Patents

Literature

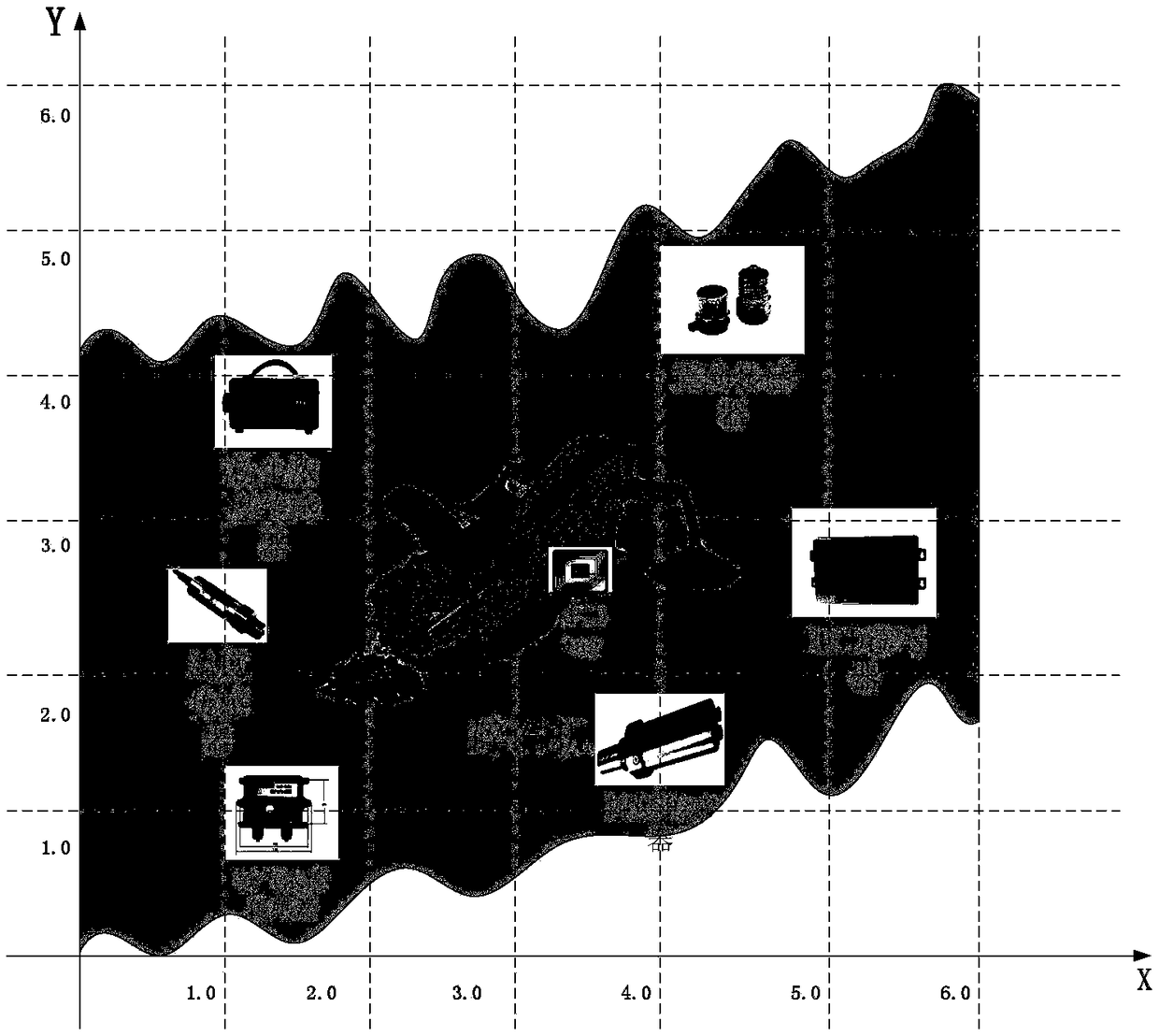

59results about How to "Good positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

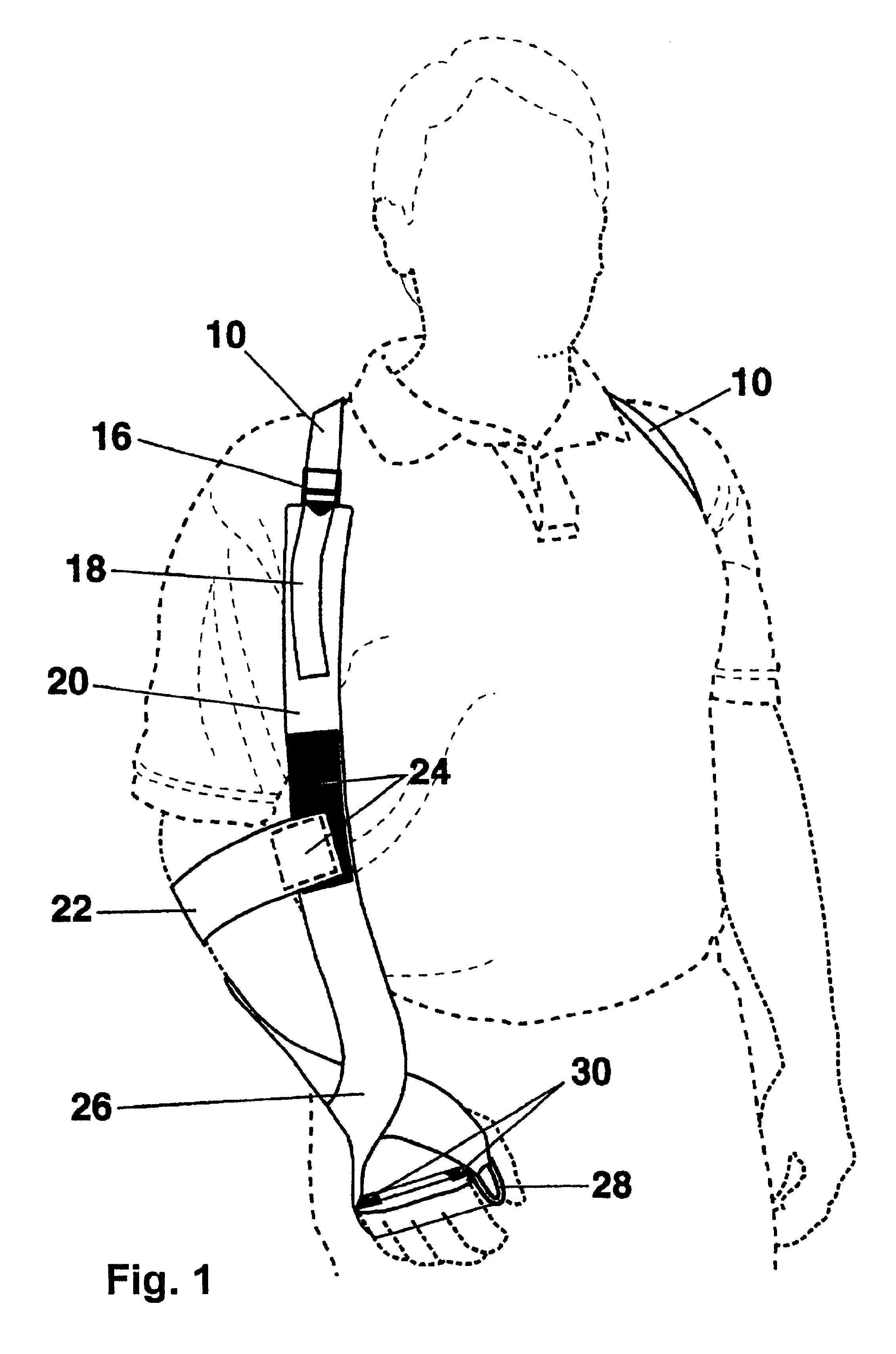

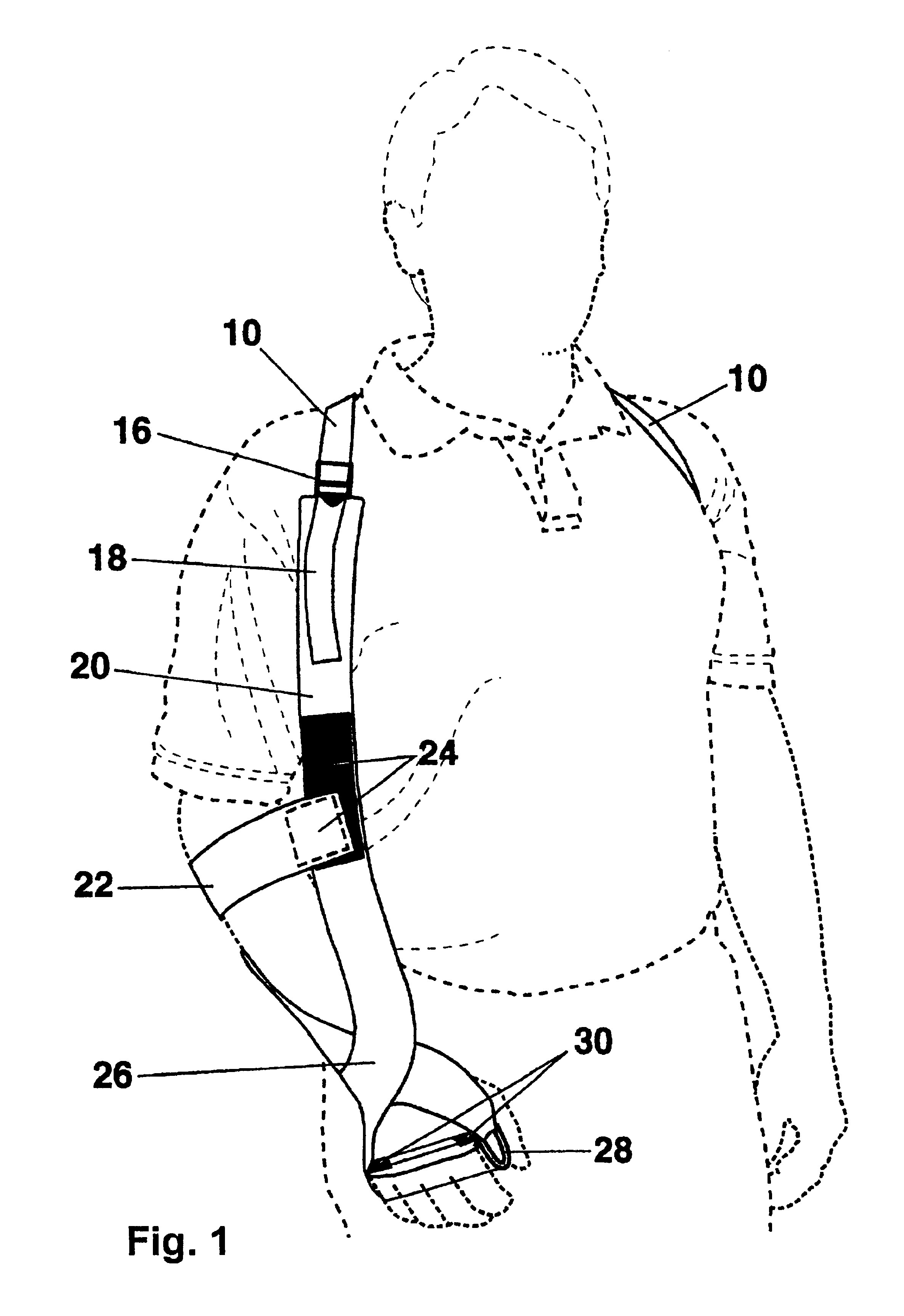

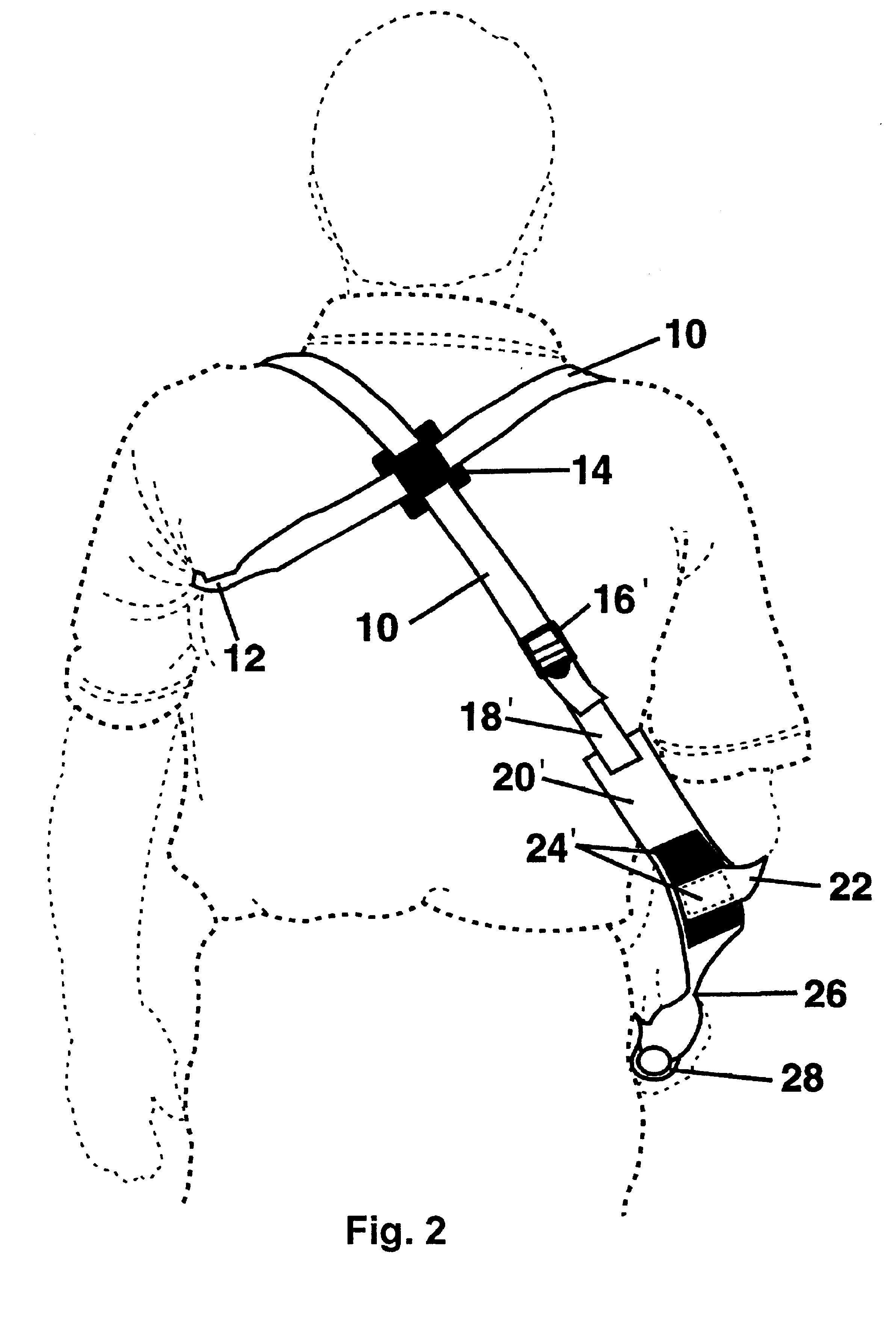

Flaccid upper extremity positioning apparatus

InactiveUS6945945B2Easy to put and useGood positioningRestraining devicesNon-surgical orthopedic devicesHand armWrist

A positioning apparatus for facilitating normal motor return by supporting a flaccid (non-innervated muscles) arm in a functional position. The arm is held in a dependant position with the scapula held in depression, retraction and neutral rotation. The shoulder joint is held in neutral rotation or slight external rotation and mild extension with the arm held at the side of the body. The elbow is held in less than 30 degrees flexion. The wrist is held in neutral deviation and neutral to mild extension. The fingers are in slight flexion and the thumb is in moderate abduction and opposition.

Owner:GIVMOHR CORP

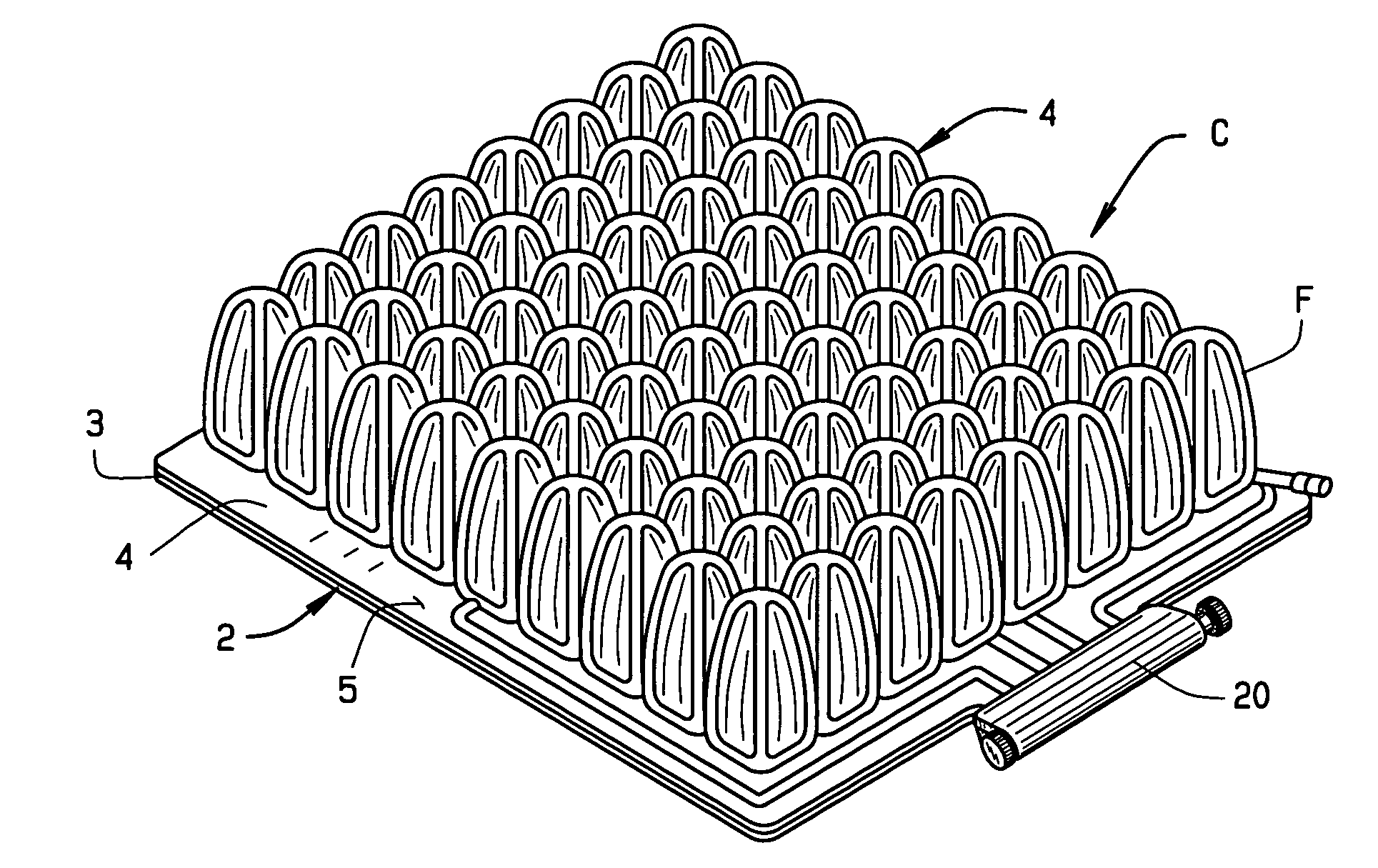

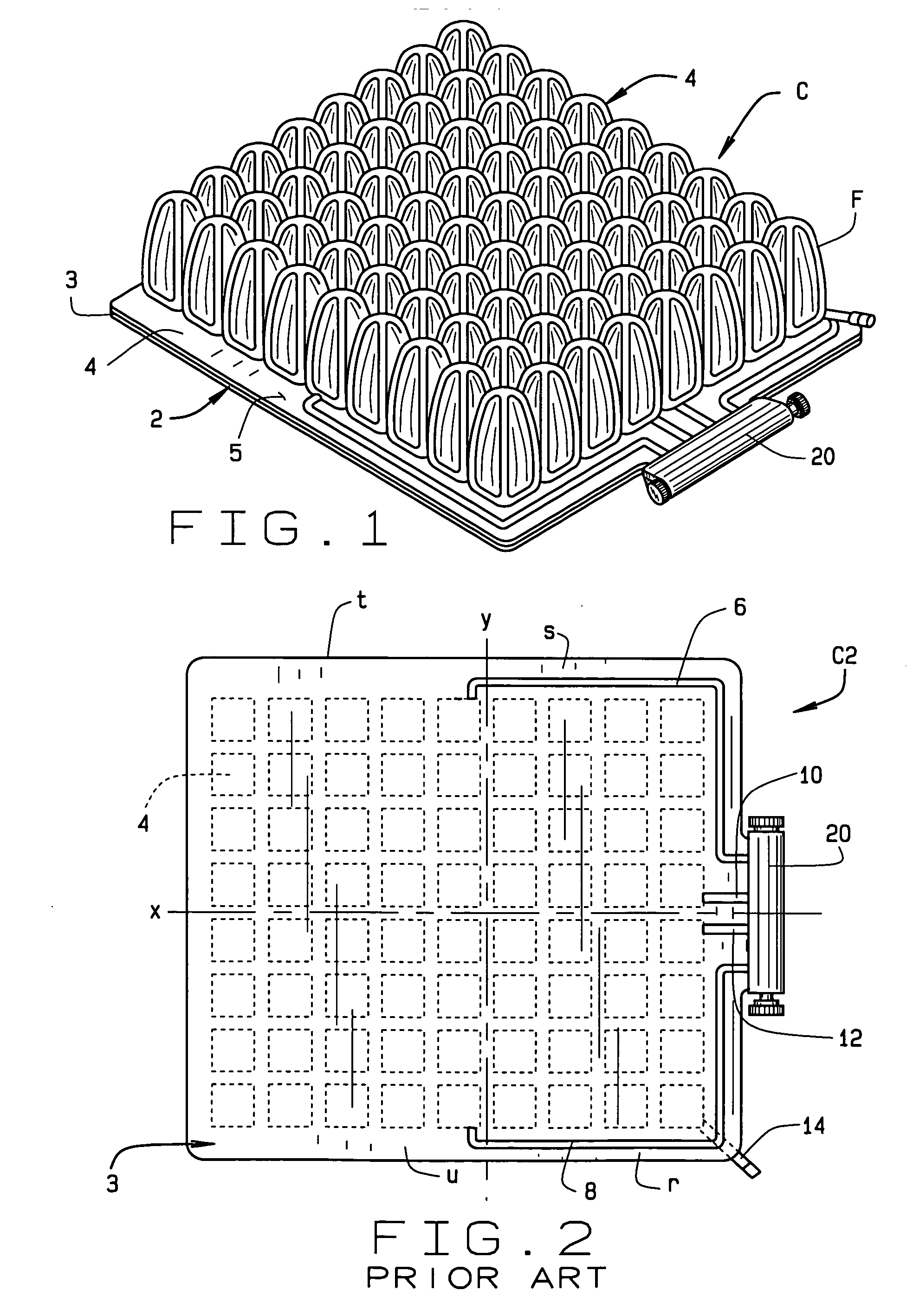

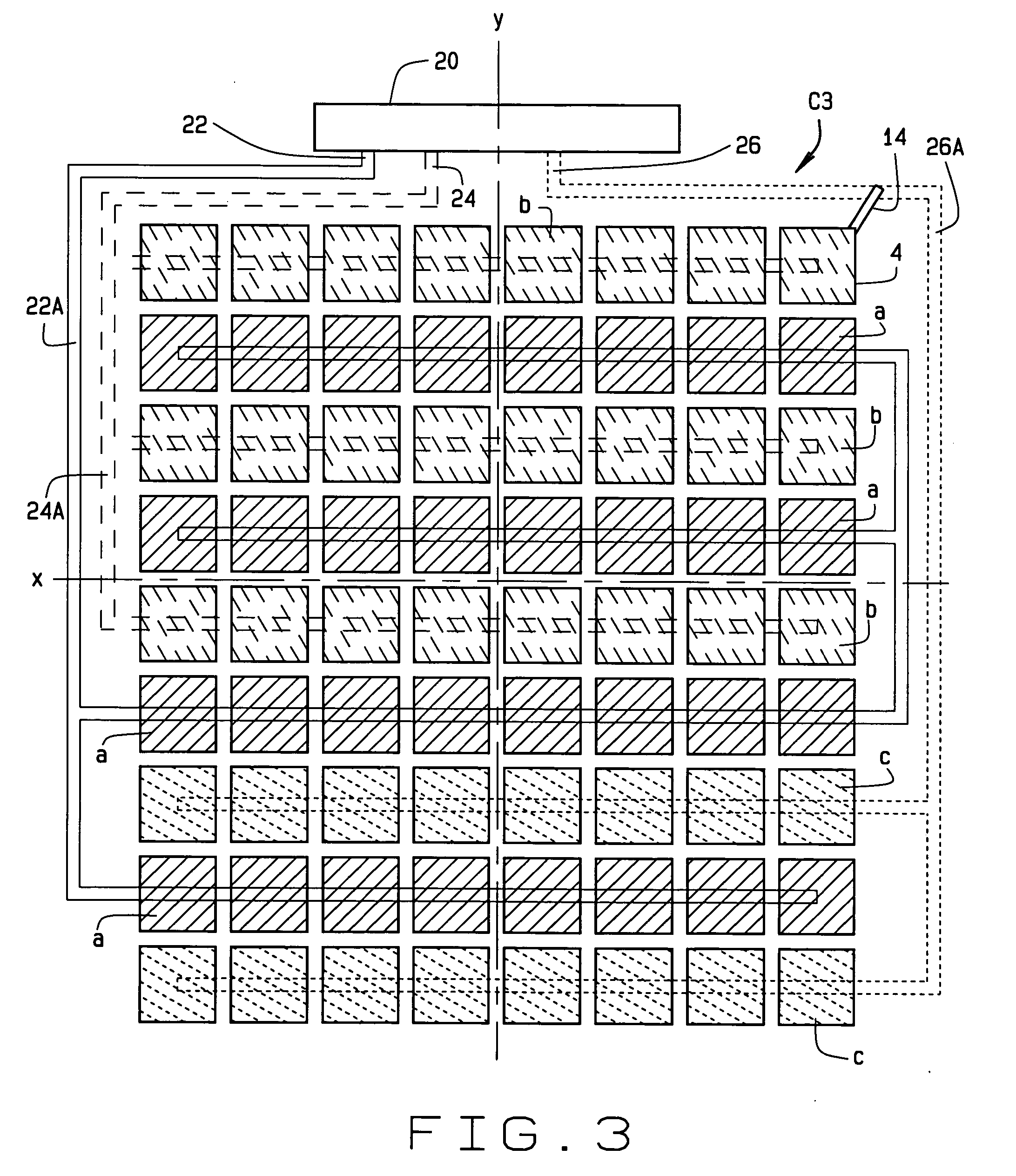

Zoned cellular cushion with fail safe inflation zones

InactiveUS20070056112A1Good positioningAdequate positioningDismountable chairsFoldable chairsCushionAir cell

A pattern of airflow pathways among inflatable air cells in an inflatable air cell cushion that result in discrete, isolated inflation zones that allow the optimal immersion depth and support of a seated,user when fully inflated and maintain acceptable immersion depth and support of the seated user in the event of an air leak from one of the inflation zones. The airflow pathways are operably connected to a valve wherein opening of the valve places the normally isolated inflation zones in fluid communication and closing of the valve isolates the inflation zones.

