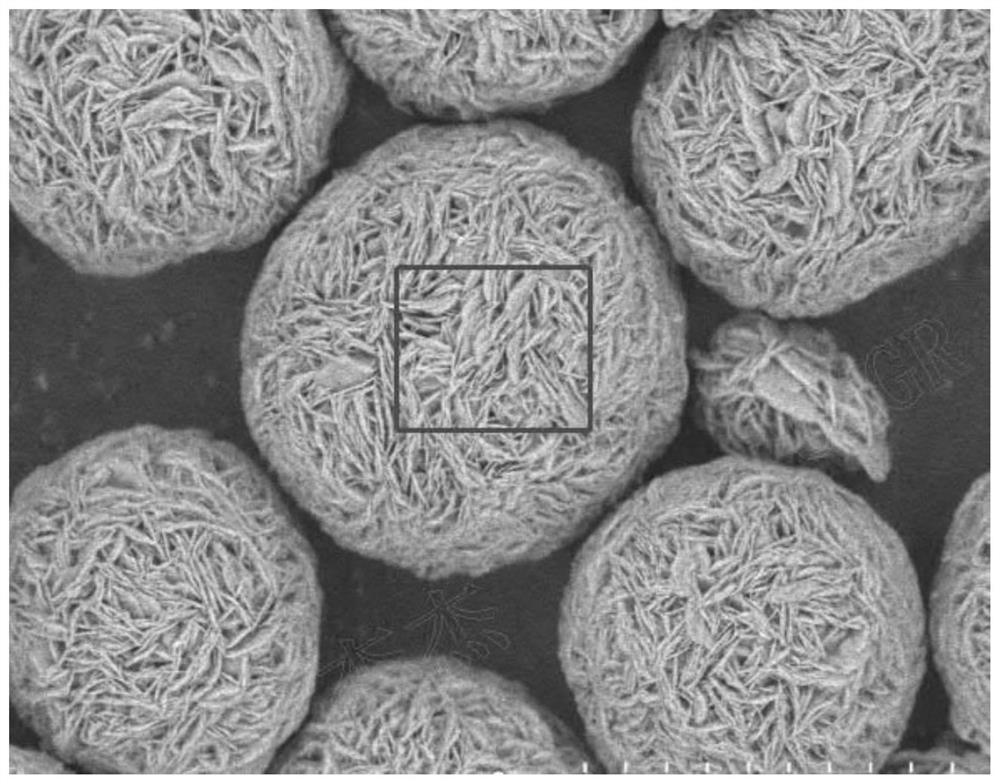

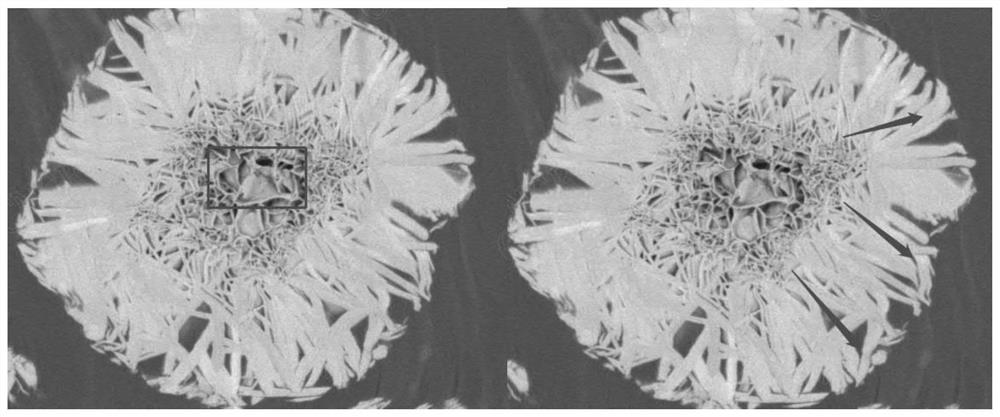

Embodiment 1

[0114] The nickel and manganese sulfate crystals (molar ratio 0.75:0.25) are configured into a 2mol / L uniform binary metal salt mixed solution; 10mol / L sodium hydroxide solution and 8mol / L ammonia water are mixed to prepare a pH of 11.7 Add the bottom liquid into the reaction kettle with stirring device, under the stirring speed of 600r / min, then slowly add ammonia water, sodium hydroxide solution, binary metal salt mixed solution in a certain proportion, wherein the reaction kettle removes The temperature of the ionized water is 55℃, the addition rate of the binary metal salt mixed solution is 3-4-5L / h, the addition rate of the sodium hydroxide solution is 1.2-1.6-2.0L / h, and the addition rate of the ammonia water is 0.15L / h h, the high-nickel and cobalt-free binary precursor was obtained by consuming 319 L of the binary metal salt mixed solution.

[0115] The above-mentioned precipitate is centrifugally washed and dried in an oven to obtain a dry material; after the obtained...

Embodiment 2

[0120] The nickel and manganese sulfate crystals (molar ratio 0.75:0.25) are configured into a 2mol / L uniform binary metal salt mixed solution; 10mol / L sodium hydroxide solution and 6mol / L ammonia water are mixed to prepare a pH of 11.7 Add the bottom liquid into the reaction kettle with stirring device, under the stirring speed of 600r / min, then slowly add ammonia water, sodium hydroxide solution, binary metal salt mixed solution in a certain proportion, wherein the reaction kettle removes The temperature of the ionized water is 55°C, the stirring rate is 600-500r / min, the addition rate of the binary metal salt mixed solution is 3-4-5L / h, and the addition rate of the sodium hydroxide solution is 1.2-1.6-2.0L / h , the addition rate of ammonia water is 0.15L / h, and the high-nickel and cobalt-free binary precursor is obtained under the condition of consuming 423L of binary metal salt mixed solution.

[0121] The above-mentioned precipitate is centrifugally washed and dried in an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com