Super-fine-denier polyester fiber and manufacturing method thereof

A polyester fiber, ultra-fine denier technology, applied in the direction of fiber type, fiber treatment, dyeing method, etc., can solve the problems of poor tow cohesion, industrial production, easy to be damaged, etc., to improve smoothness and reduce surface tension. , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

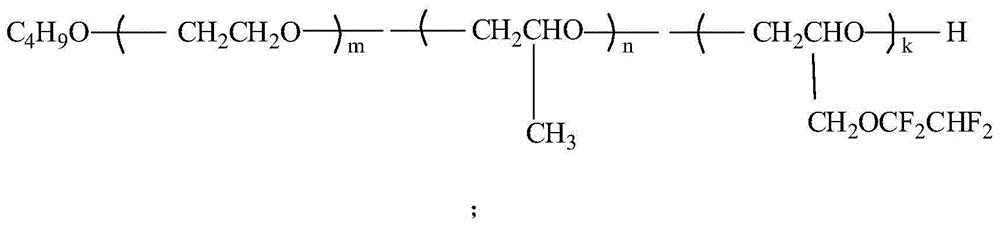

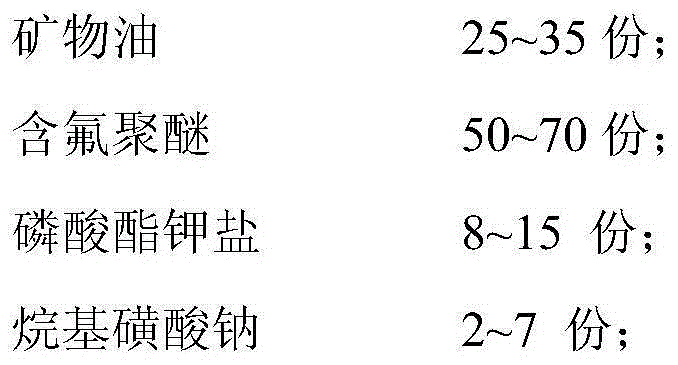

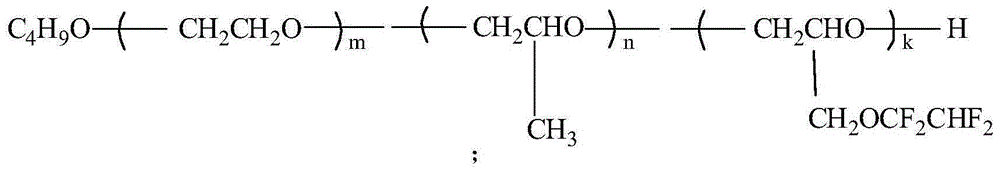

[0053] A method for preparing ultra-fine polyester fiber, firstly preparing an oiling oil agent, the specific preparation steps are: blending the initiator butanol and strong alkali potassium hydroxide, then heating up to 105°C, and then adding and mixing Homogeneous ethylene oxide, [(1,1,2,2-tetrafluoroethoxy)methyl] ethylene oxide and propylene oxide, the amount of butanol is ethylene oxide, [(1,1 , 2,2-tetrafluoroethoxy) methyl] 1‰ of the total mass of ethylene oxide and propylene oxide, the amount of strong alkali potassium hydroxide is ethylene oxide, [(1,1,2,2 -1‰ of the total mass of -tetrafluoroethoxy)methyl]oxirane and propylene oxide, ethylene oxide, [(1,1,2,2-tetrafluoroethoxy)methyl]epoxide The molar ratio of ethane and propylene oxide is 10:1:20, the polymerization reaction is carried out under the protective atmosphere of nitrogen atmosphere, the reaction pressure is 0.4MPa, and after the relative molecular weight is 1000, the fluorine-containing polyether is obt...

Embodiment 2

[0067] A method for preparing ultrafine denier polyester fibers. Firstly, an oiling oil is prepared. The specific steps are: blending the initiator butanol and strong alkali sodium hydroxide, then raising the temperature to 125°C, and then adding the well-mixed Ethylene oxide, [(1,1,2,2-tetrafluoroethoxy)methyl] ethylene oxide and propylene oxide, the amount of butanol is ethylene oxide, [(1,1,2 , 2-tetrafluoroethoxy) methyl] 5‰ of the total mass of ethylene oxide and propylene oxide, the amount of strong alkali sodium hydroxide is ethylene oxide, [(1,1,2,2-tetra 5‰ of the total mass of fluoroethoxy)methyl]oxirane and propylene oxide, ethylene oxide, [(1,1,2,2-tetrafluoroethoxy)methyl]oxirane The molar ratio of propylene oxide and propylene oxide is 20:3:30, and the polymerization reaction is carried out under the protective atmosphere of an inert gas atmosphere, the reaction pressure is 0.5MPa, and after reaching a relative molecular weight of 4000, neutralization, adsorption...

Embodiment 3

[0081] A preparation method of superfine denier polyester fiber. Firstly, an oiling oil is prepared. The specific steps are: blending the initiator butanol and strong alkali sodium hydroxide, then raising the temperature to 115°C, and then adding the well-mixed Ethylene oxide, [(1,1,2,2-tetrafluoroethoxy)methyl] ethylene oxide and propylene oxide, the amount of butanol is ethylene oxide, [(1,1,2 , 2-tetrafluoroethoxy) methyl] 2‰ of the total mass of ethylene oxide and propylene oxide, the amount of strong alkali sodium hydroxide is ethylene oxide, [(1,1,2,2-tetra 1.5‰ of the total mass of fluoroethoxy)methyl]oxirane and propylene oxide, ethylene oxide, [(1,1,2,2-tetrafluoroethoxy)methyl]oxirane The molar ratio of propylene oxide and propylene oxide is 12:1:30, and the protective atmosphere is an inert gas atmosphere to carry out polymerization reaction, the reaction pressure is 0.8MPa, and after reaching a relative molecular weight of 3000, neutralization, adsorption, vacuum d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com