Reflective curved surface LED lamp

A LED lamp, reflective technology, applied in the field of reflective curved surface LED lamps, can solve the problems of lack of actual economic benefits, insufficient irradiation distance, and limited application range, etc., and achieve simple structure and material requirements, easy large-scale production, Good positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

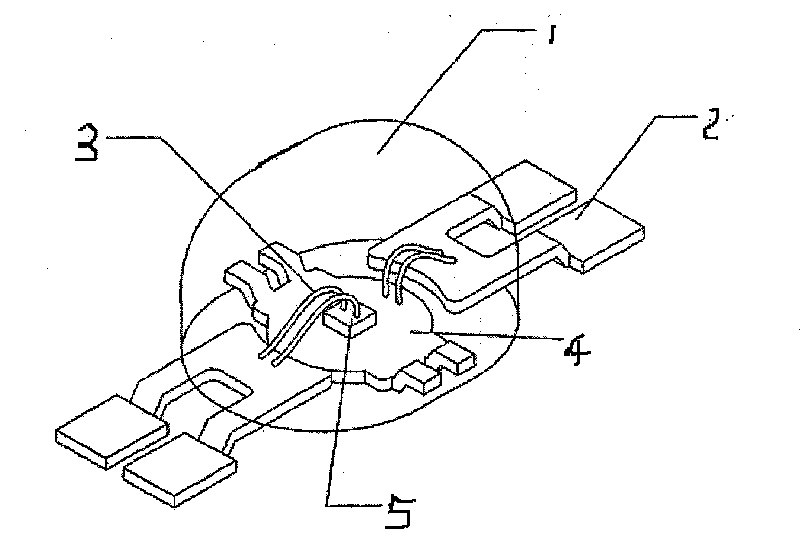

[0014] figure 1 It is a structural schematic diagram of the reflective curved surface LED lamp of the present invention.

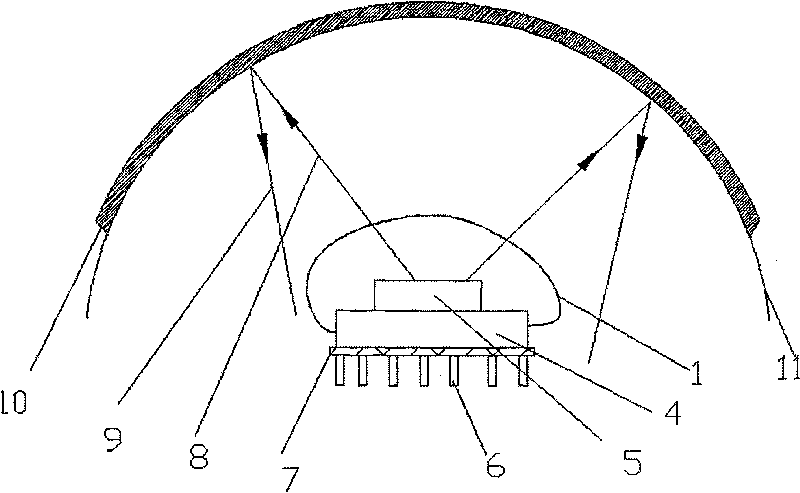

[0015] to combine figure 1 and figure 2 Further explain the present invention

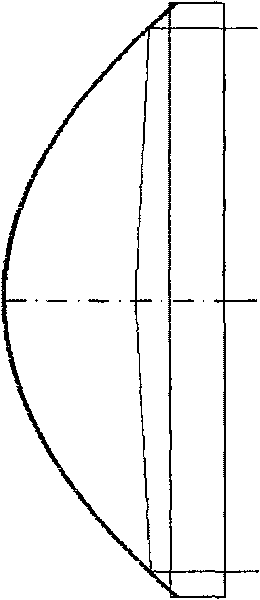

[0016] figure 2 It is a schematic diagram of the principle of the reflective curved surface LED lamp of the present invention. The reflective curved surface LED lamp includes a reflector, a light emitting device and a heat sink, wherein the reflector is composed of a reflective film 10 and a transparent protective cover 11, that is, the transparent protective cover 11 is coated with a reflective film 10, which can make its wavelength During the period of 400nm-700nm, 98% of the light is reflected back. At the same time, the reflective film 10 can also be plated on the inner surface of the transparent protective cover 11 as required, and the reflective surface of the reflective device can be selected from a spherical surface, a secondary and high-order aspheric surface, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com