Acidic zinc-plated carrier and a preparation method and application thereof

A technology of acid galvanizing and carrier, which is applied in the field of acid galvanizing carrier and its preparation, which can solve the problems of losing the solubilization and uniform dispersion of the main brightener, difficulty in balancing the brightness of the coating, and deterioration of the performance of the plating solution, etc., to achieve broadening of the brightness The effect of current density range, strong walking ability, increasing coverage ability and fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

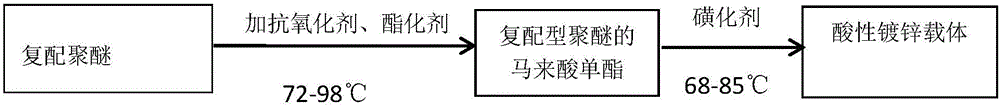

Method used

Image

Examples

Embodiment 1

[0030] Add antioxidants and maleic anhydride to the compound polyether at a temperature of 88°C, and keep warm for 5.0 hours to obtain the maleic acid monoester of the compound polyether, further add a sulfonating agent, Under sulfonation for 2.0h, an acidic galvanized carrier was obtained.

[0031] In this example: according to the number of parts by mass, the naphthol block polyether OX-625 in the compound polyether is 37.2 parts, the isomeric fatty alcohol polyoxyethylene ether 1307 is 18.7 parts, the straight chain fatty alcohol polyoxyethylene ether AEO-15 is 20.6 parts, alkylphenol polyoxyethylene ether NP-15 is 23.5 parts; antioxidant is 0.1 part of 2,6-di-tert-butyl-4-methylphenol and 0.5 part of sodium hypophosphite; The sulfonating agent is an aqueous solution of sodium sulfite; the input amounts of compounded polyether, maleic anhydride, and sulfonating agent are: 77.5 parts, 12.8 parts, and 9.7 parts, respectively.

Embodiment 2

[0033] Add antioxidants and maleic anhydride to the compound polyether at a temperature of 95°C, and keep warm for 3.5 hours to obtain the maleic acid monoester of the compound polyether, further add a sulfonating agent, Under sulfonation for 2.0h, an acidic galvanized carrier was obtained.

[0034] In this example: in terms of parts by mass, 42.5 parts of naphthol block polyether OX-625 in the compounded polyether, 15.7 parts of isomeric fatty alcohol polyoxyethylene ether JFC-15, 15.7 parts of straight-chain fatty alcohol polyoxyethylene Vinyl ether AEO-12 is 17.0 parts, alkylphenol polyoxyethylene ether NP-21 is 24.8 parts; antioxidant is 0.3 part of dimethyl ketoxime and 0.5 part of sodium hypophosphite; sulfonating agent is sodium sulfite aqueous solution; The input amounts of compounded polyether, maleic anhydride, and sulfonating agent are respectively: 69.3 parts, 13.4 parts, and 17.3 parts.

Embodiment 3

[0036] Add antioxidants and maleic anhydride to the compound polyether at a temperature of 73°C, and keep warm for 4.0 hours to obtain the maleic acid monoester of the compound polyether, further add a sulfonating agent, Under sulfonation for 1.0h, an acidic galvanized carrier was obtained.

[0037] In this example: according to the number of parts by mass, the naphthol block polyether OX-625 in the compound polyether is 29.8 parts, the isomeric fatty alcohol polyoxyethylene ether 1307 is 20.4 parts, and the straight chain fatty alcohol polyoxyethylene ether is 20.4 parts. AEO-12 is 25.6 parts, alkylphenol polyoxyethylene ether NP-21 is 24.2 parts; antioxidant is 0.3 parts of 2,6-di-tert-butyl-4-methylphenol and 0.3 parts of dimethyl ketoxime The sulfonating agent is an aqueous solution of sodium metabisulfite; the input amounts of compound polyether, maleic anhydride, and sulfonating agent are respectively: 72.9 parts, 16.7 parts, and 10.4 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com