Owner:GRAEBE ROBERT H

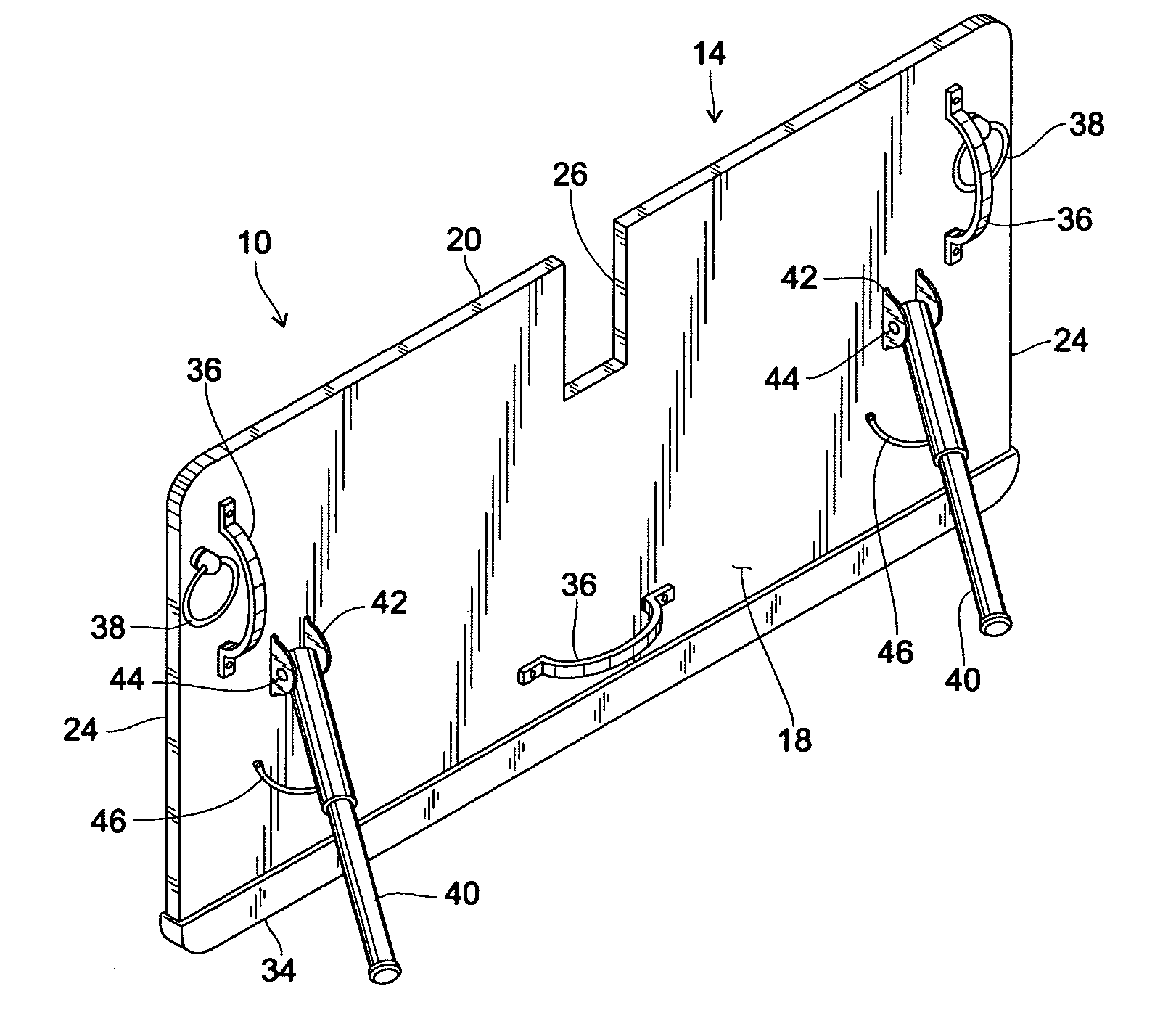

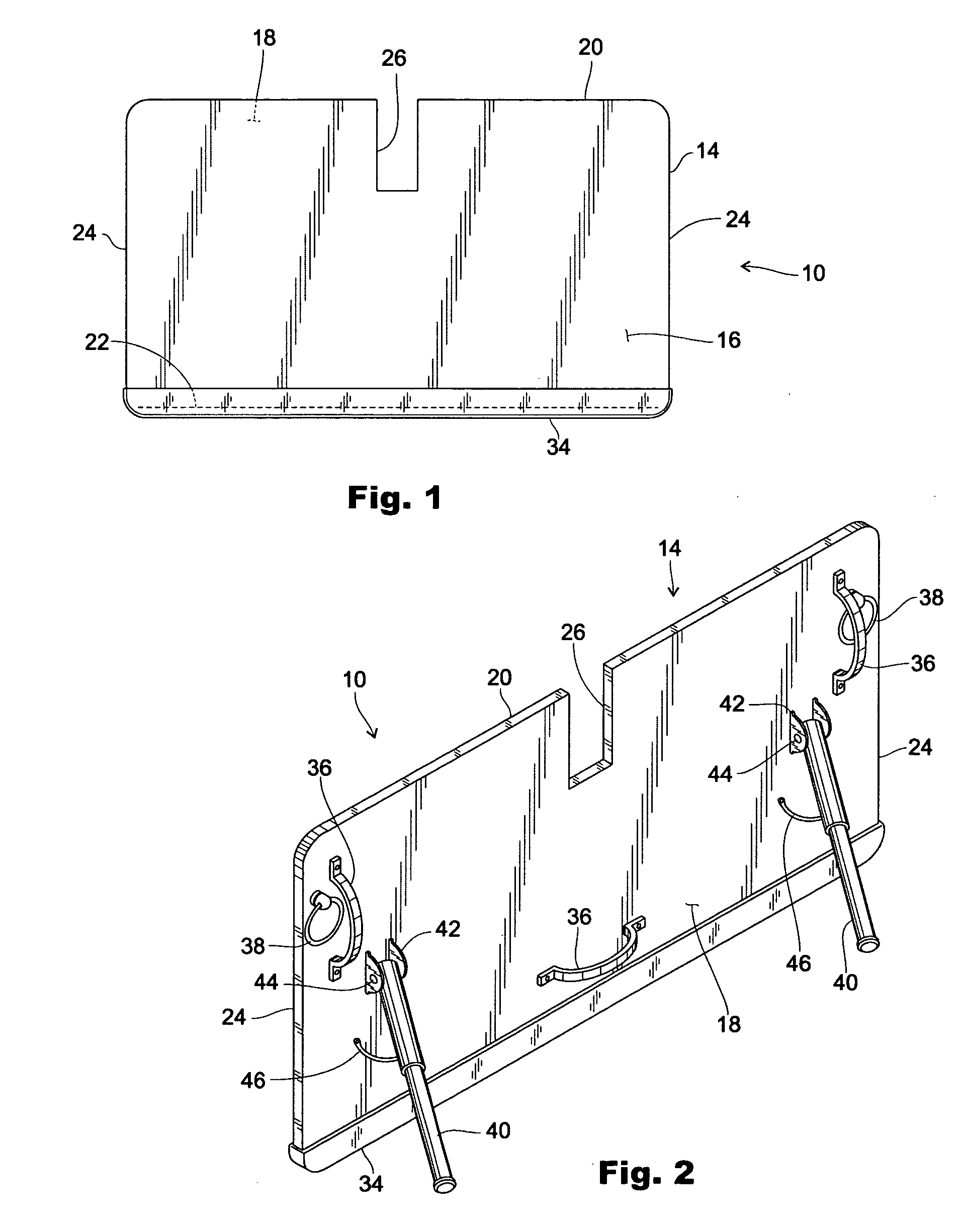

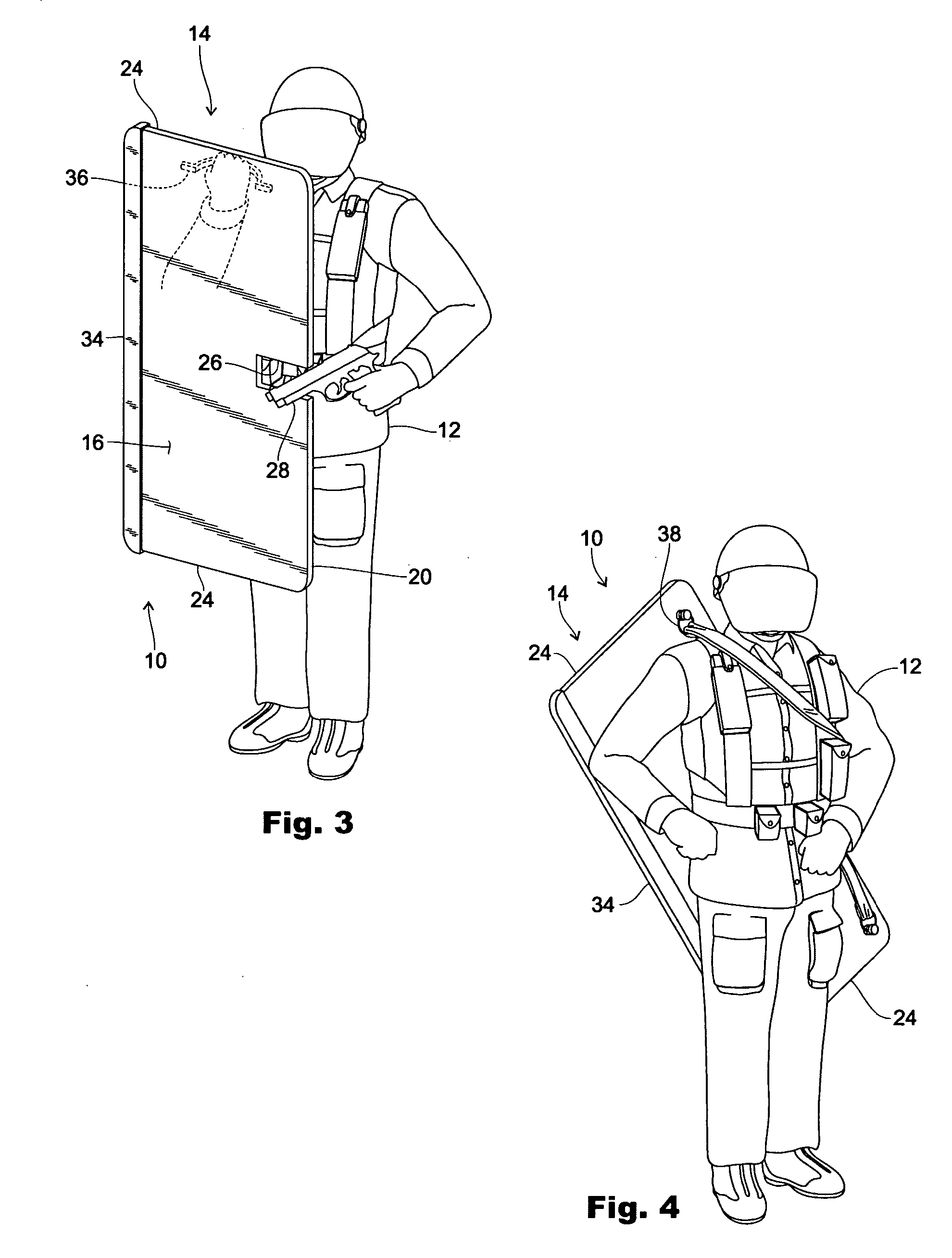

Portable ballistic shield and shooting platform for police and military personnel

InactiveUS20060230916A1Quickly set up and broken downGood positioningDoor/window protective devicesArmoured vehiclesTerrainCamouflage

A portable ballistic shield for use by civilian and military SWAT teams that provides both mobile and stationary cover, protection and a shooting platform for sniper and observer teams deployed behind the shield includes a rectangular-shaped planar member having a front surface that can include camouflage patterns, a rear surface and a lower edge having a rubber strip attached thereto for stabilizing the ballistic shield when disposed on the supporting surface. A centrally located gun slot is cut out adjacent the upper edge of the planar member and pivotally mounted to the rear surface is a pair of support legs for supporting the planar member. A slip-on camouflage cover is provided for covering at least the front surface so that the camouflage pattern can be adapted to suit the terrain and environment, such as urban, desert and midnight blue, where the shield is being deployed.

Owner:SAND MICHAEL A

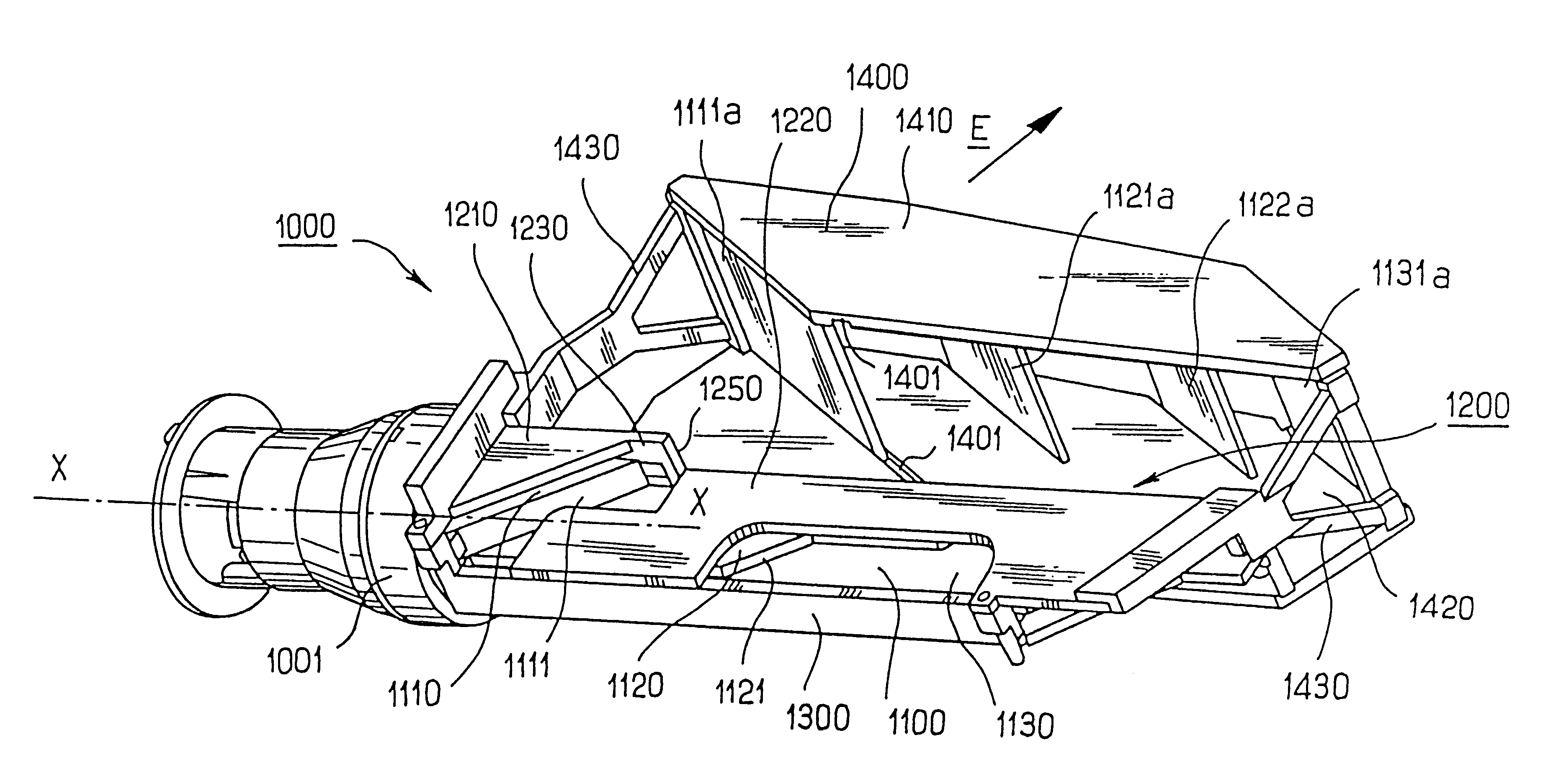

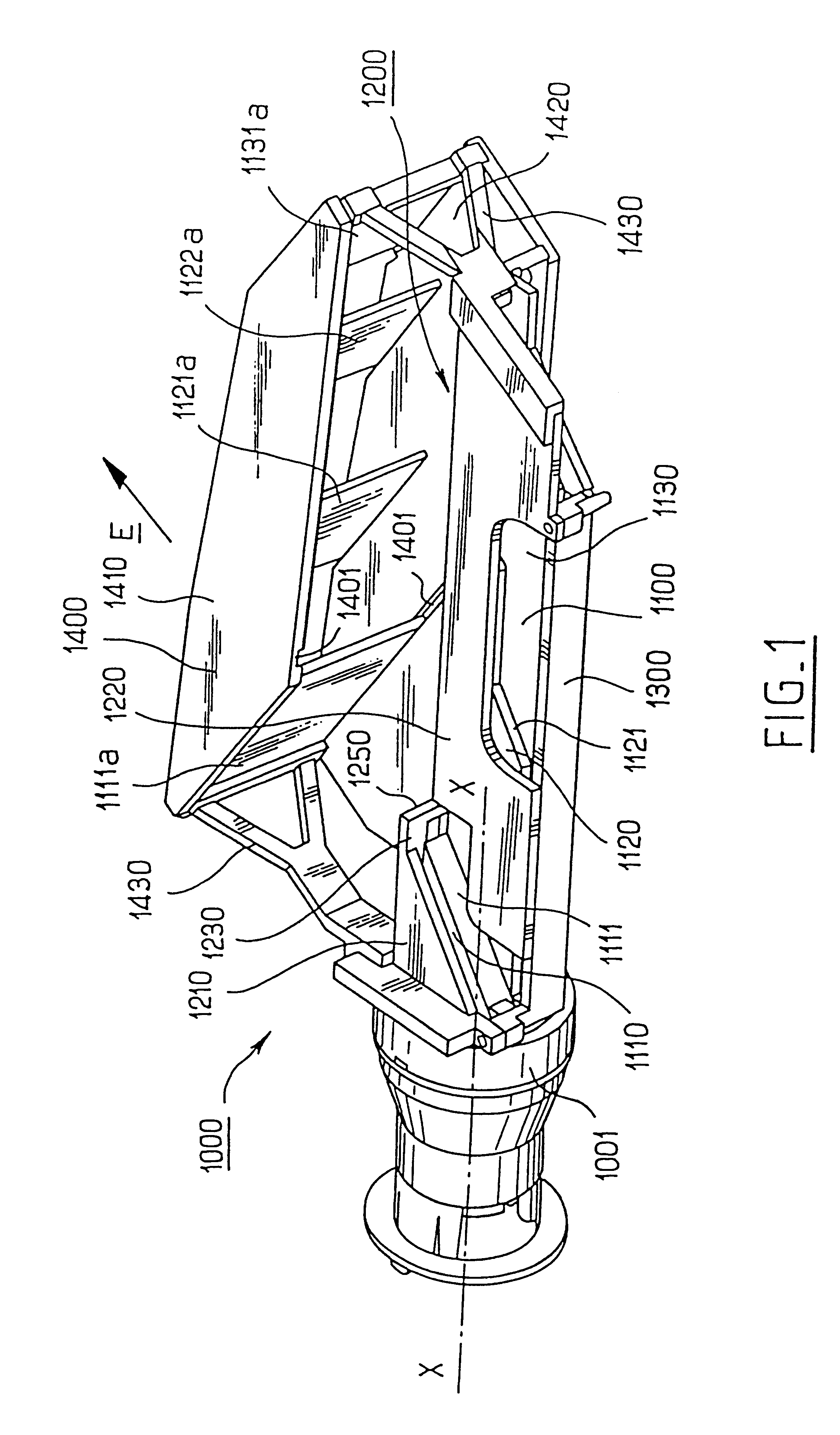

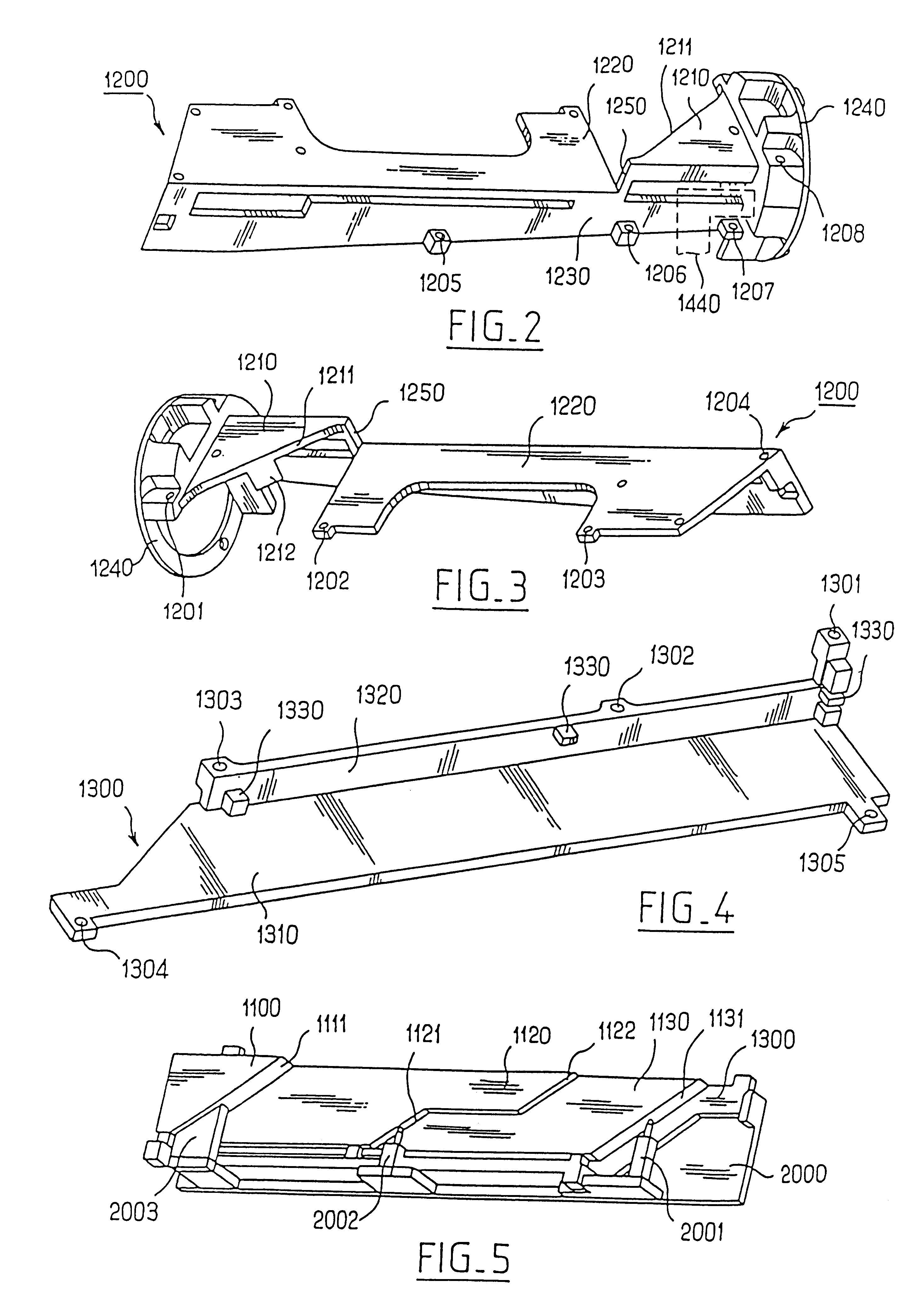

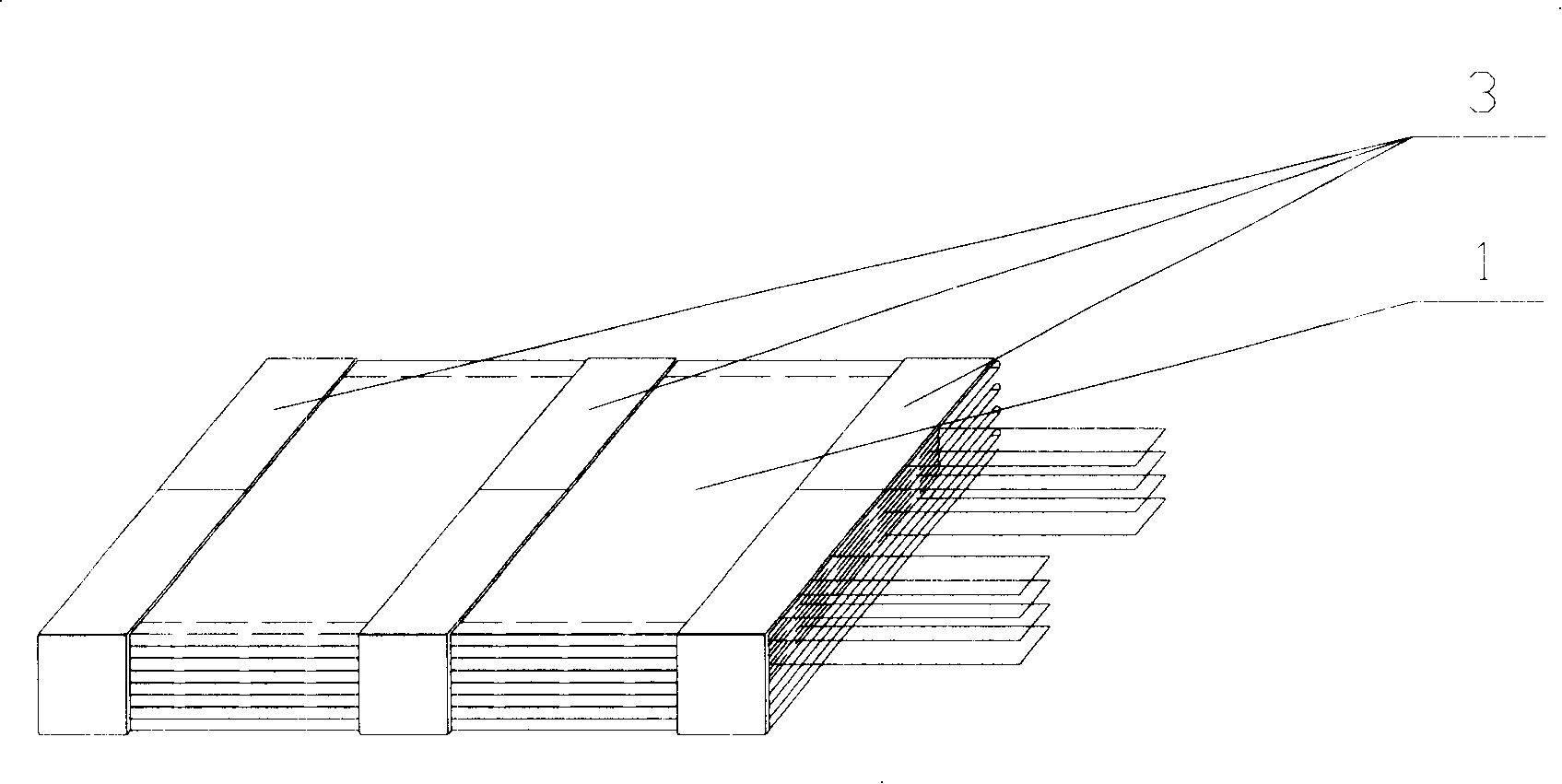

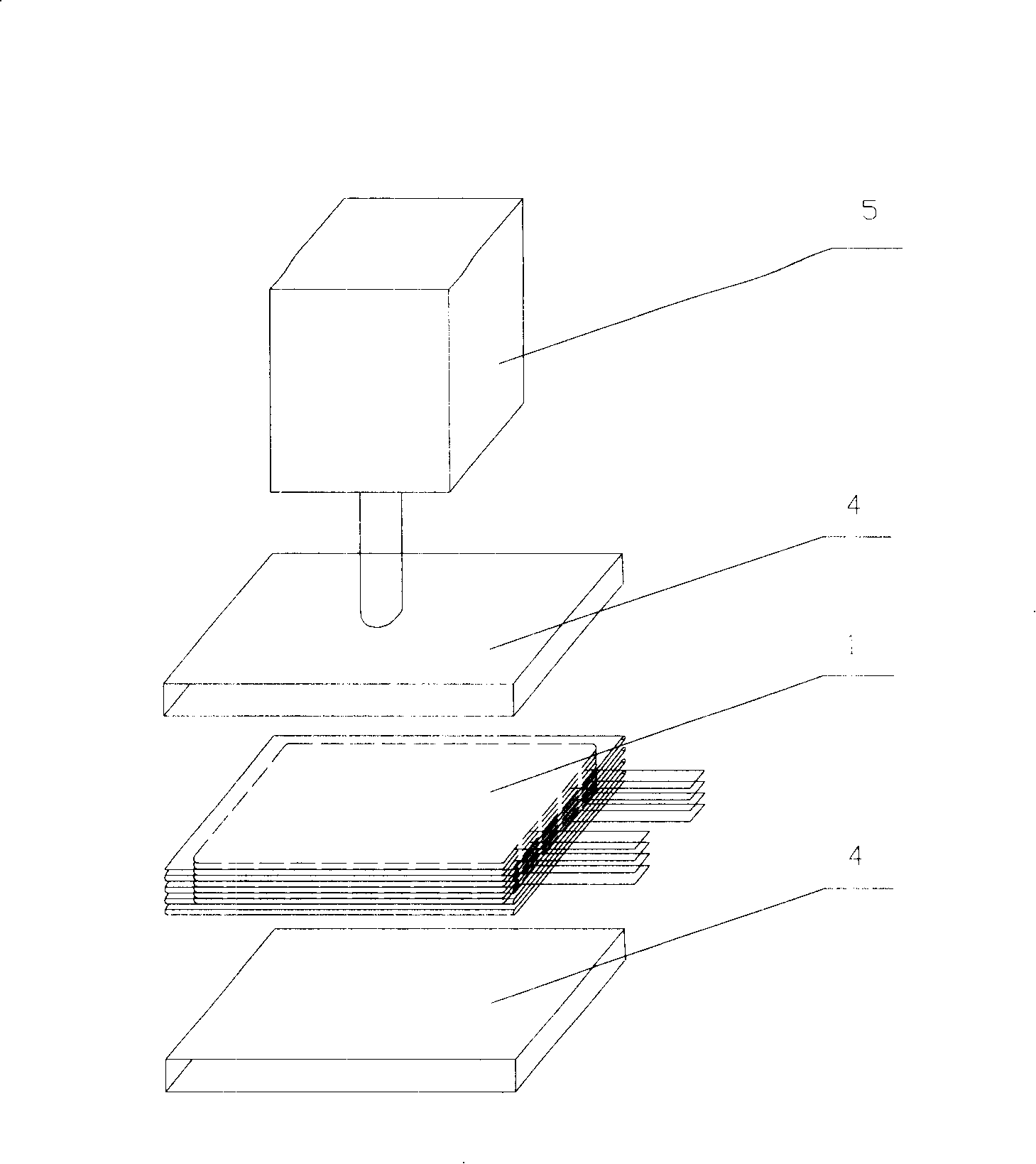

Lighting module with a light guide for a motor vehicle

InactiveUS6174079B1Good positioningPrecise positioningMechanical apparatusVehicle headlampsHeadlampEngineering

A lighting module for a motor vehicle headlight, in which light from a light source is received by the input end of a light guide having a plurality of oblique facets, which are reflective by total reflection and cooperating with lenses.The light guide comprises a set of transparent strips stacked together, and the module includes a reference member comprising a first portion which defines a horizontal reference plane, and a second portion which defines a vertical reference plane. The stacked transparent strips are abutted against these two portions of the reference member in a predetermined position on the longitudinal axis of the light guide, so that their facets will cooperate with the lenses to project in the emission direction images corresponding to the facets.

