Method for locating laminate type battery pole piece

A positioning method and stacked technology, applied in battery electrodes, primary batteries, electrode manufacturing, etc., can solve the problems of battery energy density improvement, battery performance deterioration, battery space occupation, etc., to achieve improved energy density, simple operation, The effect of good positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

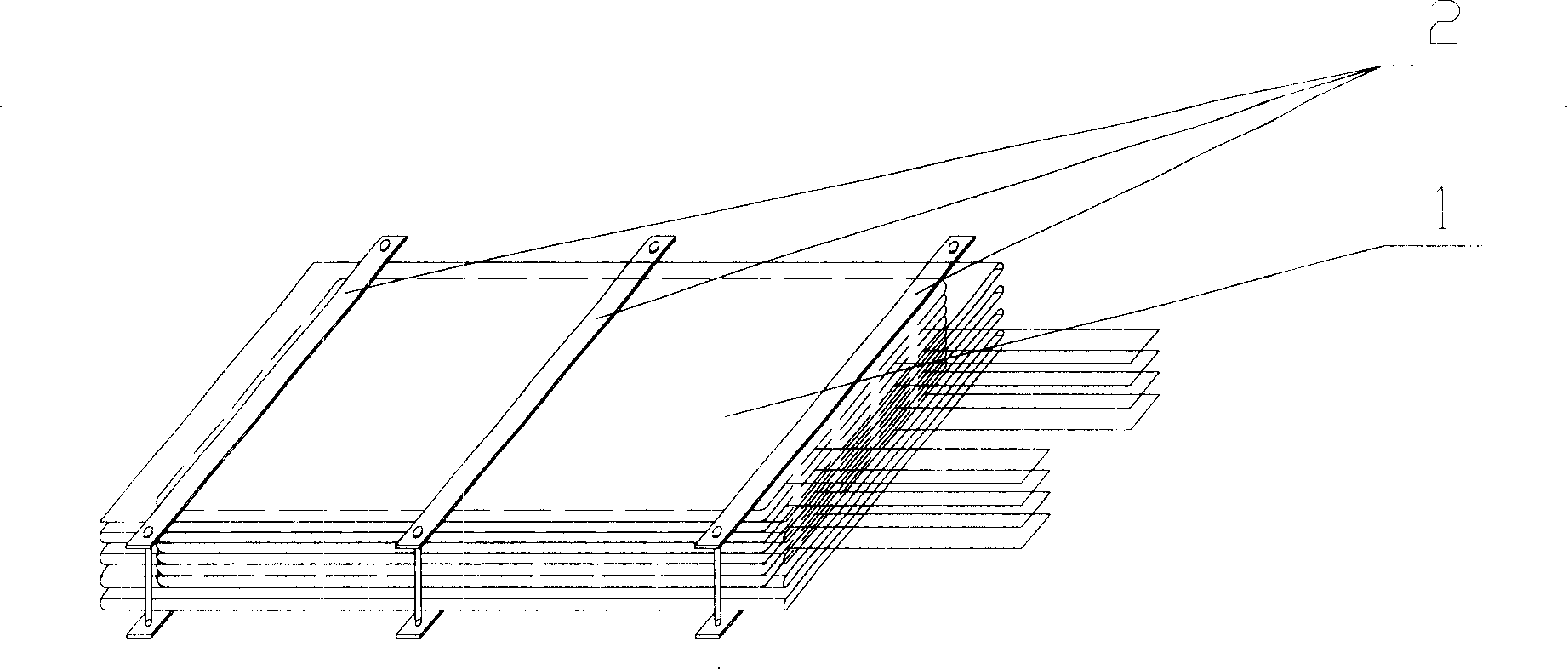

[0018] This embodiment takes pole piece positioning of a laminated lithium-ion battery as an example to illustrate the pole piece positioning method provided by the present invention.

[0019] 1. First, prepare the positive electrode sheet and the negative electrode sheet according to the following method.

[0020] (1) Preparation of positive electrode sheet

[0021] 1000 g of positive electrode active material LiCoO 2 , 30 grams of binder PVDF, 50 grams of conductive agent acetylene black were added to 600 grams of solvent NMP, and then stirred in a vacuum mixer to form a stable and uniform dispersed positive electrode slurry. The slurry is evenly and intermittently coated on both sides of a wide aluminum foil (500 mm in width and 20 microns in thickness), then dried at 120° C., and rolled into a pole with a thickness of 120 microns on a rolling mill. Use a punching machine to punch out a positive electrode sheet with a length of 200 mm, a width of 150 mm, and a thickness o...

Embodiment 2

[0032] This embodiment takes pole piece positioning of a laminated lithium-ion battery as an example to illustrate the pole piece positioning method provided by the present invention.

