Polyamide sea-island fiber and preparation method and application thereof

A sea-island fiber and polyamide technology, applied in the field of polyamide materials, can solve the problems of uneven distribution of island components, large difference in component thickness, uneven blending, etc., and achieve good dyeing performance, high dyeing rate, and reduce greenhouse effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

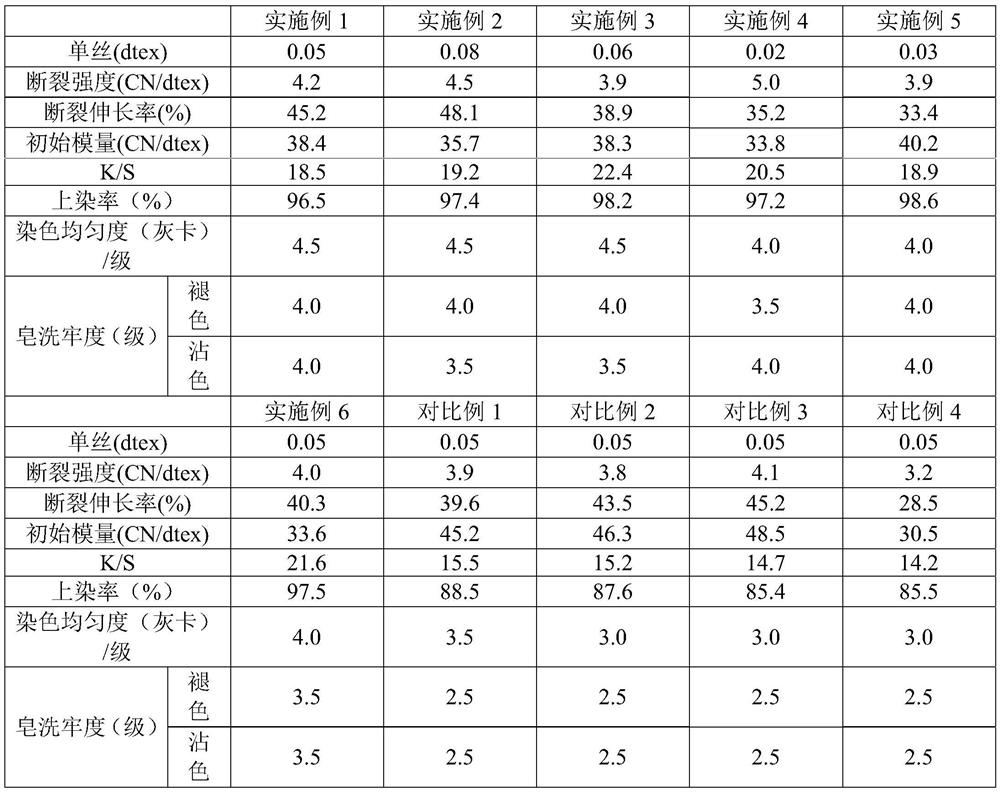

Examples

Embodiment 1

[0098] This embodiment provides a polyamide 56 / polyethylene island-fixed sea-island fiber preparation method, which includes the following steps:

[0099]1) Dry the island component polyamide 56 and the sea component polyethylene resin separately, control the moisture content of the island component to 800ppm after drying, and control the moisture content of the sea component to 60ppm after drying;

[0100] 2) Heat and melt a certain proportion of the above-mentioned island component and sea component resin respectively, the mass ratio of the island component and the sea component in the sea-island fiber is 70:30, and the two melts are transported to the spinning through the melt pipeline In the box, after being accurately metered by the metering pump, it is injected into the sea-island composite component in the spinning box, and is evenly distributed through the distribution pipe in the component, and finally the two melts are merged and extruded at the entrance of the spinne...

Embodiment 2

[0113] This embodiment provides a method for preparing polyamide 56 / low-density polyethylene island-fixed sea-island fibers, which includes the following steps:

[0114] 1) Dry the island component polyamide 56 and the sea component low-density polyethylene resin separately, control the moisture content of the island component to 1000ppm after drying, and control the moisture content of the sea component to 90ppm after drying;

[0115] 2) Heat and melt a certain proportion of the above-mentioned island component and sea component resin respectively, the mass ratio of island component and sea component in the sea-island fiber is 60:40, and the two melts are transported to the spinning through the melt pipeline In the box, after being accurately metered by the metering pump, it is injected into the sea-island composite component in the spinning box, and is evenly distributed through the distribution pipe in the component, and finally the two melts are merged and extruded at the e...

Embodiment 3

[0128] This embodiment provides a method for preparing polyamide 56 / water-soluble polyester island-fixing type sea-island fibers, which includes the following steps:

[0129] 1) Dry the island component polyamide 56 and the sea component water-soluble polyester resin separately, control the moisture content of the island component to 500ppm after drying, and control the moisture content of the sea component to 30ppm after drying;

[0130] 2) Heat and melt a certain proportion of the above-mentioned island component and sea component resin respectively, the mass ratio of the island component and the sea component in the sea-island fiber is 80:20, and the two melts are transported to the spinning through the melt pipeline In the box, after being accurately metered by the metering pump, it is injected into the sea-island composite component in the spinning box, and is evenly distributed through the distribution pipe in the component, and finally the two melts are merged and extrud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com