Owner:VALEO VISION SA

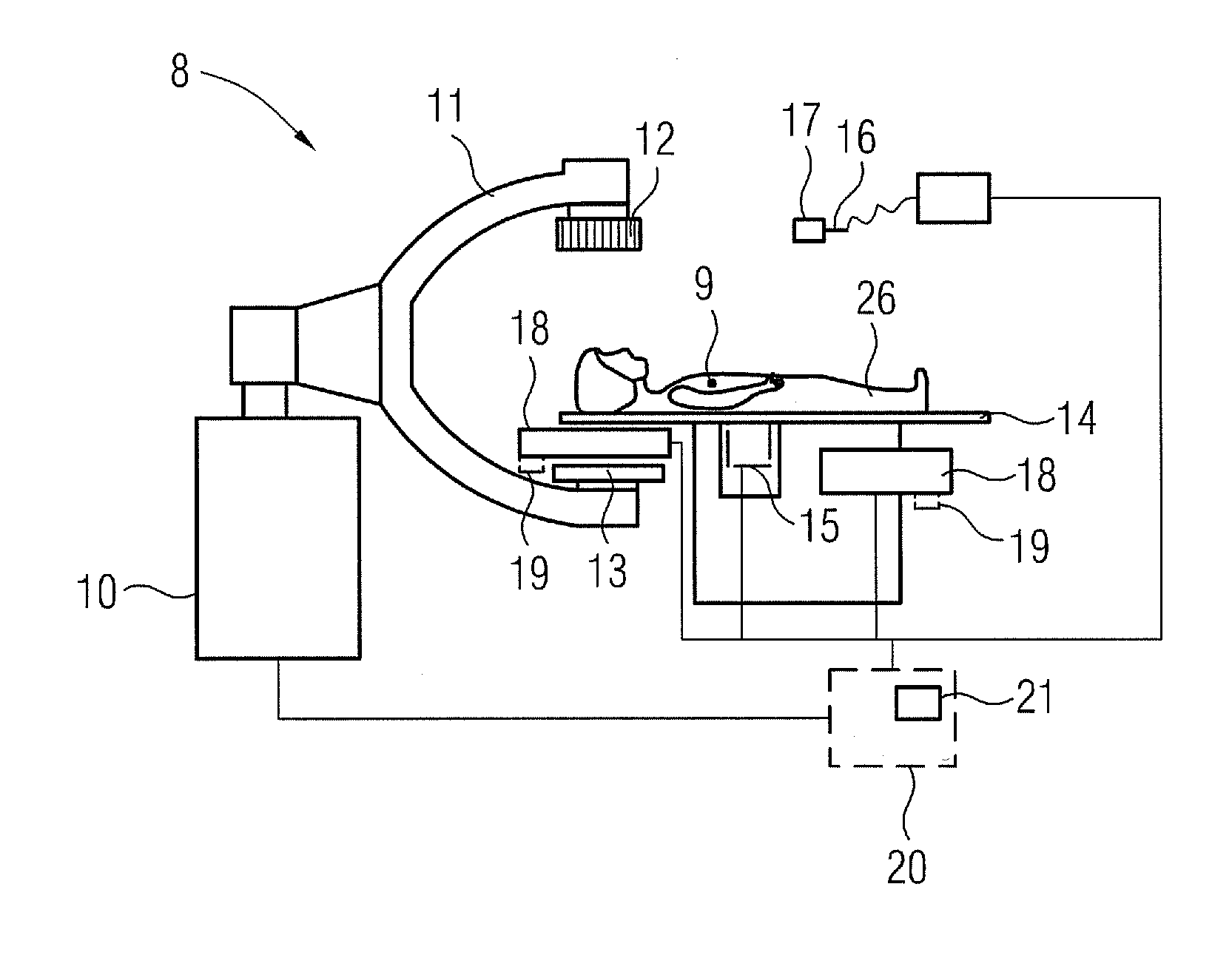

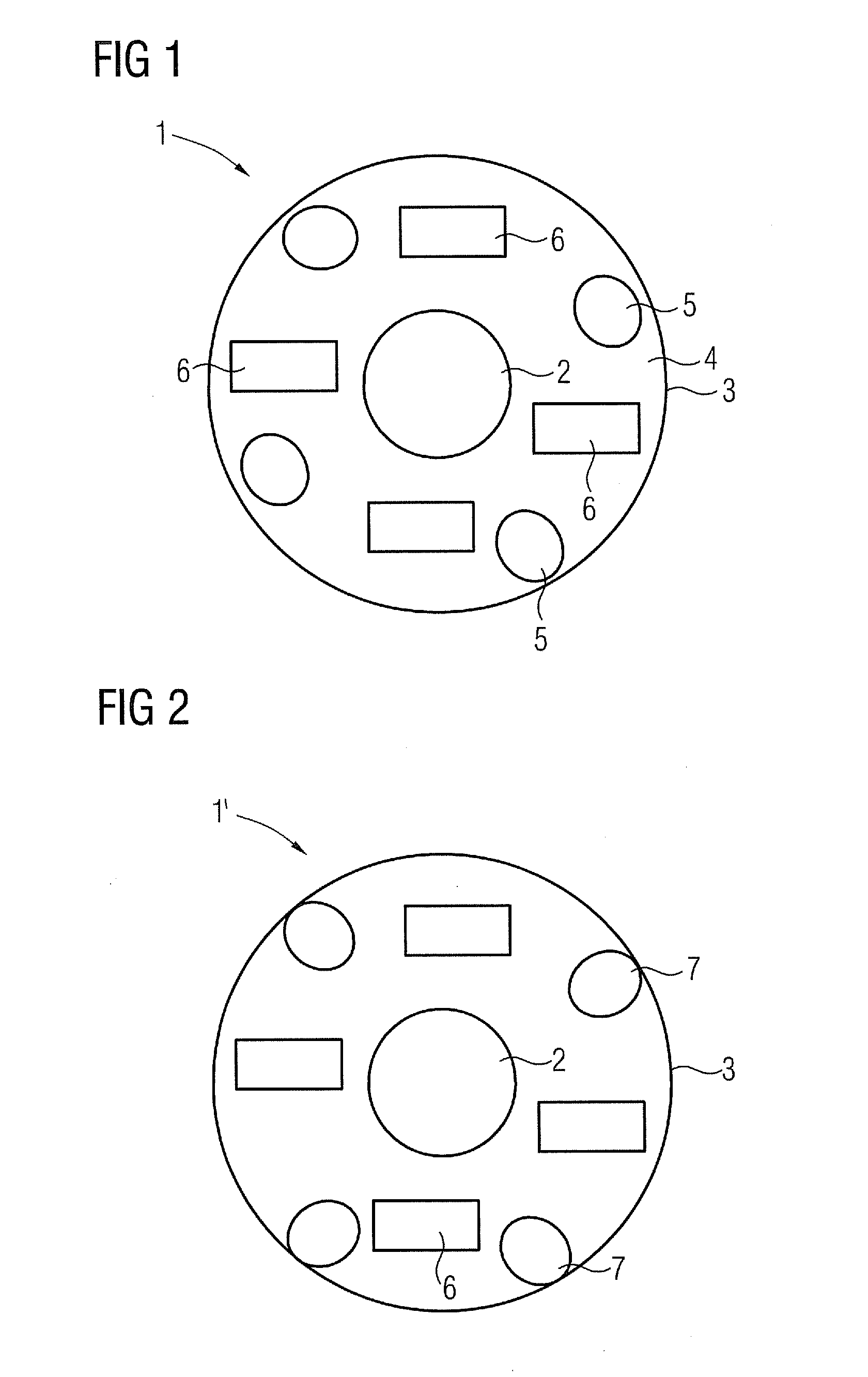

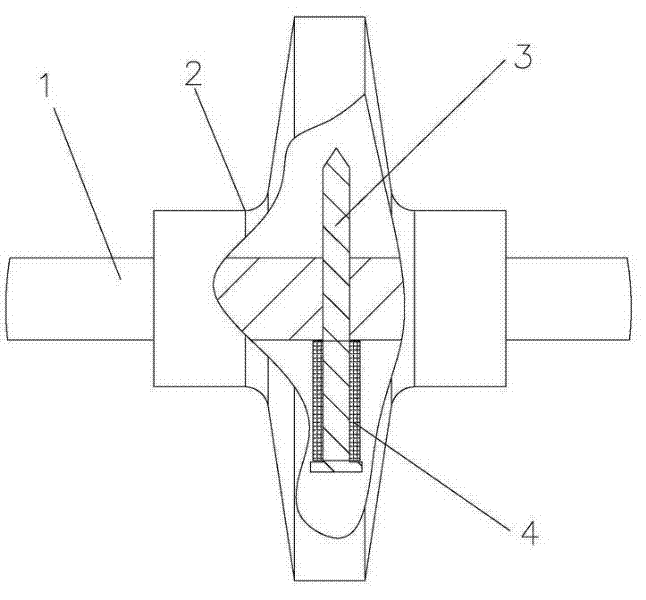

Microcapsule for local treatment of a tumor and method for positioning a magnetic gradient field guiding magnetic nanoparticles to a target location as well as apparatus for positioning a magnetic gradient field

InactiveUS20110301452A1Good positioningImprove positioning verificationBiocidePowder deliveryPhysicsActive agent

A microcapsule for the local treatment of a tumor is proposed. The microcapsule has a support material forming a casing for the microcapsule, an active agent that damages tumor cells, a marker material suitable for use as an x-ray marker, and at least one magnetic nanoparticle. The active agent in particular destroys the tumor cells.

Owner:SIEMENS AG

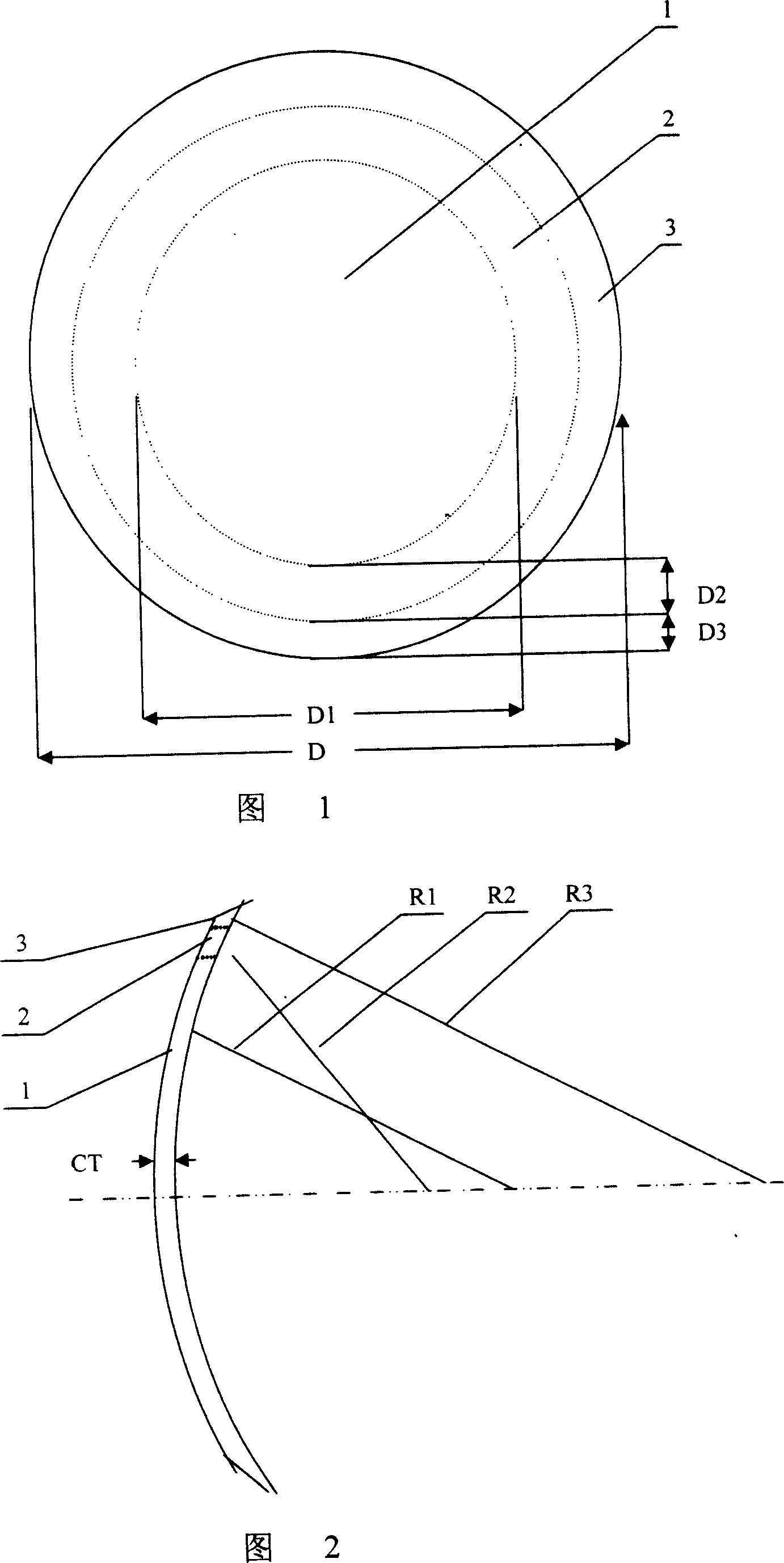

Therapeutic hard air-permeable cornea contact mirror

The invention belongs to the cornea contact lens especially for curing the hard permeability cornea. The CRGP is made up of the optical region, the middle circle part and the side arc region of the lens. The diameter of the optical region is 7.0-8.5mm and the radius of the base arc curvature is 8.7-9.2mm; the width of the middle circle is 1.5-1.8mm, the radius of the second arc curvature is 7.8-8.6mm; the width of the side arc is 0.3-0.5mm, the radius of the side arc curvature is 11-12.5mm. the whole diameter of the lens is 10.6-13.1mm and the thickness of the center is 0.08-0.18mm. So the center of the lens has the good location to decrease the higher image error efficiently.

Owner:GUANGZHOU VISION OPTICS TECH

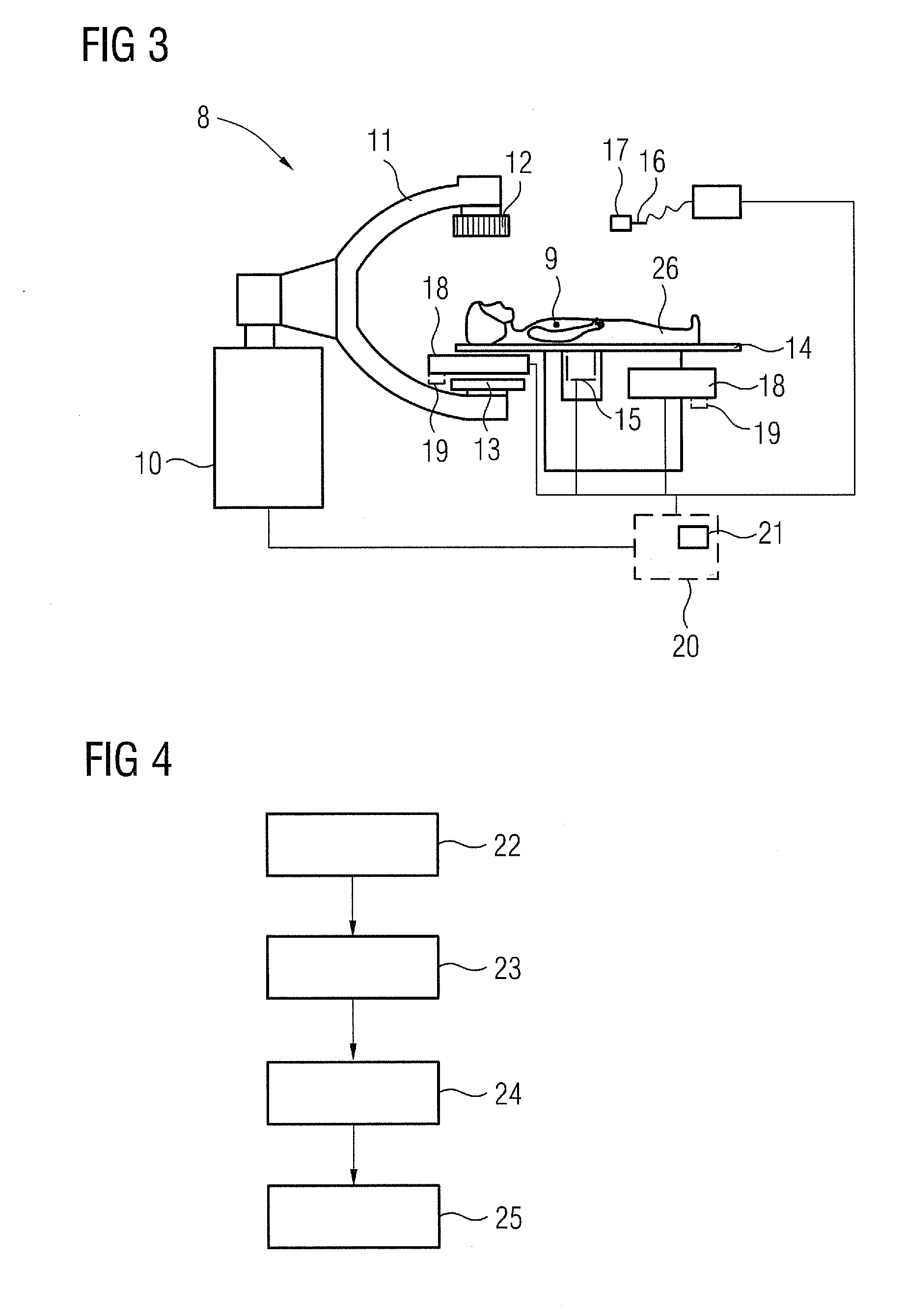

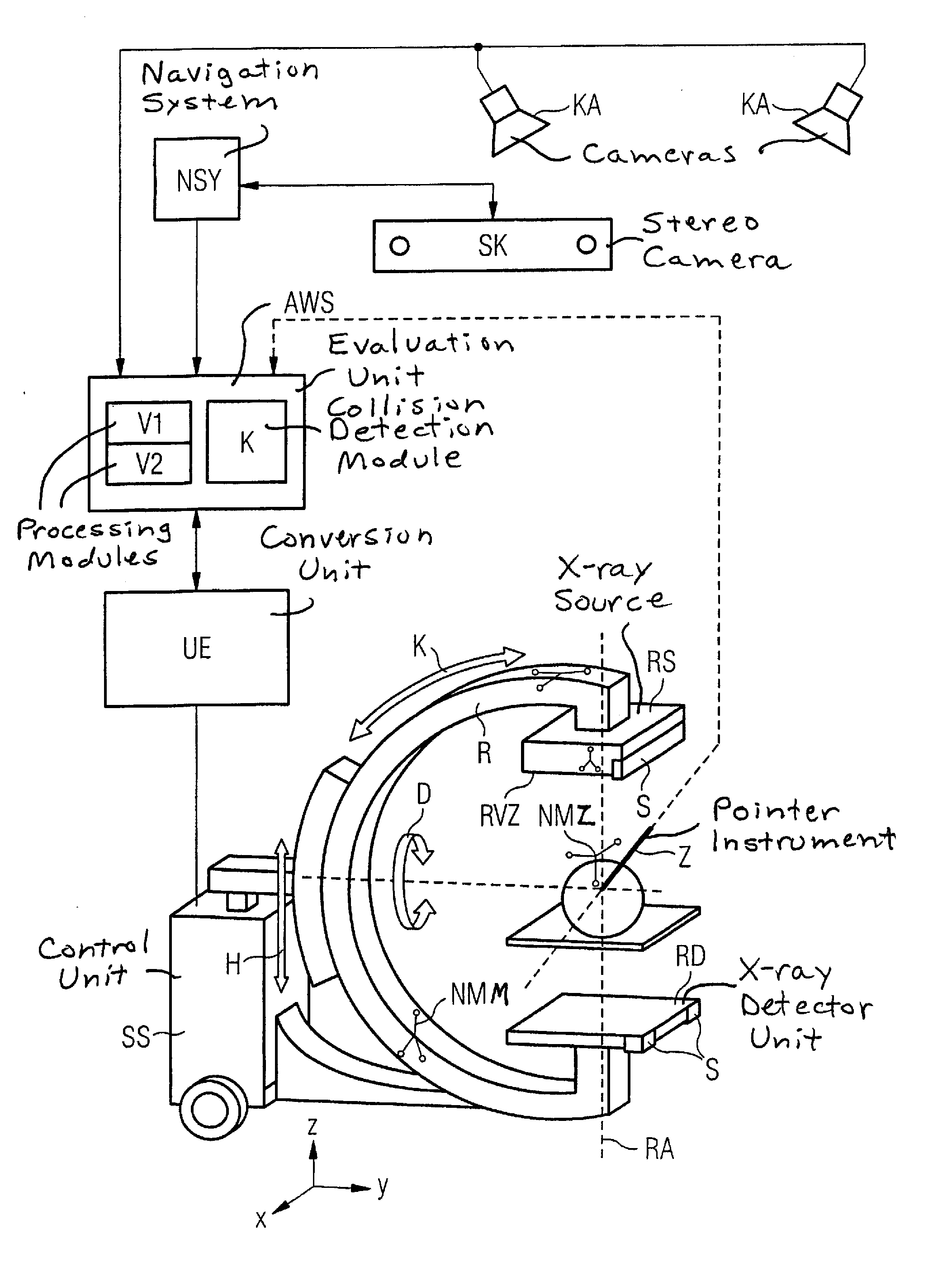

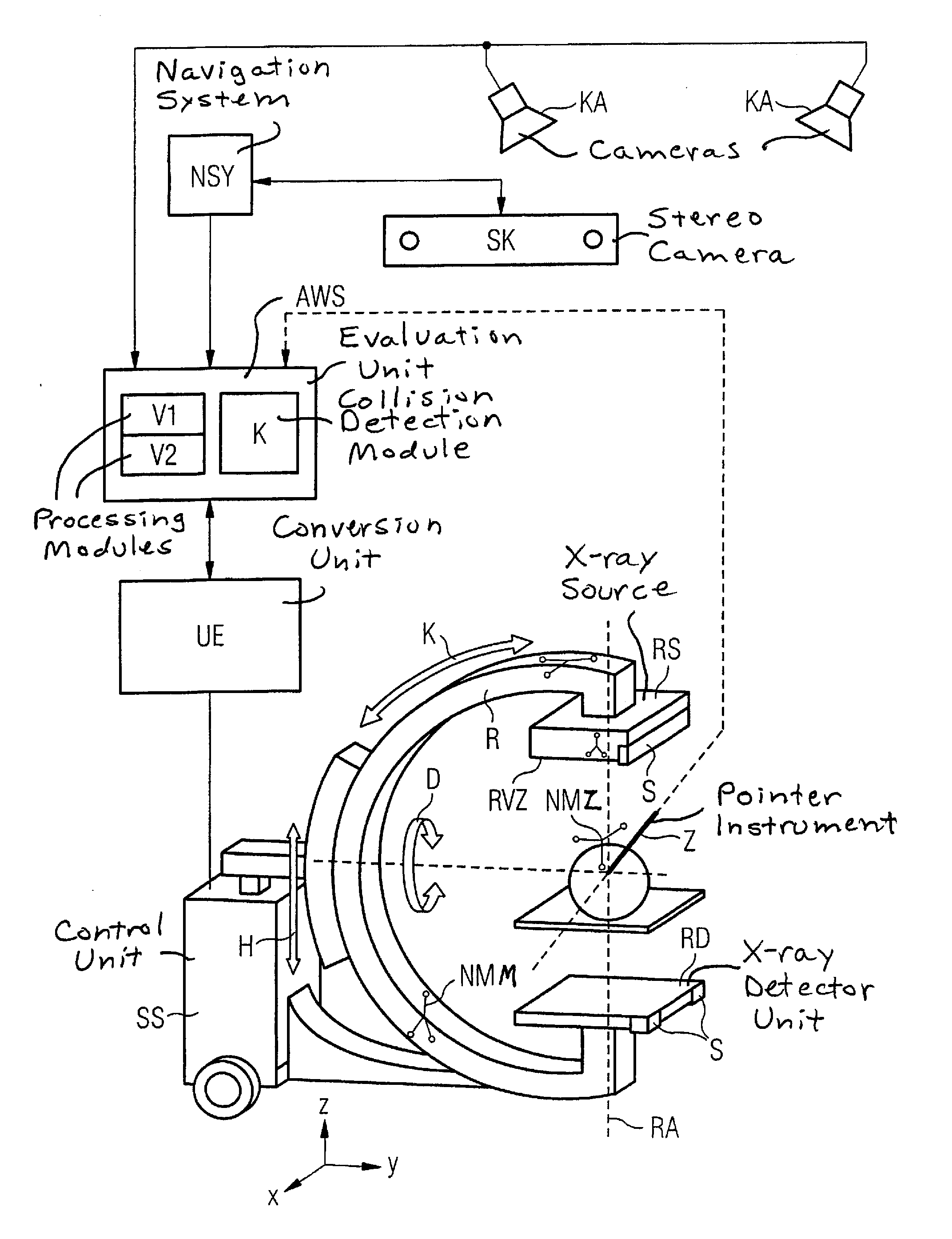

Arrangement and method for positioning of apparatuses

ActiveUS20090278702A1Avoid collisionGood positioningSurgical navigation systemsTomographyEngineeringInstrumentation

In an arrangement and associated method for positioning of apparatuses (in particular of a C-arm), the position and orientation of a C-arm and of a pointer instrument are determined by a navigation system, and an alignment of the C-arm is conducted based on the orientation of the pointer apparatus.

Owner:SIEMENS HEALTHCARE GMBH

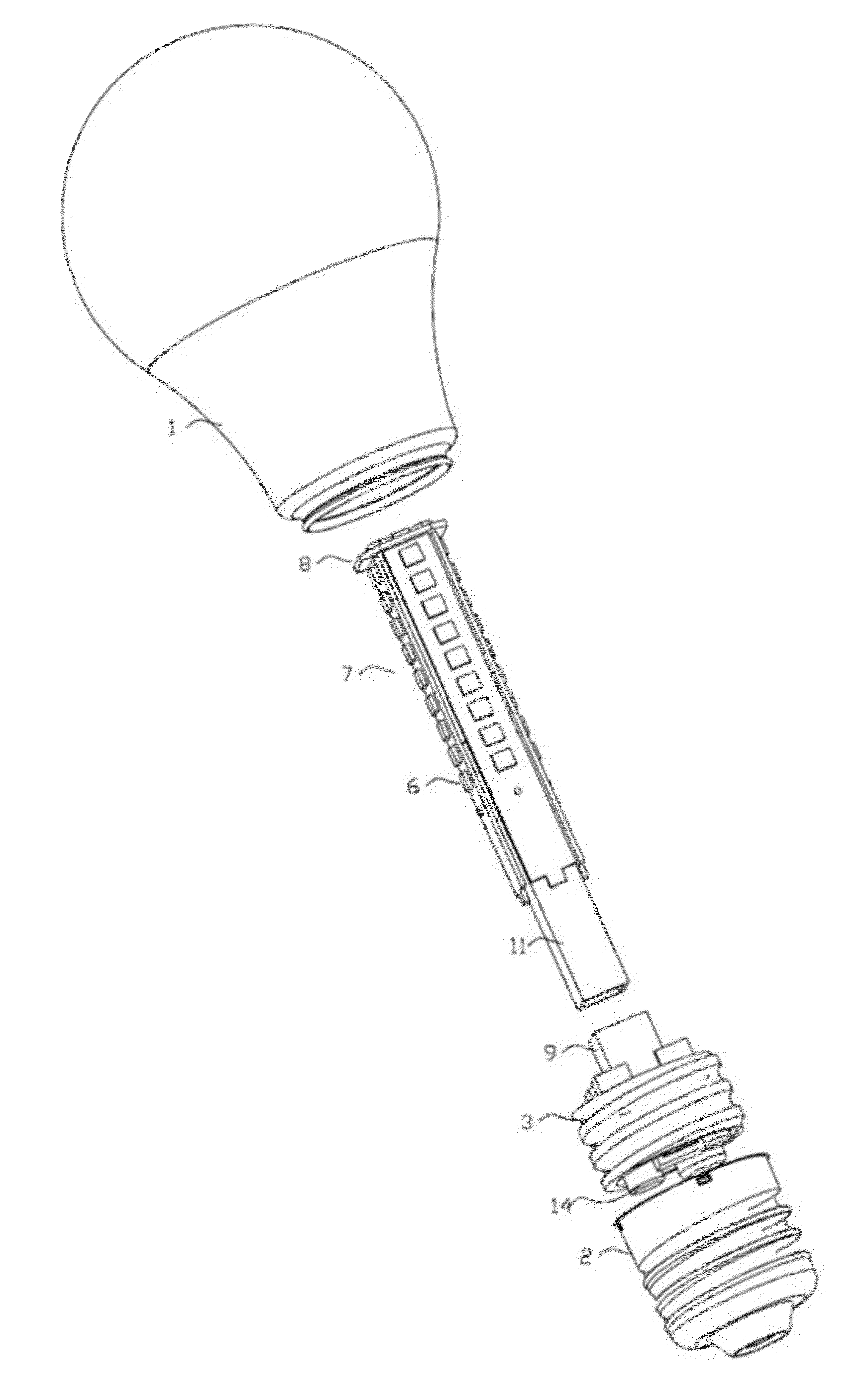

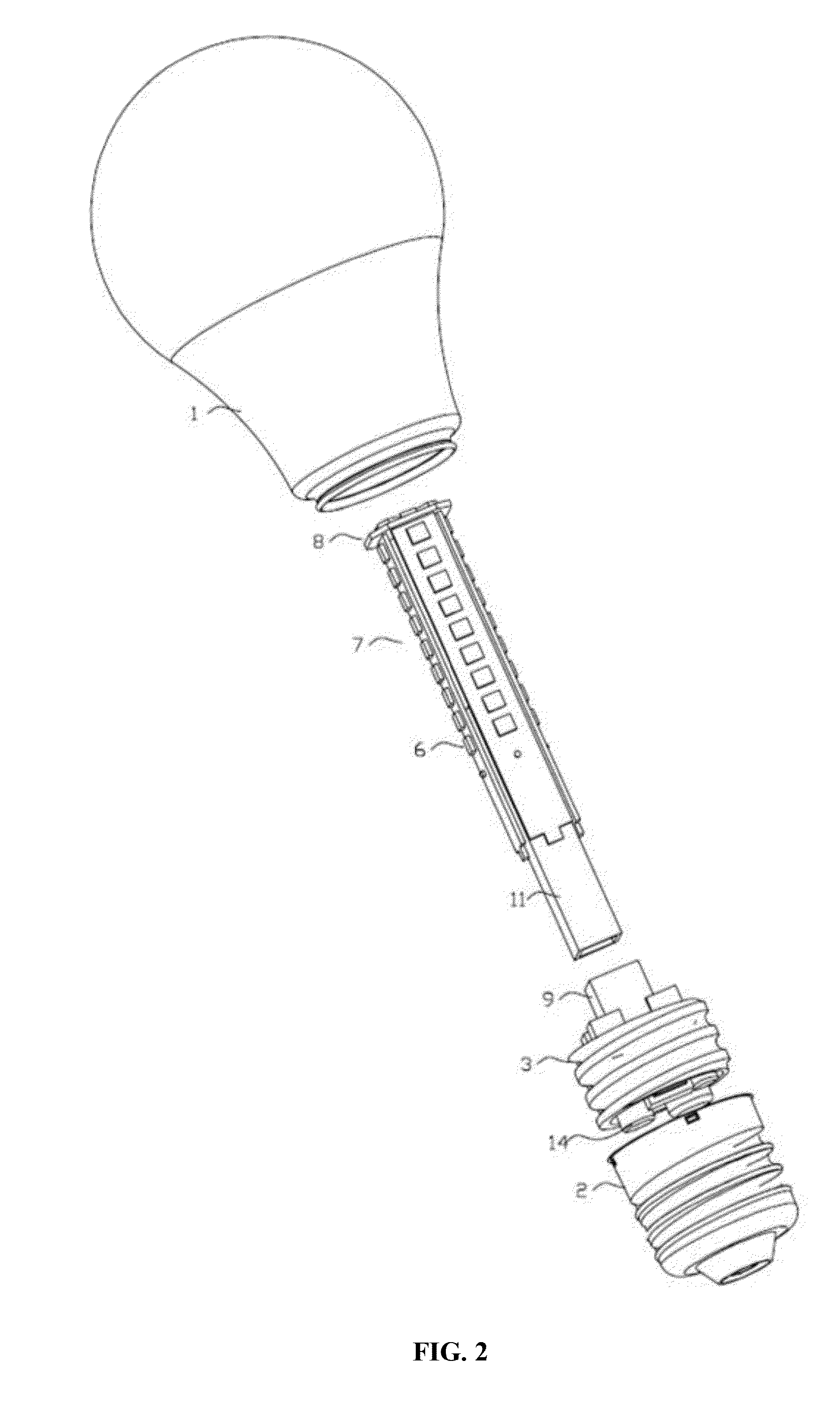

Light-emitting diode (LED) lamp bulb

InactiveUS20150117018A1Stable structureGood positioningLighting heating/cooling arrangementsGlobesEngineeringLight-emitting diode

A light-emitting diode (LED) lamp bulb, comprises a lampshade, a lamp holder and a fixing base, wherein internal threads are formed in the lamp holder; external threads are formed on an outer wall of the fixing base; the fixing base is extended into the lamp holder from an open end of the lamp holder; the fixing base is in threaded connection with the internal threads in the lamp holder through the external threads of the fixing base, or alternatively, viscose glue is coated between the fixing base and the lamp holder and the fixing base is directly adhered to the lamp holder; the lampshade is connected with the open end of the lamp holder; aluminum bases are fixed on the fixing base; and LEDs are disposed on the aluminum bases which are disposed in the lampshade.