[0033] 1. According to the method described in Example 1, 1000 battery cells were prepared, and the thicknesses of the prepared battery cells were measured with a vernier caliper, and the average thickness of the battery cells was obtained to be 43 mm.

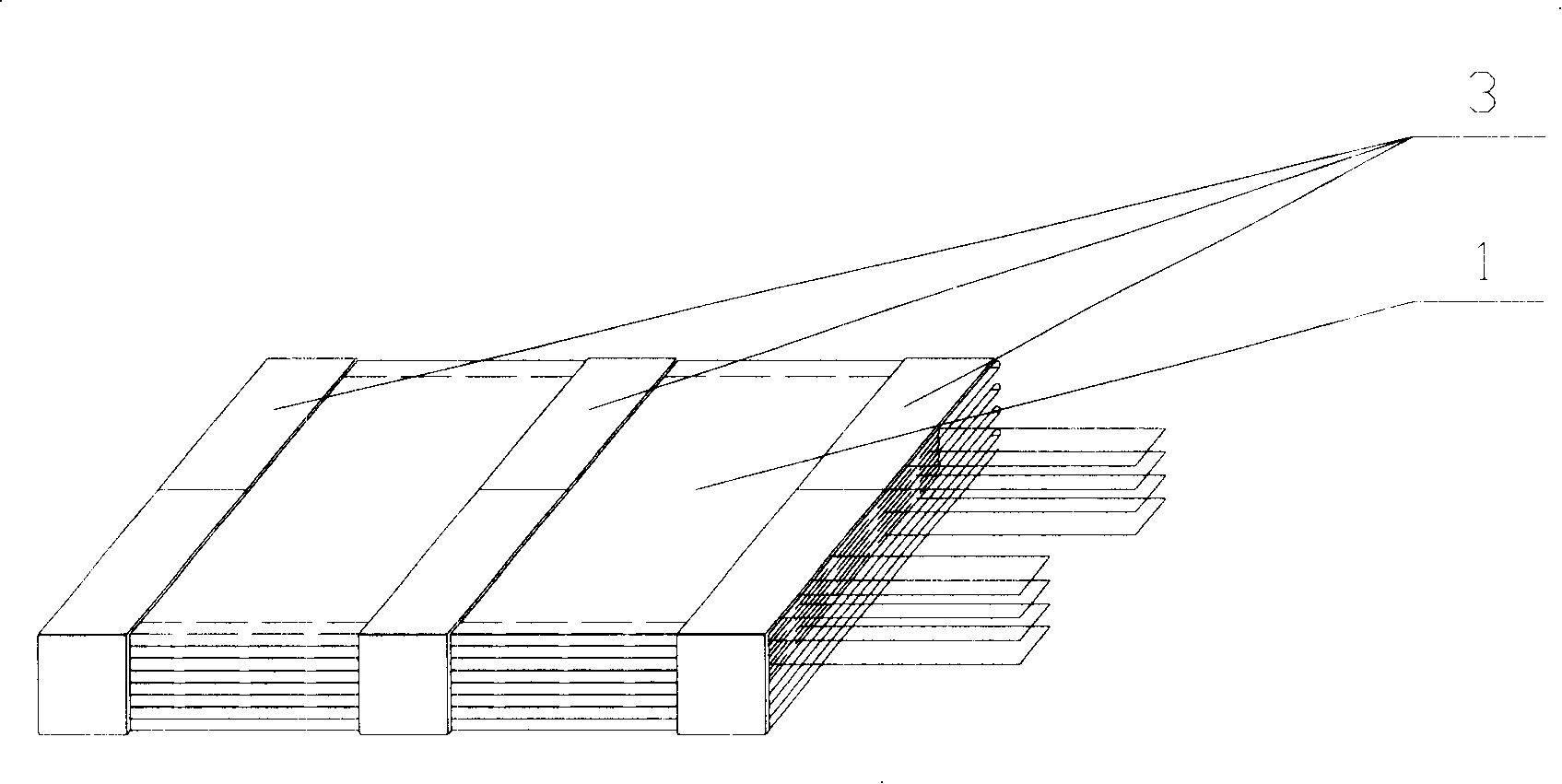

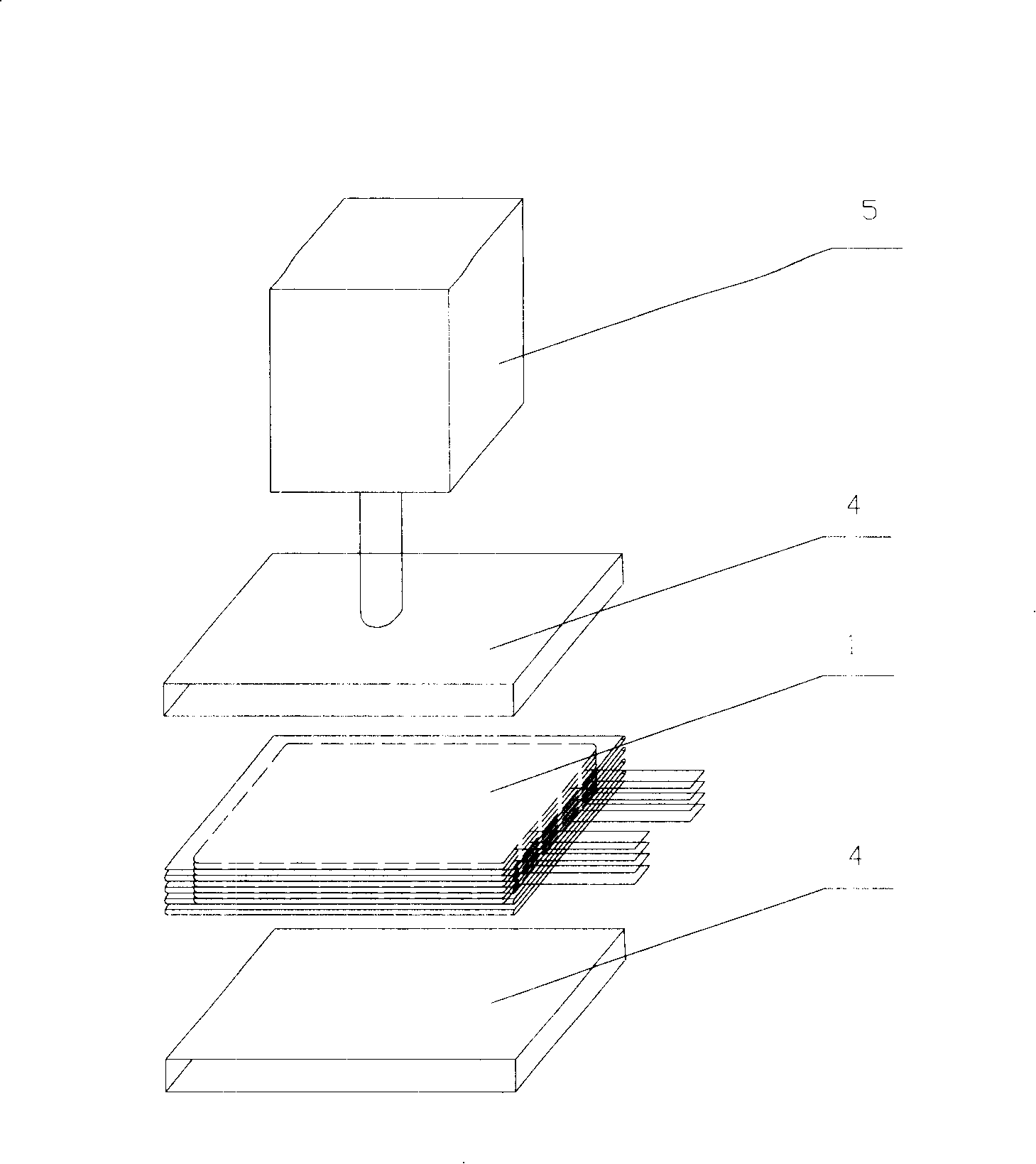

[0034] 2. Position the pole pieces in 1000 batteries respectively, the positioning method is as follows:

[0035]Select two smooth steel plates with a length of 250 mm, a width of 200 mm, and a thickness of 30 mm as the pressure plate, place one of the pressure plates on a flat workbench, place the battery on the pressure plate, and make the long side of the battery and the pressure plate The long side of the battery cell is parallel to the short side of the pressure plate, so that the battery cell is in full contact with the pressure plate, an...

Embodiment 3

[0038] This embodiment takes pole piece positioning of a laminated lithium-ion battery as an example to illustrate the pole piece positioning method provided by the present invention.

[0039] 1. According to the method described in Example 1, 1000 battery cells were prepared, and the thicknesses of the prepared battery cells were measured with a vernier caliper, and the average thickness of the battery cells was obtained to be 43 mm.

[0040] 2. Position the pole pieces in 1000 batteries respectively, the positioning method is as follows:

[0041] Select two smooth steel plates with a length of 250 mm, a width of 200 mm, and a thickness of 30 mm as the pressure plate, place one of the pressure plates on a flat workbench, place the battery on the pressure plate, and make the long side of the battery and the pressure plate The long side of the battery cell is parallel to the short side of the pressure plate, so that the battery cell is in full contact with the pressure plate, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com