Low-polarity and high-resilience polyurethane hot melt adhesive as well as preparation method and application thereof

A polyurethane hot melt adhesive and thermoplastic polyurethane technology, applied in the field of polyurethane materials, can solve the problems affecting the application of thermoplastic polyurethane hot melt adhesives, easy to form cross-linked network, poor hydroxyl reactivity, etc., and achieve excellent resilience, surface polarity and surface The effect of low free energy and enhanced polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

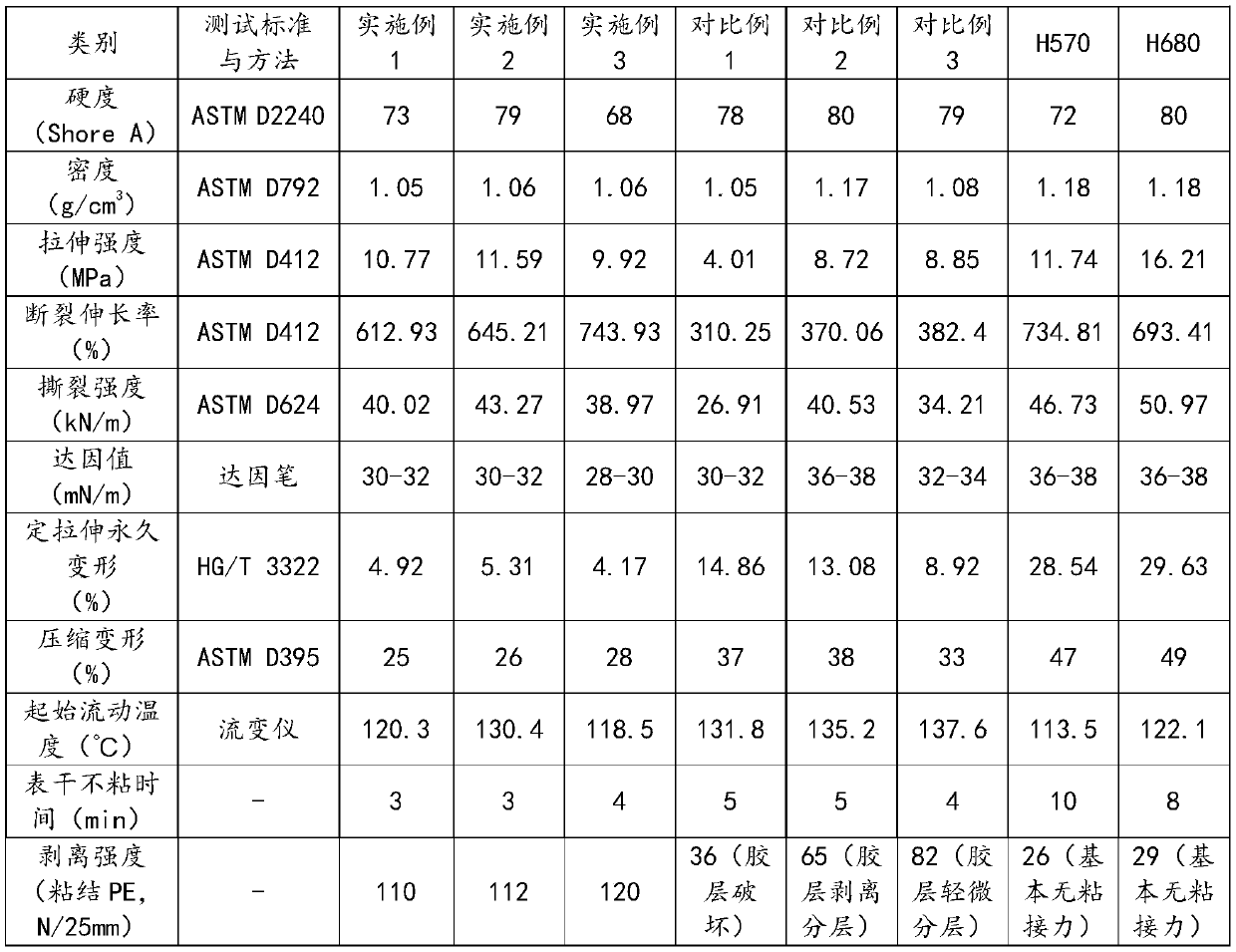

Examples

Embodiment 1

[0025] A preparation method of a polyurethane hot-melt adhesive with low polarity and high resilience, the steps are as follows:

[0026] (1) Preparation of modified hydroxyl-terminated hydrogenated polybutadiene polyols

[0027] Put 500kg of hydroxyl-terminated hydrogenated polybutadiene with a molecular weight of 1000g / mol and 500kg of caprolactone monomer into the reaction kettle, raise the temperature to 120°C under the protection of nitrogen, add 0.1kg of catalyst tetraisopropyl titanate, stir evenly and then raise the temperature to 160°C, react for 20 hours, pump the system to a vacuum of -0.095MPa and react for 3 hours to obtain the modified hydroxyl-terminated hydrogenated polybutadiene polyol. The hydroxyl value is 57.1mgKOH / g and the acid value is 0.02 by titration analysis method. mgKOH / g, the molecular weight is 1965g / mol;

[0028] (2) Preparation of thermoplastic polyurethane elastomer

[0029] The modified hydroxyl-terminated hydrogenated polybutadiene polyol ...

Embodiment 2

[0032] A preparation method of a polyurethane hot-melt adhesive with low polarity and high resilience, the steps are as follows:

[0033] (1) Preparation of modified hydroxyl-terminated hydrogenated polybutadiene polyols

[0034] Put 2000kg of hydroxyl-terminated hydrogenated polybutadiene with a molecular weight of 2000g / mol and 1100kg of caprolactone monomer into the reaction kettle, and raise the temperature to 120°C under the protection of nitrogen, add 0.35kg of the catalyst stannous octoate, stir evenly, and raise the temperature to 160°C. React for 20 hours, pump the system to a vacuum of -0.095MPa and react for 3 hours to obtain a modified hydroxyl-terminated hydrogenated polybutadiene polyol. The hydroxyl value is 35.5 mgKOH / g and the acid value is 0.023 mgKOH / g by titration analysis. , the molecular weight is 3169.5g / mol;

[0035] (2) Preparation of thermoplastic polyurethane elastomer

[0036]Take the modified hydroxyl-terminated hydrogenated polybutadiene polyol,...

Embodiment 3

[0039] A preparation method of a polyurethane hot-melt adhesive with low polarity and high resilience, the steps are as follows:

[0040] (1) Preparation of modified hydroxyl-terminated hydrogenated polybutadiene polyols

[0041] Put 1500kg of hydroxyl-terminated hydrogenated polybutadiene with a molecular weight of 3000g / mol and 450kg of caprolactone monomer into the reaction kettle, raise the temperature to 120°C under the protection of nitrogen, add 0.35kg of organic bismuth catalyst, stir evenly and raise the temperature to 160°C, and react After 20 hours, the system was evacuated to a vacuum of -0.095MPa and reacted for 3 hours to obtain the modified hydroxyl-terminated hydrogenated polybutadiene polyol. The titration analysis method was used to test the hydroxyl value of 28.77mgKOH / g and the acid value of 0.03mgKOH / g. The molecular weight is 3899.9g / mol;

[0042] (2) Preparation of thermoplastic polyurethane elastomer

[0043] Take the modified hydroxyl-terminated hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com