Owner:CHEN CHING HUI

Magnetic target carrier system

InactiveCN101264327AGood positioningImprove targetingStentsInorganic non-active ingredientsMagnetic coreReference function

The invention relates to a magnetic targeting carrier system, belonging to the technical field of biotechnology, comprising a magnetic targeting drug and a magnetic targeting bracket. The magnetic targeting carrier system is characterized in that: the magnetic targeting drug comprises a magnetic core, a carrier and a drug for repairing tunica intima. The magnetic targeting carrier system directs the drug on the lesion site through a magnetic implanted bracket. The magnetic targeting carrier system has the advantages of excellent drug targeting positioning, and ability to administrate according to needs without applying magnetic field for human body, not only suitability for coronary heart disease, but also reference function for therapy of local lesion such as tumor, and cancers.

Owner:BEIJING ZHONGFU YOUXIN MEDICAL TECH

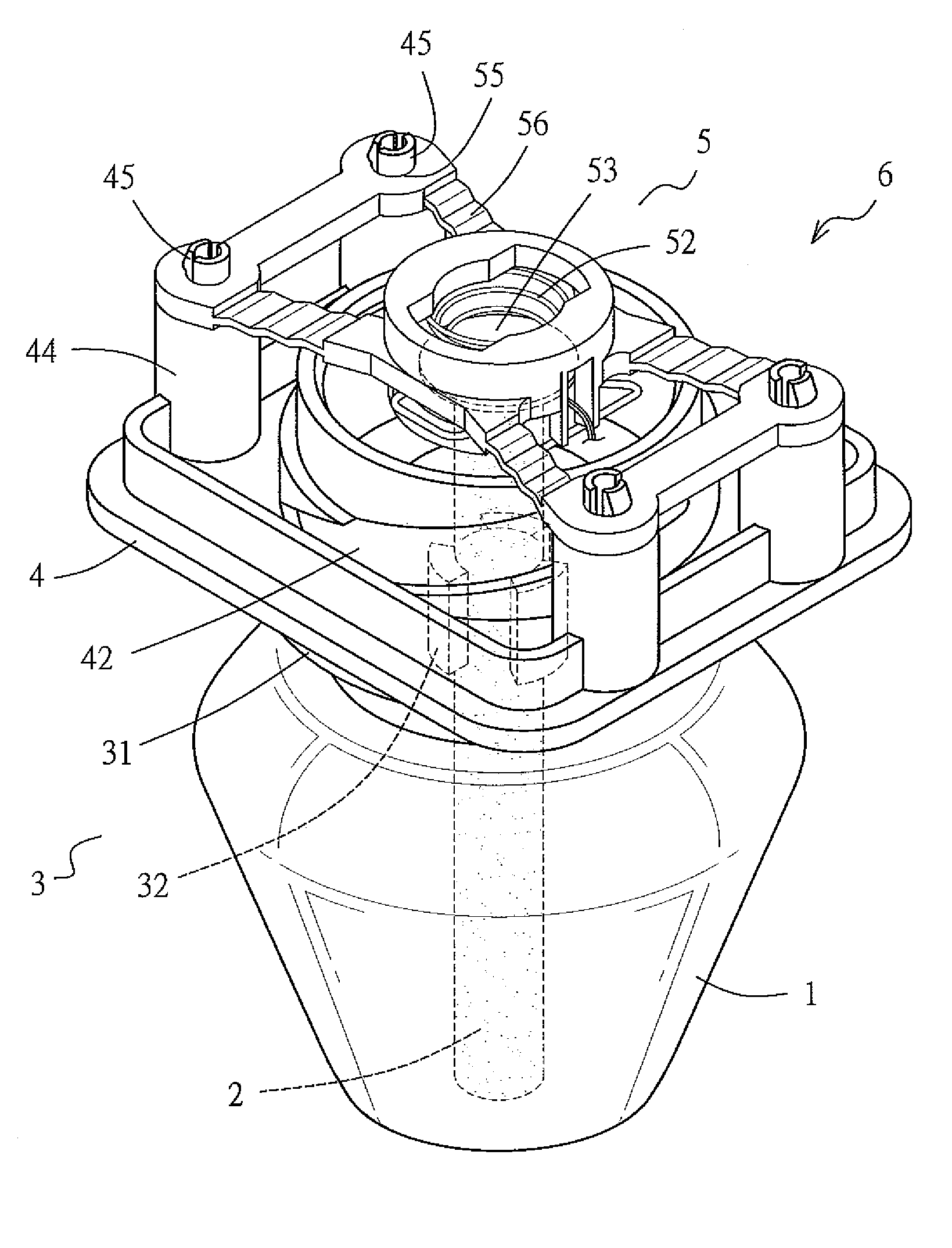

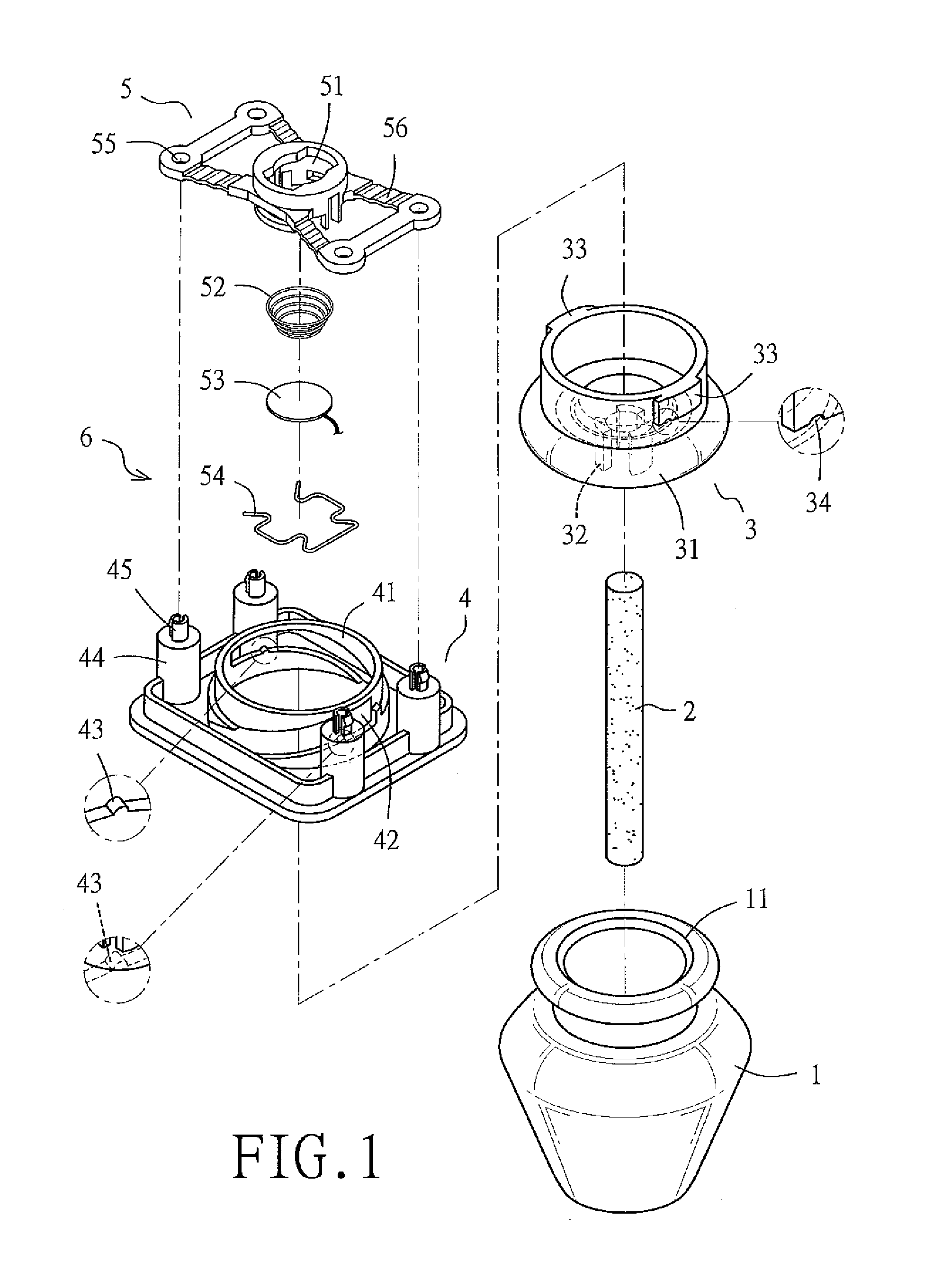

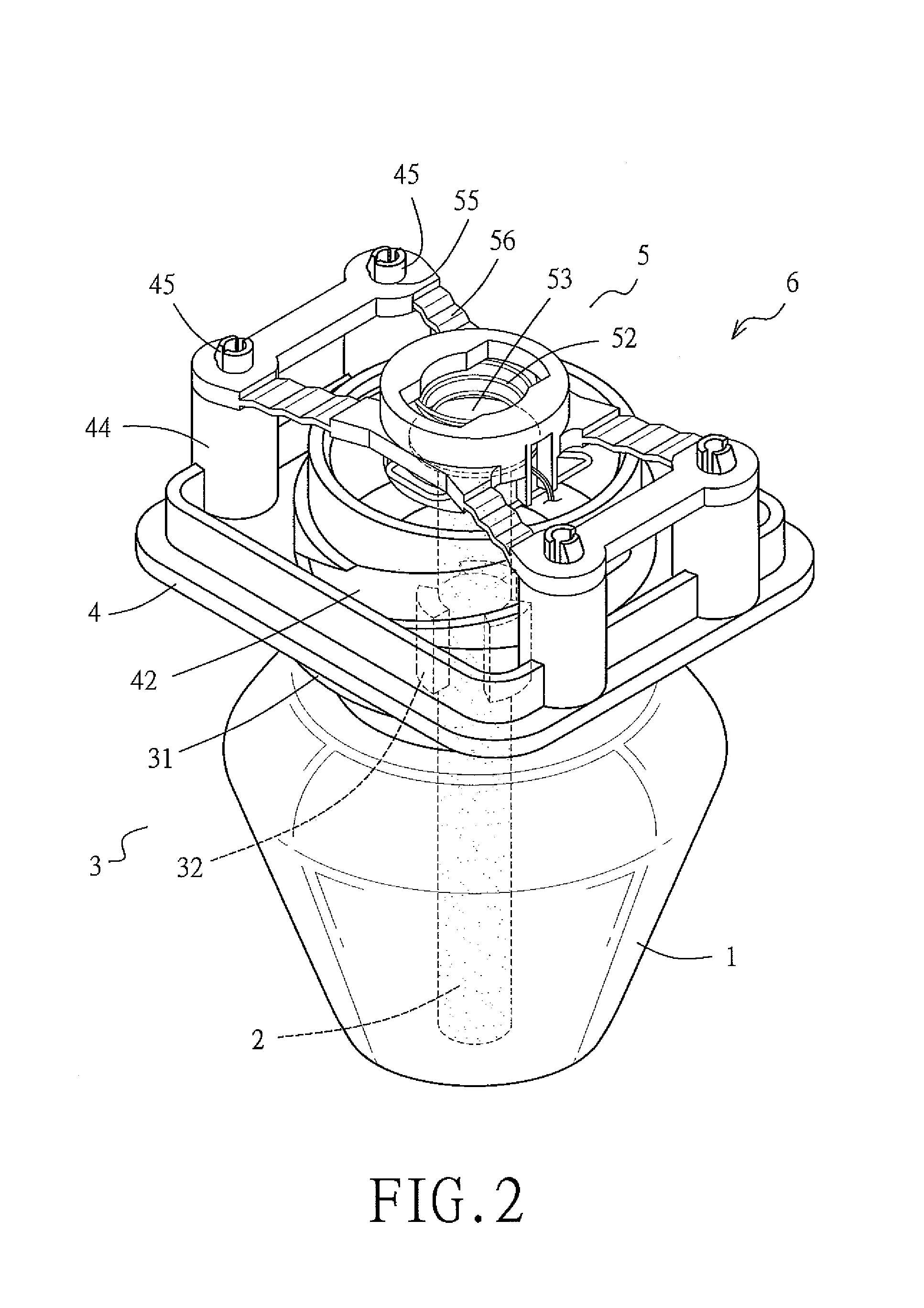

Fragrance vibrating and nebulizing module

InactiveUS7424979B1Reduce numberGood positioningMovable spraying apparatusSpray nozzlesEngineeringMechanical engineering

An improved fragrance vibrating and nebulizing module comprises a holding unit which is installed on an opening of a container, so that a plurality of retainers can retain a wick in place. Two engaging portions formed on an outer periphery of the holding unit can cooperate with guide grooves formed on a central annular portion of a vibrating and nebulizing base and be rotationally connected to be in place. After a receiving space of a top retaining unit is mounted with a resilient element and a vibrating plate, the resilient element and the vibrating plate are retained in place by a resilient retainer. Through holes of the top retaining unit are connected with resilient tenons on the vibrating and nebulizing base. While in use, the vibrating and nebulizing module can draw up a fragrance via the wick, so that the fragrance is nebulized and dispersed in contact with outside air.

Owner:EVERGREAT ELECTRUNIC +2

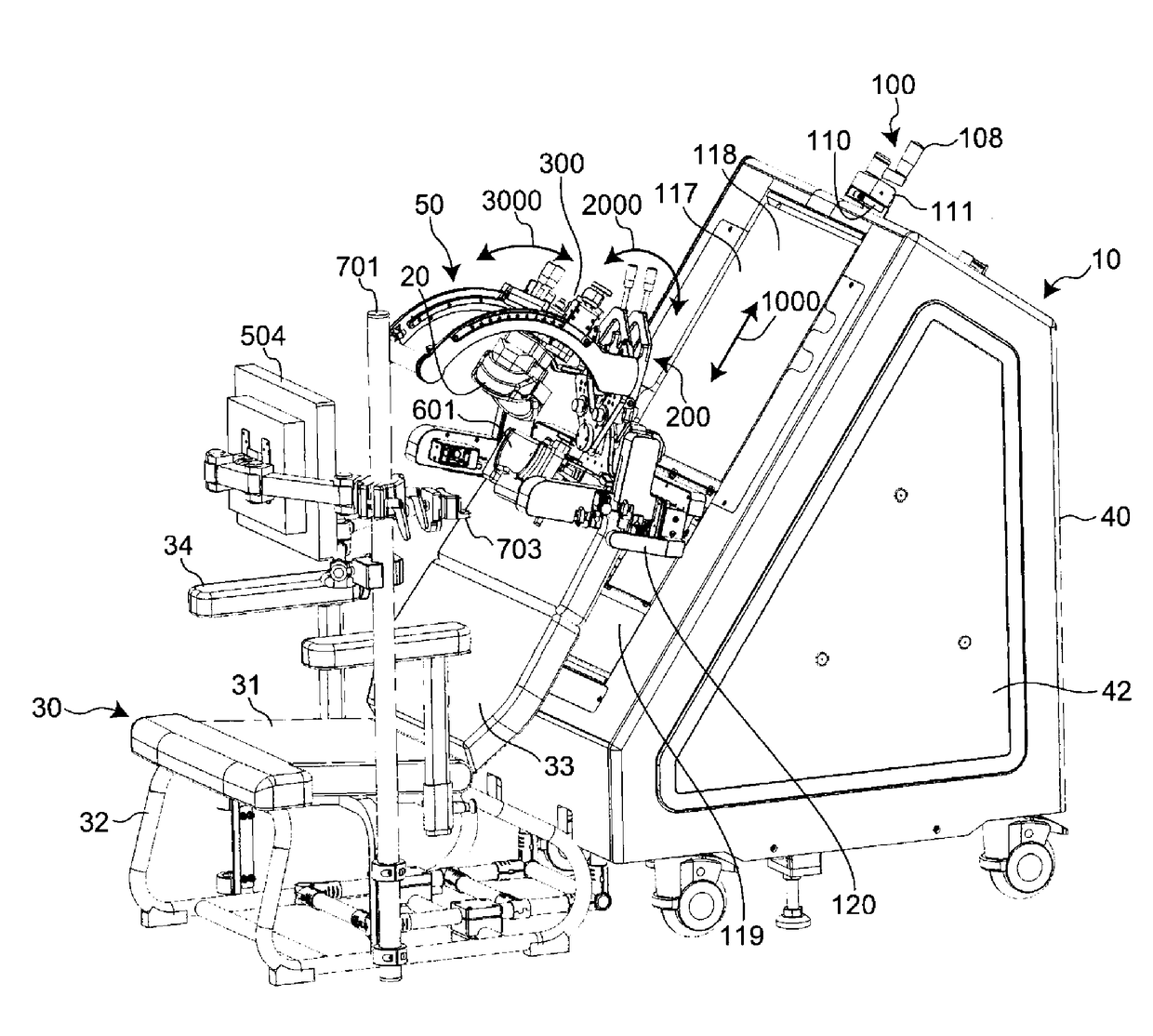

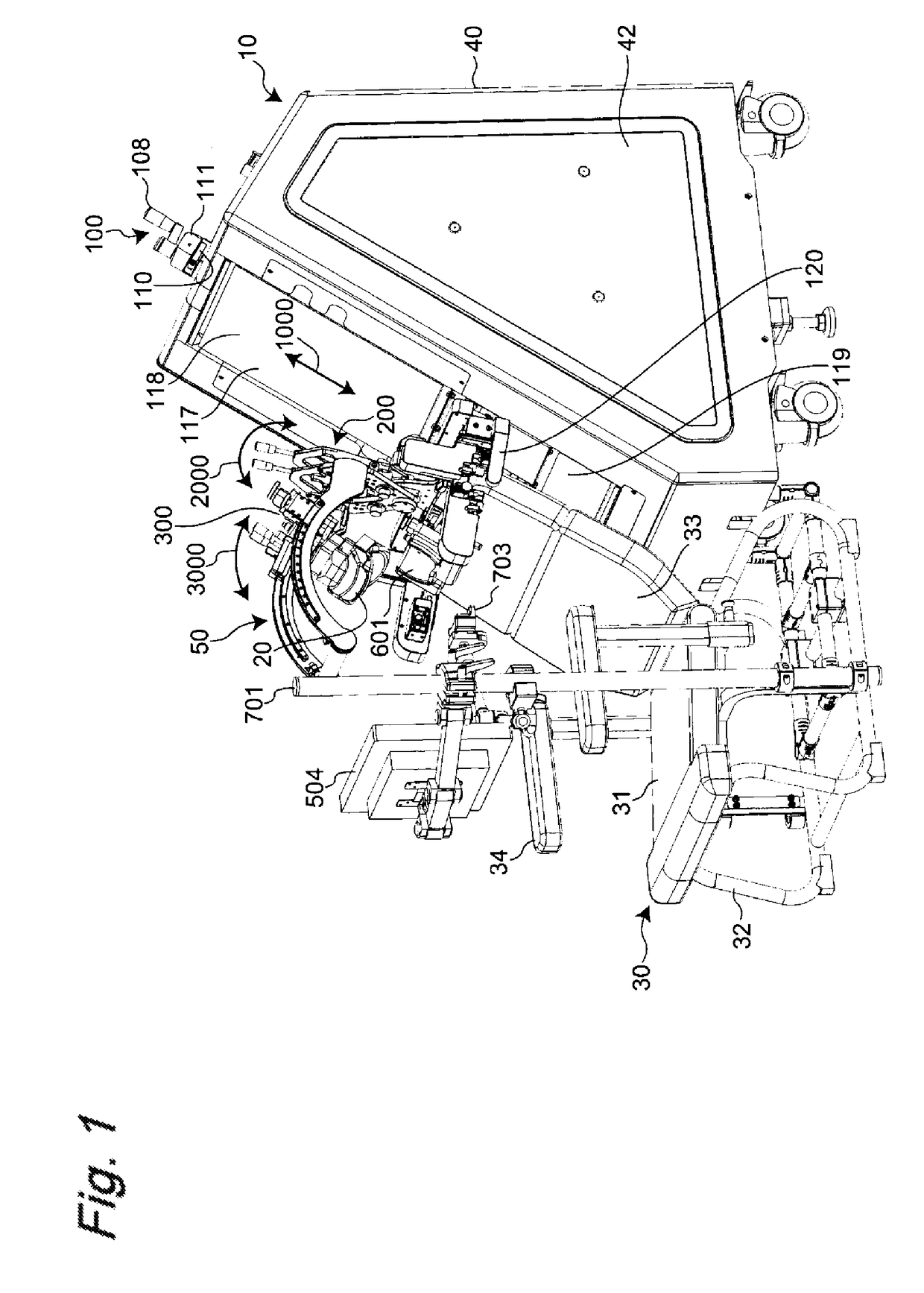

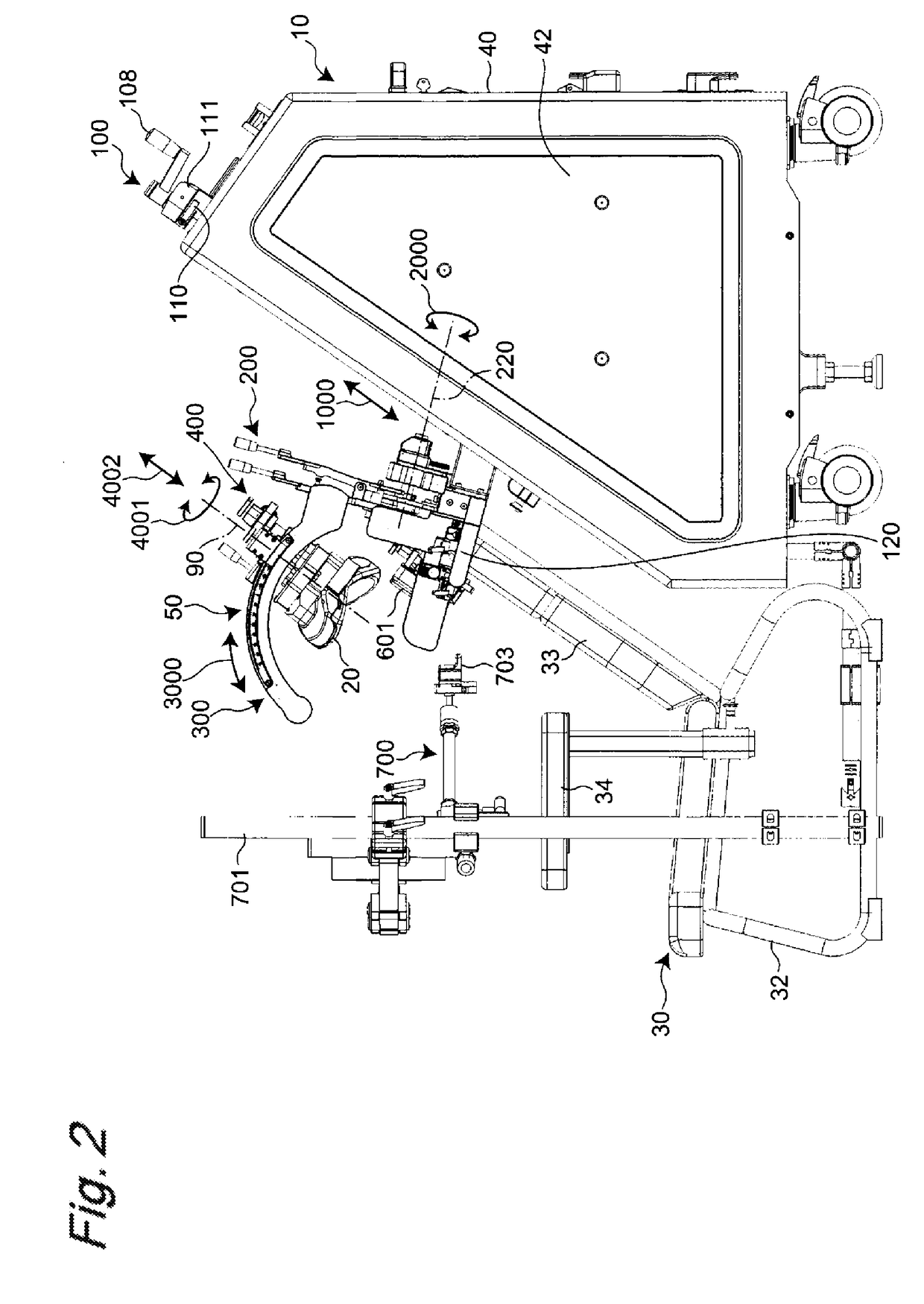

Transcranial magnetic stimulation system

InactiveUS20170291037A1Good positioningConducive to reproductionHead electrodesMagnetotherapy using coils/electromagnetsPatient supportMedicine

The purpose of the invention is to provide a transcranial magnetic stimulation system capable of being readily set into an optimum position for treatment. The system 1 of the invention includes a support mechanism 30 configured to support a patient, a first mechanism 200 configured to move the coil in a left and right direction of the patient about a first axis 220 extending in a back and forth direction of the patient relative to a head of patient supported by the support mechanism, and a second mechanism 300 configured to move the coil in the back and forth direction about a second axis 320 extending in the left and right direction relative to the head of the patient.

