Coil component

A coil component and body technology, which is applied to transformer/inductor components, electrical components, printed inductors, etc., can solve the problems of decreased magnetic particle filling rate, increased resin, frequency limitation, etc., and achieves good inductance characteristics. The effect of ensuring excellent insulation and magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, the present invention will be described in detail with reference to the drawings as appropriate. However, the present invention is not limited to the forms shown in the drawings, and the drawings may sometimes emphasize the characteristic parts of the invention, so the accuracy of the scale in each part of the drawings is not necessarily guaranteed.

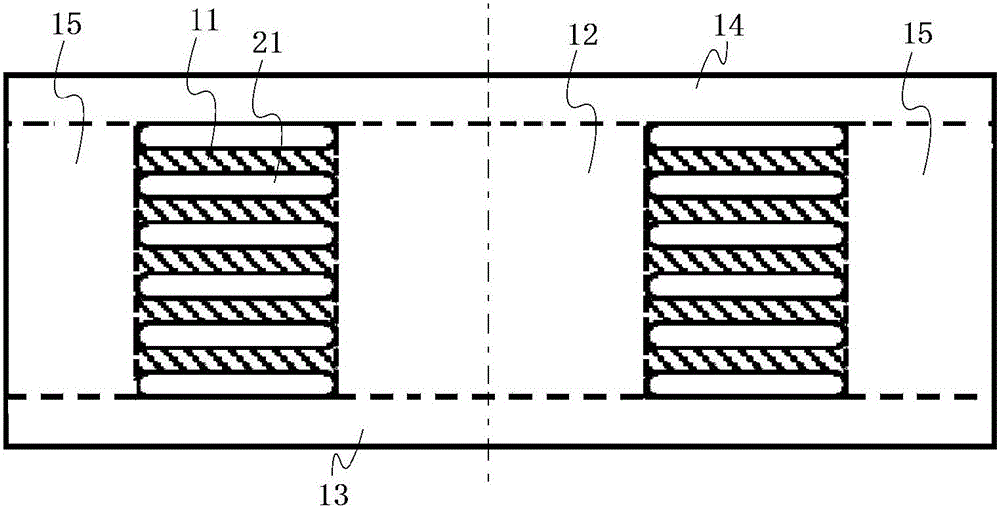

[0018] figure 1 It is a schematic cross-sectional view of a laminated inductor which is a typical example of a coil component. In the following description, a laminated inductor is cited as a specific embodiment of a coil component which is the object of the present invention, but the coil component may be, for example, a transformer, a common mode filter for a power supply, or the like. The multilayer inductor has a structure in which an inner conductor 21 is embedded in a magnetic body portion (a laminated body composed of magnetic body layers). Typically, the inner conductor 21 is a coil formed in a helic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com