Cable disc structure and manufacturing method thereof

A manufacturing method and cable-reel technology, which are applied in the directions of conveyors, transportation and packaging, and conveying bulk materials, can solve the problems of troublesome manufacturing, small pulling force, easy slippage of the disc, etc., so as to improve the processing and manufacturing efficiency, uniform force, Easy to locate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

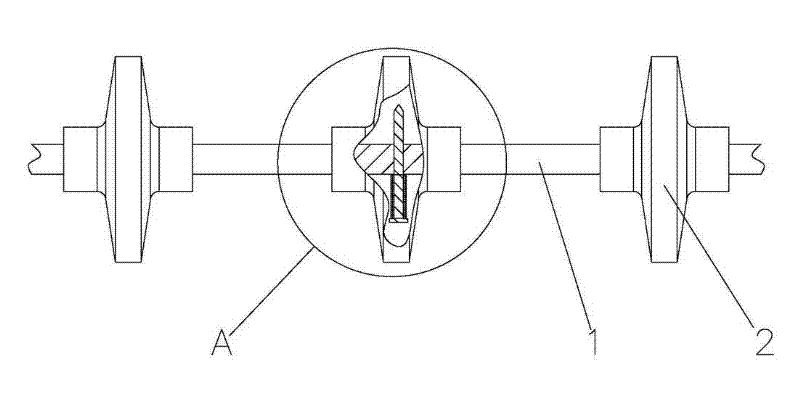

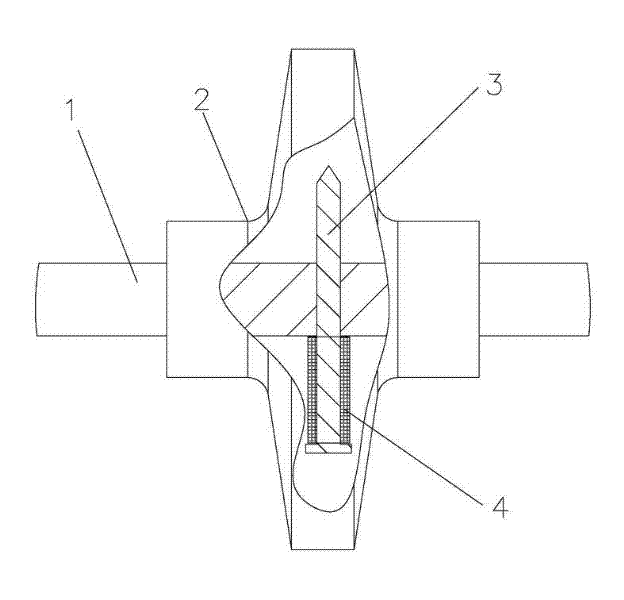

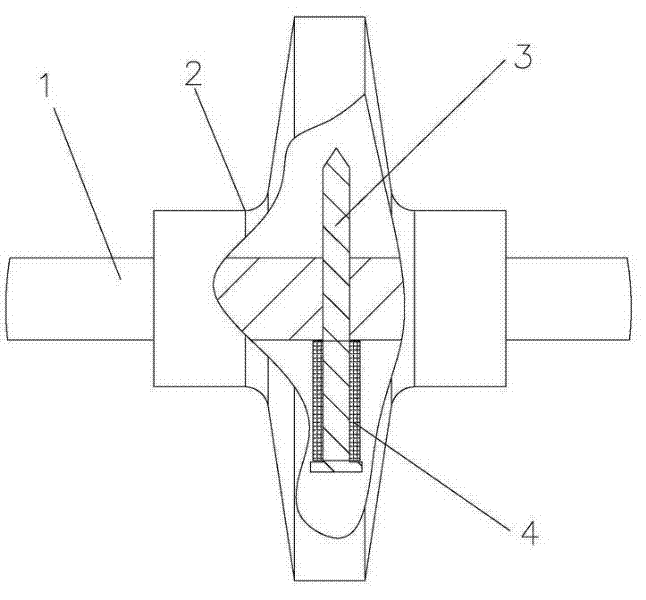

[0029] like figure 1 , 2 As shown, a cable reel structure includes a steel cable 1 and a feeding disc 2. The feeding disc 2 is equidistantly fixed on the steel cable 1 by injection molding. The number of feeding discs and the distance between the two feeding discs Set according to actual needs. Also be provided with a nail 3 in each feed disc 2, nail 3 passes steel cable 1. The big end of nail 3 preferably establishes a pipe sleeve 4, and the cross-sectional diameter of steel cable 1 is 1 / 3rd of nail 3 lengths, and the length of pipe sleeve 4 is 1 / 3rd of nail 3 lengths. By providing the sleeve 4, the nail 3 can be easily positioned, and the distance between the exposed two sides after passing through the steel cable 1 can also be ensured to be equal, so that the injection-molded feeding disc 2 is evenly stressed and more stable.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com