Owner:TEIJIN PHARMA CO LTD

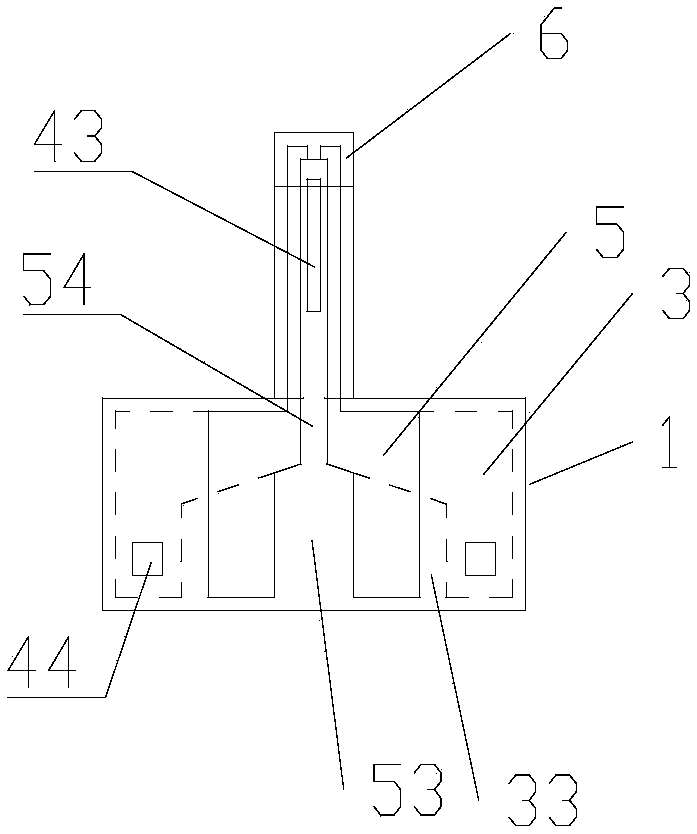

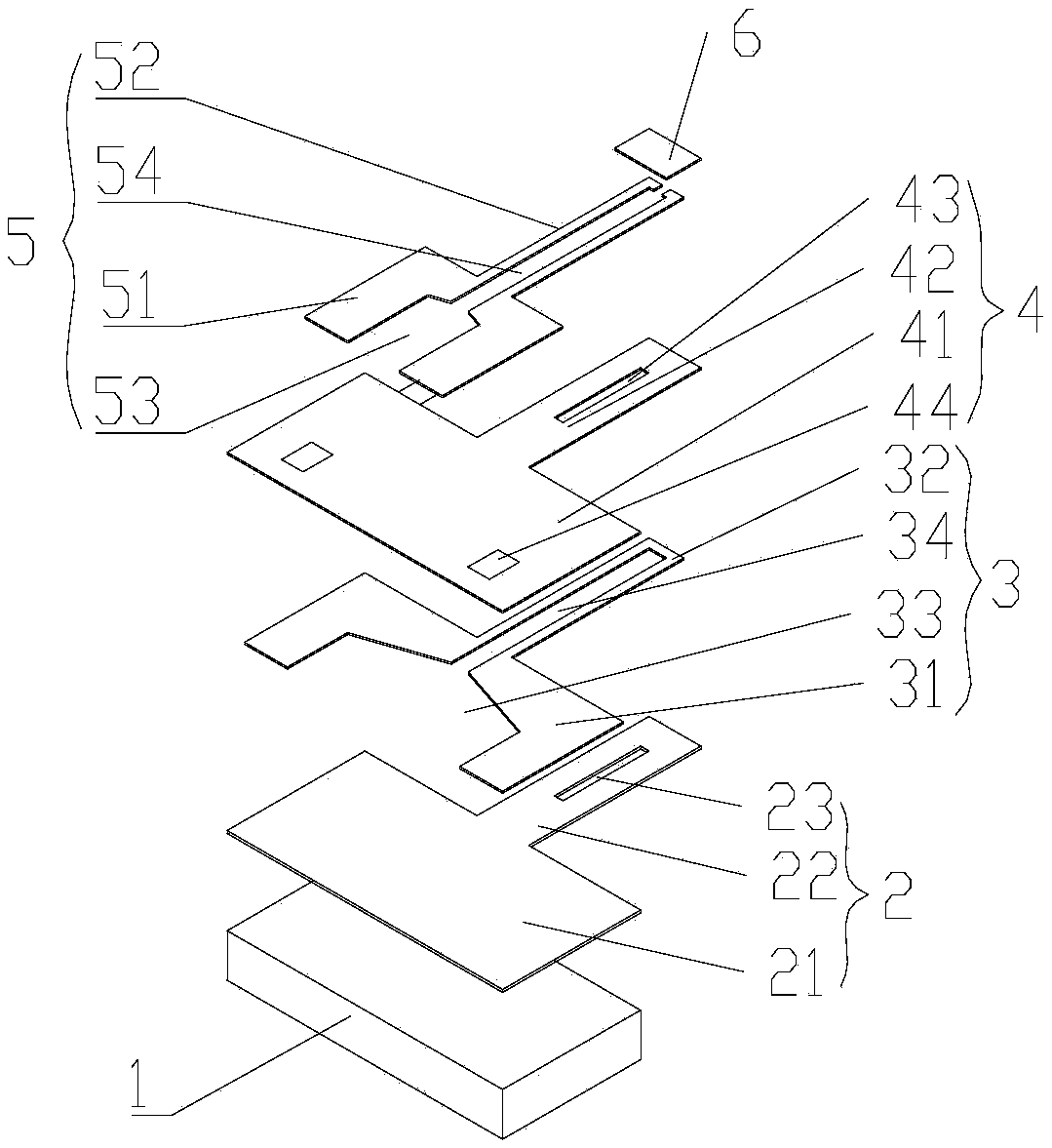

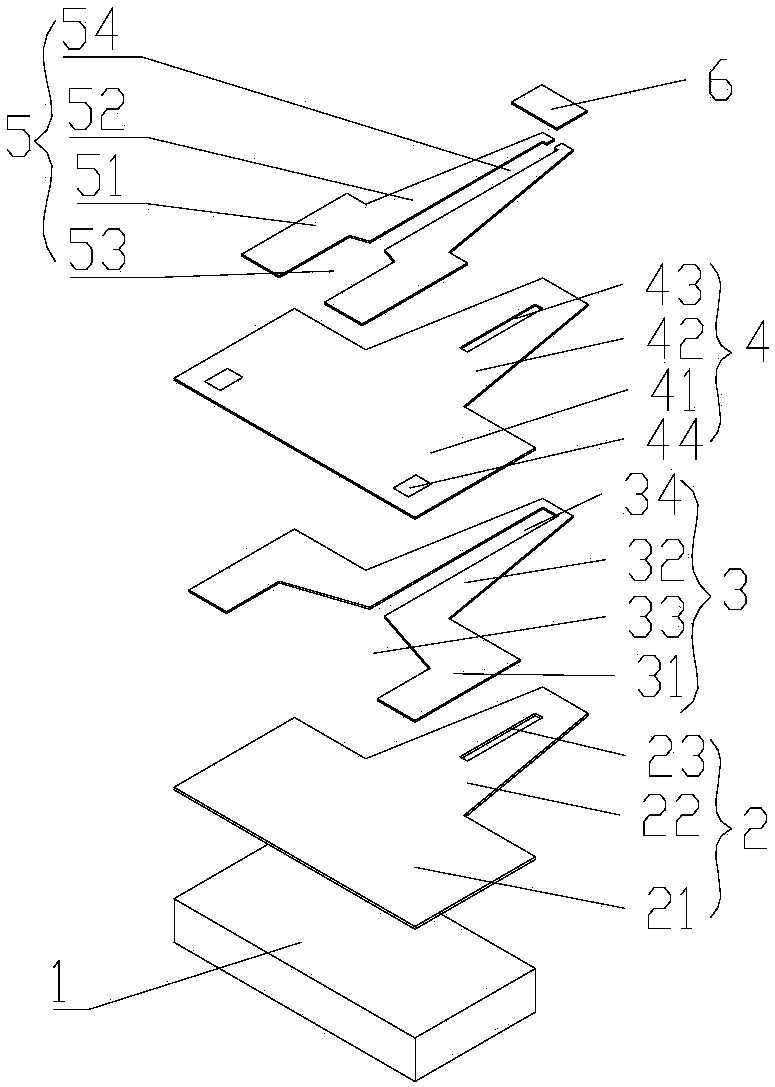

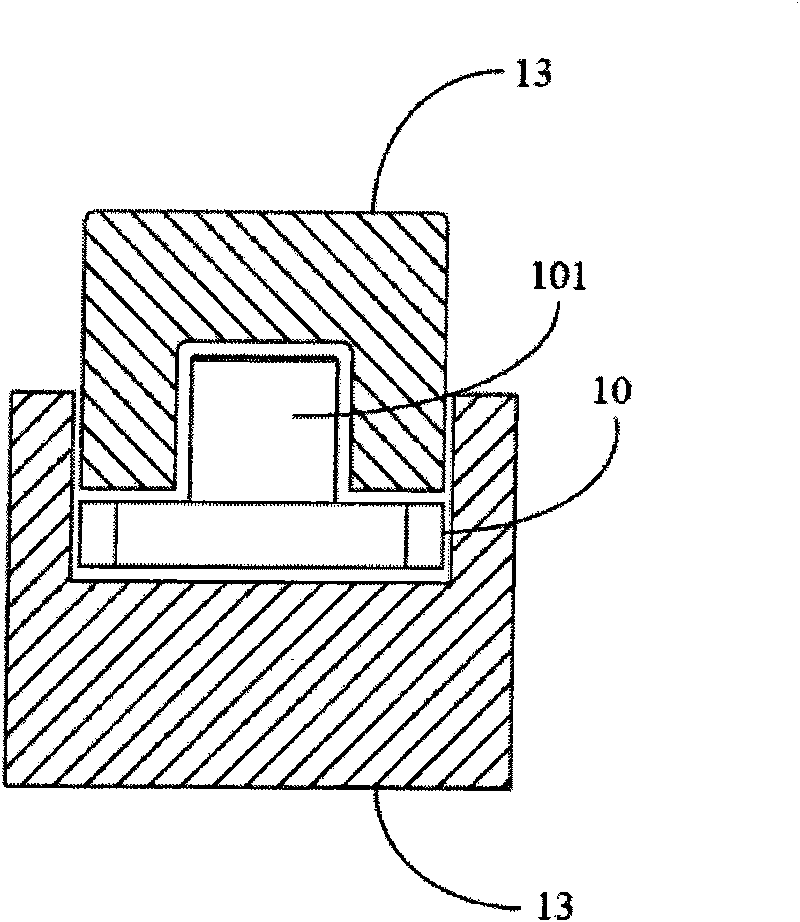

Single suspension beam gas sensor, sensor array and preparation method of sensor

PendingCN108318548ASimple processGood positioningMaterial resistanceAir quality improvementThin membraneMembrane configuration

The invention discloses a single suspension beam gas sensor which comprises a silicon substrate, a support membrane, a heating resistor, an isolation membrane and a detection electrode which are successively laminated in arrangement. The gas sensor takes on a T-shape and has a basal body structure and a suspension arm structure, and an end part of the suspension arm structure is provided with a gas sensitive material. The invention further provides a sensor array, which consists of the single suspension beam gas sensor, and a preparation method of the gas sensor, wherein the method comprises the following steps of (1) selection of the silicon substrate; (2) preparation of the support membrane; (3) preparation of the heating resistor; (4) preparation of the isolation membrane; (5) preparation of the detection electrode; (6) release of a thin membrane; and (7) loading of the gas sensitive material. The single suspension beam gas sensor has the advantages that the sensor is low in power consumption, small in size, high in integration level, simple in production process and easy to locate, and improves the production efficiency effectively.

Owner:HEFEI MICRO NANO SENSING TECH CO LTD

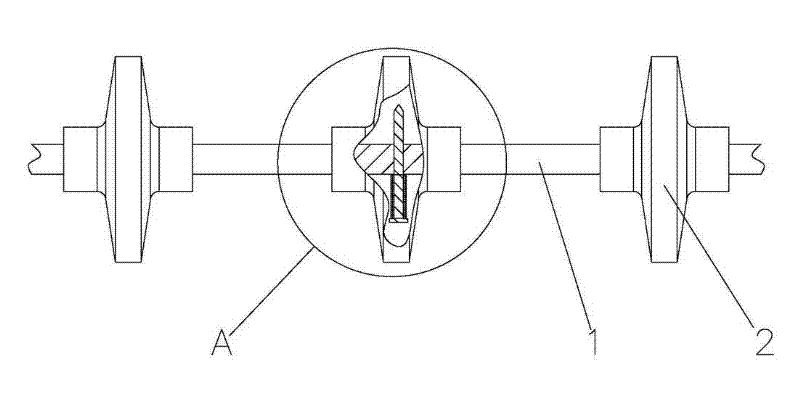

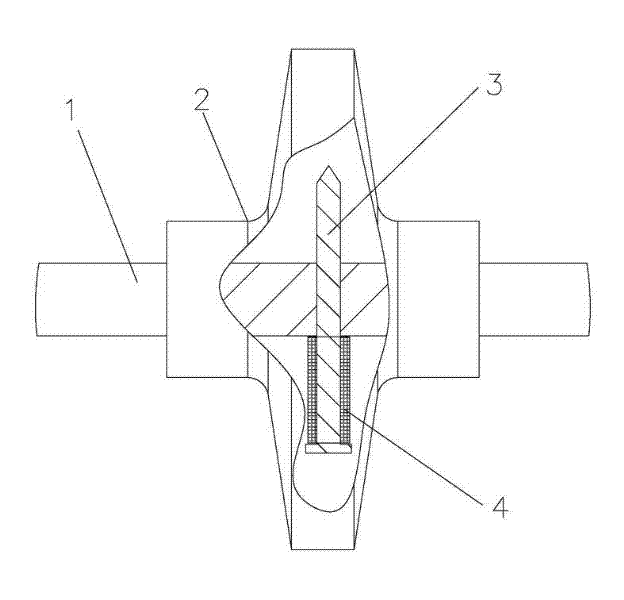

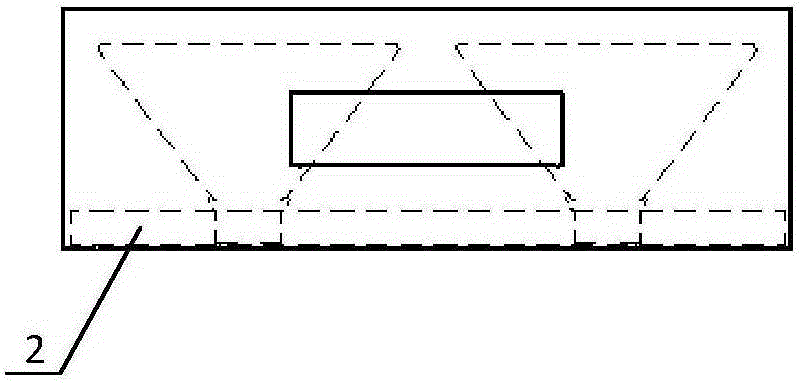

Cable disc structure and manufacturing method thereof

The invention discloses a cable disc structure, which comprises a steel cable and feeding discs. The feeding discs are fixed on the steel cable at the same interval through injection molding, and a nail is arranged in each feeding disc and penetrates through the steel cable. The invention further discloses a manufacturing method of the cable disc structure, which includes: preparing an injection molding machine which is provided with a punching workstation for punching the nails to penetrate through the steel cable and an injection molding workstation for molding the feeding discs in an injection manner, setting holes for holding the nails and a groove for holding the steel cable on a mold, enabling one nail to penetrate through the steel cable, forming the feeding discs wrapping the nails in an integrated injection molding manner and circulating the above steps to complete manufacturing of an integral cable disc. The cable disc structure has the advantages of simple structure, high bearing tension, long service life, simplicity and convenience in manufacturing process and high production efficiency.

Owner:广东广兴牧业机械设备有限公司

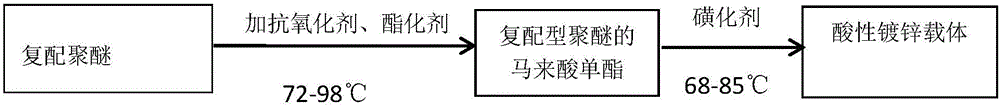

Acidic zinc-plated carrier and a preparation method and application thereof

The invention discloses an acidic zinc-plated carrier and a preparation method and application thereof. The preparation method of the acidic zinc-plated carrier includes the following steps that an antioxidant and maleic anhydride are added to compound polyether under the temperature condition of 72-98 DEG C, heat preservation and esterification are performed for 2.5-5.5 hours to obtain maleic monoester of the compound polyether, and sulfonation is performed under the temperature condition of 68-85 DEG C to obtain the acidic zinc-plated carrier. The naphthol blocked polyether with a special structure is used as a main raw material and is supplemented with isomeric alcohol ethoxylates, linear alcohol ethoxylates and alkylphenol ethoxylates, and the obtained acidic zinc-plated carrier is free-cloud-point and low-foam and has strong blocking capability.

Owner:WUHAN OXIRAN SPECIALTY CHEM CO

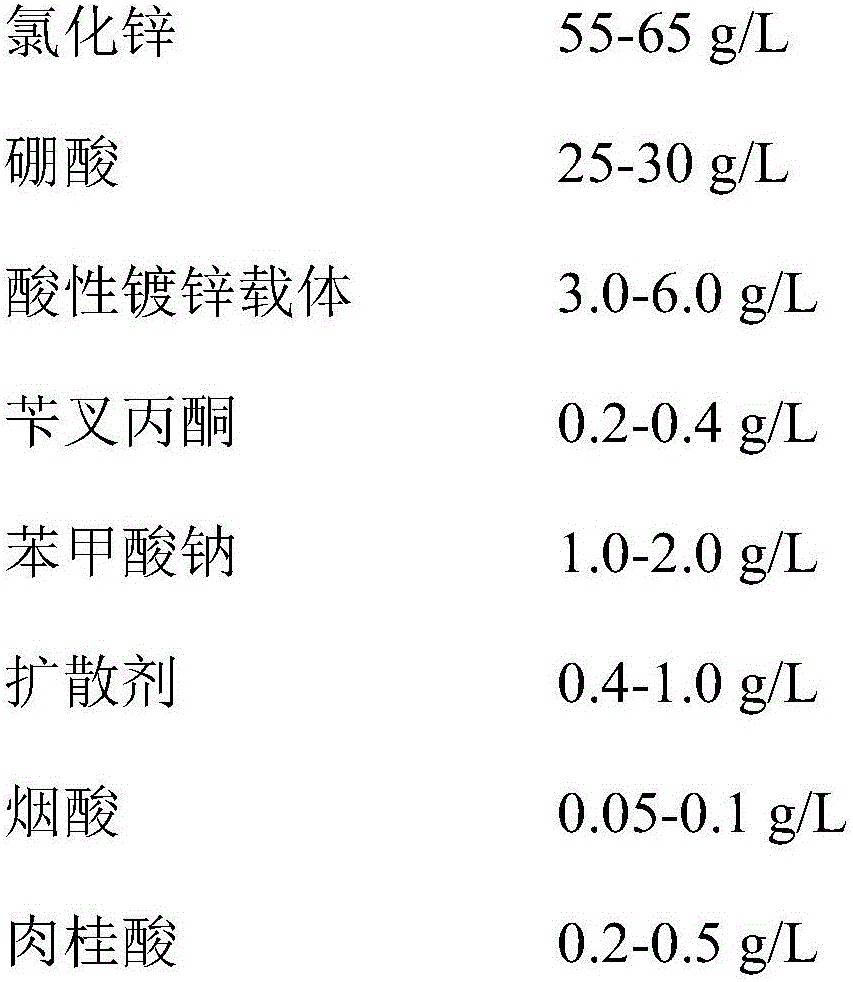

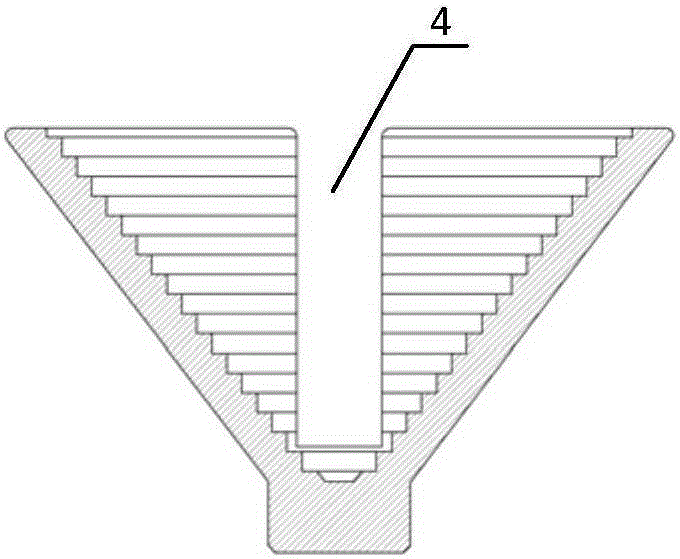

High-efficiency packing for counter flow cooling tower

The invention discloses high-efficiency packing for a counter flow cooling tower. The packing is combined by a plurality of waveform packing sheets, and a corresponding thermal mass exchange zone is formed on each packing sheet, wherein the packing sheets are of ladder shaped waveform, and are crossed and overlapped to form a packing body; and a fluid channel is formed among waveforms of the packing sheets. By the high-efficiency packing, the relationship between the specific surface area of the packing and the resistance is optimized, and assembly blocks are adhered by glue, so the packing is convenient to assemble.

Owner:SHANGHAI KING SUN COOLING EQUIP

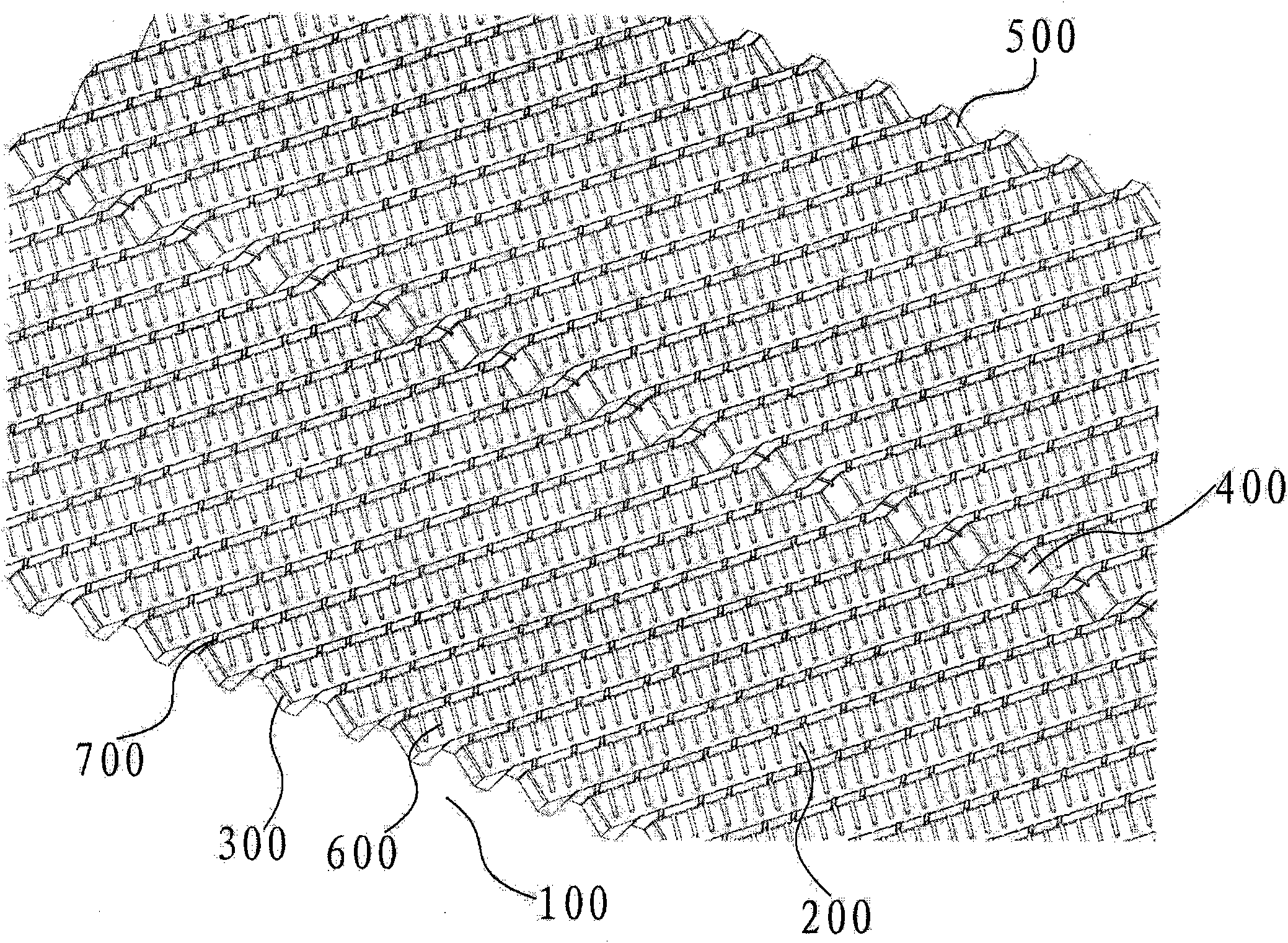

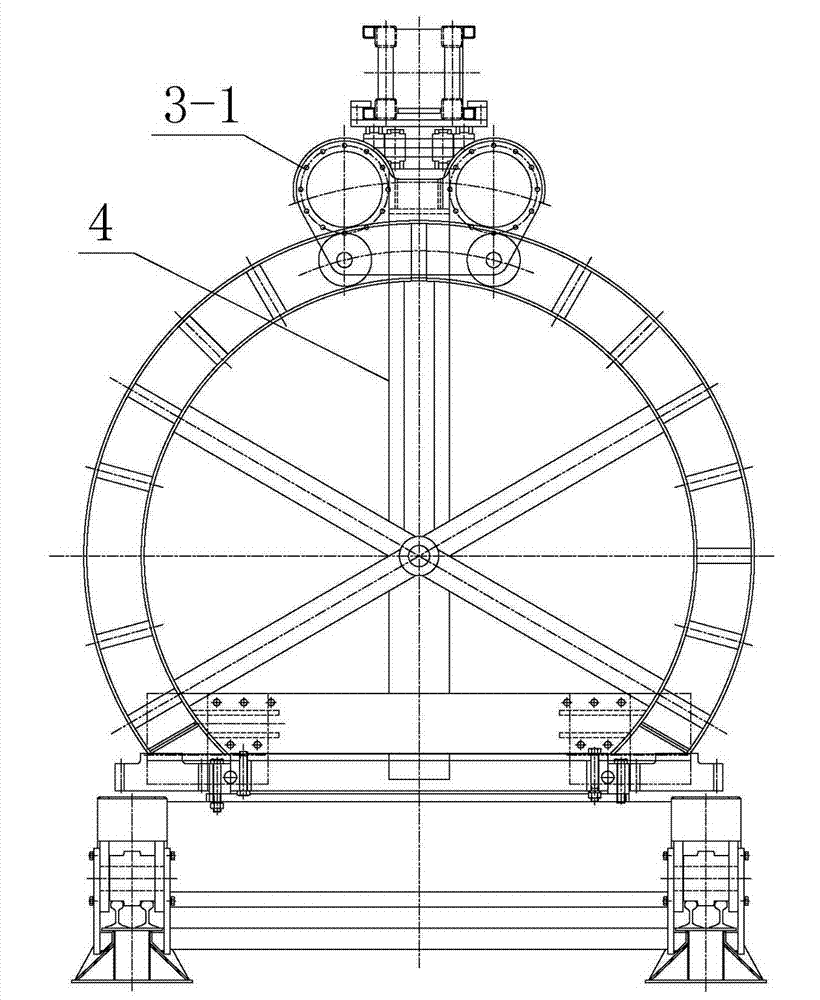

Special drilling machine for horizontal rotary spraying construction

ActiveCN104763330AHigh positioning accuracyGood positioningDerricks/mastsDirectional drillingDrilling systemStructural engineering

The invention provides a special drilling machine for horizontal rotary spraying construction. The special horizontal rotary spraying drilling machine for construction comprises a drilling machine platform, a drilling system and a walking system. Slipping devices are arranged on a front arch ring and a rear arch ring of the drilling machine platform and drive the drilling system arranged on a tower to move along the front arch ring and the rear arch ring, and then a drill pipe can be quickly and accurately positioned. The walking system moves a drilling machine to a working face or out of the working face through a walking device and an auxiliary walking device. According to the special horizontal rotary spraying drilling machine for construction, single-point positioning of a traditional rotation center shaft type horizontal rotary spraying drilling machine is changed into two-point positioning, and positioning is more efficient and more accurate; moreover, the tower of the drilling system is divided into two parts, transportation is facilitated, the function of setting one-time allowed drilling length is increased, and deformation of equipment is avoided; meanwhile, the drilling machine platform, the drilling system and the walking system are ingeniously combined, the flexibility and convenience of movement of the equipment are improved, and repeated dismounting and mounting of the equipment are avoided. The a special horizontal rotary spraying drilling machine for construction can be widely applied to construction operation such as horizontal rotary spraying and advance grouting in tunnels.

Owner:BEIJING SHOUER ENG TECH

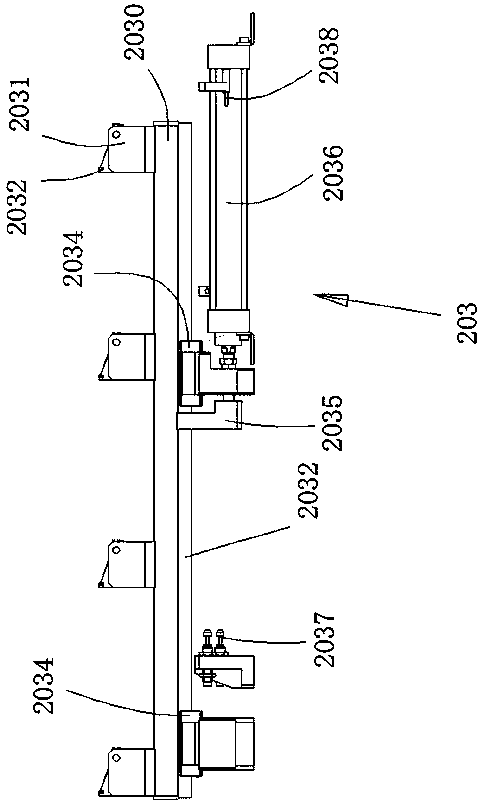

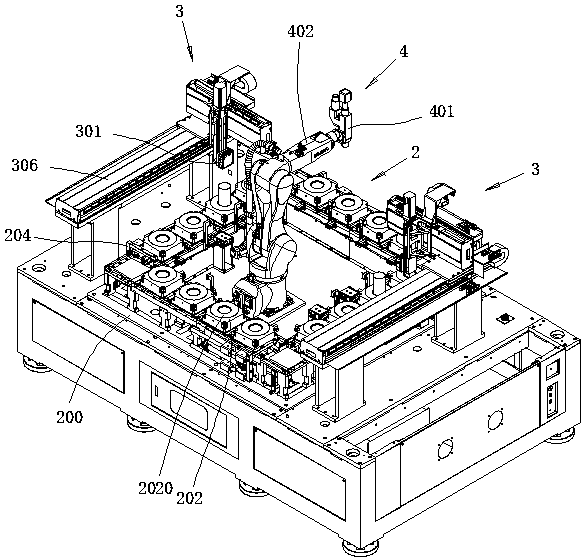

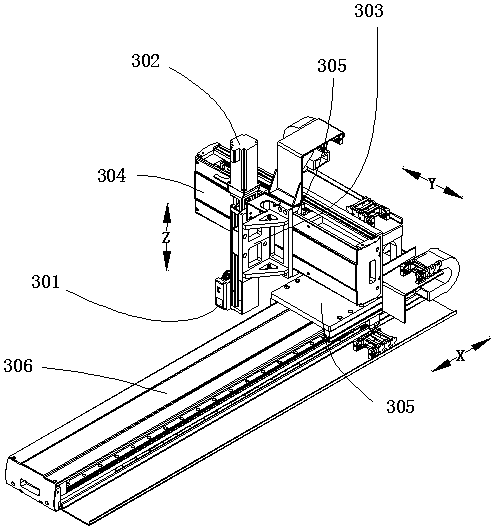

Welding method for welding seam of metal vacuum cup port and automatic welding equipment thereof

ActiveCN107598377AGood positioningImprove weld smoothnessLaser beam welding apparatusWeld seamEquipment use

The invention discloses a welding method for a welding seam of a metal vacuum cup port and automatic welding equipment thereof. The welding method comprises the following steps of collecting of the welding seam data, screening of the welding seam data and controlling of welding. The automatic welding equipment using the method comprises a data measuring device, an automatic welding device and a four-power independent conveying one-way circulation device, and the automatic welding device is a laser welding device; the four-power independent conveying one-way circulation device is used for transporting and positioning a metal vacuum cup to be welded, and the four-power independent conveying one-way circulation device comprises a base 200 and conveying guiding rails 201; and a one-way drivingmechanism is arranged underneath the conveying guiding rails, and a rail changing mechanism of a sliding seat is arranged in the jointing part of the adjacent conveying guiding rails 201. According to the welding method for the welding seam of the metal vacuum cup port and the automatic welding equipment thereof, the welding quality and welding speed of the metal vacuum cup port can be improved,labor intensity is relieved, and the automatic welding equipment has extensive application market and huge economic benefits.

