Protective device for avoiding optical lens surface scratch

A technology for optical mirrors and protection devices, applied in optics, optical components, installation, etc., can solve problems such as scratches, achieve good positioning, save space, and have a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

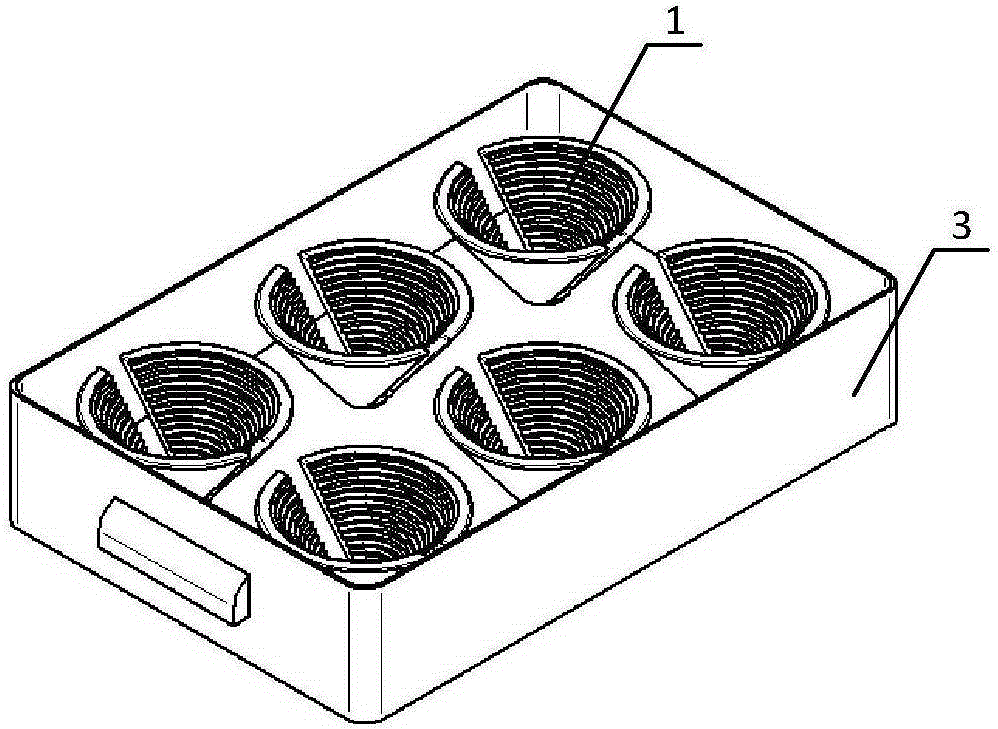

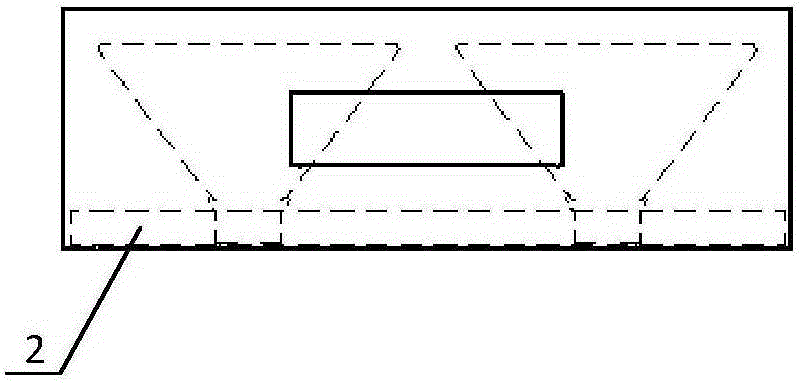

[0023] like Figures 1 to 5 As shown, the protective device for preventing scratches on the optical mirror surface of the present invention mainly includes a box body, a mirror holder and a mirror holder seat. The mirror holder is assembled on the mirror holder seat, and the mirror holder holder is placed in the box body, and the box body is provided with a dustproof cover.

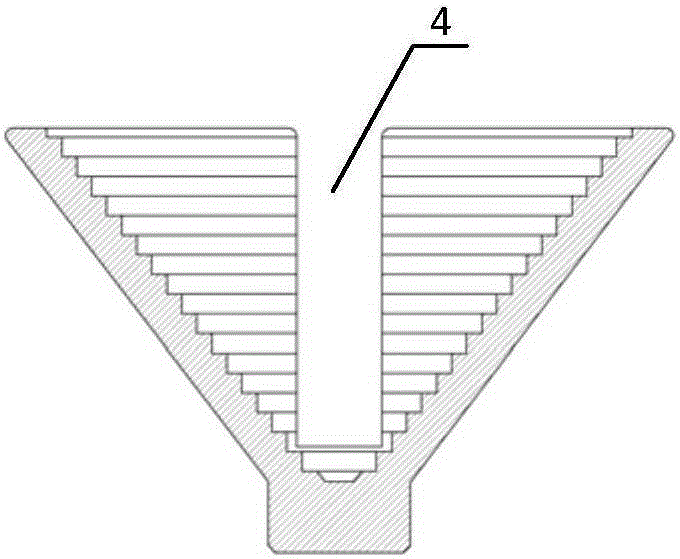

[0024] The inner wall of the mirror holder is designed with an annular stepped surface distributed in a step shape, and the inner diameter of the annular stepped surface is larger than the inner diameter of the non-working surface of the optical lens to be placed on it. like Image 6 As shown, the non-working surface of the optical lens mentioned here is the inward annular zone (usually unilateral 1mm) of the optical lens, and the inner side of the annular zone is the light-passing aperture. If it is an optical lens equipped with a frame, the frame will also have a wall thickness equivalent to the size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com