Method for manufacturing sectioned die casting inductor

A manufacturing method and segmented mold technology, applied in the manufacture of inductors/transformers/magnets, inductors with magnetic cores, circuits, etc., can solve problems such as deformation or damage, displacement, inductive component yield and performance degradation, etc., to achieve Better inductance characteristics, the effect of increasing magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

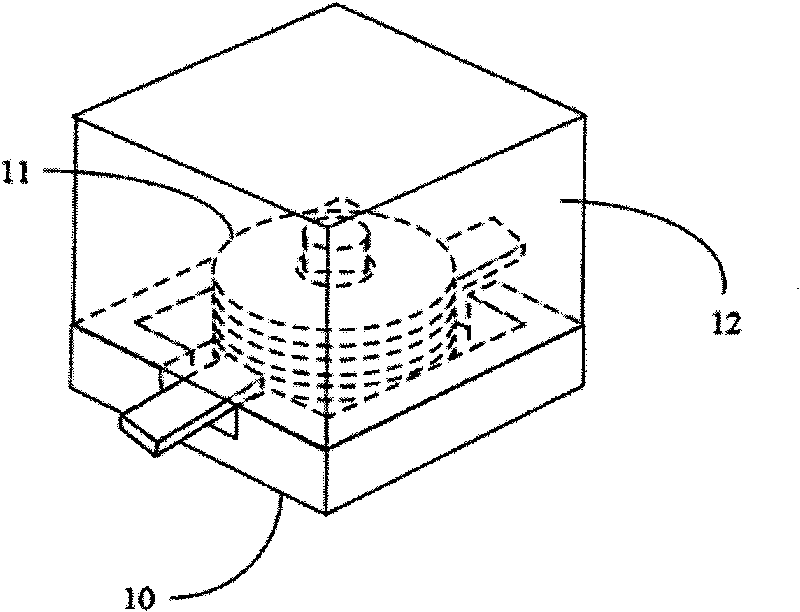

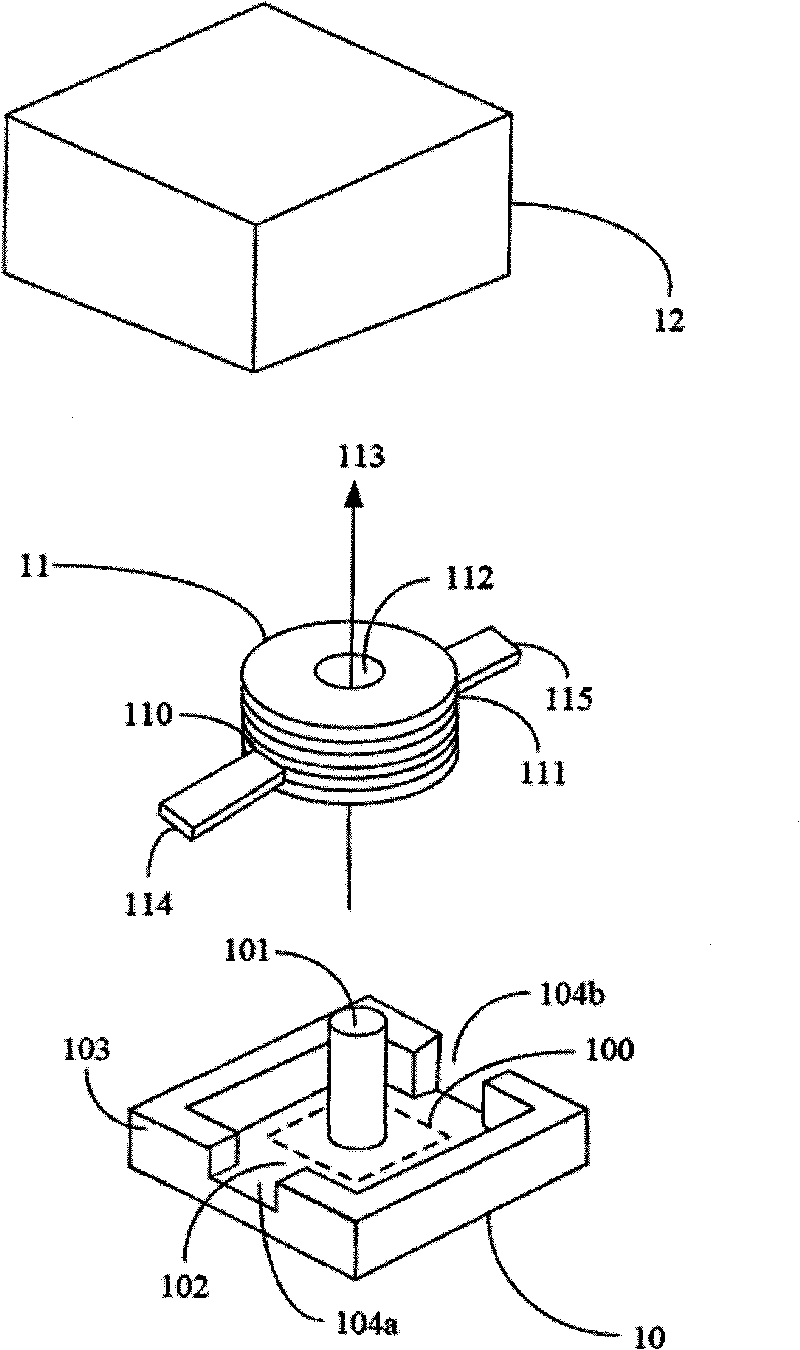

[0029] Such as figure 1 As shown: the segmented molded inductor includes a base 10 formed by the first high-pressure process, a metal coil 11 and a cladding structure 12 formed by the second high-pressure process.

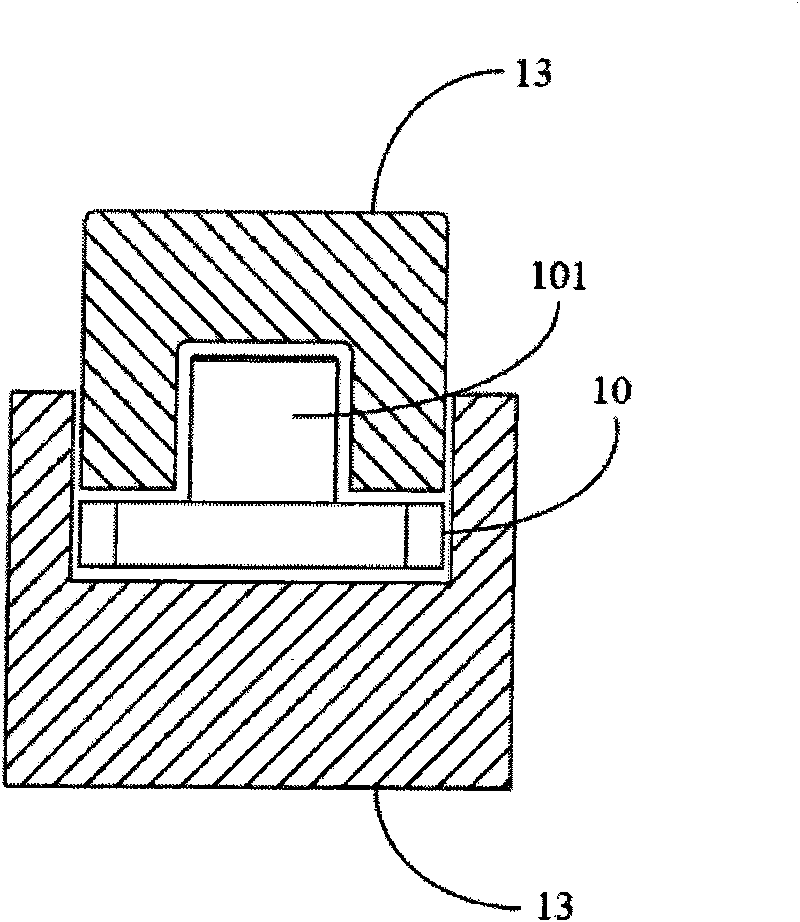

[0030] Specifically, combining figure 2 It can be seen that the central area 100 of the base 10 formed by the high-pressure process in the first stage includes a central pillar 101 . The base 10 is substantially formed by applying a high-pressure process to the first magnetic material. The first magnetic material is usually a substance such as iron powder or non-alloy powder. that is, image 3 As shown, the first magnetic material is inserted into the base mold 13 with a pre-determined shape, and after the base mold fixes its shape, a high pressure is applied to press the first magnetic material into a shape such as figure 2 The base 10 comprising a flat plate 102 and side walls 103 is shown in FIG.

[0031] Looking further, the metal coil 11 includes two end...

Embodiment 2

[0035] Such as Figure 5 , Image 6 As shown: the segmented molded inductor includes a base 20 , a metal coil 21 and a covering structure 22 . The central area 200 of the base 20 includes a central column 201 , and the central column 201 of the base 20 passes through the hollow portion 212 of the metal coil 21 . The base 20 is also provided with a flat plate 202 on which two openings 202a and 202b are formed. The metal coil 21 includes two ends 210 , 211 and a hollow portion 212 , wherein the two ends 210 , 211 extend along a direction parallel to the central axis 213 of the metal coil 21 . The covering structure 22 is combined on the base 20 and the metal coil 21 . The two ends 210, 211 of the metal coil 21 pass through the two openings 202a, 202b of the base 20, and protrude outward respectively.

[0036] It can be seen from the above text description and the accompanying drawings that after adopting the present invention, in the combined forming process of the covering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com