Owner:ZHEJIANG HAERS VACUUM CONTAINERS CO LTD

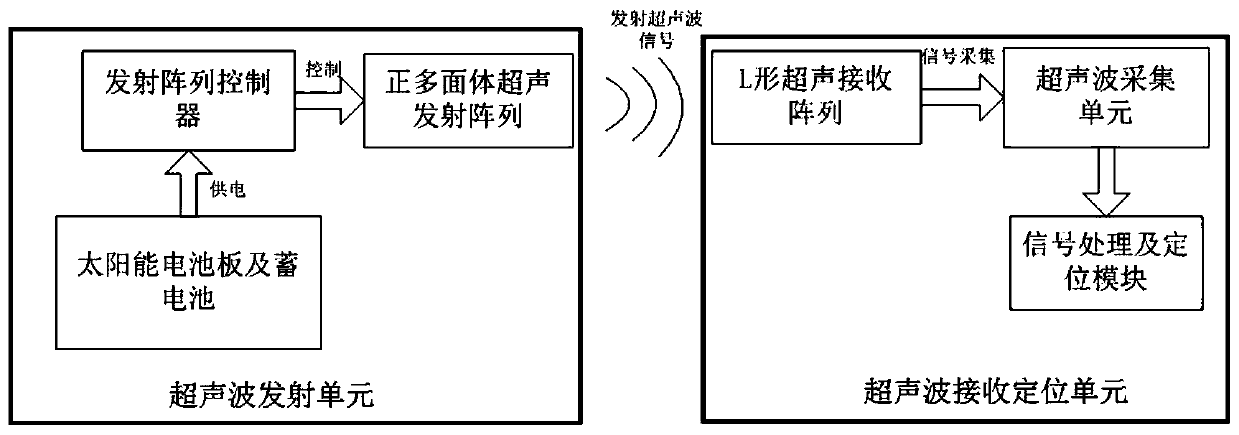

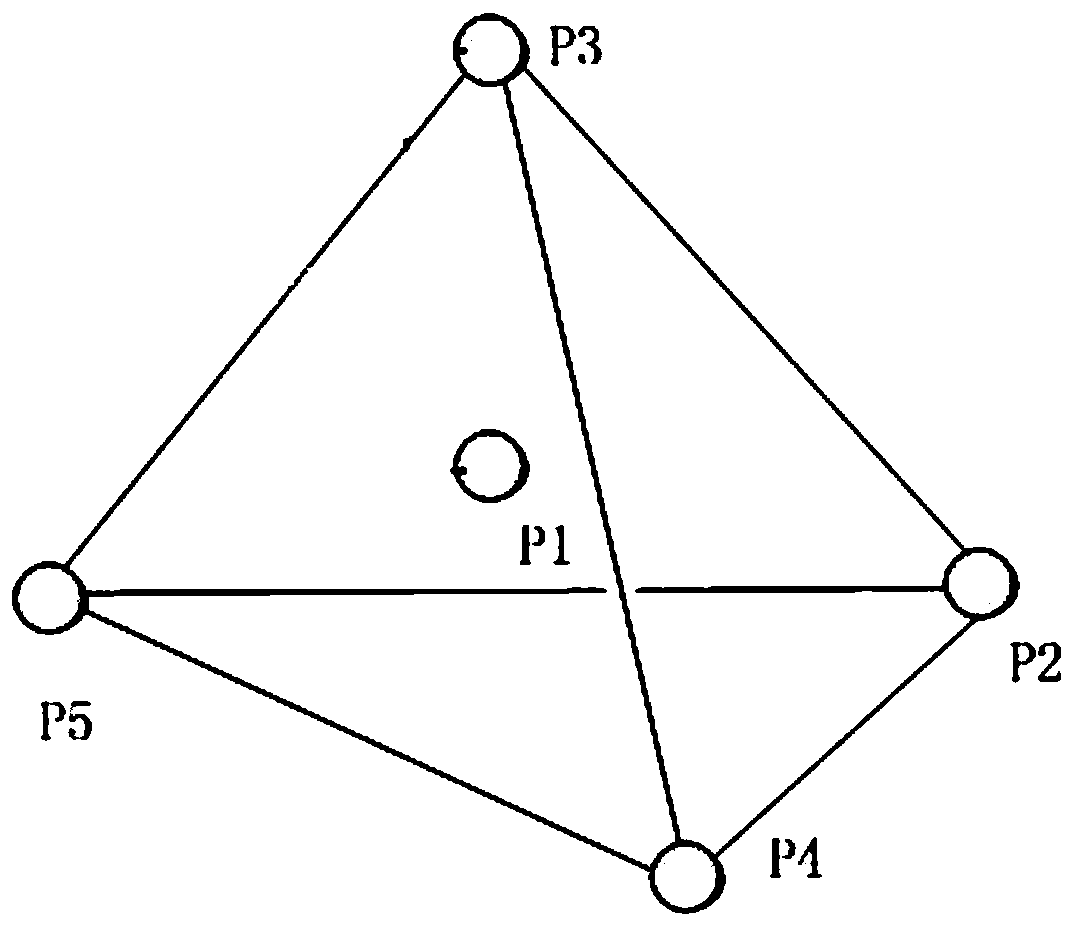

Ultrasonic positioning device for unmanned aerial vehicles and positioning method thereof

PendingCN109856592AGood positioningAchieve positioningBeacon systems using ultrasonic/sonic/infrasonic wavesSpecial designEngineering

The invention relates to an ultrasonic positioning device for unmanned aerial vehicles and a positioning method thereof. The positioning device comprises an ultrasonic transmitting unit installed on atransmission line tower and an ultrasonic receiving and positioning unit installed on an unmanned aerial vehicle. The ultrasonic transmitting unit comprises a regular polyhedral ultrasonic transmitting array, a transmitting array controller, a solar cell panel and a storage battery connected in turn. The ultrasonic receiving and positioning unit comprises an L-shaped ultrasonic receiving array, an ultrasonic acquisition unit and a signal processing and positioning module connected in turn. Through the special design of the ultrasonic transmitting array and the receiving array, the communication between the transmitting part and the receiving and positioning part is not needed. The transmitting part transmits signals all the time, and the receiving part installed on the unmanned aerial vehicle can complete positioning only by receiving signals. Therefore, positioning is realized efficiently.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

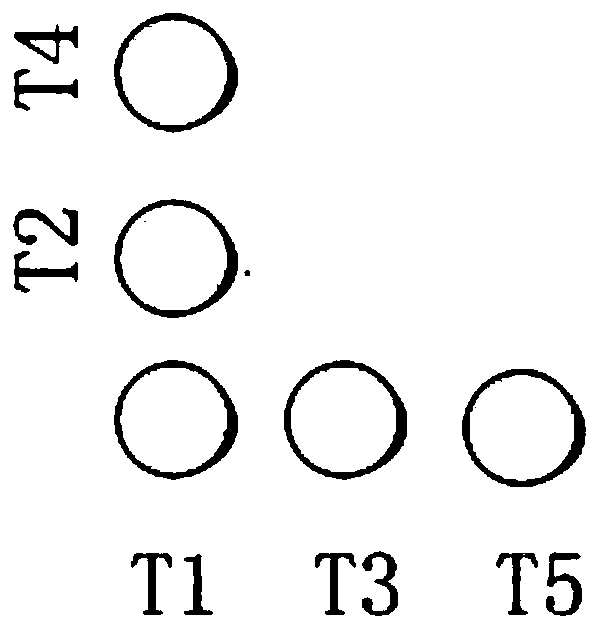

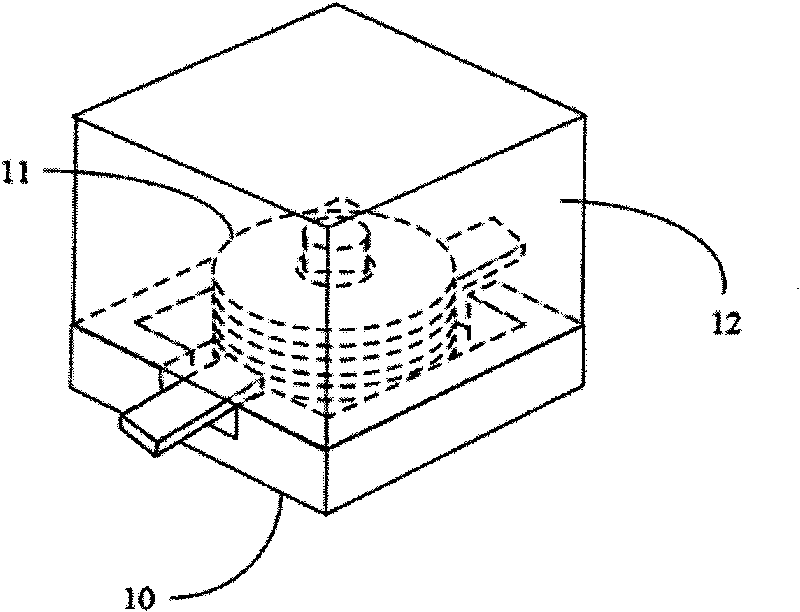

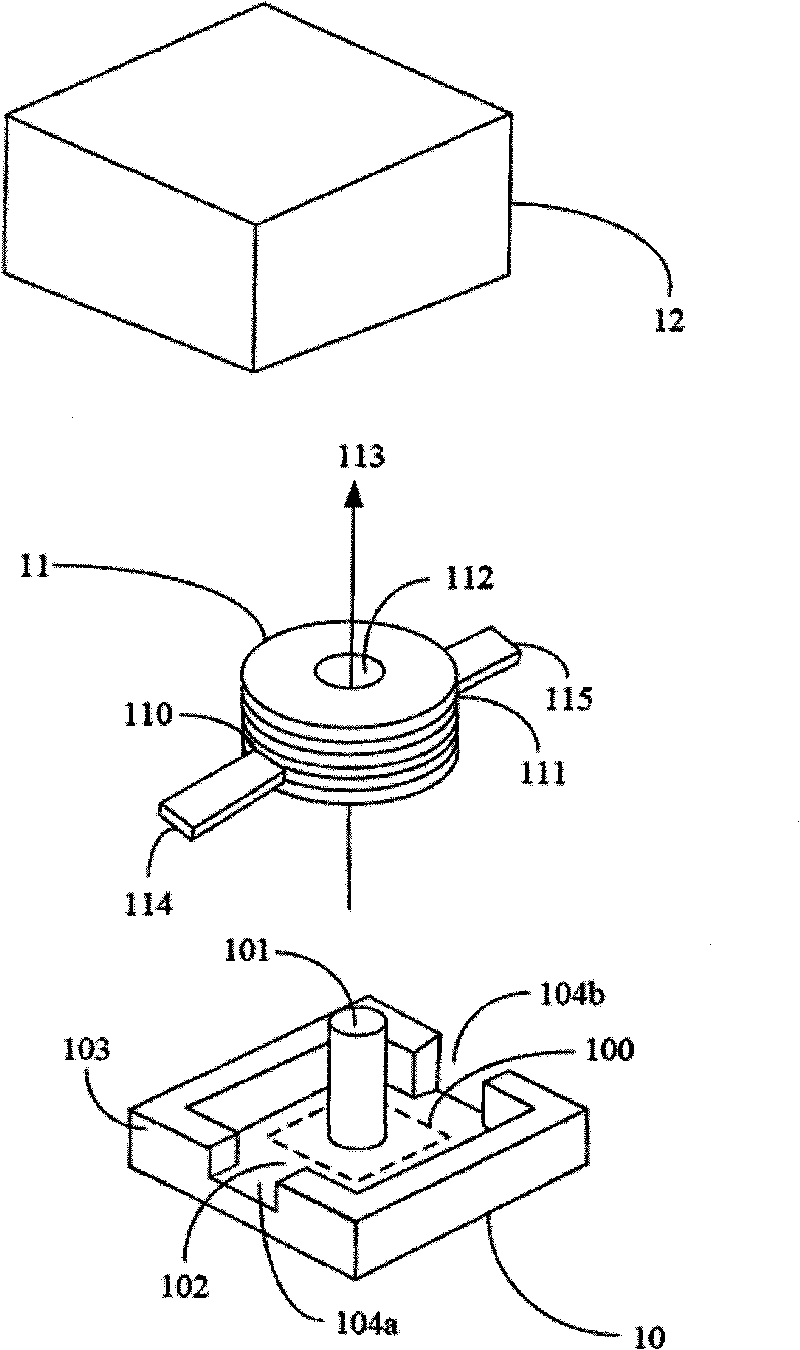

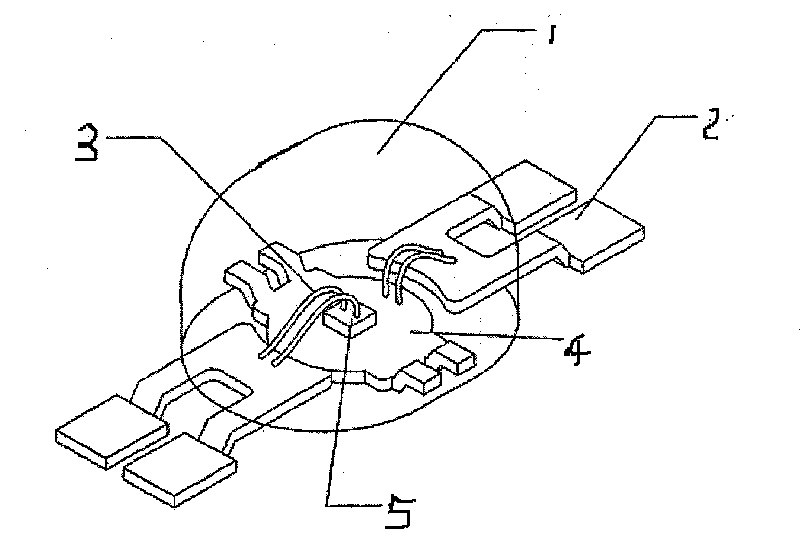

Method for manufacturing sectioned die casting inductor

InactiveCN101728057AGood inductance characteristicsIncrease magnetic fluxTransformers/inductances coils/windings/connectionsInorganic material magnetismHigh densityDie casting

The invention relates to a method for manufacturing sectioned die casting inductor and is characterized by firstly applying high pressure manufacture procedure on primary magnetic material to form a seat, of which the central area is provided with a center pillar; then providing a metal ring comprising a hollow part, penetrating the center pillar through the hollow part of the metal ring to combine the metal ring and the seat; embedding the seat combined with the metal ring into an encapsulation molding die; filling secondary magnetic material by high pressure manufacture procedure to form an encapsulation structure on the metal ring and the seat so as to finally form a die casting inductor structure. By adopting the invention, the seat and the center pillar supply best bearing force and positioning action to the overall formation of the inductor, thus avoiding the defect that extrusion and deformation easily appearing in the formation of the encapsulation structure worsens the properties of the inductor; meanwhile, the center pillar formed by high density magnetic materials can further increase magnetic flux of the metal ring, so that the metal ring has better inductance property.

Owner:TRIO TECH SUZHOU

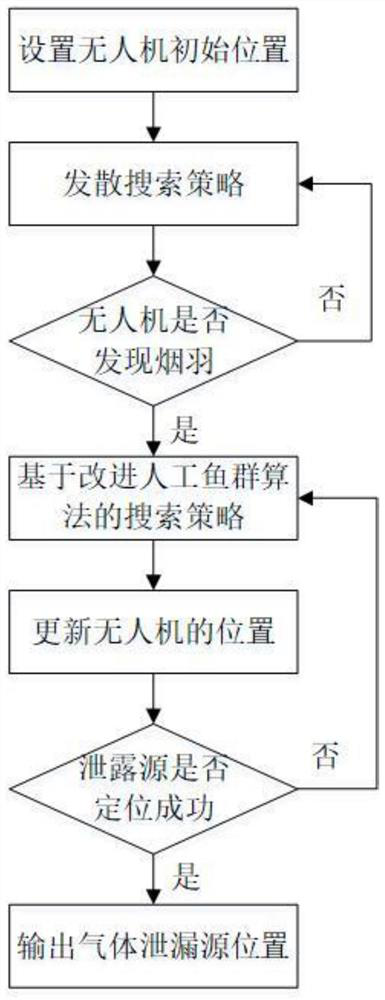

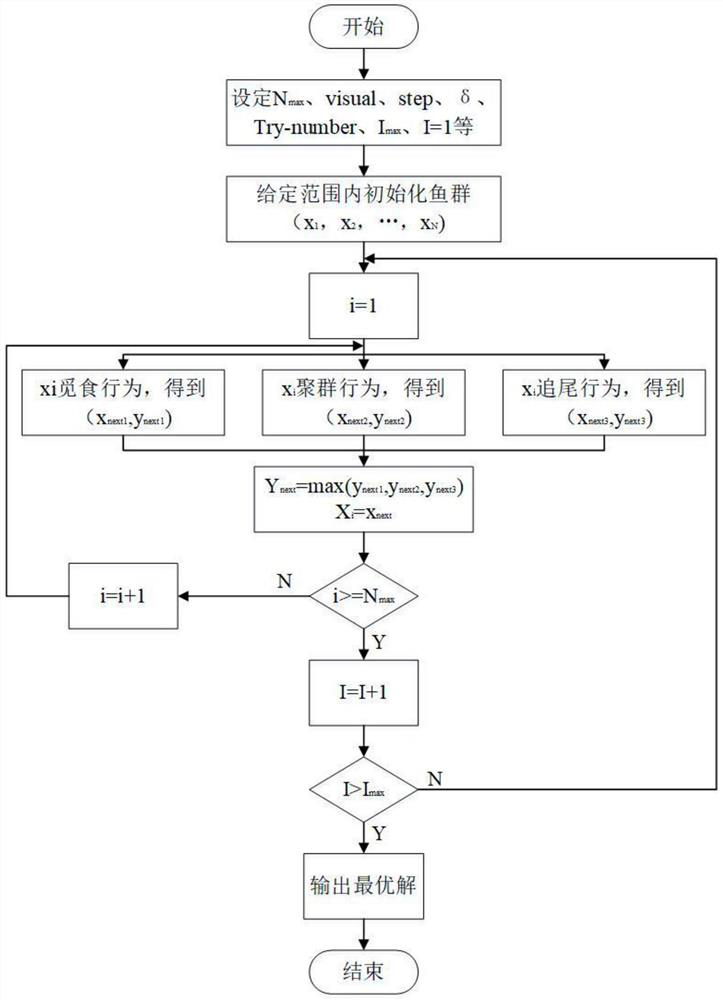

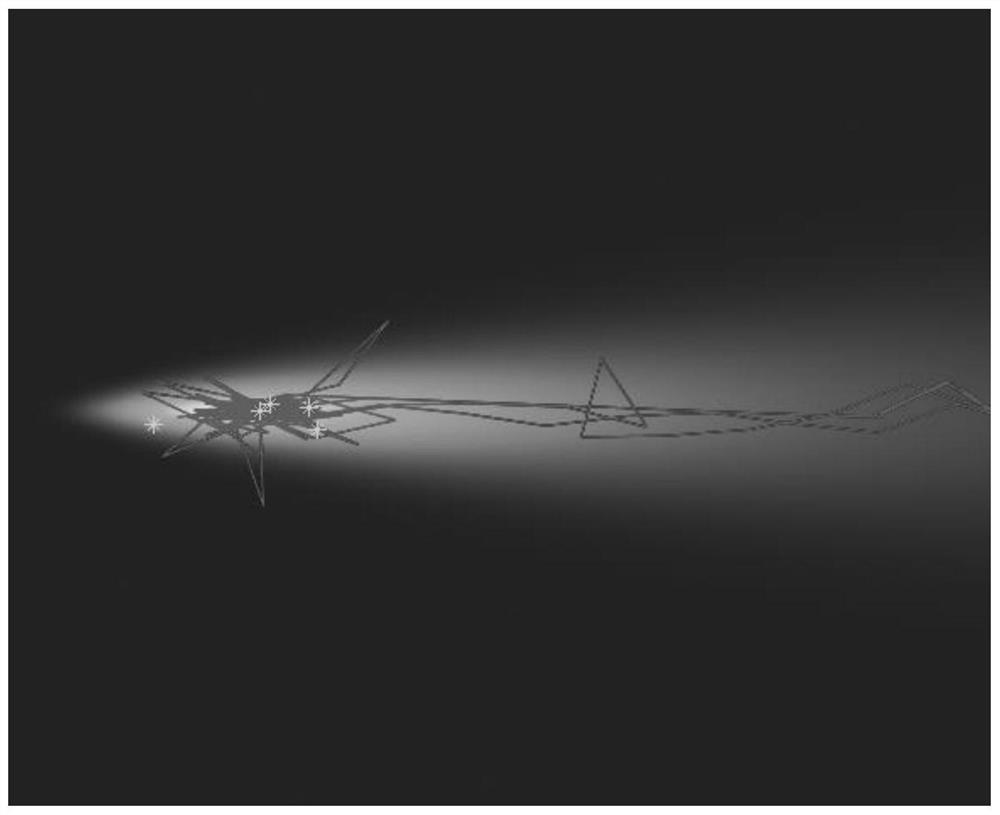

Gas leakage source positioning method based on improved artificial fish swarm algorithm

PendingCN112446457AGood positioningAvoid shock phenomenonDetection of fluid at leakage pointArtificial lifeSelf adaptiveSmoke plume

The improved artificial fish swarm algorithm is creatively combined with an unmanned aerial vehicle cluster, and rapid and efficient positioning of a gas leakage source is achieved. A traditional fixed monitoring network method has limitation and is difficult to meet the positioning requirement of an existing positioning gas leakage source, a system with multiple unmanned aerial vehicle clusters has the advantages of maneuverability, flexibility, wide monitoring range and the like, the defects of an existing fixed monitoring station can be overcome by using the system as an environment monitoring platform, and active tracking and positioning of the harmful gas leakage source are facilitated. According to the smoke plume search strategy, an improved artificial fish swarm algorithm is adopted, a curiosity model is introduced on the basis of the standard artificial fish swarm algorithm, the search visual field and the moving step length of the unmanned aerial vehicle can be adjusted in aself-adaptive mode, and algorithm defects caused by the fact that the visual field and the step length are constant values in the standard artificial fish swarm algorithm are avoided.

Owner:CHINA JILIANG UNIV

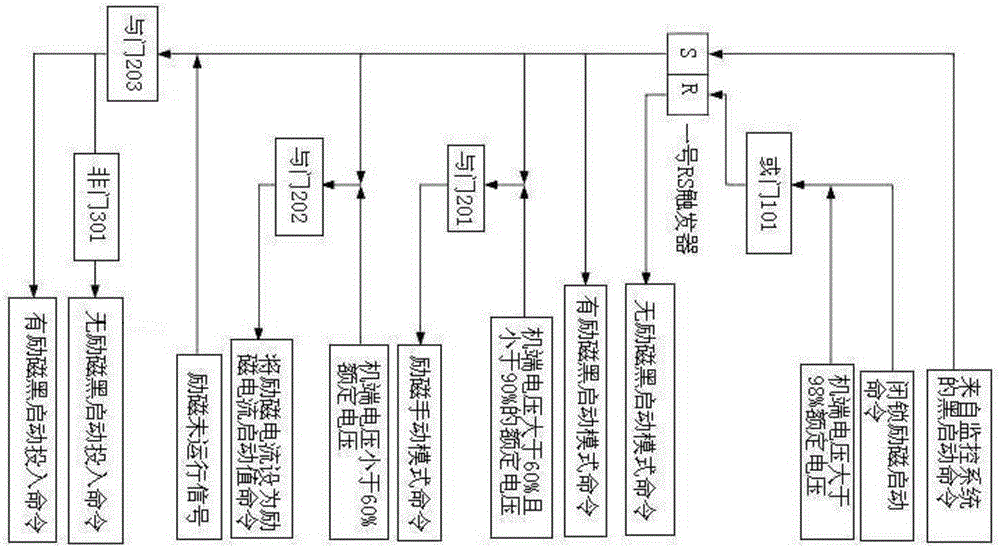

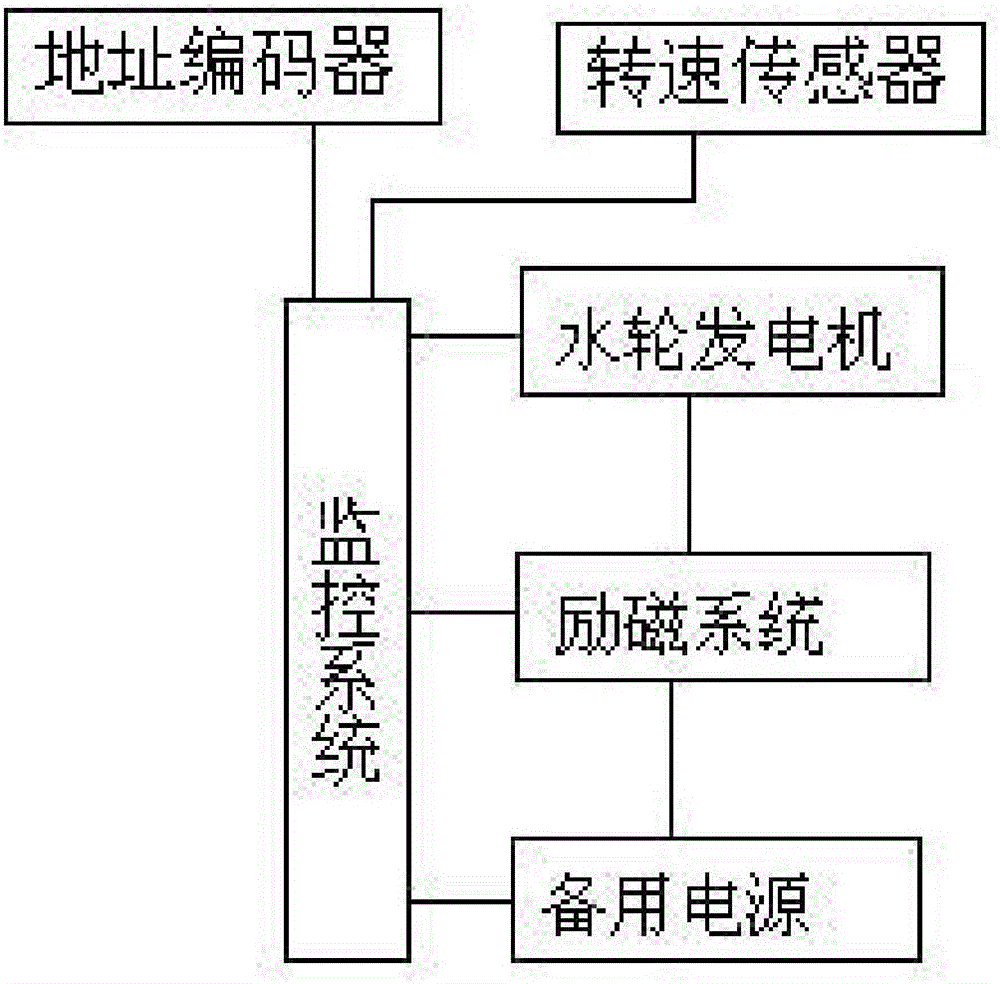

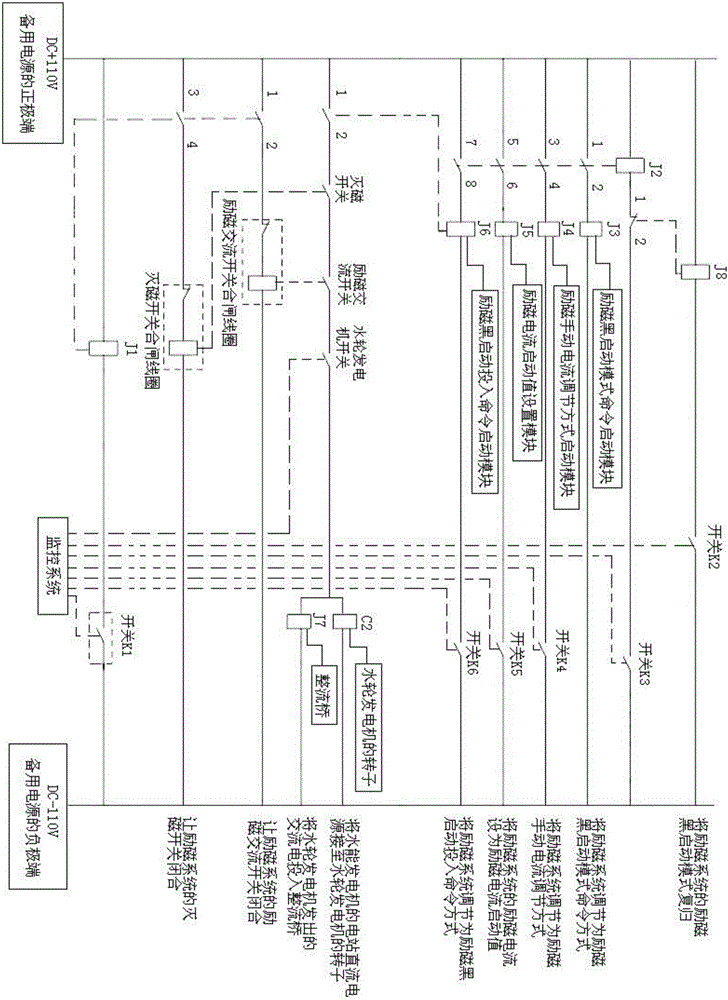

Black start control system and method for excitation system of pumped storage power station

The invention discloses a black start control system and method for the excitation system of a pumped storage power station and relates to the technical field of hydropower station black start. The black start control system and method solve a problem that a hydraulic generator can be automatically black started within preset time after being stopped by faults so as to rapidly restore the power supply of a power system, and are high in reliability and good in safety. The black start control system comprises a standby power supply, a monitoring system, an excitation system, and a hydraulic generator. The standby power supply, the excitation system, and the hydraulic generator are connected with the monitoring system. The standby power supply and the hydraulic generator are connected with the excitation system. After the power system powered by the hydraulic generator is subjected to power outage, a generator set with a black start capability is started to generate power and further drive the hydraulic generator without a black start capability to generate power, thereby gradually restoring the whole power system.

