Preparation method of high-viscosity silicon raw rubber emulsion and application

A silicon raw rubber, high-viscosity technology, applied in textiles and papermaking, fiber type, fiber treatment, etc., can solve the problems of inability to disperse high-viscosity silicon raw rubber, poor stability of silicon raw rubber emulsion, etc., to reduce production costs , high fabric smoothness, good hand feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

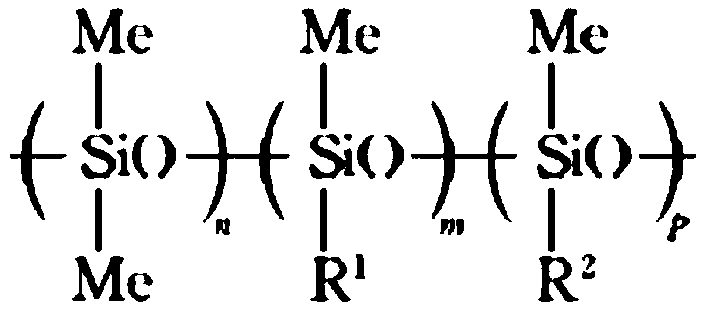

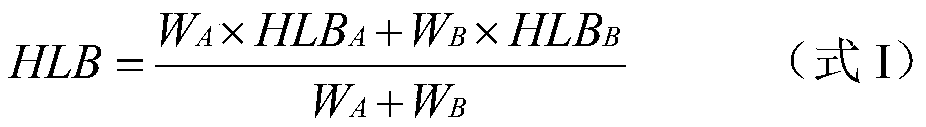

[0037] Add 200g hydroxyl silicone oil (viscosity 5000cp) and 100g amino silicone oil (viscosity 3000cp) into a 1L anchor reactor, add 100g hydroxyl raw rubber (molecular weight 550,000, viscosity 20 million cp) under normal temperature stirring conditions, stirring speed is 100rpm, stir After 2 hours, add 38g Emcol PS-50 and 12gLX-490A compound emulsifier (its HLB value is estimated to be 10.7 according to the above formula I) and 5gDM-115M (viscosity 2000cp) as emulsification aids, continue to stir for 1 hour, add emulsification 53g of water, stirred for 2 hours, and then slowly added dropwise 497g of dilution water to prepare a silicone raw rubber emulsion of the desired concentration.

preparation example 2

[0039] The operation is the same as in Example 1, except that the compound emulsifier is 40g Atmul 67 and 10g SY-830. After estimating according to formula I, its HLB value is 11.04.

preparation example 3

[0041] The operation is the same as in Example 1, except that the compounded emulsifier is 42g Emcol DM-50 and 8g SY-840, and after estimating according to formula I, its HLB value is 11.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com