Carrier walk agent of kalium-salt zincification and preparation method thereof

A technology of moving agent and carrier, which is applied in the field of carrier moving agent and its preparation for potassium salt galvanizing, which can solve the problems of slow zinc coating and low work efficiency, achieve bright coating, increase work efficiency, and have good electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

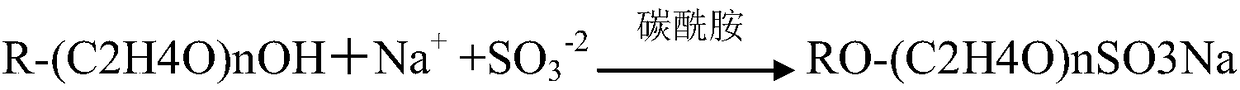

[0031] The preparation method of the carrier displacement agent for potassium salt galvanizing comprises the steps of: heating the emulsifier to 90-120°C, vacuum removing water for 3-5h; adding catalyst carbonamide, heating to 180-220°C, and keeping warm for 5-8h ; Then add sulfamic acid and stir at a speed of 150-220 rpm to obtain a carrier displacement agent. Wherein the molar ratio of the emulsifier to the sulfamic acid is (0.8-1.1):(1-1.3), and the molar number of the catalyst is 2-5% of that of the sulfamic acid.

[0032] Preferably, the emulsifier is low-carbon alcohol polyoxyethylene ether, the general formula is R-(CH2CH2O)n-OH, wherein R is C7-10, and n is an integer of 5-15.

[0033]

[0034] Alcohol ether sulfonic acid sodium salt

Embodiment 1

[0036] C7H15O(CH2CH2O)10NaSO3

[0037] Heat the emulsifier to 90°C, remove water under vacuum for 5 hours; add catalyst carbonamide, then heat to 220°C, and keep warm for 8 hours; then add sulfamic acid, and stir at a speed of 200 rpm to obtain a carrier displacement agent. Wherein, the molar ratio of emulsifier to sulfamic acid is 1.1:1, and the molar number of catalyst is 5% of that of sulfamic acid.

Embodiment 2

[0039] C8H17O(CH2CH2O)6NaSO3

[0040] Heat the emulsifier to 120°C, remove water under vacuum for 4 hours; add catalyst carbonamide, then heat to 200°C, and keep warm for 6 hours; then add sulfamic acid, and stir at a speed of 220 rpm to obtain a carrier displacement agent. Wherein, the molar ratio of emulsifier to sulfamic acid is 0.9:1.3, and the molar number of catalyst is 3% of that of sulfamic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com