Owner:STATE GRID CORP OF CHINA +2

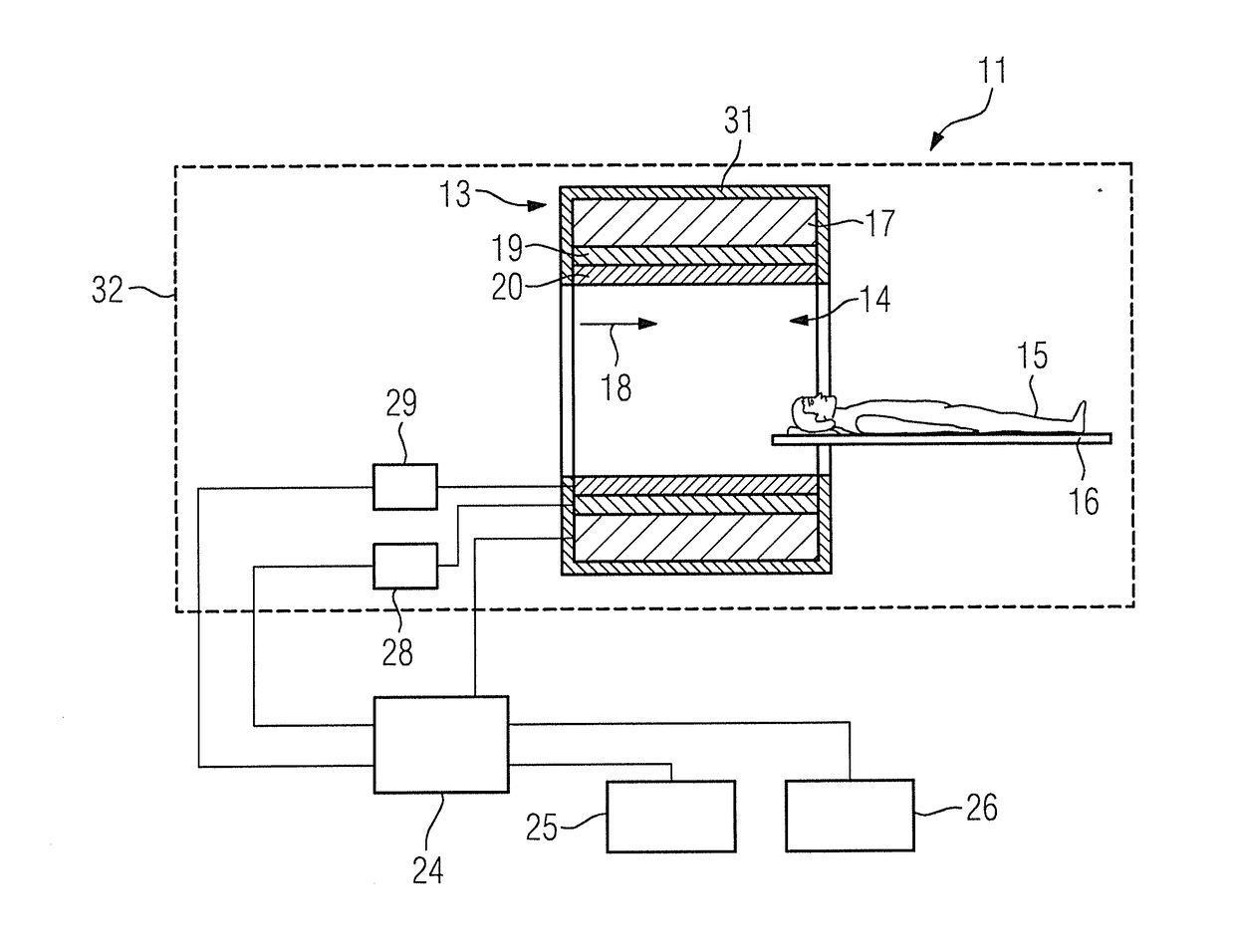

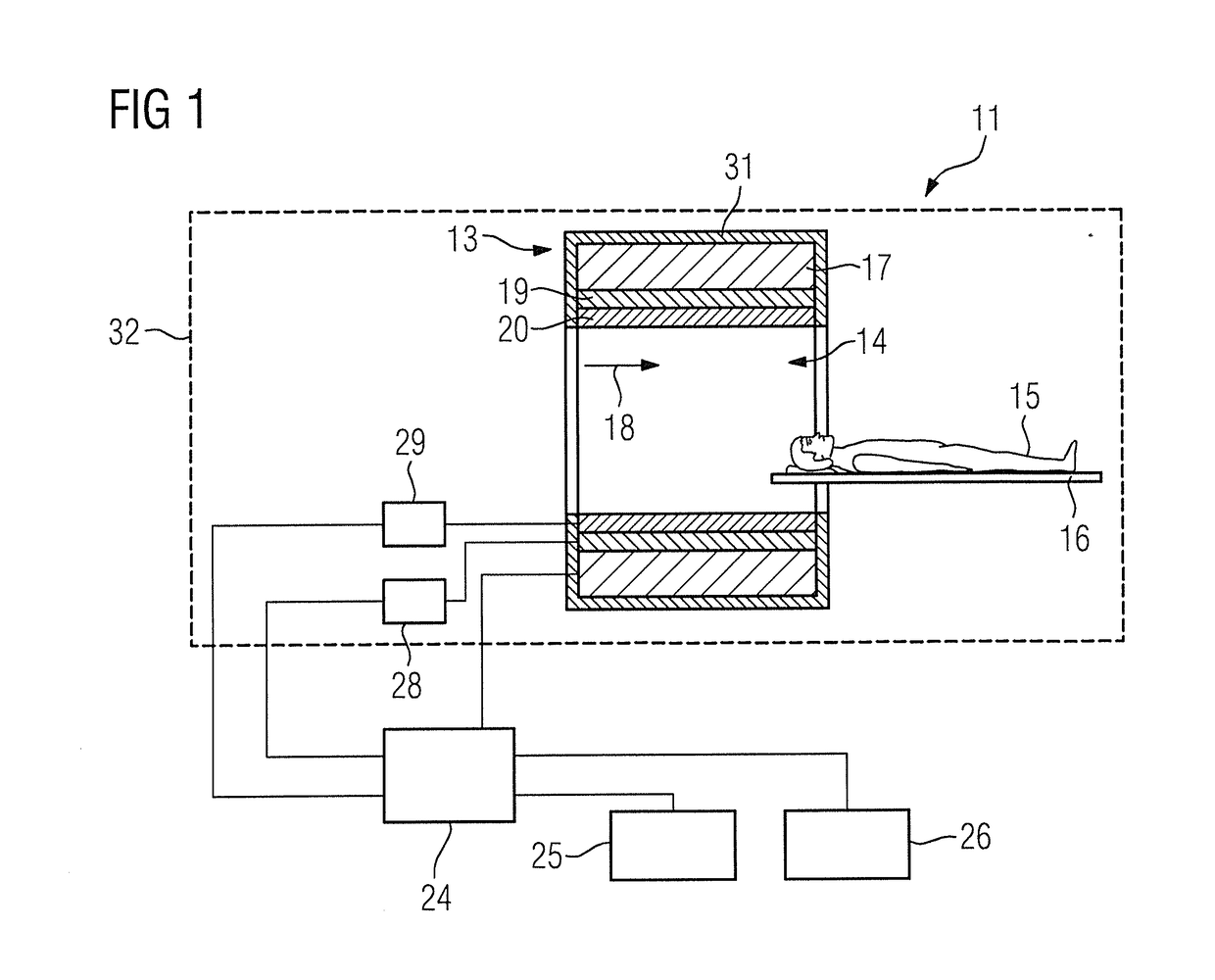

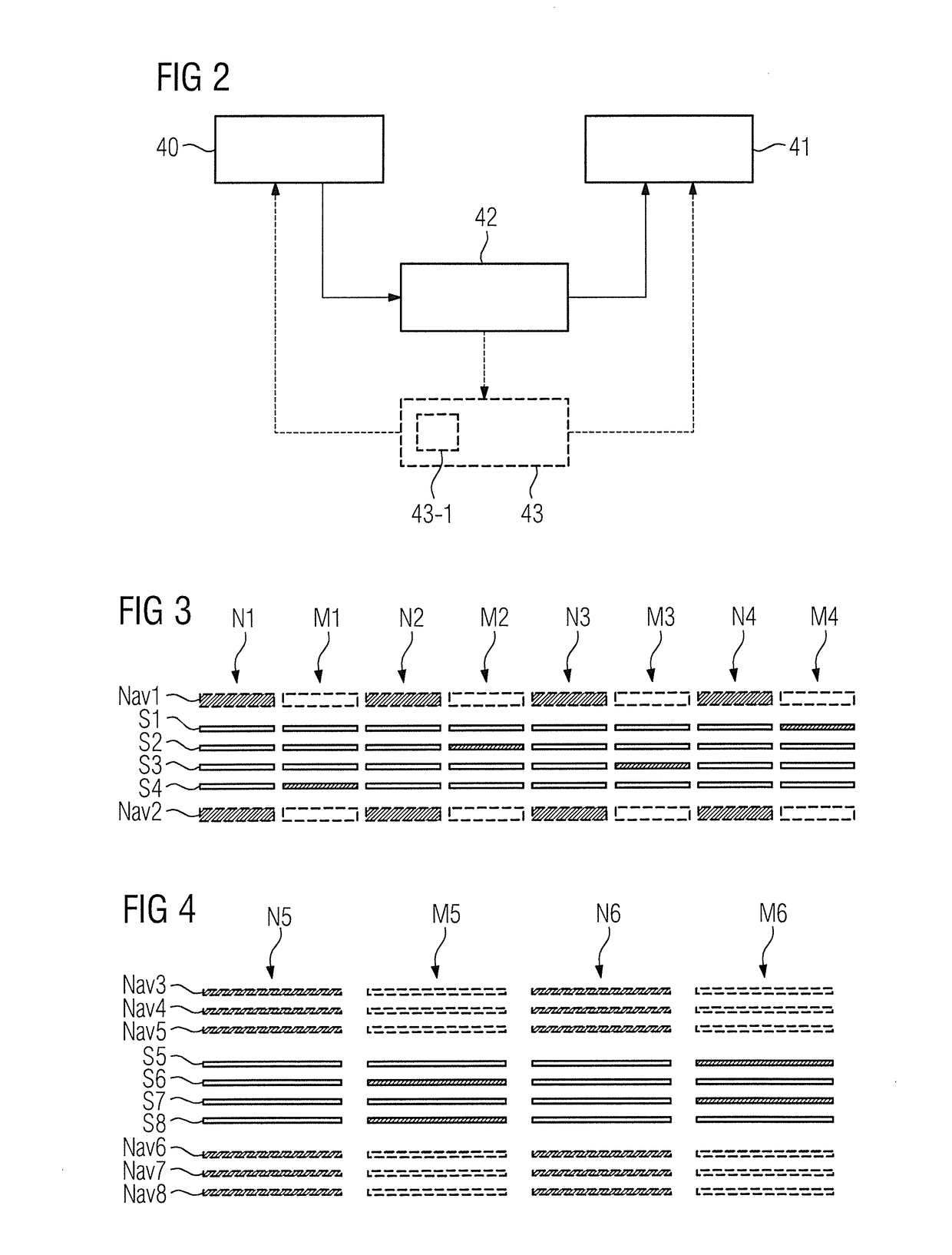

Method and apparatus for magnetic resonance imaging

ActiveUS20170205487A1Good compensationGood positioningMagnetic measurementsResonanceComputer science

In a method and apparatus for magnetic resonance imaging, a first diagnostic imaging scan is executed that includes a recording of first set of magnetic resonance scan data from a first subregion of an examination region, and a second diagnostic imaging scan is executed that includes a recording of a second set of magnetic resonance scan data from a second subregion of the examination region. A navigator scan is executed chronologically between the first diagnostic imaging scan and second diagnostic imaging scan, wherein the navigator scan includes a recording of at least two navigator slices arranged on opposite sides of the examination region.

Owner:SIEMENS HEALTHCARE GMBH

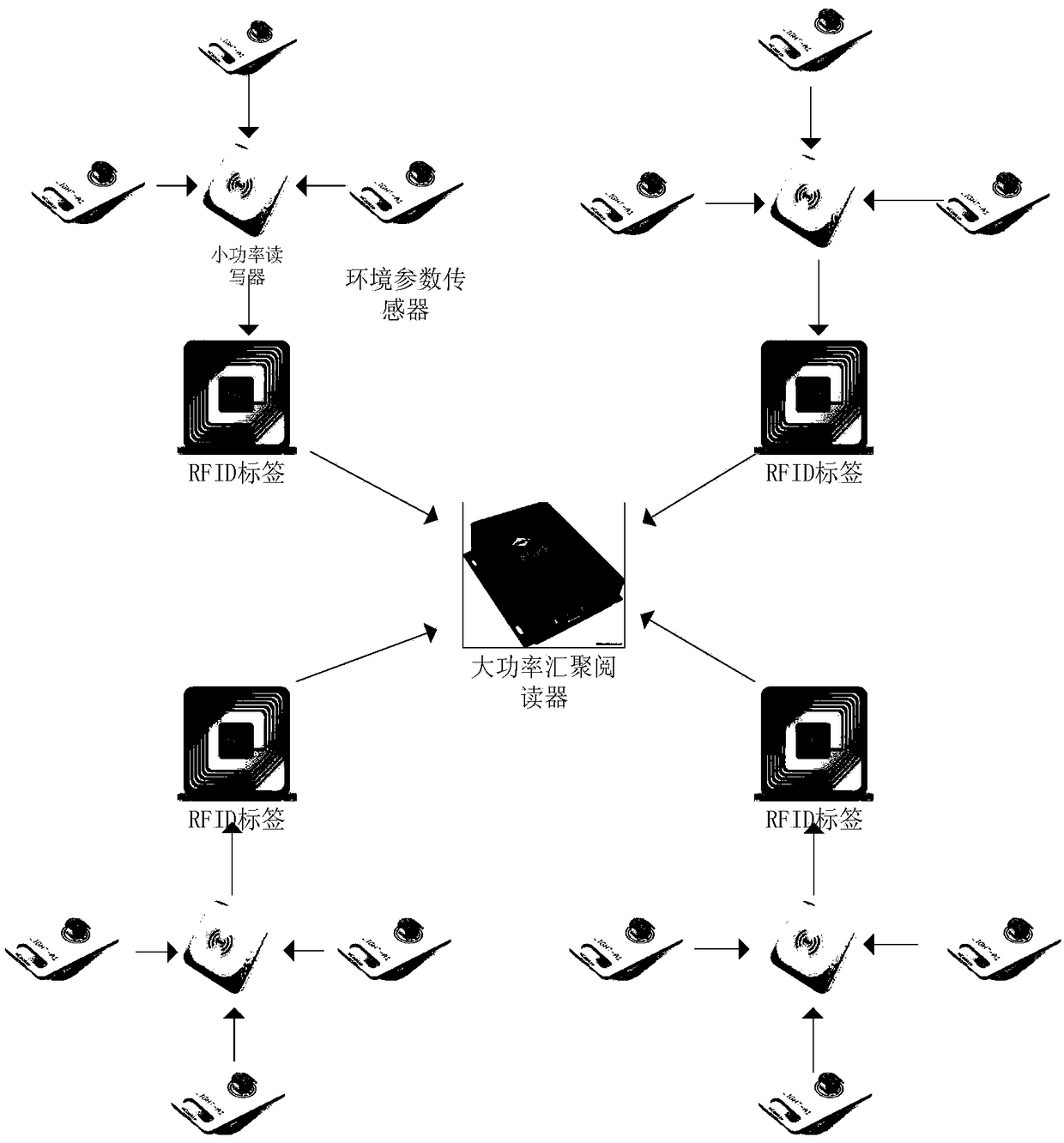

Data collection and device positioning method based on RFID under mine environment

ActiveCN108718443AImprove stabilityImprove reliabilityPower managementMining devicesData centerData acquisition

The invention discloses a data collection and device positioning method based on RFID under a mine environment. The method includes the steps of arranging a wireless sensor node network under the mineenvironment; positioning each mine device and mapping coordinates of sensor nodes in the wireless sensor network through RFID labels; collecting data of the sensor nodes within an identification range through a low-power RFID reader, then writing the data and the position information of the devices into data areas of the RFID labels, forwarding data of the data areas to a high-power RFID reader through the RFID labels, and transmitting the data to a background data center for analysis to achieve positioning of targets and monitoring of errors of the devices. Combined storage and forwarding ofdata are carried out through an RFID technology and a WSN technology, and the stability and reliability of data collection are improved. By using the RFID readers different in power, the purpose of reducing energy consumption is achieved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

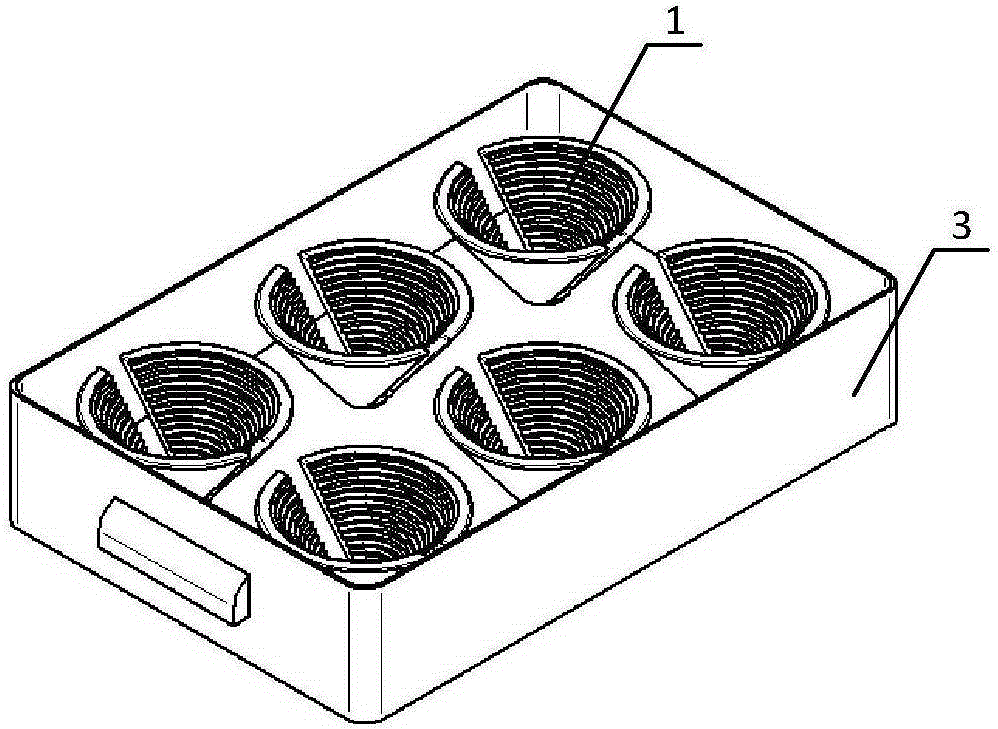

Protective device for avoiding optical lens surface scratch

The present invention provides a protective device for avoiding optical lens surface scratch, and the protective device can avoid scratch caused by the lens storage box carrying. The protective device mainly includes a box body, lens holders and a lens holder support. The lens holder support is putted in the box body, and the box body is provided with a dust cover. The inner wall of the lens holder is provided with multi-step annular stepped faces, wherein, the multi-step annular stepped faces are in a cone-shaped distribution mode on the whole, and the inner diameter of each step of the annular stepped faces is larger than the inner diameter of a non-work face of the optical lens to be putted so as to ensure the non-contact placement of the optical lens. The inner wall of the lens holder is symmetrically provided with a trough passing through the multi-step annular stepped faces so as to take out and put lens conveniently. The protective device has the simple structure and saves the space, a plurality of lens with various sizes can be putted in the same lens holder through the multi-step annular steps, and the optical lens can be exactly putted on the annular stepped face which is suitable for the outer diameter of the optical lens.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

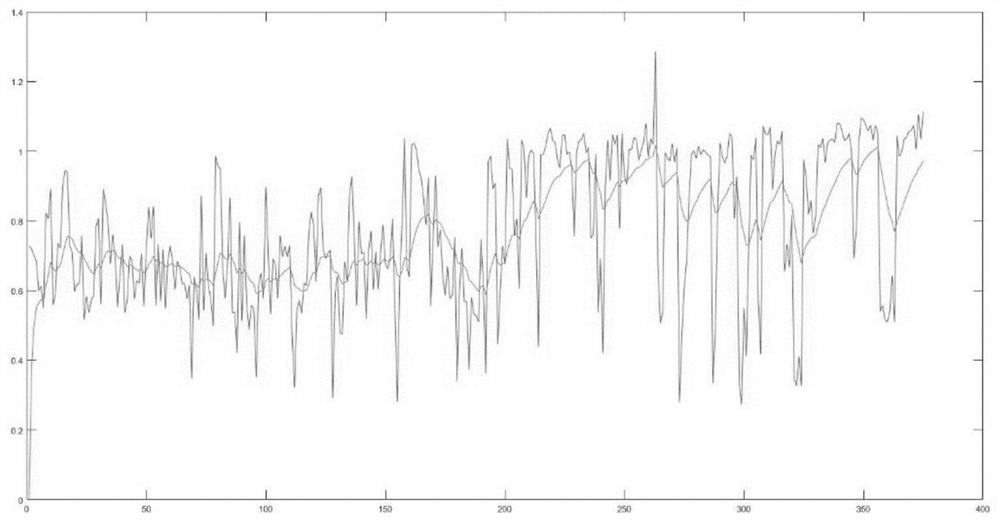

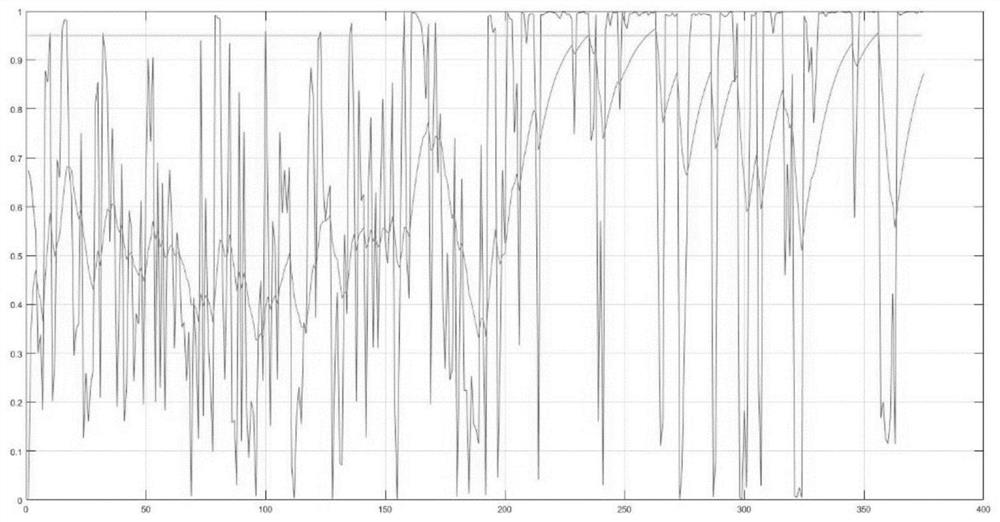

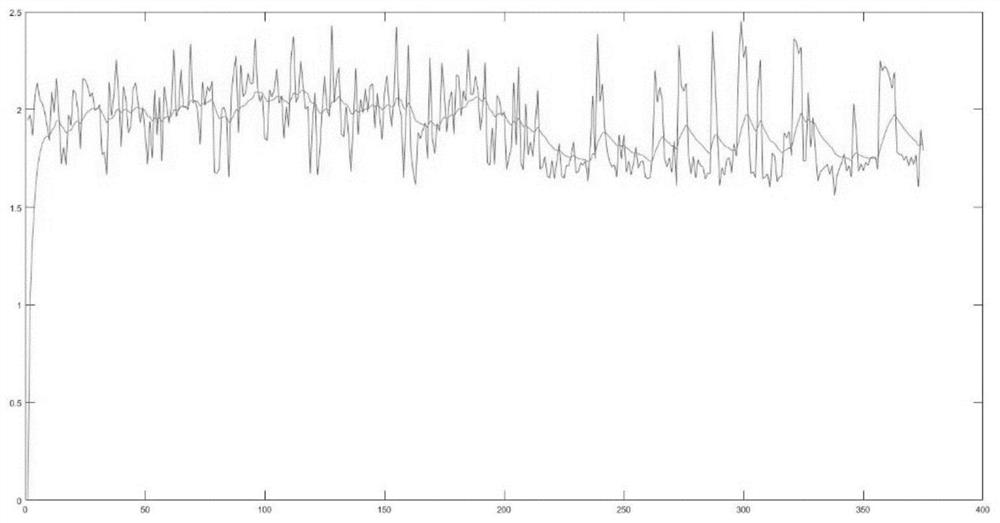

Wind generating set gearbox fault positioning method based on CMS system big data in combination with standard deviation and wavelet entropy

ActiveCN111721527AGood positioningMeet practical application requirementsMachine part testingAlgorithmIndustrial engineering

The invention discloses a wind generating set gearbox fault positioning method based on CMS system big data in combination with standard deviation and wavelet entropy. The method comprises the steps of 1) calculating the standard deviation of original vibration data and filtering; 2) establishing Gaussian model of the standard deviation of a normal interval, and judging whether fault occurs in thesystem or not by using the model, and 3) calculating wavelet entropy of the vibration data to judge the fault type. The method has the advantages that the positioning effectiveness is good, and the requirements of practical application are met.

Owner:ZHEJIANG UNIV OF TECH +1

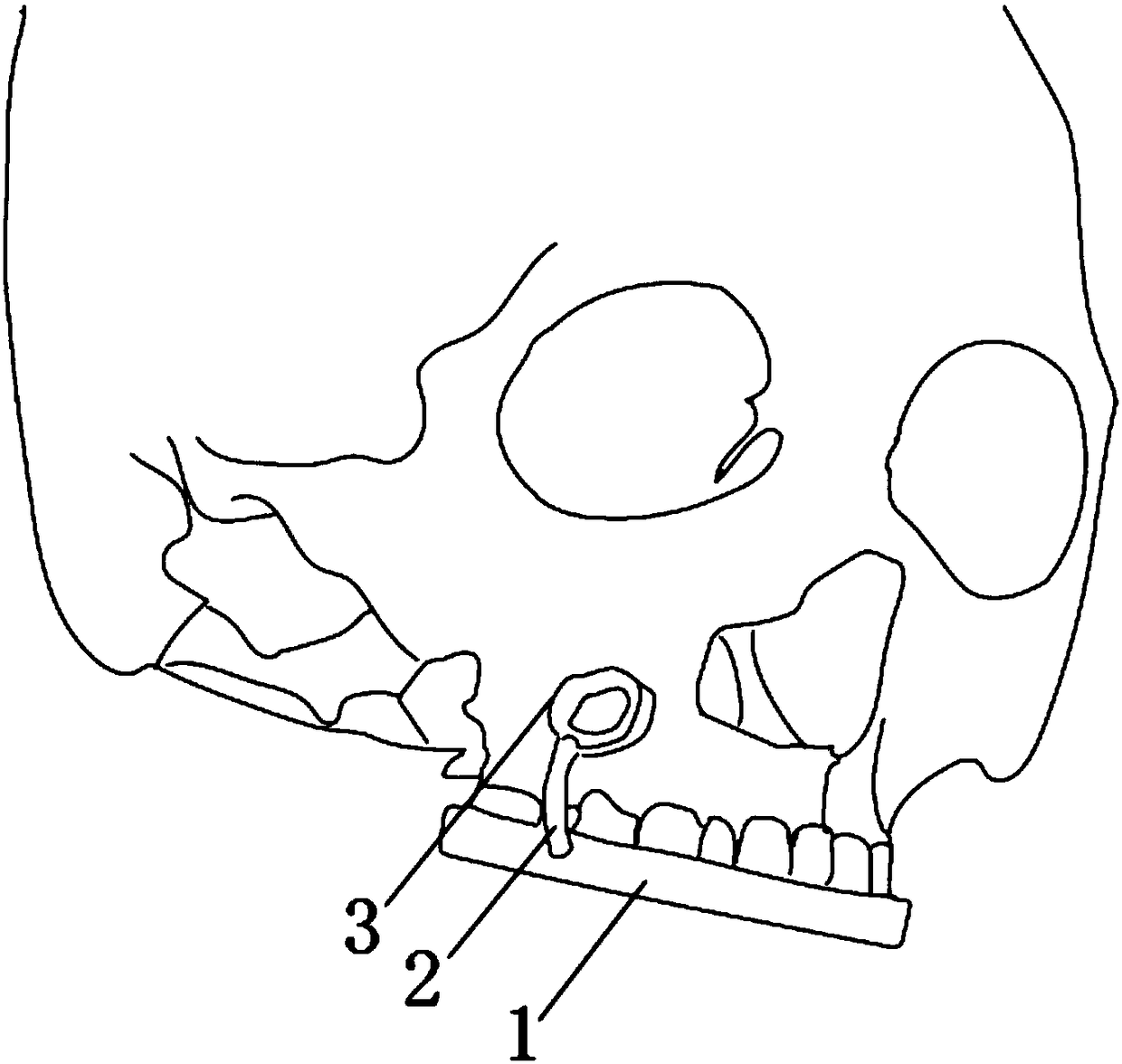

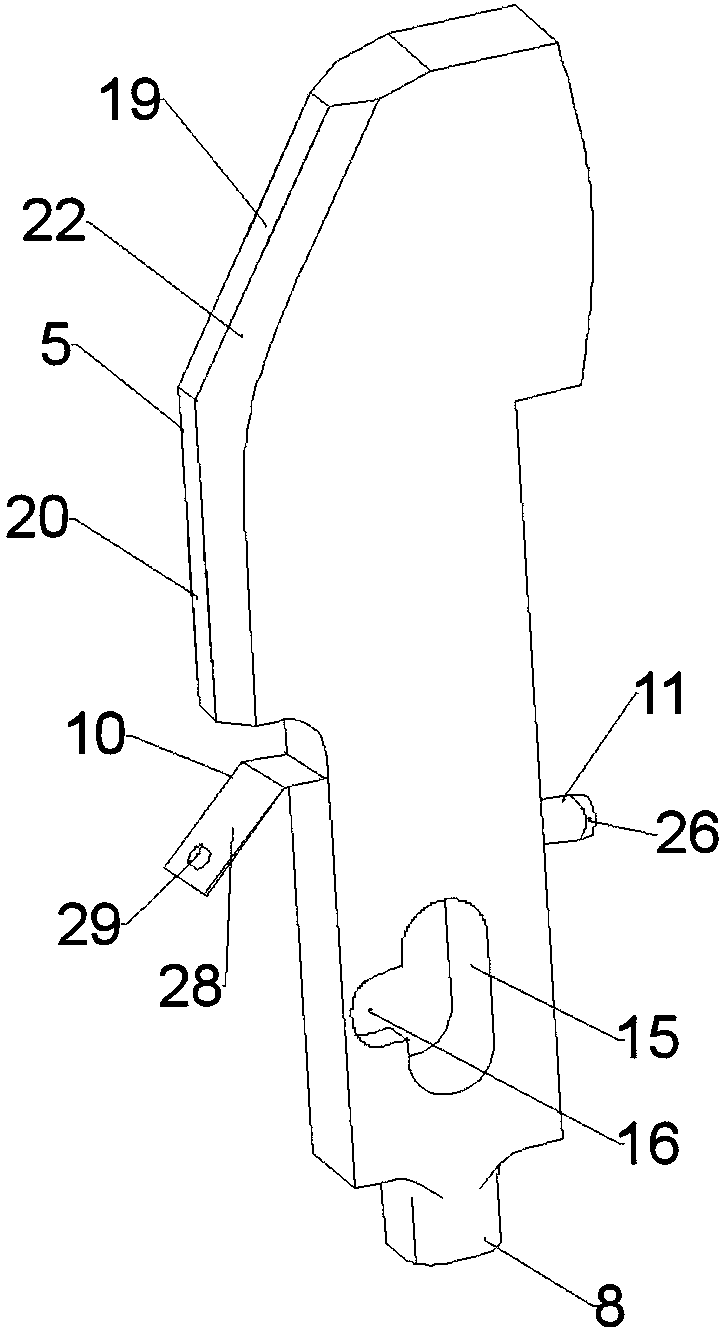

Upper jaw embedded tooth buccal side admission passage pullout guide plate and manufacturing method thereof

PendingCN108578005AGood positioningShorten operation timeAdditive manufacturing apparatusDental toolsEmbedded teethThree dimensional model

The invention relates to an upper jaw embedded tooth buccal side admission passage pullout guide plate and a manufacturing method thereof. The pullout guide plate comprises a dentition supporting part, a guide rod and a positioning ring, the dentition supporting part is provided with a cavity cooperating with the upper dentition of a patient, the inner surface of the positioning ring is an arc-shaped hook face and matched with the radian on the buccal surface of the upper jaw bone of the patient, the positioning ring is connected with the dentition supporting part through the guide rod, and the position of the positioning ring corresponds to the position of a to-be-pulled-out embedded tooth extraction site. The method comprises the following steps that 1:1 three-dimensional model reconstruction is carried out on the upper jaw bone and upper dentition of the patient; according to an upper dentition model, the dentition supporting part is designed; according to the position of the embedded tooth dental crown, a tooth extraction site is determined on the buccal portion of the upper jaw bone model; according to the tooth extraction site and the surface radian of the buccal portion of the upper jaw bone model on the tooth extraction site portion, the positioning ring is designed; the guide rod is designed to connect the dentition supporting part and the positioning ring to form an entirety; and 3D printing is performed to prepare a finished product. The upper jaw embedded tooth buccal side admission passage pullout guide plate and the manufacturing method thereof have the advantages that the tooth extraction site can be positioned accurately and efficiently, the surgical trauma is reduced, and the risks of damaging teeth are reduced.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

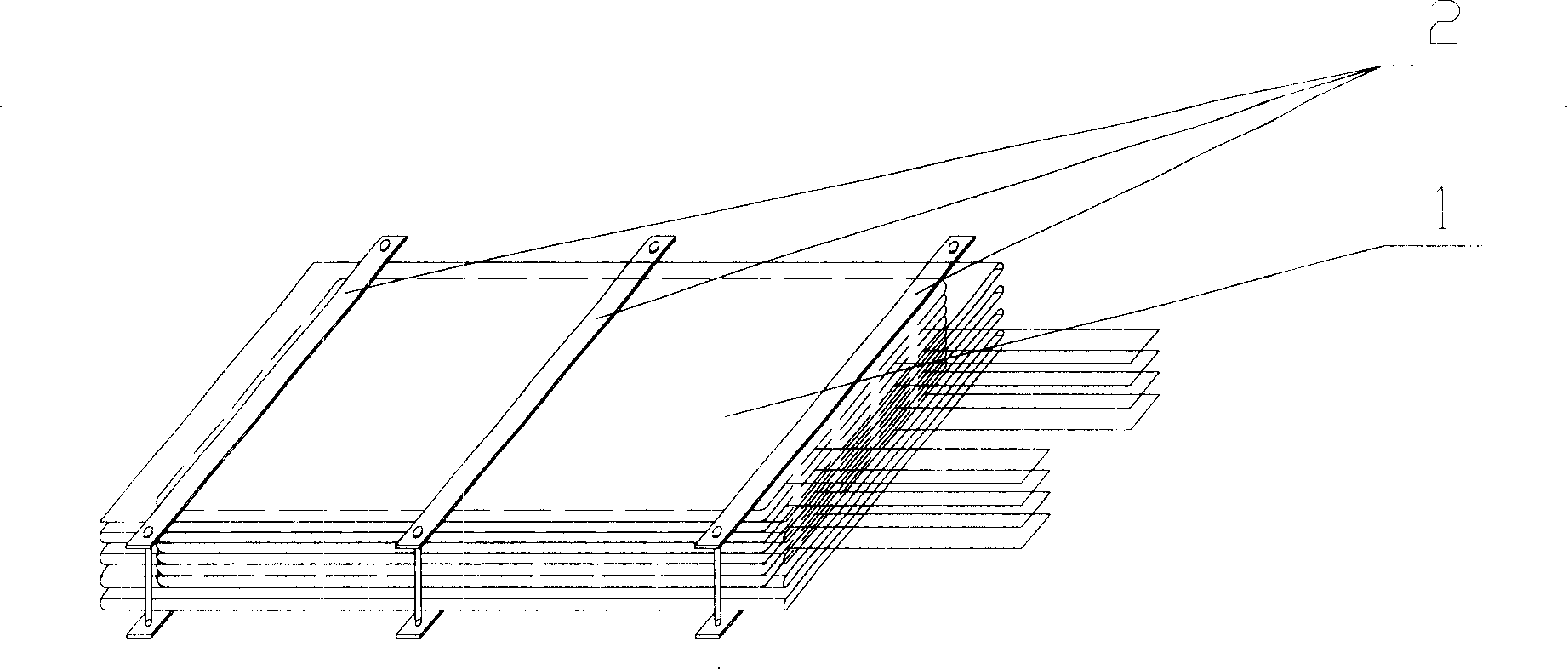

Method for locating laminate type battery pole piece

InactiveCN101207226AIncrease energy densityGood positioningElectrode manufacturing processesFinal product manufactureEnergy densityPole piece

The invention provides a polar piece positioning method of a stack-up type battery; wherein, the method comprises the steps that the pressure vertical to the plane is uniformly applied to one plane or two planes of the electric core parallel to the polar piece. When the polar piece positioning method provided by the invention is adopted to position the polar piece, the good positioning of the polar piece can be realized, and the positioned electronic core occupies the less space of the battery, and the energy density of the battery is enhanced. In addition, the operation of the polar piece positioning method provided by the invention has the advantages is simple, and the invention is easy to be implemented.

Owner:SHANGHAI BYD

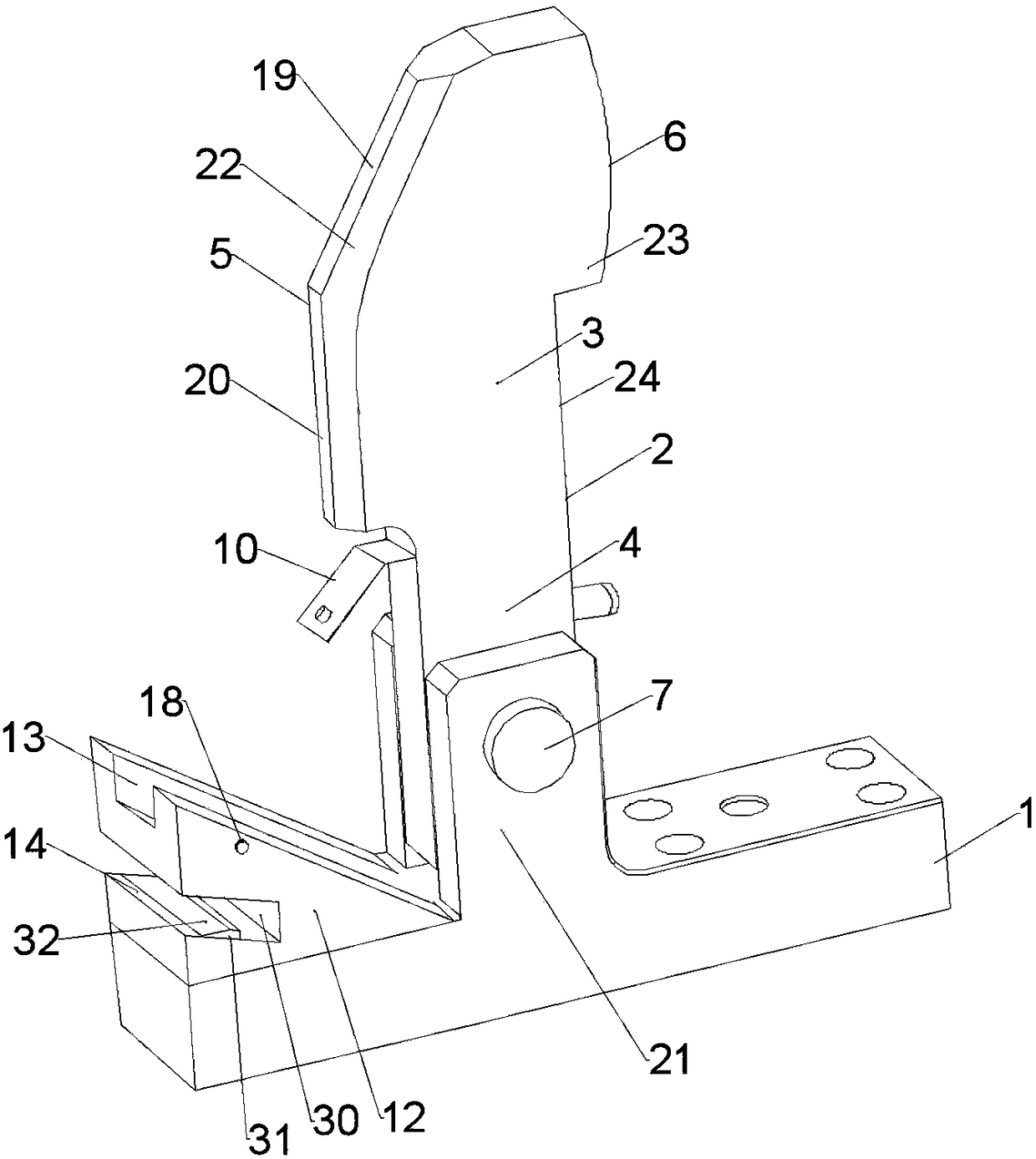

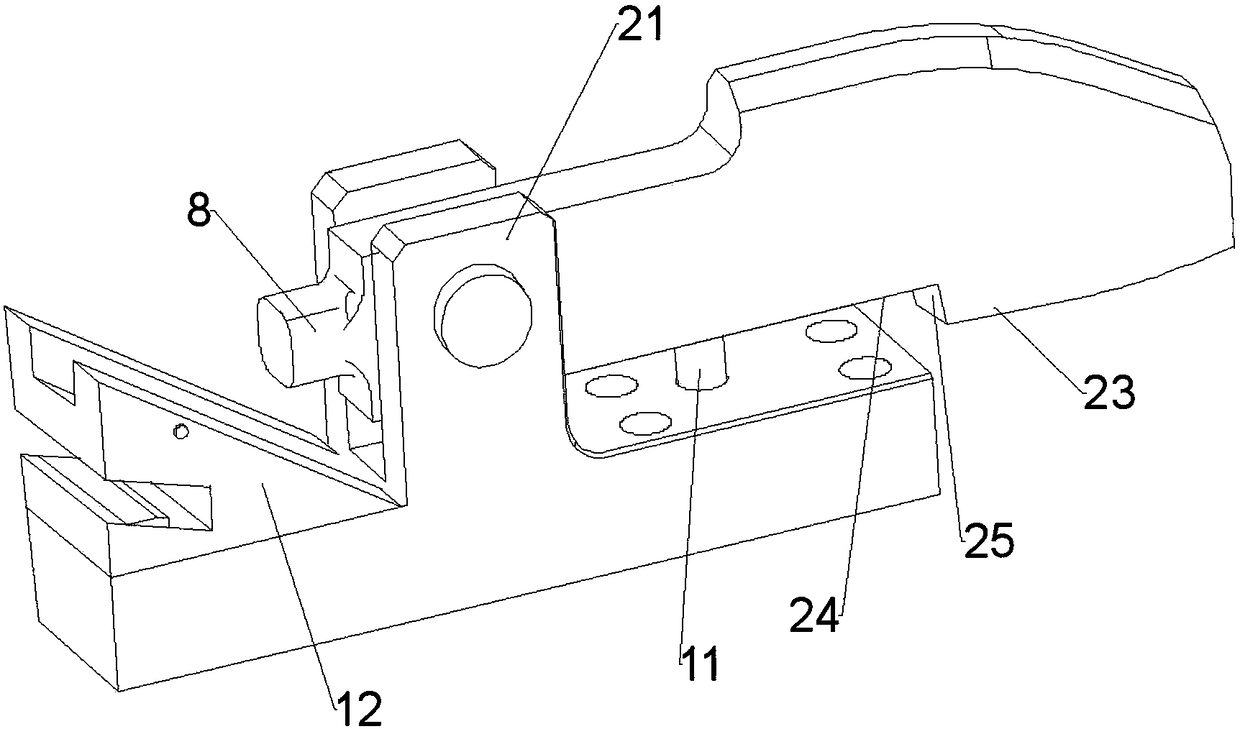

Multi-station mold positioning device

ActiveCN108526969AEasy to adjustGood positioningPositioning apparatusMetal-working holdersMarine engineeringPositioning system

The invention provides a multi-station mold positioning device. The multi-station mold positioning device comprises a pedestal and a positioning mechanism; an inclined strut structure is arranged on the pedestal; a horizontal limiting structure is arranged at the other end of the pedestal; the positioning mechanism comprises a positioning plate; the positioning plate comprises a stop part and a positioning part positioned at the lower part of the stop part; a first stop surface is arranged on one side, facing the inclined strut structure, of the stop part; a second stop surface is arranged onone side, facing the horizontal limiting structure, of the stop part; the positioning part is hinged to a bracket of the pedestal through a hinged shaft; a positioning fork is arranged at the lower end of the positioning part; a positioning hole is formed in the positioning base; a first positioning piece is arranged on one side, facing the inclined strut structure, of the positioning part; and asecond positioning piece is arranged on one side, facing the horizontal limiting structure, of the positioning part. The multi-station mold positioning device can provide a plurality of positioning modes and can adapt to various working conditions; and the multi-station mold positioning device is simple in structure and convenient and quick in operation, so the production efficiency can be improved effectively, foundation is laid for high-precision mold processing, the qualification rate of finished products is high and the processing precision is guaranteed reliably.

Owner:深圳市益华诚模具有限公司

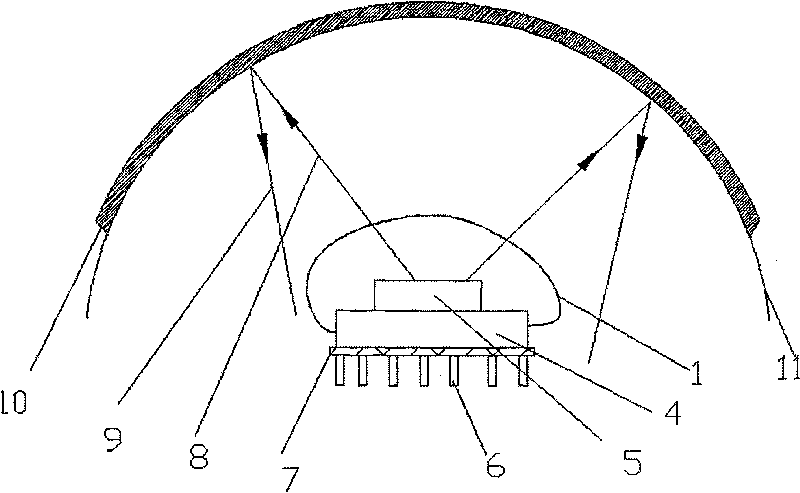

Reflective curved surface LED lamp

InactiveCN101737661AGood positioningSimple structure and material requirementsPoint-like light sourceElectric circuit arrangementsAstigmatismEngineering

The invention provides a reflective curved surface LED lamp which comprises a reflecting device, a light-emitting device and a heat radiating device, wherein the reflecting device is a transparent protective cover 11 plated with a reflective film 10; and the light-emitting device consists of a light-emitting chip 5, a substrate 4, a leading wire 3 and a leading wire support 2, the whole light-emitting device is placed in a solid lens 1 molded by one-time plastic injection, the light-emitting chip 5, the leading wire 3, one end of the leading wire support 2, the inner surface of the substrate 4 and the like are wrapped in the solid lens 1, and the heat radiating device comprises a semiconductor refrigeration piece 7 and a heat radiating sheet 6. The heat radiating device is mounted on the outer surface of the substrate, and the whole light-emitting device and the heat radiating device are arranged on the lower surface of the reflecting device. The reflective curved surface LED lamp can solve the technical problems that divergent light with large angle is converged in a smaller range, thereby leading the radiation distance to be farther and leading the positioning of a light beam to be better. The requirements on the structure and materials of the reflective curved surface LED lamp are very simple, thereby being easy to carry out large-scale production and realizing broad prospects.

Owner:武汉精准光科技有限公司

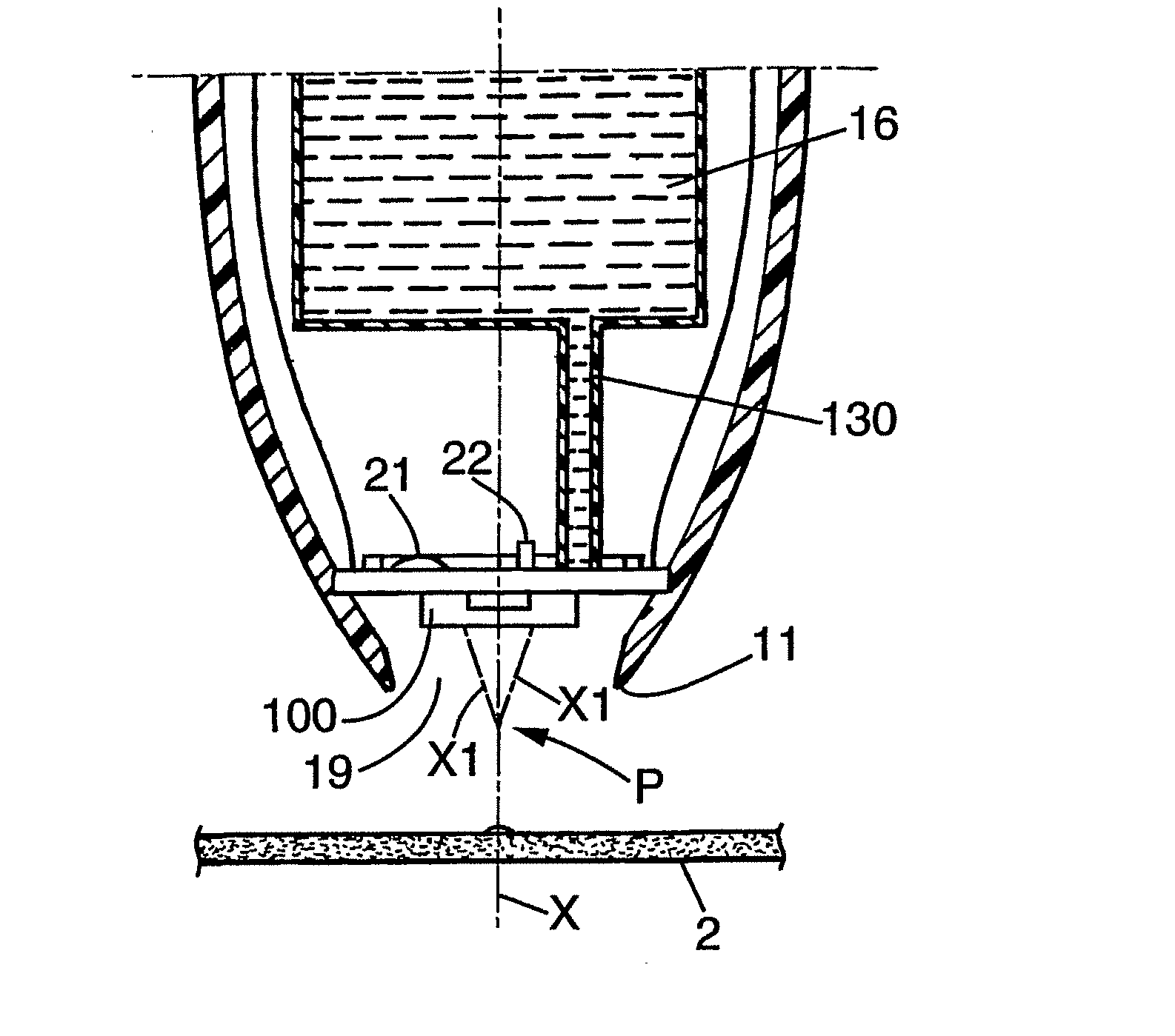

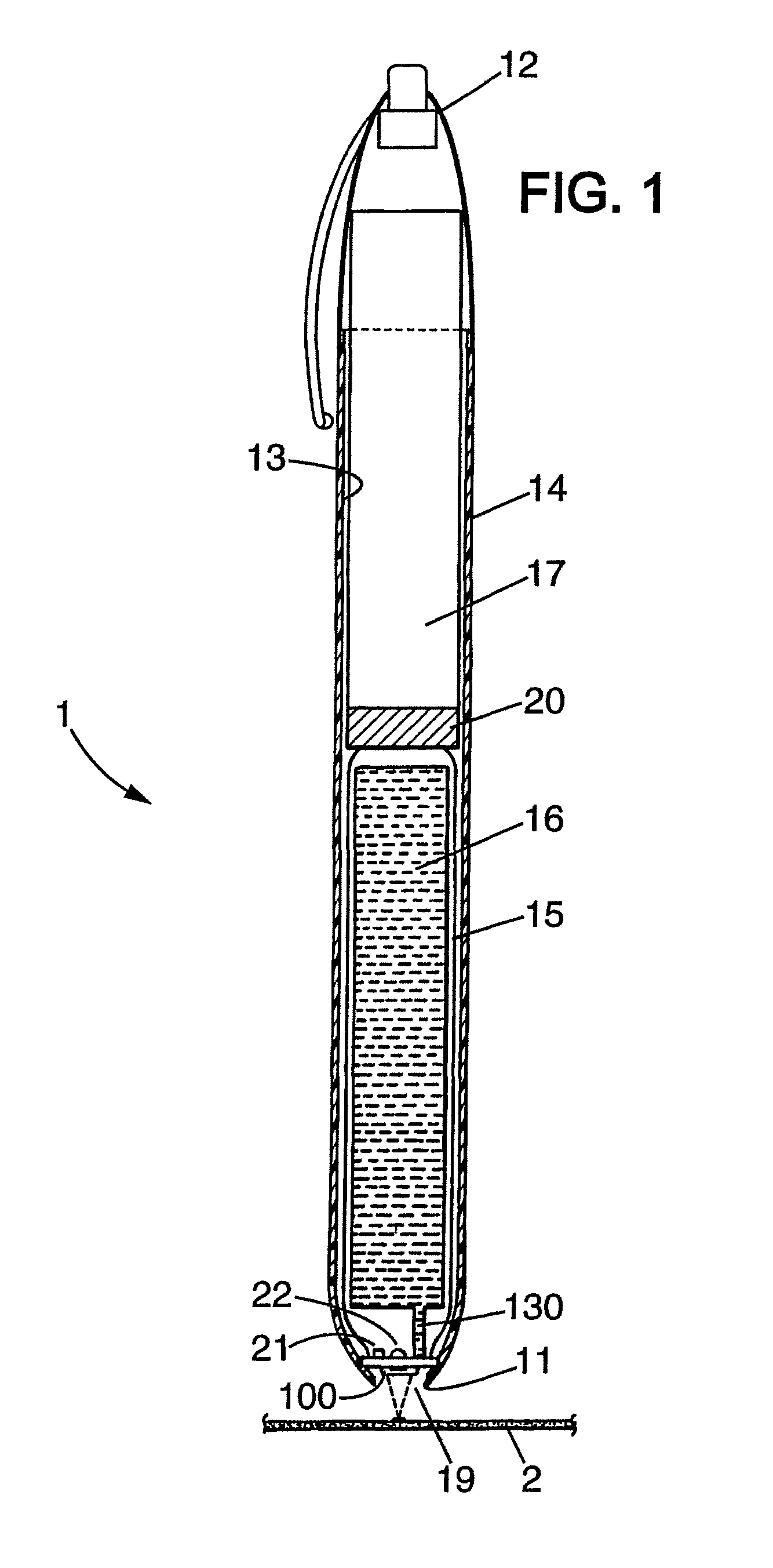

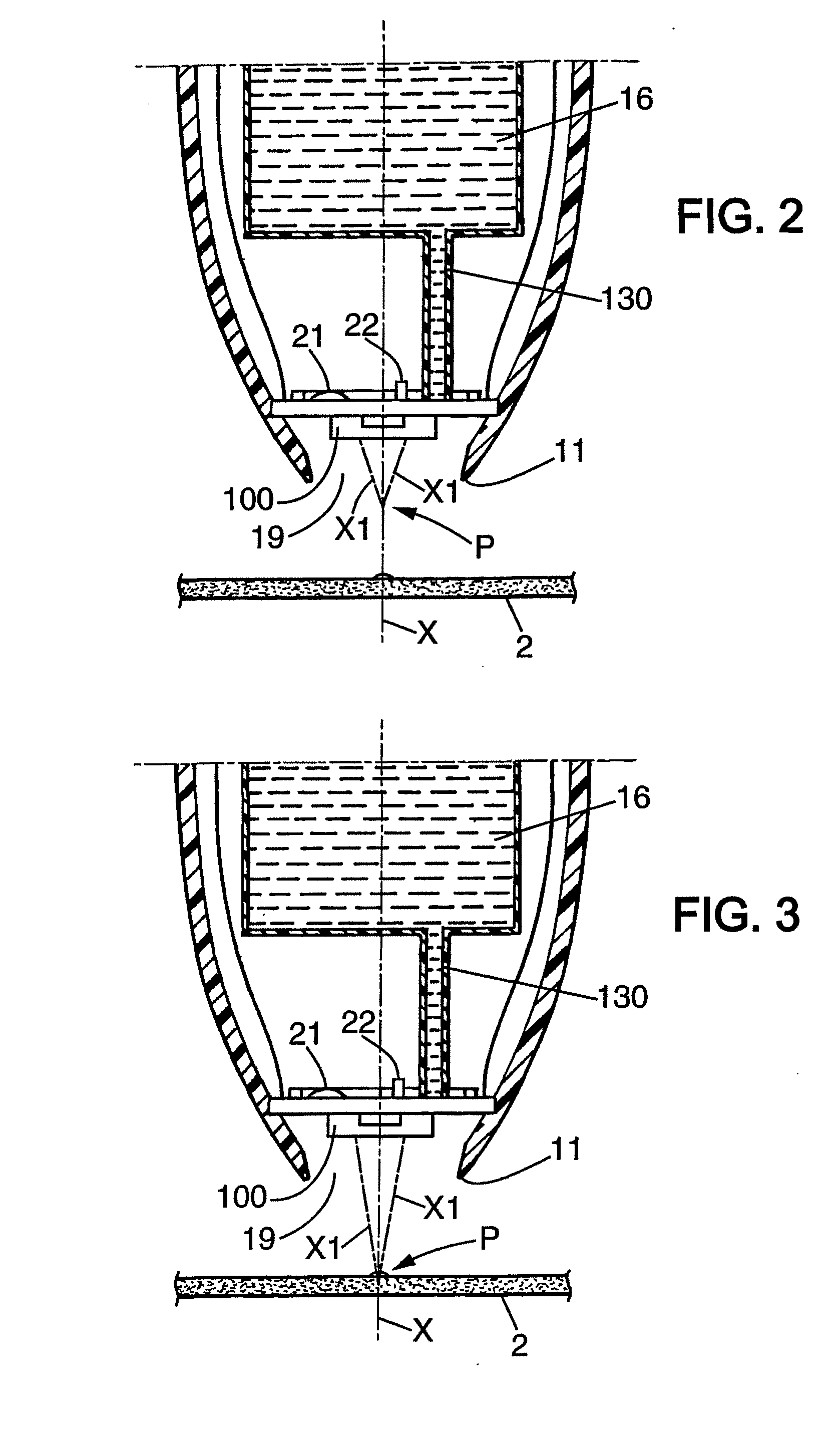

Multi-Nozzle Liquid Droplet Ejecting Head, a Writing Instrument Comprising Such a Head, and a Method of Ejecting Liquid Droplets From Same

InactiveUS20080204517A1Good positioningGood reliabilityTypewritersOther printing apparatusInjectorLiquid jet

A liquid droplet ejecting head designed to be mounted in a liquid ejecting instrument that includes ejection nozzles through which droplets are to be ejected from the head, and actuating chambers, each actuating chamber having at least one inlet to be in fluidic connection with a liquid reservoir for providing liquid to the actuating chamber. The ejecting head also includes at least one actuating unit suitable for creating a pulse wave in the liquid contained when activated by energy received from a control device and at least one outlet portion in fluidic connection with at least one ejection nozzle.

Owner:SOC DITE SOC BIC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com